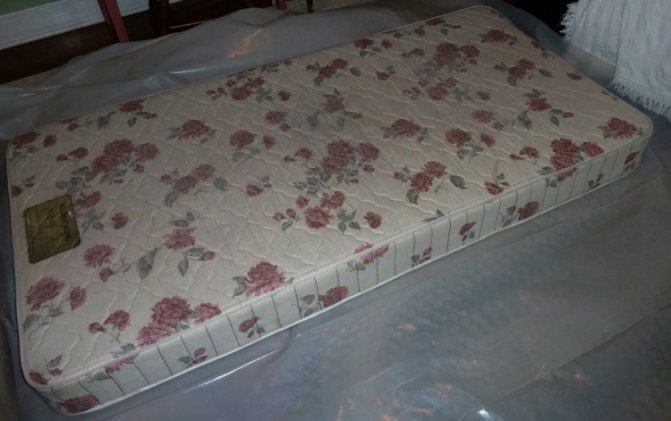

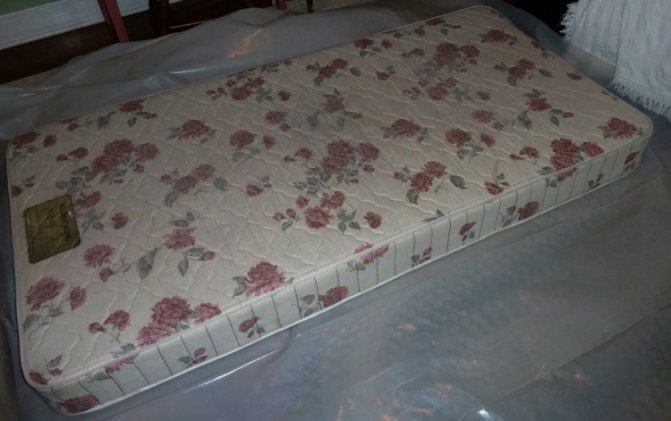

Polyurethane mattress, its properties

Polyurethane, the filler of these mattresses, is exclusively synthetic, but this does not mean that it is dangerous for the human body. This artificial material does not contain harmful substances and does not emit toxins, therefore it is ideal for making sleep items. Foamed structural polyurethane of various hardness is chosen for use as a filler; after hardening, air cavities are formed in its structure. It is thanks to this airy property that the material perfectly keeps its original shape, does not rot, attack by pests, it is not harmed by moisture and changes in air temperature.

The most effective are mattresses made of denser and more expensive polyurethane. It consists of hollow cells of different volume, which react differently to the pressure exerted on them. Small cells allow the mattress to be soft, and large cells retain elasticity, it is the combination of these properties that form the optimal quality of mattress rigidity.

When buying a mattress in a store, you should look at its label, the foam hardness parameters are the optimal indicator of 32 kg per 1 m3. The lower the cost of a polyurethane mattress, the less dense it is and the less comfortable it will sleep on - this rule you need to know when buying. Considering that the price of orthopedic products for sleeping has never been low and the fact that polyurethane mattresses are not the most expensive of this category of products - to provide optimal body support during rest, you should not chase a low price, but choose the optimal combination of quality and price. ... However, it is not recommended to use polyurethane mattresses for babies under 1 year old, since they simply do not suit them in terms of rigidity. For these babies, spring mattresses or coconut fiber mattresses are ideal.

The most important quality of a polyurethane mattress is its orthopedic properties. After a person's sleep, the mattress completely recovers its shape. A person rarely sweats on it due to the fact that the material "breathes", and vice versa does not freeze, again due to the air pockets. All these qualities will be possessed by a polyurethane mattress and will serve its owners for a long time, if it is properly operated and looked after.

Hazardous properties of polyurethane foam

However, it is too early to fall into euphoria, because PUF contains active chemical components, among which phenol is the most dangerous. In addition, it contains resins, catalysts, and solvents. During combustion (and foam rubber burns in the presence of a direct fire source) toxic components - formaldehydes - are released into the air.

