Gasification of a private house is a rather expensive and laborious process. However, if you have made the decision to supply gas to your house, then you need to know what is required for this - what permits are needed to gasify the house, what work will need to be done, and how much it will cost.

First of all, you need to find out who is the owner of the gas pipeline (as a rule, it is GorGaz), a meeting with which will determine the possibility of tapping into its gas pipeline. If you received a positive response from him, then the next instance will be the design organization, which will develop and manufacture a project for connecting your house to this particular gas pipeline.

Already with the finished project, you go to the installation organization, which will take on the solution of all problems related to the installation of the gas pipeline. She is also responsible for the commissioning of this section of the gas pipeline, therefore, she must necessarily have an appropriate license to carry out this type of work. It is advisable to carry out all settlement operations with the installation organization only after the site has been handed over to the State Control authorities.

When all of the above steps have been passed, and all stages of the work have been done, you can use the gas for your own purposes and at your discretion.

But let's look at in order how to start gasification at home and what you need for this.

First stage. A set of documents for gasification of a house

- permission of the heads of the architectural and planning department (APU) for gasification of a private house;

- a copy of the technical passport of the Bureau of Technical Inventory (BTI) for a private house;

- topographic survey of the site with the landing of the most private house and gasified structures on the site at a scale of 1: 500 with applied communications and a gas pipeline, certified by the local gas service;

- written permission from neighbors to connect to the gas pipeline, if it is laid along their sections (however, as a rule, such permission must be obtained from GorGaz, since it is he who in most cases is the owner of the gas pipeline).

Stages of gasification of the house in the order of execution

Gasification of the village

So, to your settlement, let's call it a settlement, the main gas pipeline has been or has been connected. The question before you is whether you need to gasify your home and what you have to do for this. Everything in order.

- If your village is sufficiently organized, and you decide to gasify all or most of the houses collectively, then you need to start with two points:

- Create a non-profit organization for the gasification of your village;

- Order and agree on a project for gasification of the village.

- According to this project, the gas pipeline will be laid through the village and the places of the gas pipeline tie-in for each house will be determined. Collective work is being completed by laying the gas pipeline around the houses of the village.

Gasification of the house

For your home, you have to do a lot more paperwork and preparatory work. Namely:

- Obtaining technical specifications (TU) for gasification of a built house;

- Order, pay and receive a project for gas input and gasification of the house;

- Agree on this input project and the project for gasification of the house;

- Buy gas equipment;

- Order a project of ventilation and heating of the house;

- Carry out a set of works on the construction of a gas input, including the installation of a DRP;

- Collection of executive documentation for registration;

- Hand over the gas inlet of the house to the inspector;

- Gas pipeline cut-in by the regional gas company;

- Start up the gas.

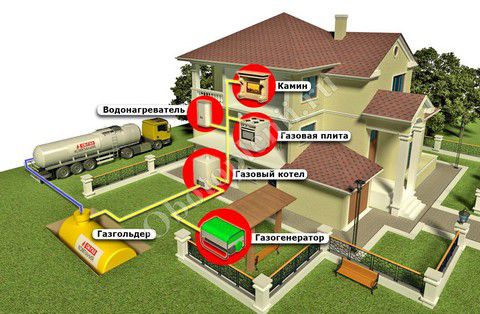

And now in detail about each stage of individual work on the gasification of your home. Autonomous gasification of the house is somewhat different from the main gasification.

Design

Having solved all the issues in GorGaz, your path lies in the design organization, of which there are a huge number today. Attention! When contacting a particular design organization or design institute, be sure to check for a license to perform this type of work.

The difference in the cost of services sometimes reaches from 10 to 50 thousand rubles (i.e. approximately from 280 to 1400 $). But it will be better if you immediately ask GorGaz which design firm they recommend, then there will be fewer problems.

If you need a visit to the house of an engineer - designer, to carry out all the necessary measurements, then please note that this item is stipulated in the contract.

It is with the designer that you agree on the placement of gas appliances in the house and the brand of the desired heating equipment. When the project is ready, the person in charge (designer) will have to coordinate it with the technical department of GorGaz without fail. This procedure can take from 10 to 14 calendar days.

