How to determine which pipes for a heating system are best to use to heat your home? How to choose the only correct material that will last for decades and will not fail even in the most severe frosts? In our review, we will analyze in detail the features of the application of all currently available options from the point of view of their operation in autonomous systems of various types. We will not touch upon the heating of apartment buildings, but we will formulate the advantages and disadvantages of each product exclusively from the perspective of the owners of private suburban housing. See our rating of heating pipes for a private house at the end of the article.

Selection of pipe materials

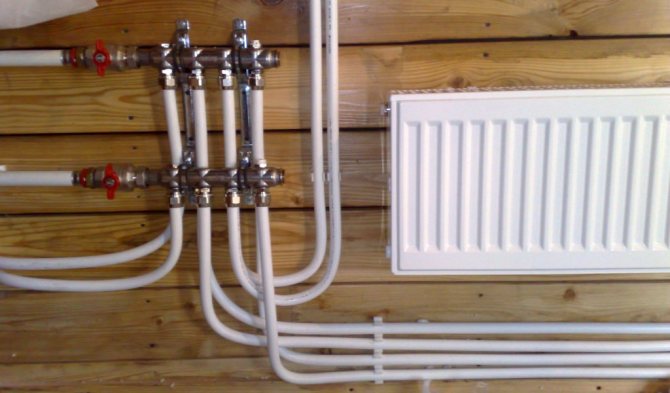

Probably, it is no secret to anyone that the use of plastic (polymer) pipelines in a private house is the most optimal option, both in terms of price and quality. However, many homeowners would like to see quality and durability as the main parameters, and the choice among polymer pipes is already quite high and how they differ is not always clear.

If you want to understand in more detail the properties of pipe materials, then this article is for you. In it we will consider: steel, copper, metal-plastic (PEX / AL / PEX, Pe-rt / Al / Pe-rt), polypropylene (PP) and cross-linked polyethylene (PEX) pipes.

More about requirements

The selected products for the heating system must have certain characteristics that will allow the use of the network for a long time.

For a complete list of the most important requirements, see below:

- Heating products must withstand high temperatures, which can reach 95 degrees... Although in individual houses, such indicators are rare.

- Elements of the heating system should be selected that can withstand a pressure of 1.5 atmospheres... Exceeding this indicator is found only in case of gross violation of the design rules.

- It is necessary to purchase products that can successfully withstand mechanical stress, since they are simply inevitable... If the stability is insufficient, the entire network will fail.

- Pipes for heating a private house must be resistant to corrosion, because water usually acts as a coolant... The period of operation will depend on this.

Copper products are reliable but expensive.

Addition! It is best to buy conductive elements for heating systems, which, when connected, form a structure with a high level of sealing, otherwise leakages are possible.

Selection criteria for pipe materials

We want to say right away that there are no bad or good pipes and materials from which they are made. There are high-quality or low-quality pipes, respectively, as well as a good or bad manufacturer. Each type of pipeline products is convenient and optimal for its specific case, which is determined by the criteria or parameters of the heating system. After choosing the material for the pipes, a specific manufacturer is selected, and the service life of the system and the convenience of its maintenance depend no less on this.

The main parameters of heating and water supply systems, according to which materials for pipes are selected:

- liquid temperature (maximum and nominal)

- fluid pressure

- method of laying pipelines

- purpose (heating systems, underfloor heating, water supply)

Steel

Steel elements have been used in heating systems for a long time. They are the best choice for autonomous gravity systems.Such pipes are characterized by an increased diameter size compared to other types, which greatly complicates the installation of the system and is not suitable for a small house.

The figure shows steel pipes for the heating system.

Steel pipeline elements have not lost their relevance, as they have high thermal conductivity and high pressure resistance. Steel is characterized by increased strength, wear resistance, and an affordable price. For the installation of steel pipelines, you will have to use special equipment and choose professionals who can do this type of work.

Steel tubes

The main material of pipelines in the 20th century. Currently, they are used as risers for cold and hot water supply and in the installation of heating systems in high-rise apartment buildings. In addition, there is no other alternative to pipes made of "ferrous" metal so far in gravity gravity heating (stove or using AOGV), which requires large diameters and resistance to high temperatures and mechanical stress.