We also advise you to read the article: Foam mattresses

The most dangerous component of polyurethane foam is phenol. Dangerous fumes can last for years, and fumes from new material are more dangerous. Phenol has a destructive effect on the most important systems of the human body: cardiovascular, nervous, and respiratory. That is why it is worth thinking 100 times before giving your child a toy stuffed with foam rubber or placing him on a foam mattress.

Phenol vapors can cause serious health problems:

- allergic reactions;

- pulmonary pathologies.

Dangerous consequences of harmful fumes are frequent headaches, loss of coordination of movements up to loss of consciousness, possibly impaired liver and kidney function.

When using polyurethane foam as a basis for a mattress, up to 30 volatile chemical compounds are released into the air and phenol is not the only one that can harm a person.

Pros and cons of polyurethane mattresses

The advantages of polyurethane mattresses are obvious:

- The optimal combination of quality and price.

- Possesses orthopedic properties.

- Hygienic (does not rot, indifferent to pests).

- They do not cause allergic reactions.

- Completely safe filler.

- Long-term operation and preservation of qualities.

- Ease of care and cleaning (not afraid of water).

While sleeping on a polyurethane mattress, the filler adjusts to the contours of the human body, supporting it and relaxing the muscles. Despite this, the mattress is quite elastic, it correctly supports the spine, improves blood circulation, thereby eliminating congestion in the body. Polyurethane mattresses are recommended for overweight people, bedridden patients in the postoperative periods, or during periods of illness, as they prevent bedsores.

Undoubtedly, it is pleasant that the polyurethane mattress does not hold together, does not deform or wrinkle. If there is a need for transportation, it can be easily rolled up and transported to the desired place, after which it will again take its original shape.

With such significant advantages, polyurethane mattresses also have disadvantages. Namely:

- Quickly absorbs liquid, even vapor.

- Cheap polyurethane mattresses wear out and deform quickly.

- They require careful maintenance (ventilation, cleaning).

- Relatively short service life up to 10 years.

After the expiration of the service life (more than 10 years), polyurethane gradually collapses, it deforms and this immediately affects its orthopedic properties, the comfort of sleep and rest. The disadvantages of polyurethane mattresses are insignificant and they are fully compensated by its advantages, but to buy it or not, everyone must make a choice on their own.

Similar posts

- Steel h12mf for knives: characteristics, pros and cons

- Eucalyptus blanket: the pros and cons of choosing

- Steel 110x18 for knives: pros, cons and features

- Pros and cons of vacuum packaging

- Satellite TV: advantages and disadvantages

- Giro scooter: pros, cons and what you need to know

- Electric stove: advantages and disadvantages

- Solid fuel boilers - the pros and cons of choosing

How to make a foam mattress with your own hands

Experts recommend using exclusively orthopedic mattresses in everyday life, in addition to comfortable rest, this is also the prevention of diseases of the musculoskeletal system. Unfortunately, the price of factory-made mattresses is quite high and not everyone can afford it. Meanwhile, making a foam mattress with your own hands is not such a difficult task.

Factory Orthopedic Mattress Structure

When sewing a mattress, you can go in two ways:

- to simplify the task as much as possible and use a thick layer of highly elastic material as a filler. After cutting, it remains only to process the edges of the material, sheathe it with a cloth and place it in a cover. Foam mattress 10 cm created in this way will be quite convenient and comfortable;

- you can complicate the task and try to combine a layer of foam rubber and a spring base in the mattress. In this case, the output will be an analogue of factory orthopedic mattresses.

One of the best options is a spring base with independent springs. In this case, the person is guaranteed to be able to take a comfortable position. In the proposed design, the spring base will be placed in a box glued from pieces of foam rubber. For the side edges, you can use foam rubber with a thickness of about 30 mm, but for the upper and lower parts - at least 50 mm. You will also need felt, fabric for upholstering the mattress and sewing the cover, braid.