After completing all the necessary steps described above, you will be able to make calculations and make an approximate estimate of all work in accordance with the project documentation. Next, you draw up a contract for the conduct of technical supervision and provide an act of inspection of chimneys by the VDPO service.

Gas supply system design

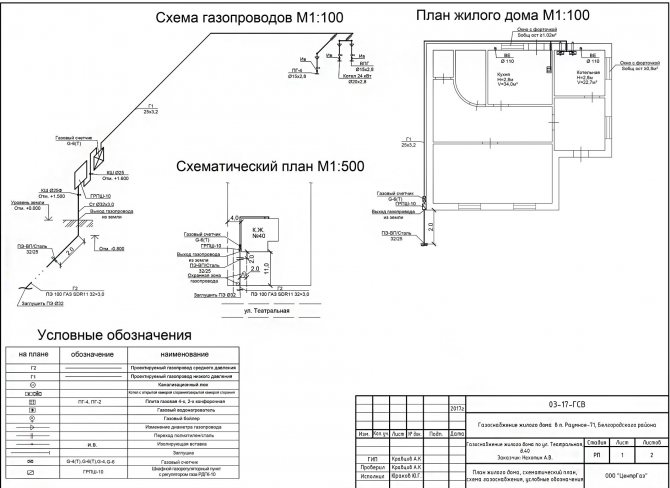

Topographic plan. (Click to enlarge)

Before signing the contract, in order to start creating the project, a number of important documents are collected:

- Topographic plan, which shows all engineering communications.

- The technical passport of the house or the project on which it was built.

- Equipment passport and boiler application description.

- Information about the location of ventilation and flues.

- The number of hot water points.

Measurements and approvals are often done directly on site, as the designer will be able to suggest the most acceptable option. Therefore, it is important to prescribe this clause in the contract. The whole stage should be done in two weeks.

Contract with a construction and installation organization

When all the necessary documents have been signed and all the affairs with GorGaz and the design organization are settled, you are sent to the installation organization, which will subsequently carry out all the necessary construction and installation work. Do not hesitate to check her license as well, since it is the installation organization who must hand over the work to GorGaz, therefore, an entry in the GorGaz register must testify to its existence.

Note: in most cases, installation organizations are licensed to perform not only installation, but also design work, in this case, if you order the implementation of the project directly from the installation organization, then the cost of gasification of the house is reduced by 25-30% of the total amount.

When you have agreed with the installers the timing and cost of the work, be sure to sign an agreement with them, so that in which case you have at least some guarantees from the contractor.

The contract will spell out guarantees and obligations from the installation organization.

Guarantees in the process of laying the external and internal gas pipelines:

- during construction and installation work, the contractor must have all the necessary fire extinguishing means, as well as a protective screen necessary to protect the surface of the walls from heating;

- after the final calculations for the work performed, the installation organization sends you the executive and technical documentation;

- the construction and installation organization undertakes to timely and efficiently perform all work under this contract.

In the process of performing commissioning works:

- to establish optimal modes of gas equipment to ensure the rational use of gas;

- instruct you on the correct operation of the equipment;

- if it is impossible to debug the operation of gas equipment or individual units, establish the reason for such an impossibility to fix it in the act and suspend work until the identified deficiencies are eliminated;

- hand over the result of work with the registration of a bilateral act for the work performed.

Turnkey private house gasification

Every person understands that you cannot do without professionals here, are you not a specialist in this field yourself or have already encountered this. Considering the complexity of the process and the waste of time, it is quite convenient if someone does absolutely everything for you. Gas connection to a turnkey private house in our company consists of several stages that will be performed from and to practically without your intervention:

- Consultation - we will answer all your questions.

- Departure of an engineer who makes an inspection and calculates the cost of the gasification project.

- Development and approval of the project, preparation of an act of selection of the route for central gas pipelines, receipt of technical specifications in Mosoblgaz.

- Free delivery of all components of the gas system.

- Installation of low, medium and high pressure gas pipelines, depending on the situation.

- Installation of GRPSh, DRP of various levels.

- Checking in Mosoblgaz.

- Tie-in and commissioning activities.