Pros and cons of using steel piping

- High mechanical strength

- The service life does not decrease at coolant temperatures above 95 ° C.

- Small linear expansion

- High installation costs

- High labor costs and requirements for installers (welders)

- High corrosion rate and poor quality of pipe production

- Aesthetics (steel pipes are recommended to be mounted outside, while the aesthetic appearance is not the best)

What you need to know

The best pipes are those that are selected according to various performance criteria. They are chosen taking into account the specifics of heating the house and the equipment used to solve this problem. When the selection of pipes for heating is carried out, the pressure indicators in the heating system are necessarily calculated. Immediately you need to pay attention to the way they are installed.

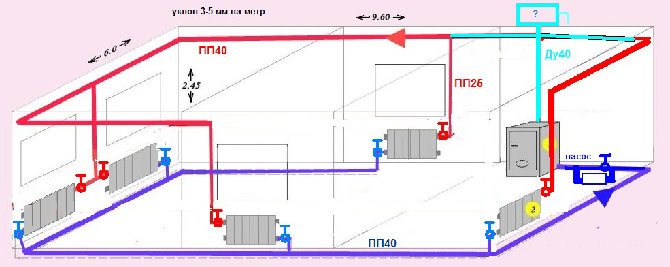

Property owners can choose either external or internal (hidden) installation. Heating systems are of two types: gravitational and forced circulation. Selection is carried out with the obligatory consideration of this paragraph. Those who choose pipes for heating for the first time have a common mistake: buyers forget about specifying the characteristics of the coolant temperature.

Varieties

Previously, all pipelines in Russia were made only of metal. Today, elements for heating a house or apartment are made from both metal and polypropylene or metal-plastic. Depending on the main material, the primary division of products into structural types is carried out. Each variety is designed for use in specific operating conditions for which the properties of the selected material are optimal.

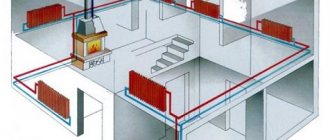

Layout

The strengths and weaknesses of heating pipes of various types must be analyzed before purchasing them. The layout of the house where the heating system will be laid or repaired is also a fairly significant factor in the selection. If the heating is installed taking into account its features, this will have a positive effect on the quality of the system's functioning.

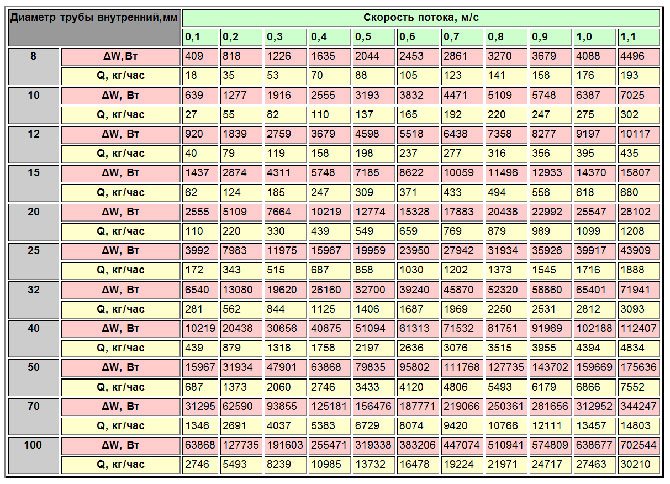

Standard size

The marking includes data on its length, diameter and wall thickness. The diameter of the flow area is an important indicator when selecting a variety of pipes. The optimal value of the diameter is determined taking into account the specifics of the operation of the heating equipment, including the working pressure. It is necessary to pay attention to the speed of movement of the coolant.

Combination of different materials

The most common mistake among property owners is the error that occurs when trying to combine different types of materials without taking into account their technical characteristics.Do not forget about the selection of components for the heating system, the connecting elements of which will be combined with pipeline communications. The operation of the equipment is designed for many years, so it is better to initially foresee all the nuances.

Copper

Copper pipes belong to the class of elite pipelines. In Europe, the engineering systems of many private houses are made of copper.

- Durable, non-corrosive

- The service life does not decrease at coolant temperatures above 95 ° C.

- Long service life

- Concealed mounting option (for solder joints)

- Very high pipe cost

- Not the ability to use soldering in houses with decoration

- High requirements for the qualifications of workers

- The use of better materials for thermal insulation

Recently, copper pipelines have been giving the initiative to high-quality pipes made of various types of polyethylene.