The main part of the mattress

The base of the mattress is a structure consisting of two layers of foam rubber, two layers of felt and a spring base located between them. After cutting out the foam rubber and felt, first a layer of foam rubber is laid on any horizontal surface, then there is felt, a spring base, again a layer of felt and this "cake" is covered with a layer of foam rubber. Felt is used here so that the springs under load do not damage the surface of the polyurethane.

The structure of the future mattress

On the sides, the free space must be closed with inserts from the same polyurethane, as a result, a closed box should be obtained. It is better to use special glue to glue the elements of the box. You can do with ordinary PVA and or liquid nails, but, firstly, the drying time of the adhesive layer will increase, and secondly, a hard crust forms at the bonding site, which simply cracks during deformation.

Bonded mattress base

It is not necessary to additionally fix the felt and the spring base. They will not move during operation.

For additional strength, you can put a wide board on the foam rubber when gluing, and place a load on it.

Cover sewing instructions

For the cover you will need batting and fabric; when cutting, you just need to take into account the size of the foam "box". And, of course, leave some margin for processing the edges.

In the first step, the batting is sewn onto the fabric. On a flat surface, the batting and fabric are aligned with each other and manually stitched along the long side of the rectangle several times. After that, you can move on to processing the edges.

First, the excess batting is cut off, which protrudes beyond the limits of the fabric, after that, along the perimeter, the part of the future cover is stitched with an overcast seam. After that, you can sew the narrow parts of the cover into one piece.

Sew on large parts using a decorative tape that hides the seam. First, the braid is sewn along the perimeter of a large part, then the edge of the narrow part is applied to the same braid, the braid is folded and stitched. The zipper is sewn on the same principle so that the mattress can be reached when washing the cover.

Finished mattress

Reviews of polyurethane foam mattresses

Analysis of customer reviews of polyurethane foam mattresses shows that most consider them to be an excellent budget option. Some indicate that the service life of such models is less than that of more expensive ones, but the low cost completely covers this drawback.

There are negative reviews about a persistent unpleasant odor, but most often we are talking about models purchased in dubious stores. Fake mattresses rarely meet the stated quality and safety criteria.

If you want to buy an inexpensive high-quality mattress of medium elasticity - models with polyurethane foam filling will be an excellent choice. The main thing is to buy them in specialized stores, from the manufacturer's authorized dealers.

PPU is a fire hazardous material. Is it so?

Let's start with what we mean by combustible and non-combustible material. To do this, let us refer to GOST 30244-94 “Building materials. Flammability Test Methods ". In this document, building materials are divided into combustible (G) and non-combustible (NG). Non-combustible materials include metal (and even then not all alloys), stone, glass, expanded clay, basalt, etc. All wood-based or polymer-based materials are flammable and are divided into flammability groups:

- G1 - slightly flammable (for PPU, this means that it is not capable of ignition, is resistant to the effects of open fire and thermal radiation, but under the influence of flame it loses mass, smolders)

- G2 - moderately flammable (resistant to the effects of open fire and heat radiation, does not support combustion, in the absence of a flame extinguishes on its own)

- G3 - normally combustible (in the absence of a flame, it extinguishes on its own, cannot be a source of ignition)

- G4 - highly flammable (supports combustion and can be a source of ignition)

In addition, during the tests, other factors are taken into account - flammability, smoke release, weight loss, flame propagation speed, decay time, release of toxic substances and a number of other factors. After such comprehensive studies, a conclusion and a fire safety certificate are issued, which regulates the scope of application of a particular material in construction.

Polyurethane foam is good because, depending on its composition (type and amount of fire retardant used), it can belong to all four groups of flammability. And the choice depends directly on the scope and wishes of the Customer. So, for example, polyurethane foam with a flammability group G1 and G2 can be used as insulation in residential and industrial facilities with open access to the insulation (roofs, facades, plinths, etc.). While the use of polyurethane foam with a flammability group G3 and G4 is justified for refrigeration units, when the polyurethane foam is concluded between other non-combustible building structures, etc.