- Maintenance and repair.

Our engineers will even take on complex and non-standard tasks. We purchase adjustment devices only from trusted German manufacturers, thanks to which we achieve the perfect functioning of the entire system. This extends its service life and saves costs.

It is imperative to properly balance the oxygen and gas supply. Fine tuning the owner of the house saves up to 15% of fuel during operation

... In case of errors, soot forms inside the heat exchanger, which clogs the lumen, due to which the equipment wears out faster and the fuel is consumed uneconomically. It is for these reasons that the gas connection to a private house should be carried out exclusively by experienced specialists with professional devices that they know how to use.

Among other advantages is SRO admission. We pay membership fees, which allow us to insure all work performed. This is an indisputable advantage when working with us.

Drawing up executive and technical documentation

The installation of the gas pipeline has been completed, as well as all the necessary equipment, then the executive and technical documentation is drawn up, and the installed gas pipeline is accepted by a special commission consisting of their customer, contractor and representative of GorGaz.

The acceptance period by the commission can be from 14 to 30 working days. If no comments were made, the GorGaz representative will write you a receipt for technical supervision, which you will have to pay and then give a copy to the installation organization. On average, the payment is about 1,500 rubles ($ 43).

Please note that at the time of acceptance, not only must be installed, but also all the equipment listed in the project documentation must be connected. After the commission is completed, the installation organization will prepare and transfer to GorGaz all the necessary technical documentation, where it will be stored.

Based on the decision of the commission and on providing GorGaz with all documents, within 21 working days, the meter will be sealed and an agreement will be concluded with you for the supply of gas, as well as for further maintenance of both the gas pipeline itself and the gas equipment located inside the house.

Required Documentation

To consider in a gas distribution organization (GDO) an application for the technological connection of a residential building to the gas distribution network, the following documentation must be collected:

- documents confirming the applicant's ownership of the house and land;

- a document confirming the compliance of the technical conditions of the house with the gas distribution network (TU);

- copy of your passport;

- the scheme of the land plot and the adjacent territory;

- calculation of the planned gas consumption;

- gasification project.

And also in the application, the location of the house, which must be connected to the gas main, is indicated in the application, the applicant's passport data and the postal address, e-mail address or telephone number for communication. The application can be submitted in electronic format on the GDO website, sent by mail or at the document reception center of the gas distribution organization. For the inaccuracy of documents attached by the applicant in electronic format, the legislation provides for administrative liability. The address of the gas distribution organization can be found in local government bodies or found on the Internet, indicating the name of the subject of the Russian Federation.

Stages of gasification at home

The contractor considers the application within three days from the date of receipt. If the applicant has not fulfilled all the requirements, he will be notified that all missing information and documents must be provided within 20 days. Consideration of the application for this time is suspended.

Safety briefing

When all of the above list of actions is left behind, you will definitely have to undergo safety instructions when using gas.

You can go through the briefing directly in GorGaz, where you will be instructed by a safety engineer, after the briefing, you sign in the journal that remains in GorGaz.

You can also be instructed at home by a certified specialist to conduct safety briefings during the commissioning of gas equipment. You, in the same way as after the briefing in Gorgaz, sign in the TB log, in the future this log will be transferred to GorGaz.

Commissioning works

After starting the gas, you will need to contact the organization with which you signed a service agreement for all provided gas equipment in order for it to activate this equipment. This will be one of the most important conditions for the warranty service of your equipment within the prescribed periods in the warranty service agreement (what warranty period will be established depends on your place of residence, on average, the warranty period for servicing gas equipment is from 1 to 3 years)

You will also need documents to perform a heat engineering calculation, which will help determine the required boiler power to provide heating and hot water supply to a private house (for this, you can contact specialists from housing and communal services):

- floor plans of all heated premises of the house with explication, as well as indication of heights and areas;

- types and number of hot water intake points (such as washstands, bathtubs, showers, etc.);

- a description of the possible use of a gas boiler for technological needs.

The owner of a private house has the right to do all the approvals both independently and to contact an organization that deals with gasification of the house and installation of a gas pipeline.