Copper

Copper heating pipes are not widely used in Russia, but they have a lot of advantages. Their most noticeable drawback is their high price. When operating copper pipelines, any thermal regime can be used. They are not afraid of high temperatures, do not freeze, withstand water shocks, and are resistant to high pressure. They can last about 100 years on average.

Copper pipes are rarely used due to their high cost.

This metal looks aesthetically pleasing and over time acquires a special shade, which makes it similar in color to platinum. If a person strives to make heating at home not only reliable, but also fashionable, he chooses copper.

Metal-plastic, metal-polymer pipes

Reinforced-plastic pipes are a multi-layer structure: polyethylene - glue - aluminum (foil) - glue - polyethylene. These pipes are flexible enough, lightweight, have high corrosion resistance, insignificant thermal expansion. Connected using press or collet fittings. Collet connection for heating and water supply systems is not considered below, due to its low quality and not the possibility of concealed installation. The presence of an inner layer of aluminum with a thickness of 0.2-0.4 mm prevents oxygen from entering the system and significantly reduces the linear elongation of the polyethylene layers and the entire pipe, respectively. For some manufacturers, the thickness of the aluminum layer for the 16th pipe is 0.4 mm, for others the aluminum layer is solidly drawn, all these, seemingly not always noticeable characteristics, lead to an increase in the pipe's service life and its reliability, but also lead to an increase in the cost of the pipe.

- Flexible and sufficiently heat-conducting - convenient for underfloor heating systems

- The maximum temperature of the coolant is slightly higher than that of polypropylene pipes

- Low thermal expansion (5 times less than glass fiber reinforced polypropylene)

- Convenience and ease of installation

- High cost of fittings

- Reduced bore of fittings

- Pipes practically do not withstand defrosting

- Not a very clean look when installed outdoors

- Quite expensive press tool

When choosing a specific pipe manufacturer, it is worth considering what the outer and inner layers of the pipe are made of.... They are available in PEX and heat-resistant PE-RT. "Perth" has a linear expansion, several times less than that of "infantry", so the voltage between the layers of polyethylene and aluminum foil, in the second case, will be much higher. Almost all eastern and Chinese manufacturers of metal-plastic pipelines use exactly PEx materials, while the quality of "cross-linking" of such polyethylene can be low, and, accordingly, low price and short service life.

Our company, as a metal-plastic pipe for underfloor heating and radiator heating, recommends using a German pipe SANHA MULTIFIT FLEX 16X2.0 (PE-RT / Al / PE-HD). Having a low price, the pipe is of high quality and good installation characteristics (flexibility).Made in Germany, which is confirmed by the inscription on the pipe and the barcode on the box.

Currently, the main competitor to metal-plastic pipes is cross-linked polyethylene, a material that is cheaper to manufacture and has good characteristics. When choosing between these options we always focus on the manufacturer. For example, Sanha, Tece, Prineto, Uponor, etc., which are actually produced in Europe, and comply with the European DVGW standard (the inscription can be found on the pipe itself).

Types of pipes for heating

The industry has succeeded in creating components for any kind of communication. Today pipes are made of various materials - homogeneous metal, alloys, composite raw materials, polymers. They are distinguished not only by their cost, but also by their acceptability for the assigned tasks. In particular, heating can be performed from the following:

- Copper and brass.

- Steel and stainless steel.

- Metal-plastic.

- Polyethylene.

- Polypropylene.

Any raw material from the above has advantages and disadvantages over others. In order to correctly find your own version, they need to be disassembled. In addition, it is important to accurately resolve issues related to heating. Namely:

- The option of laying is hidden or external. Radiators, of course, should remain in plain sight, and the pipes with the carrier are often hidden in the walls by the method of chasing.

- Maximum media temperature and pressure. The rise must not be allowed to have a destructive effect on the pipe material.

- Complexity of installation. Some materials require welding or soldering skills.

- Maintainability. It is important to be able to quickly replace the heating section in case of an emergency.

Based on the above, a choice is made in favor of one or another material. The price plays an important role - the length of the wiring from expensive raw materials, together, will cost the owners a decent amount.