In the section "certificates" on our website you can see examples of fire safety certificates for PPU: https://himtrust.ru/products/certs/napylitelnye/

Is polyurethane foam harmful to health

This question is of interest to many. After all, insulation is most often applied from the inside of the walls. And since it is a polymeric substance produced by a chemical reaction, people are afraid that it will release toxic substances.

Indeed, while liquid polyurethane foam is sprayed onto walls, contact with the skin or the respiratory tract can be dangerous. Therefore, all work is recommended to be carried out in a respirator and protective clothing.

But after hardening, the polyurethane foam no longer causes harm. And it dries up in 20 seconds, so the finished layer of heat-insulating material is absolutely safe.

Spraying process

Recently, there have been a lot of rumors about the dangers of mattresses with polyurethane foam filler. They are explained by the composition. Anyone will be intimidated by chemical dyes, phosphorus, formaldehyde and even arsenic.

But it must be borne in mind that all these substances in the process of foaming entered into a reaction and after the foam solidified, they became completely harmless. They can be active only when the material is heated to 200 ° C or during combustion. In an apartment it is impossible to obtain such a temperature, which means that substances hazardous to health will not be released.

It is better to pay attention to the positive characteristics of polyurethane foam mattresses:

- elasticity;

- anatomy;

- hypoallergenic;

- affordable price.

We suggest that you familiarize yourself with How to clean a frying pan from carbon deposits (42 ways)

The last argument turns out to be the most powerful one. It is he who makes mattresses with polyurethane foam in demand among consumers.

PPU is an expensive material. Is it so?

Indeed, the cost of 1 m3 of polyurethane foam is more expensive than most other traditional insulation materials. But it’s not so obvious. After all, for some reason we also do not buy the cheapest things and do not drive the cheapest cars.

- First argument, installation costs. For the installation of PPU, no fasteners are needed, the cost of the insulation, as a rule, already includes work on "turnkey" spraying. Insulation sheet requires installation work and the purchase of a substantial amount of fastening material, as well as material for sealing joints. All this must be calculated separately.

- The second reason is that membranes are not needed. For the correct installation of mineral wool insulation in order to extend their service life and reduce the risk of getting wet, moisture and windproof membranes are required. These membranes also require fasteners and are an additional item in the contract cost estimate. In addition, membranes are very difficult to assemble tightly and to work effectively.

- The third reason is that the equivalent layer of insulation can be very different.So, for example, 50 mm of polyurethane foam is equivalent to 100 mm of mineral wool or 80 mm of ball polystyrene. That is, to achieve a similar thermal insulation effect, you need 2 times less polyurethane foam than mineral wool.

- Fourth argument, logistics. When spraying with PU foam, the starting material is supplied in liquid form and consists of 2 barrels and 1 installation with tools. All this easily fits into a minibus or "gazelle". To deliver a sheet of insulation, you will need a transport with a volume of 20-30 times more, while you will, in fact, transport air. Of course, this will be reflected in the budget.

- Fifth argument, service life. Not only is the service life of the PU foam comparable to the service life of the supporting structures, which is incommensurably greater than the main competitors. It is also necessary to take into account changes in efficiency over time, which is associated with the loss of the original properties of the insulation. So for mineral wool insulation, the loss of thermal insulation properties ranges from 3 to 8% per year, depending on the operating conditions and the type of material. This means that in 5 years, heat loss and heating costs will increase by 15-40%. At the same time, the study of buildings of the 60-80s in Europe and Japan with the use of polyurethane foam allows us to say that for 25-30 years, changes in the initial physical-mechanical and thermal properties do not exceed 5-7%. At the same time, science has stepped far forward and the PPU formulations are now more perfect.

How is it used

By itself, polyurethane foam is quite an expensive material. And finding a mattress filled only with it is quite problematic. It is important to know when buying a polyurethane foam mattress: such products, as a rule, contain filling, consisting of several layers: in addition to the main material, coke fiber is often used.