Types of gas pipelines

Now that you have familiarized yourself with the conditions for gasifying your home, consider what types of gas pipelines exist and which one to choose for gasifying your home.

According to their location relative to the surface of the earth, gas pipelines are divided into underground and aboveground, which are distinguished by the method of entering into the building both the internal gas supply networks themselves and risers, which serve to distribute gas to the floors of the house, and all gas-consuming devices.

It is known that the construction of an underground gas pipeline is much more expensive (by about 60%) than an aboveground one. But, nevertheless, such a high cost (1 linear meter of laying an underground gas pipeline costs about 1,300 rubles) does not make the underground gas pipeline less popular. This is due to the fact that a pipe passing through the ground is much more protected than a pipe passing through the air, which means that it will last much longer. Moreover, it is less hazardous to the environment.

During the laying of the underground gas pipeline, it is necessary either to completely block traffic, or to restrict travel on certain sections of the road. To do this, the organization executing the installation work, on the basis of the project documentation available to it, draws up terrain-specific traffic patterns for both vehicles and pedestrians, as well as the placement of equipment with an indication of the geometric parameters of the desired section and entrances to houses, detours and places of arrangement of road signs.

Schemes for organizing traffic and fencing places for laying the underground gas pipeline are coordinated with the department of the state traffic safety inspectorate (GIBDD), which issues an order for this type of work.

As for the aboveground gas pipeline, it has both advantages and disadvantages. For example, open sections of a gas pipeline are more susceptible to corrosion, and it is easier to connect to such systems without permission. Underground gas pipelines are considered more reliable, but their repair is accompanied by additional costs.

Let's compare two types of gas pipelines in order to make it easier for you to make your choice - which of these types will suit you best:

- if in the area where you live, the soil has high corrosion rates, then in this case it is appropriate to lay the aboveground gas pipeline;

- if a high-voltage power transmission line passes near the place of laying the gas pipeline, then in this case the best option would be to lay an underground gas pipeline;

- if the gas pipeline runs along a neighboring land plot, then in order to avoid damage to the fertile layer of the earth along the entire gas pipeline leading to your house, it is best to choose the laying of an elevated type of gas pipeline, in which case it will be easier to obtain permission from neighbors to lay the gas pipeline along its land plot;

- if you have to lay a gas pipeline across the road, then in this case you can choose a combined option: an underground gas pipeline is laid across the road, and an overground gas pipeline is laid across the land plot.

Gas pipeline material

Now, knowing what types of gas pipelines are, in this part we will consider the question of what types of pipes are used when laying a gas pipeline.

Some 10-15 years ago, pipes for a gas pipeline were made only of steel. Today, polyethylene pipes are in great demand, which not only are not inferior in their properties to steel ones, but also have a number of advantages:

- such pipes are highly resistant to the negative effects of various chemical compounds and environmental factors;

- they are strong and, at the same time, sufficiently flexible, which makes it possible to lay a gas pipeline in regions with particularly severe climatic conditions.

Note: at low temperatures down to -45 degrees, polyethylene does not lose impact strength.

- Since plastic is not a conductor of electric current, such pipes are absolutely insensitive to the effects of stray currents and, therefore, have reliable protection against electrochemical destruction. Therefore, plastic pipes do not need additional protection before laying them in the ground;

- the weight of plastic pipes is 7 times less than that of steel. Moreover, they are delivered in special compact coils, which greatly simplifies their transportation;

- installation of such pipes is simple and convenient;

- The warranty period for plastic pipes is 2 or even 3 times longer than for steel pipes, and is more than 50 years.

Important! the entry of gas pipelines into the house is carried out only with steel pipes, as well as the distribution of the gas pipeline inside the house.

But gas pipelines made of polyethylene pipes have not only advantages, but also restrictions on their use for the construction of gas pipelines, which are stipulated by SNiP 2.04.08-87. Below are some of the restrictions on gas pipeline construction using polyethylene pipes:

- the installation of a gas pipeline from polyethylene pipes is prohibited in areas where the temperature regime of the outside air reaches below minus 45 degrees;

- it is also prohibited to install gas pipelines using polyethylene pipes in areas where seismicity exceeds 6 points;

- the installation of gas pipelines using polyethylene pipes is prohibited both above ground and above ground, as well as inside buildings, in tunnels, collectors and canals;

- on land plots where it is planned to arrange crossings over artificial and natural barriers, laying a gas pipeline from polyethylene pipes is also prohibited.