XLPE pipes PEXa, b, c, d

The so-called "cross-linked" polyethylene is a type of polyethylene. When creating a cross-linked polymer of ethylene, the links of its molecules (carbon and hydrogen), due to cross-links, form a three-dimensional network with wide cells. Thus, the strength characteristics of cross-linked polyethylene are laid down at the molecular level, and it is very difficult to break such bonds.

When choosing PEX pipes, attention should be paid to the degree of crosslinking. The stitching method affects the durability and performance as well as the cost of the pipes. There are three ways to obtain crosslinked polyethylene, affecting the degree of crosslinking.

Pyroxide (PEX - a) - pyroxides are introduced into polyethylene. The degree of crosslinking is up to 85%.

Silane (PEX - b) - organosilanides are added to polyethylene. The degree of crosslinking is not less than 65%.

Radiation (PEX - c) - the degree of crosslinking is 60%.

If the degree of crosslinking is 0%, then the pipes become too brittle and prone to cracking. Too little stitching can have equally serious consequences. Be careful when choosing a pipe manufacturer, even if it says that it is crosslinked using the PEXb silane method - this does not mean that the degree of crosslinking is at least 65%. Choosing European manufacturers, you guarantee for yourself a high quality product and an honest level of stitching.

- Low wall thickness

- Fittings do not narrow the flow area

- Expensive tool of European manufacturers

- Fairly expensive fittings

If we consider the trends in the use of various plastic pipes in Europe, then PEX pipes are in the lead, and annually take several percent of the market from polypropylene and MP pipes.

Unlike polypropylene pipelines, cross-linked polyethylene systems from European manufacturers can be described as - installed and forgotten. However, this will have to pay a higher cost.

When choosing this type of pipe, it must be borne in mind that all its good properties are manifested when using high-quality materials and production technologies.The majority of pipes are imported to Russia from China and the level of crosslinking of such polyethylene is not known.

It should also be remembered that PE-RT is not cross-linked polyethylene - it is heat-resistant polyethylene with lower performance and cost than PEX cross-linked polyethylene.

Useful Tips

If it is not burdensome for your wallet, then opt for such a material as copper.

A good and durable option is a fiberglass reinforced system.

Both in terms of cost and reliability, this version will suit homeowners with an average income.

It depends on which side to look at the solution of this issue.

If you believe the old truth, then a good product cannot be cheap. But the most expensive thing is not always appropriate.

Therefore, do not really trust the judgments of the sellers of hardware stores and the so-called specialists. Gather a family council and there together try to find the optimal solution..

Ask neighbors or friendswho live in the countryside, how they solved this problem. Perhaps some information will be useful to you.

First, study the entire range of the market, do not rush to choose. The main thing in this matter is not to be mistaken. After all, not every year you will change the steam heating in the house.

Which pipes are best suited for heating: plastic, steel or copper, experts will tell you about this, see the video.

Subscribe to updates by E-Mail:

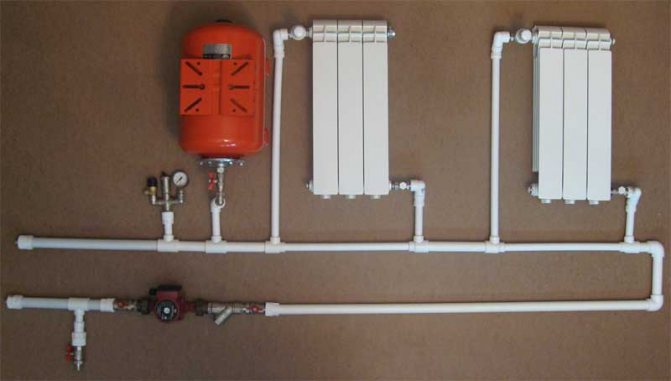

Polypropylene PP pipes

Currently, most of the radiator heating and water supply systems are assembled from polypropylene pipes and connections. High popularity of polypropylene systems was given by: low cost of pipes and fittings, the possibility of self-assembly, high quality pipes and connections. The connection of the pipe and fittings is carried out by welding (soldering).