We suggest that you familiarize yourself with Aluminum cookware is harmful to health, another lie or is it true

For greater effect, manufacturers additionally strengthen the walls and corners of the mattress. Because of this, when you lie down on the bed, the mattress does not change shape so abruptly (after all, this can usually be inconvenient). It also prolongs the life of the mattress, which gets additional protection from damage.

But sometimes you can find mattresses, which are a solid block of polyurethane foam. Their price is higher, but this is no accident. They have no springs and are more dense. Therefore, they can be placed even on uneven surfaces, while maintaining the feeling that you are sleeping in your bed. True, they make these mattresses last longer, which also makes them difficult to buy.

conclusions

Of course, we have listed not all negative opinions and not all the arguments for. But, I hope, we were able to make it clear that many fears are associated with ignorance or unsubstantiated rumors.

However, there is no smoke without fire. Probably, someone has come across unscrupulous or inexperienced contractors, perhaps even with a defect in the raw materials from which the PUF was obtained, or with non-compliance with the work schedule. If your Mercedes breaks down, this does not mean that all Mercedes cars are bad. Perhaps it was just necessary to change the oil on time.

In this regard, we recommend that you carefully approach the choice of a supplier of raw materials and a contractor. Choose only trusted, experienced teams with quality PU foam spraying equipment. Get feedback from their customers. Make sure the contractor has applied the raw materials with the stated requirements, ask for certificates. It is also not difficult to determine the density of the obtained polyurethane foam and its flammability right at the work site using a kitchen scale and a lighter. If in doubt, conduct a professional examination. All this is best done before the start of work or at the very beginning - it will save a lot of time and nerves.

The good news is that PPU continues to gain popularity and consumer confidence, at the same time occupying an increasing market share. More and more experts agree that PPU is the future in the field of energy-saving construction technologies.

For more information on this topic, see:

- PPU spraying - what is it?

- Thermal insulation (thermal insulation, thermal insulation)

- Density of polyurethane foam

Discussion

Please enable JavaScript to view the comments powered by Disqus.

Harm to health

But, despite its positive properties, this material is still capable of causing harm to health.

The thing is that the main feature of polyurethane foam, which makes it attractive to consumers, is its main disadvantage. This material is quite soft. And the fact that it takes the form of a human body is not at all good for us. This gentleness causes people to sleep in positions that they feel are more comfortable. However, these postures are unnatural. Because of them, the deformation of the spine occurs.

Such mattresses are especially dangerous for children. Their posture has not yet been formed. The spine needs support. To do this, the child must sleep on a firm mattress. Natural materials such as coconut fiber are especially popular.

There are other disadvantages of polyurethane foam as well.

- It is destroyed by exposure to direct sunlight.

- It does not tolerate prolonged contact with liquids.

- According to some experts, it emits harmful substances under the influence of temperature.

The magazine "Miss Purity" draws attention: although the last argument is not officially confirmed, many people, having tested mattresses made of artificial materials, do note that they gradually develop more and more headaches, nausea and drowsiness. Even if you are not worried about the possible consequences for the spine, pay attention to these symptoms.

Spraying process

Impact of polyurethane foam on the environment

Due to the fact that polyurethane foam covers the surface with a dense layer of thermal insulation, energy losses become minimal. There are no drafts, noise or condensation in the room. This reduces the environmental burden.

High-quality spraying and material features make it possible to make the insulation layer thin, but reliably protect from the cold. This helps save energy costs. Long service life of PU foam reduces repair costs. Insulation can be changed less often, which means that natural resources will remain intact for longer.

The environmental safety of polyurethane foam is confirmed by a low flammability class, as well as the absence of toxic emissions during operation. This makes the material one of the most environmentally friendly on the market and saves money on air purification. Ultimately, it helps to reduce harmful emissions into the atmosphere.