Projects to ban gasification of high-rise buildings

After the abolition of SNiP in 2003, which prescribes bans and restrictions on the altitude of the installation of gas appliances, many structures and departments tried to reintroduce them, especially after a series of explosions.

So, at the end of 2020, such a proposal was made by Rostekhnadzor, urging to think about electrification. Deputies of "Fair Russia" also made similar attempts. The initiators propose to enter a veto at least in new buildings, even if they leave gasification in already built houses with the replacement of stoves with devices with maximum protection "gas control".

However, this is unlikely to happen. Almost all tragedies are related to the human factor; the technical capability allows the safe use of gas equipment in high-rise buildings.

Electric stoves are considered safer than gas equipment for residents of MKD. But many are in no hurry to give up gas. There were even joke memes like those that it is impossible to roast a steak with high quality on electro.

Although many people understand that relying on the adequacy of their neighbors and the safety system of gas installations is not always advisable. There are cases when some residents of apartment buildings try to refuse gas, but their requests are not always satisfied due to various reasons, such as, for example, weak electrical wiring that is not suitable for electric stoves.

It turns out a double-edged sword. On the one hand, it is difficult to gasify a building, on the other hand, which is already equipped with such equipment, to electrify it.

Heating boiler selection

Having considered the issues related to the conditions of gasification of the house, types of gas pipelines, it is necessary to consider another of the equally important issues of gasification - this is the choice of a heating boiler.

As for the choice of a boiler, today the modern market offers many different heating gas boilers. They are subdivided into floor-standing and wall-mounted.

A distinctive feature of floor-standing gas boilers is a huge choice of equipment power, which is able to heat more than 150 m2 of premises. With the additional installation of a boiler, the gas boiler will provide maximum hot water supply.

Wall-mounted gas boilers are distinguished, first of all, by their compactness, built-in automatic safety system, the presence of an expansion tank and circulation pumps, as well as a relatively low cost. They are usually designed to heat a room with a total area of up to 150 m2 and provide up to 2 taps with hot water.

Gas input and gasification project at home

For more details about the gasification project at home, read a separate article on the site by clicking on the link.Here is short.

The gasification design contract is concluded on the basis of the received technical specifications. The gasification project itself and the gas input project are done in a licensed organization according to your terms of reference and the general conditions for gasification of the village.

The plan of your house, the place of gas injection and the room for installing equipment will be indicated in the technical condition

Tip: In the technical conditions for the project, increase the consumed volume of gas, as if a guest house was built on your site. It can come in handy, and you will not need to redo the gas connection.

The gasification project, of course, needs to be approved.

Heat exchanger material

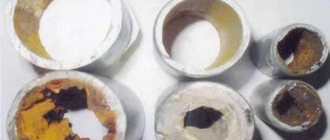

As for the material from which heat exchangers in boilers are made, it can be cast iron or steel.

The cast iron heat exchanger is characterized by a long service life (the service life of a gas boiler with a cast iron heat exchanger is 20-25 years, and a boiler with a steel heat exchanger is 10-15 years) due to its high corrosion resistance.

As a rule, the heat exchanger is made of cast iron from sections, which allows, in the event of an accident, not to dismantle the entire boiler, but to isolate only those sections that have been damaged. Keep in mind that a boiler with a cast-iron heat exchanger is highly sensitive to both mechanical and thermal shock, therefore, make-up with cold water must be carried out only after the heat exchanger has completely cooled down.

A gas boiler with a steel heat exchanger has a much lighter weight and a lower price compared to a boiler with a cast iron heat exchanger. A boiler with such a heat exchanger is not afraid of mechanical stress, but it is prone to corrosion.

Note: a boiler with a cast-iron heat exchanger weighs from 114 kg, and its cost is from 30,000 rubles ($ 845), and a floor-standing boiler with a steel heat exchanger weighs from 60 kg and costs from 12,000 rubles ($ 340).