- Due to less flexibility, they are more aesthetic in outdoor installation (relative to other plastic pipes)

- Low price of pipes and fittings

- Are not afraid of defrosting

- Concealed wiring possible due to secure connection of fitting and pipe

- Good chemical and corrosion resistance

- For high-quality installation, you need the skill of working with the tool ("soldering iron")

- At temperatures of water and coolant above 70 degrees C., the service life is sharply reduced

- Installation is possible only at positive outside temperatures

- Large wall thickness (25 PPR pipe corresponds to 20 MP pipe)

- Afraid of ultraviolet radiation

In conclusion, we would like to say that all of the above applies to pipes from well-known manufacturers who control product quality. For example, cheap polypropylene will not withstand even one defrosting - it will burst, most likely, and the service life of such a pipe will be much lower.

Polypropylene by type

You know, when I myself switched to polypropylene, I ran "on the rake". In the beginning, I didn't know which one to choose and a couple of times ran into trouble in the form of breakouts. However, now I will tell you the whole point - so as not to repeat my mistakes.

Polypropylene is divided into three types: - conventional, reinforced with aluminum and fiberglass.

Normal

It was he who appeared the very first and began to spread widely in the vastness of our homeland. It was with him that I got the first trouble!

pros

The structure here is simple - in fact, the pipe is a hollow cylinder made entirely of durable plastic.

It costs a penny, now you can find options for 50 rubles a meter.

Withstands temperatures up to 95 degrees.

Not susceptible to - rotting, oxidation, etc., can stand for a very long time on the water supply.

It seems like beauty, and only, but not everything is so simple with ordinary polypropylene, it has significant disadvantages.

Minuses:

- It has a very high thermal deformation.So, for example, for 10 meters of pipe, it can be up to 150 mm, the pipe simply sags under the influence of temperature.

- Already at 50 - 60 degrees Celsius, it begins to deform, and at higher temperatures, its deformation can reach maximum values.

These are very big disadvantages. It is because of them that many "legends" appeared about the unreliability of these pipes specifically for heating. However, this is not entirely true.

In my practice, there was such a case - during the heating season, the hot water pipe "sagged", the owner decided to straighten it, pull it up with force, and simply broke it. Often, such breakdowns were precisely because of such owners who tried to achieve the aesthetic "straightness" of the pipes.

This remained a problem for manufacturers as well. You need to do something, and you know - they came up with it.

Reinforced with aluminum

The point is also simple here. If you exaggerate, then a layer of aluminum is inserted into the middle of the pipe, the so-called "foil" or "sheet", whoever calls it what. It was this layer that was designed to combat thermal deformation of pipes for heating and hot water.

Pros:

At first, everything was fine. This option has proven itself only from the best side, its deformation has decreased several times. So the maximum that was noticed is about 3 - 5 cm. This is very good. However, these pipes are also far from ideal, and therefore are now disappearing from store shelves.

Minuses

This option had another problem, which began to appear after 2-4 years. It's all about the aluminum in the middle. This is a metal and like any other it oxidizes and decomposes (no matter how well it resists these processes), this is precisely its weak point. If the connection is poorly sealed and cleaned, then water begins to flow into this layer and slowly destroys it, the strongest effect from hot water supply.

Thus, the pipe begins to "halve" the lower and upper parts diverge, and the aluminum remains, as it were, in the middle. Individually, these layers are not designed to hold water and often break down causing leaks. Also, the disadvantages include the complexity of working with this type of pipes - it is recommended to clean the aluminum at the joints. Its price is the highest of all types of pipes - now the price can reach up to 300 rubles per meter, the running price is about 150 rubles.

I do not advise taking these pipes for either cold or hot water supply! We look at the third view, the most optimal.

Fiberglass reinforced

Here in the building, instead of aluminum, there is a layer of fiberglass, which is very firmly intertwined with both the upper and lower layers. Such a structure is very durable and can withstand all loads - temperature, pressure, oxidation.

pros

Fiberglass does not allow the pipe to "sag", the deformation is only 1.5 cm by 10 meters.

It does not deteriorate under the influence of water and remains durable throughout its service life.

It is also a pleasure to work with it, it does not require any preparatory cleanings, as, say, the version with aluminum.

The cost is slightly more expensive than conventional polypropylene, but cheaper than reinforced with aluminum. The optimal price on the market is 100 - 120 rubles.

It is he who needs to be taken for heating and hot water supply.

Minuses

Practically devoid.