Complex of works for the construction of a gas input

The complex of works on the construction of a gas input includes:

- Route preparation (earthworks);

- Gas boiler grounding circuit with acceptance certificate;

- Installation of indoor gas equipment;

- Grounding of a gas boiler and a gas pipeline;

- Gas pipeline cut-in;

- Installation of FGP and heating;

- Equipment and construction of a boiler room (furnace) in the house: installation of chimneys and ventilation ducts.

Upon completion of the delivery, you will receive:

- Ventilation readiness act;

- The act of measuring the resistance of protective grounding;

- The act of measuring the resistance of lightning protection;

- Land work act;

- The act of demarcation of work between the district repair and maintenance service and the organization that will maintain your gas equipment;

- Gas input acceptance certificate.

The presence of all these acts will allow gas to enter the house.

Non-volatile and volatile boilers

Non-volatile boilers, characterized by natural circulation, have a number of disadvantages: this is the large diameter of the pipeline itself, and the presence of an open expansion tank, and the peculiarities of installing the system with ensuring its slope, but the most important thing is the inability to regulate the air temperature in the room. In this case, the room in which the boiler with an open combustion chamber is supposed to be installed must have both tidal and exhaust ventilation and a chimney.

As for volatile boilers, they have a closed expansion tank, circulation pumps and full electronic boiler control automation. Thus, they can rightfully be considered a mini-boiler room. However, it is necessary to take into account the fact that the uninterrupted operation of the entire heating system must be ensured by a stable mains voltage of 230 ± 10% in the presence of a voltage stabilizer.

Only a specialist can determine the choice of a gas boiler, its capacity, as well as designate a piping scheme and determine the need for additional automation.To calculate the approximate power of a gas boiler, you can make calculations based on the fact that for 10 sq. m of the room requires 1 kW of boiler power + from 15% to 20% of the reserve, designed to extinguish unforeseen heat losses.

With regard to the removal of combustion products in gas boilers, this process can occur either naturally or by force (turbo). In boilers with natural draft, gas is removed by draft in the chimney; in boilers with forced draft - using a fan built into the boiler.

Gas boilers with a "turbo" system, in most cases, are installed at facilities that do not have a traditional chimney. Then the specialists install a coaxial chimney, which is a kind of "pipe in a pipe" that goes out into the street through the wall.

The outer pipe is designed for air supply, and the inner pipe is for the removal of combustion products. A forced draft gas boiler is also installed in a house, where it is undesirable to take air from the room once again.

What you should pay attention to when bringing a coaxial chimney to the street:

- the chimney pipe must be at least 2 m from the ground;

- even during the design of the gas pipeline, if a boiler with a coaxial chimney is installed in your house, you should pay attention to the fact that the exit of combustion products from the boiler does not fall back into the open windows back into the house;

- it should also be noted that condensation can form in the coaxial chimney; to drain the condensate, it is necessary to install a coaxial chimney at an angle of about 2 degrees with a slope to the ground;

- the coaxial chimney must have an unobstructed discharge of combustion products to the street, for this it is necessary that the distance from the end of the outer part of the chimney to the buildings located near the house is at least 1.2 - 1.5 m.

Basic requirements for gas supply

Due to the fact that gasification of an apartment building is carried out on the basis of legislative norms, the latter determine the area of responsibility. So, the responsibility for maintaining and caring for the gas equipment installed inside the apartment falls on the owners of the property. These devices include:

- water heaters;

- gas stoves;

- gas water heaters;

- other devices connected to the gas supply network.

Attention: the responsibility for the condition of gas networks, equipment and meters that are installed inside the house is borne by the housing and communal services or the management company.

As follows from the relevant legislation, the Criminal Code is obliged to conclude an agreement for housekeeping services with a gas distribution organization. Employees of the latter, after installing the equipment in the apartments, conduct instructions on the rules for using these devices.

View this post on Instagram

Preparation for the heating season ⠀ ⏩As soon as the heating season ends, preparations for the next heating season literally immediately begin, which involves the implementation of certain measures. ⠀ ☑️Mandatory activities in preparation for winter are: