Advantages and disadvantages of diesel heating boilers

Diesel heating boilers have many positive qualities, thanks to which they have earned good reviews from many consumers.

- Autonomy - the functioning of the heating system does not depend on the main gas supply or the power supply of the house. The main thing is to stock up on enough fuel.

- Durability - diesel boilers have an average service life of 40-50 years.

- The products have a high-quality insulated body. which ensures the safety of their use.

- High efficiency - diesel boilers provide high heat transfer in a short time, therefore they can quickly heat even large rooms.

- Additional heated burners used in modern models provide economical fuel consumption.

- All boilers have an easy-to-use control system.

- Most models can run on both diesel fuel and other fuels.

- Availability - the installation of a diesel boiler does not require special permission and can be done independently.

However, diesel heating boilers also have certain disadvantages. which, for some consumers, may negate all the available benefits.

- The installation of a heating system using a diesel boiler is very expensive. since in addition to the purchase of direct equipment, it is required to purchase tanks for storing fuel, purchase a certain amount of combustible material, equip a separate room, etc.

- The high cost of the fuel used will make the use of a diesel boiler for heating small rooms irrational.

- A diesel boiler requires constant maintenance and periodic cleaning. otherwise, the soot generated after fuel combustion can clog the mechanism and interfere with the normal operation of the device.

- Boilers equipped with an automatic regulation system operate from the mains, therefore, in the event of a power failure, the use of the automation function will become impossible.

Volumetric and mass flow rate of gas

Gas flow rate is the amount of gas that has passed through the cross section of the pipeline per unit of time. The question is what to take as a measure of the amount of gas. In this capacity, the volume of gas traditionally acts, and the resulting flow rate is called volumetric. It is no coincidence that gas consumption is most often expressed in volumetric units (cm3 / min, l / min, m3 / h, etc.). Another measure of the amount of gas is its mass, and the corresponding flow rate is called mass. It is measured in mass units (for example, g / s or kg / h), which are much less common in practice.

As the volume is related to mass, so the volumetric flow rate is related to the mass through the density of the substance:, where is the mass flow rate, is the volume flow rate, is the gas density under the measurement conditions (operating conditions). Using this ratio, for the mass flow, they switch to using volumetric units (cm3 / min, l / min, m3 / h, etc.), but with the indication of the conditions (gas temperature and pressure) that determine the gas density. In Russia, "standard conditions" (st.) Are used: pressure 101.325 kPa (abs) and temperature 20 ° C. In addition to "standard", in Europe they use "normal conditions" (n.): Pressure 101.325 kPa (abs) and temperature 0 ° C. As a result, units of mass flow rate nl / min, stm3 / h, etc. are obtained.

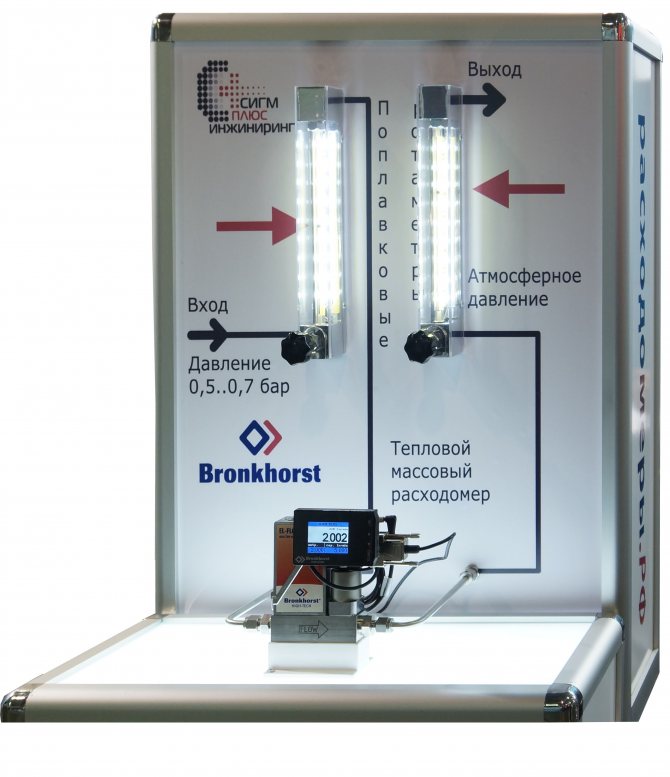

So, the gas flow rate is volumetric and mass.Which one should be measured in a specific application? How can you clearly see the difference between them? Let's consider a simple experiment where three flow meters are installed in series in a line. All gas entering the inlet of the circuit passes through each of the three instruments and is released into the atmosphere. There are no leaks or accumulation of gas at intermediate points in the system.

The source of compressed air is the compressor, from which gas is supplied to the inlet of the float flowmeter under a pressure of 0.5 ... 0.7 bar (g). The outlet of the rotameter is connected to the inlet of the EL-FLOW series thermal gas flow controller manufactured by Bronkhorst. In our scheme, it is he who regulates the amount of gas passing through the system. Further, the gas is supplied to the inlet of the second float rotameter, which is absolutely identical to the first one. With a flow rate of 2 Nl / min with the EL-FLOW meter, the first float meter reads 1.65 l / min and the second reads 2.1 l / min. All three meters give different readings, with a difference of up to 30%. Although the same amount of gas passes through each device.

Let's try to figure it out. What measure of the amount of gas in a given situation remains constant: volume or mass? Answer: mass. All gas molecules entering the system pass through it and are released into the atmosphere after passing through the second float rotameter. Molecules are precisely the carriers of the mass of gas. In this case, the specific volume (distance between gas molecules) in different parts of the system changes with pressure.

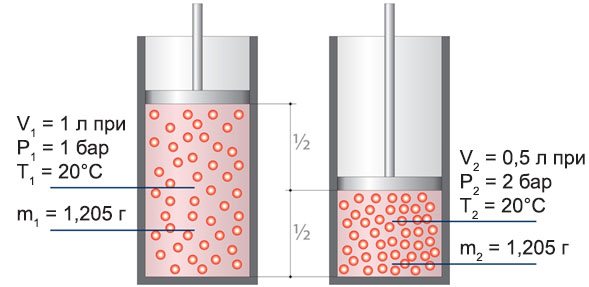

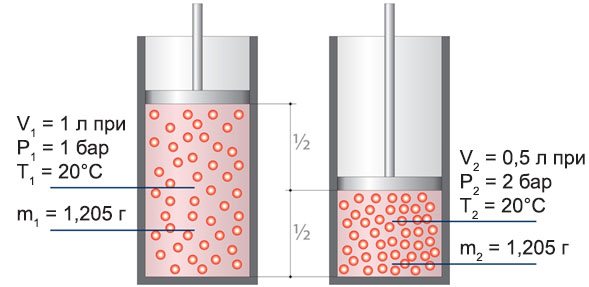

It should be remembered here that gases are compressible, the higher the pressure, the less volume the gas occupies (Boyle-Mariotte's law). A typical example: a cylinder with a capacity of 1 liter, hermetically sealed by a movable piston of low weight. It contains 1 liter of air at a pressure of about 1 bar (abs). The mass of such a volume of air at a temperature of 20 ° C is 1.205 g. If you move the piston half the distance to the bottom, then the volume of air in the cylinder will be halved and will be 0.5 liters, and the pressure will rise to 2 bar (abs), but the mass of gas will not change and will remain 1.205 g. After all, the total number of air molecules in the cylinder has not changed.

Let's go back to our system. The mass flow (the number of gas molecules passing through any cross section per unit of time) in the system is constant. At the same time, the pressure in different parts of the system is different. At the inlet to the system, inside the first float flowmeter and in the measuring section of the EL-FLOW, the pressure is about 0.6 bar (g). While at the EL-FLOW outlet and inside the second float flowmeter, the pressure is almost atmospheric. The specific volume of gas at the inlet is lower than at the outlet. It turns out that the volumetric gas flow rate at the inlet is lower than at the outlet.

This reasoning is confirmed by the readings of the flow meters. The EL-FLOW meter measures and maintains a mass air flow of 2 Nl / min. Float flowmeters measure volumetric flow under operating conditions. For a rotameter at the inlet, these are: pressure 0.6 bar (g) and temperature 21 ° C; for a rotameter at the outlet: 0 bar (g), 21 ° C. You will also need atmospheric pressure: 97.97 kPa (abs). For correct comparison of volumetric flow readings, all readings must be brought to the same conditions. Let us take as such the "normal conditions" of the EL-FLOW: 101.325 kPa (abs) and a temperature of 0 ° C.

The recalculation of the readings of float rotameters in accordance with the calibration procedure for rotameters GOST 8.122-99 is carried out according to the formula:

, where Q is the flow rate under operating conditions; Р and Т - working pressure and gas temperature; QС - consumption under conditions of reduction; Рс and Тс - pressure and temperature of the gas corresponding to the conditions of reduction.

Recalculation of the readings of the rotameter at the inlet to normal conditions according to this formula gives a flow rate of 1.985 l / min, and of the rotameter at the outlet - 1.990 l / min.Now the scatter of flow meter readings does not exceed 0.75%, which is an excellent result with a rotameter accuracy of 3% URL.

The example shows that the volumetric flow rate is highly dependent on the operating conditions. We have shown the dependence on pressure, but the volumetric flow rate also depends on temperature (Gay-Lussac's law). Even in a single-inlet, one-outlet flow diagram that is free of leaks and gas build-up, the flow meter readings will be highly site-specific. Although the mass flow rate will be the same at any point in such a scheme.

It is good to understand the physics of the process. But, nevertheless, which flowmeter to choose: volumetric flow or mass flow? The answer depends on the specific task. What are the requirements of the technological process, what gas to work with, the size of the measured flow rate, the accuracy of measurements, the operating temperature and pressure, the special rules and regulations in force in your field of activity, and, finally, the allotted budget. It should also be borne in mind that many flow meters that measure volumetric flow can be equipped with temperature and pressure sensors. They are supplied with a corrector, which records the readings of the flow meter and sensors, and then brings the readings of the flow meter to standard conditions.

But, nevertheless, you can give general recommendations. Mass flow is important when the focus is on the gas itself and the number of molecules needs to be controlled regardless of the operating conditions (temperature, pressure). Here we can note the dynamic mixing of gases, reactor systems, including catalytic systems, commercial gas metering systems.

The measurement of volumetric flow is necessary when the focus is on what is in the gas volume. Typical examples are industrial hygiene and ambient air monitoring, where it is necessary to quantify the volume of air pollution under real conditions.

Advantages and disadvantages of diesel heaters

A diesel heating boiler has a number of significant advantages, so many property owners prefer to install a heating system of this type:

- the equipment is distinguished by significant power and with its help it is possible to heat large premises without problems, which is confirmed by a sufficiently high efficiency

- fuel for such units can be purchased without problems - it is affordable and inexpensive compared to electricity;

- ease of maintenance;

- modern diesel-fueled heat generators have automatic control systems that allow you to control the heating process in accordance with the specified parameters;

- there is an opportunity to regulate the temperature of the coolant, and hence the temperature regime in the living quarters and utility rooms;

- automatic control one hundred percent ensures compliance with the norms and requirements regarding the implementation of fire safety rules.

In addition to its advantages, a diesel-fueled heat generator has a number of disadvantages:

- boilers for this type of heat source require a separate building (boiler room). In most cases, oil boilers are sold in floor-standing design. All the necessary conditions will be provided in the boiler room, specially equipped with ventilation and extractor hood;

- to store diesel fuel for heating, a special container is required. It must be kept in a separate room, which must be equipped in accordance with fire safety standards. It is connected to the heat generator using separate pipes;

- when the unit is operating, the burner makes noise, which is another reason for arranging a separate building for it;

- a working diesel heater is insignificant, but depends on an uninterrupted supply of electrical energy.If it is absent, the boiler stops working;

- at an ambient temperature below 5 degrees Celsius, diesel fuel tends to become thicker and it moves through pipes much more slowly. This consistency of fuel often clogs filters, and besides that, diesel fuel stops burning. Eliminate the drawback by insulating the pipeline and filter, but heating them is the best option. The optimal solution is heating the room where the fuel is stored.

Mains gas for heating needs

A gas mixture of the G20 brand is supplied to private houses from a centralized highway. In accordance with the accepted standard DIN EN 437, the indication of the minimum value of the specific heat during combustion of G 20 fuel is 34.02 MJ / cubic meter.

If a highly efficient condensing boiler is installed, the minimum specific heat value for "blue fuel" category G 20 is 37.78 MJ / cu. meter.

Formula for calculating fuel consumption

To determine the gas consumption, taking into account the energy potential embedded in it, a simple formula is used:

V = Q / (Hi x efficiency)

- V - the required value, which determines the gas consumption for the generation of heat energy, is measured in cubic meters / hour;

- Q - the value of the estimated thermal power consumed to heat the building and ensure comfortable conditions is measured in W / h;

- Hi - the value of the minimum value of the specific heat during fuel combustion;

- Efficiency - coefficient of efficiency of the boiler.

The efficiency of the boiler generator shows the efficiency of using the thermal energy generated during the combustion of the gas mixture, which is directly consumed for heating the coolant. It is the passport value.

In the passports of modern boilers, the coefficient is indicated by two parameters: for the highest and lowest heat of combustion. Both values are written through the slash "Hs / Hi", for example: 95/87%. To obtain the most reliable calculation, take as a basis the one indicated in the "Hi" mode.

The "Hs" value indicated in the table determines the highest value of the calorific value of the gas. It is indicated in the table for the reason that the water vapor released during the combustion of gas is also capable of converting latent thermal energy. If this thermal energy is used correctly, it is possible to increase the total return on the consumed fuel.

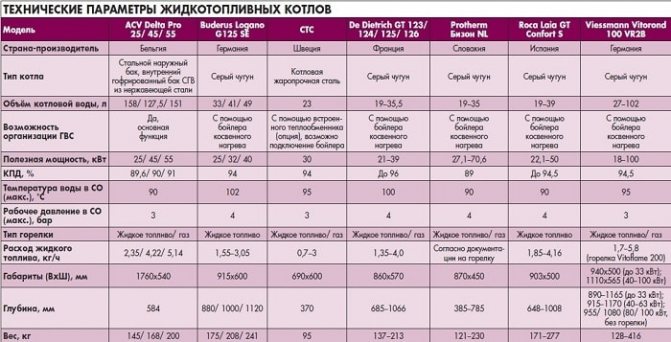

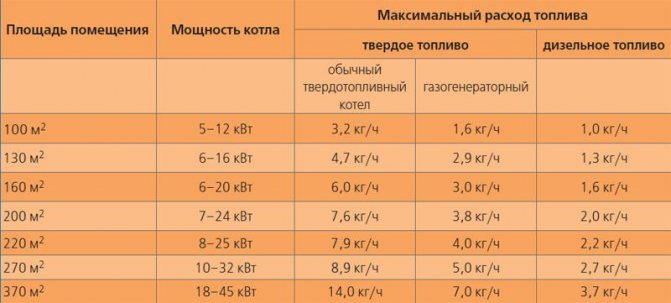

Calculation of the amount of fuel for a month and a season

To find out which diesel boiler is right for you, you need to calculate the approximate consumption of diesel fuel for one month and the entire heating season. The amount of diesel fuel (DF) for heating a house depends on many parameters: the area of the house, the quality of wall insulation, the height of the ceilings, the winter air temperature in your region, the number of sections in the radiators. It is impossible to take into account absolutely all the parameters, but we can approximately calculate how much diesel fuel the model you need consumes, starting from the area of the room.

It is believed that to heat 10 square meters of a house built according to all standards, 1 kW of the boiler's thermal power is needed. Liquid fuel equipment consumes a mass of diesel fuel equal to 10 of its capacity. That is, a 15 kW apparatus consumes 15 * 0.1 = 1.5 kg of diesel fuel per hour. Accordingly, to calculate consumption per day, this indicator should be multiplied by 24. For example, a 20 kW model uses 20 * 0.1 * 24 = 48 kg of fuel per day.

Fuel consumption per month is equal to the daily volume multiplied by 30. Equipment for 30 kW, for example Ferroli Atlas D 30, consumes 30 * 0.1 * 24 * 30 = 2160 kg per month. The length of winter varies greatly depending on the region of residence. When calculating, you need to take the indicator of your area. Take, for example, the 111-day average, from November 27 to March 17.

The final formula for calculating fuel for the heating season is as follows: boiler power * 0.1 * 24 hours * number of cold days.Let's make calculations for the boiler of the South Korean company Kiturami Turbo. The Kiturami Turbo 13 has a power of 15.1 kW. Substituting this value into the formula, we get: 15.1 kW * 0.1 * 24 hours * 111 days = 4022.64. This means that in a year you will spend about 4 tons of diesel fuel to heat a house with an area of 150 square meters.

It is also recommended to select the boiler power with a margin, so that the heating equipment runs at maximum power less often. This will extend the life of the device.

Initial data for calculation

The calculations themselves, with the help of which the amount of wood burned in the boiler furnace is determined, are quite simple. The difficulty lies in choosing the right input data for performing calculations. Of course, the easiest way is to use some online calculator that is posted on various Internet resources, and thus find out for yourself the rates of firewood consumption for heating your home. Only now there is only one way to check the correctness of the calculation: to do it yourself, manually.

For this reason, we initially suggest going this way, then you will be sure of the result. But you can check its correctness on several online calculators. Below we will present the methodology and at the same time, as an example, we will calculate the consumption of the amount of firewood for heating a house of 100 m2. But first of all - the initial data, here is a list of them:

- the kind of wood with which it is supposed to heat the premises;

- the degree of their moisture;

- Efficiency of a furnace or solid fuel boiler;

- heat power required for heating the building.

Those who have used the stove at least once have probably noticed that when firewood is burned, an unequal amount of heat is emitted from different trees. For example, birch logs give more heat than poplar or pine. This is because different tree species have different densities and calorific values. Also, the amount of firewood per 1 kW of thermal energy depends on their moisture content. The higher it is, the more heat is spent on evaporating water from the fuel, and less is left for heating the house. As a result, more wood will be spent on heating the dwelling.

The efficiency of using the energy contained in wood depends on the efficiency of a particular heat source. For example, a fireplace or a conventional stove emit a lot of energy into the atmosphere along with combustion products, respectively, their efficiency does not exceed 60%. Another thing is a solid fuel or pyrolysis boiler, whose efficiency can reach 80%, these features must be taken into account when calculating the cost of heating a private house.

The table below provides reference data on the calorific value of 1 m3 of some wood species at a certain moisture content.

Note. The table shows the values for the "clean" cubic meter of each type of fuel, the calculation of the cubic capacity of firewood must be performed for 1 m3 of logs or logs of storage, which will be discussed below.

The value of the heat output required for heating a dwelling is best taken according to the calculation made by specialists during the design of the house. But often homeowners do not have such data, in which case the amount and cost of firewood for heating can be calculated by the average value of the required power. It is determined by a well-known method: 1 kW of heat is spent on heating 10 m2 of premises under the most unfavorable conditions, and on average 0.5 kW per season. That is, the average standard for a house with an area of 100 m2 will be 5 kWh.

Diesel boiler is profitable for me

I constantly read negative reviews about diesel boilers, and so I want to dissuade everyone. It has been in the country for many years, problems with it are 0. The house is large, two-storey, with an area of approximately 145 sq. M. in winter, he eats no more than 12 liters per day, while at home Tashkent.A year ago, I spent underfloor heating of 3 kW and a couple of converters, each one kW, and so the fuel consumption was reduced to 6 liters per day. At the same time, on the street, the temperature reaches -25 C. I take fuel on a call, a fuel truck arrives and pours what is needed into the tank, if you take more than 500 liters, then delivery is free.

The boiler is made of steel, power is about 25 kW, double-circuit model. We live with our family in the country house only on weekends, the house heats up completely in an hour of boiler operation. So I can say with confidence that it has more than enough power. In general, I am satisfied with the boiler.

+ Pros: Fast warm-up, simple and convenient

- Cons: There are none for me

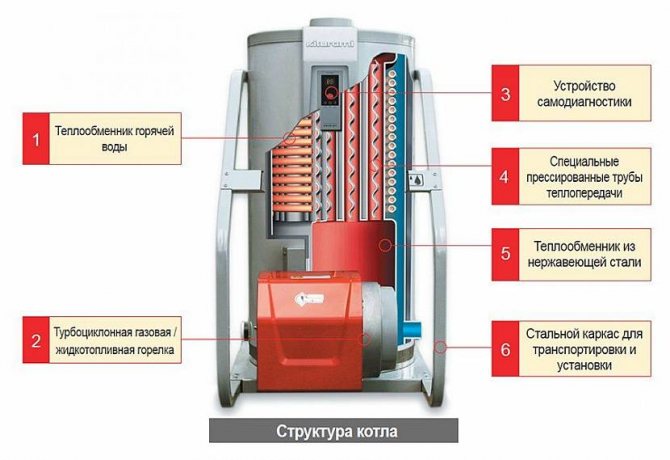

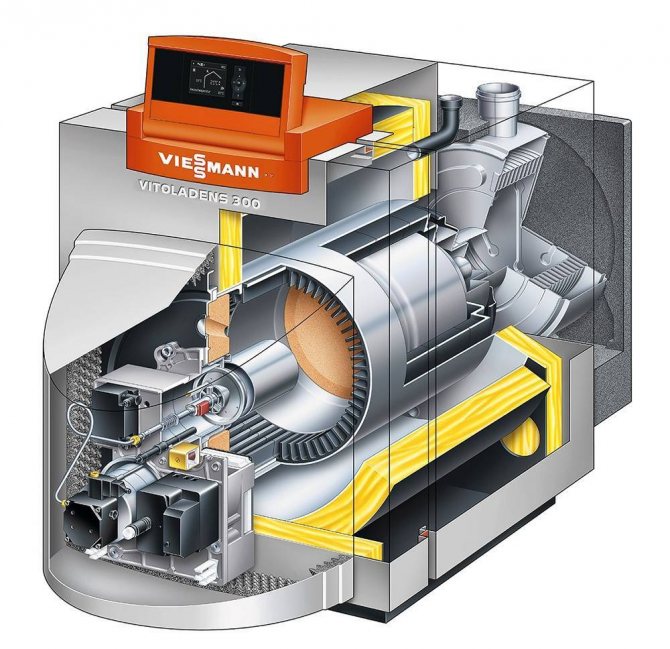

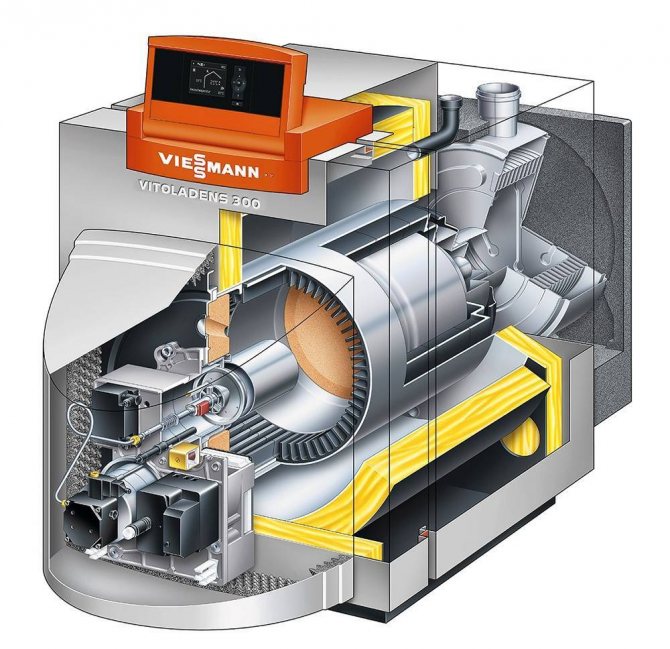

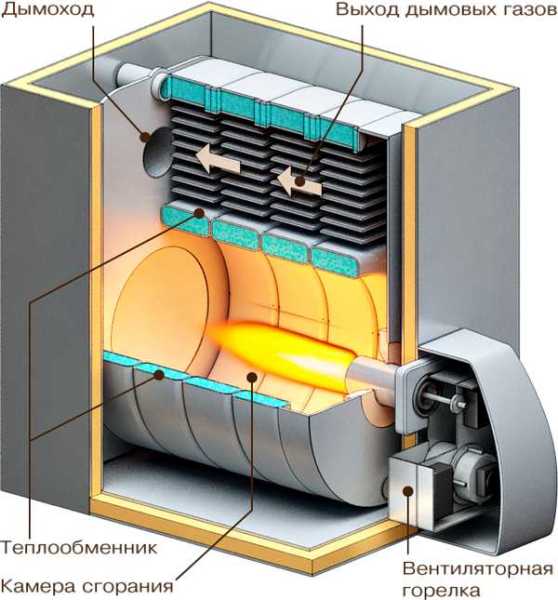

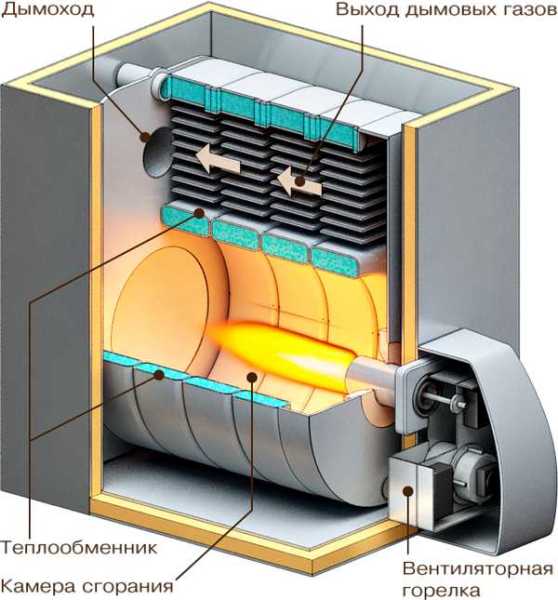

Device and principle of operation

A diesel boiler is an excellent alternative to any other type of boilers, except for gas ones - no one can compare with them in terms of cheapness and convenience. Running on diesel fuel, they generate heat automatically, requiring little or no user input. By this, they significantly benefit from solid fuel units that cannot live without a person - they need to constantly throw up firewood and remove coal and ash from them.

A diesel boiler can also benefit from electric heating equipment. First of all, low energy consumption should be highlighted - electricity is used here only for the operation of the burner and the operation of the automation. He does not need powerful electrical wiring, and the monthly expenses "for light" will be relatively modest. And secondly, diesel boilers can operate on other types of liquid fuel. If the power suddenly goes out in the house, they will be able to work on low-power uninterruptible power supplies.

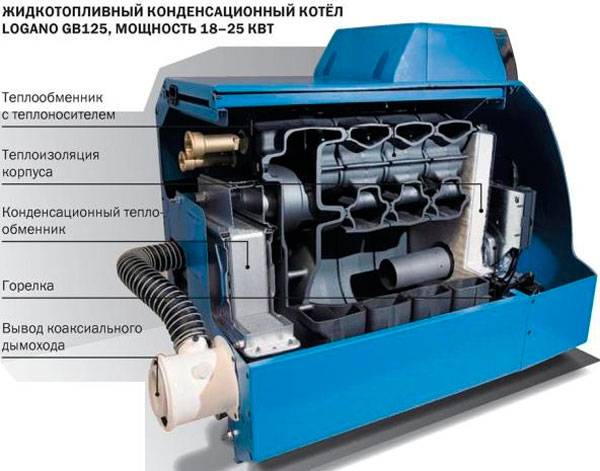

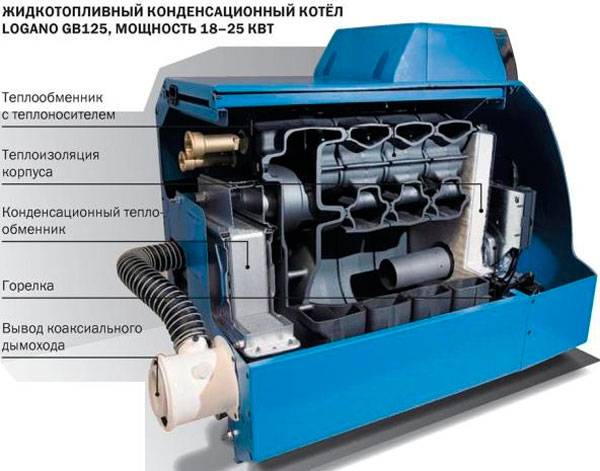

The liquid fuel diesel boiler is distinguished by a relatively simple device - in its design it resembles the most ordinary gas heating unit. The difference lies only in the design of the burner - here it runs on liquid fuel:

A diesel boiler is a rather complicated unit from a technical point of view. We strongly recommend that you follow the instructions for its operation exactly - otherwise, expensive repairs cannot be avoided.

- The fuel pump delivers fuel to the burner;

- Air is supplied here with the help of a fan;

- A fuel-air mixture is formed, which enters the combustion chamber;

- In the combustion chamber, the fuel mixture ignites and burns with the release of a large amount of thermal energy.

In order to increase productivity, diesel fuel boilers are often equipped with fuel heating systems.

Approximately the same fuel combustion scheme is used in diesel engines, only diesel engines are arranged differently. But the air-fuel mixture is practically the same here.

Let's see what else is there in diesel boilers:

- Main heat exchangers - used for heating the coolant, can be steel or cast iron;

- Secondary heat exchangers - used in double-circuit models for the preparation of hot water;

- Electronic or mechanical control modules - ensure compliance with the temperature regime;

- Insulated Enclosures - Provide safe operation and heat retention.

Also, on board diesel boilers, built-in piping is often installed - this is a safety group, expansion tanks and circulation pumps.

The safety group includes a pressure gauge, an automatic air vent and a safety valve.

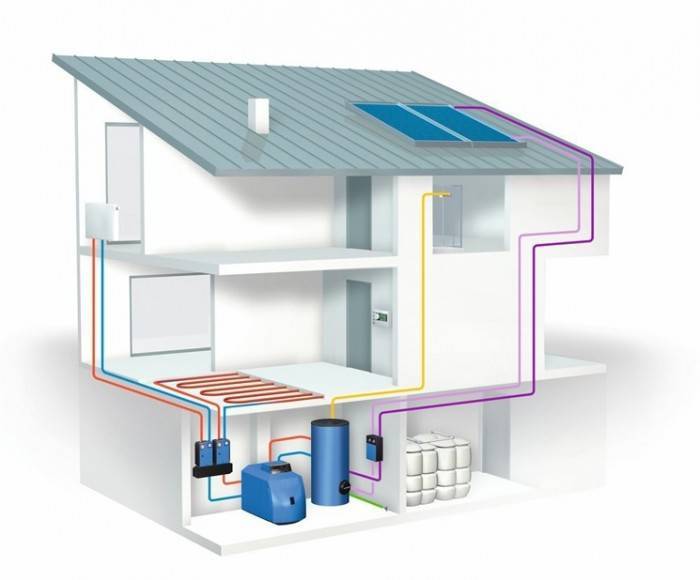

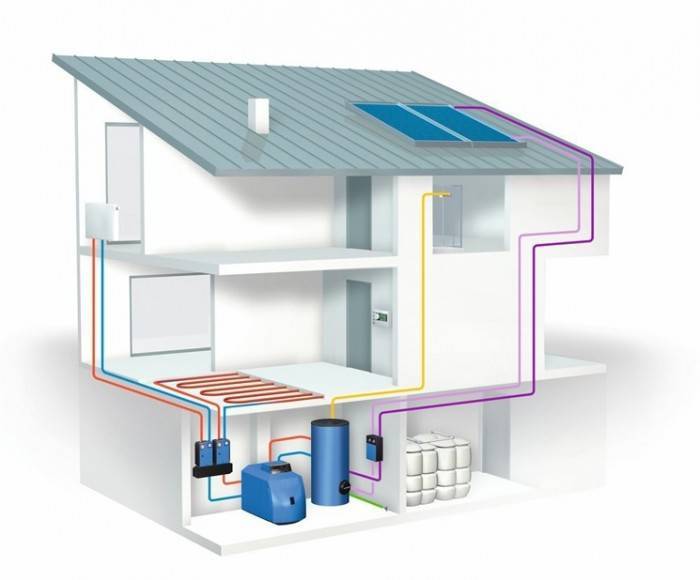

The principle of operation of a diesel boiler is quite simple and very clearly illustrated in the above picture.

Any diesel boiler works in the same way as its gas counterparts - with a command from the control module, the burner ignites, the heating medium starts heating, which continues until the command is given to turn off the burner.In double-circuit models, additional heat exchangers with three-way valves are provided - when the tap with water is opened, the heating circuit is turned off, the hot coolant circulates through the secondary heat exchanger, preparing hot water.

The consumption of a diesel boiler is approximately 1/10 of its thermal power. For example, if the selected model has a power of 24 kW, then it will consume about 2.4-2.5 l / h. The minimum fuel consumption is typical only for the most low-power units - these are typical options for a summer cottage. Heating with diesel fuel cannot be called much more profitable than heating with electricity, but it has its own advantages, which we talked about a little earlier.

In reality, fuel consumption can fluctuate in one direction or another, depending on the design features of the burner and boiler.

Determination of estimated gas flow rates (SP 42-101-2003 methodology)

Share link:

The methodology for determining the estimated gas consumption in gas distribution and gas consumption networks is set out in SP 42-101-2003 "General provisions for the design and construction of gas distribution systems from metal and polyethylene pipes."

This technique will be used in the further development of the hydraulic calculation of gas pipelines online "HYDRAULIC CALCULATION OF PIPELINES (GAS PIPELINES)".

GAS CONSUMPTION RATES

3.9 When solving issues of gas supply to settlements, the use of gas is provided for:

- individual household needs of the population: cooking food and hot water, and for rural settlements also for preparing feed and heating water for animals at home;

- heating, ventilation and hot water supply of residential and public buildings;

- heating and the needs of industrial and household consumers.

3.10 Annual gas consumption for each category of consumers should be determined at the end of the billing period, taking into account the development prospects of facilities - gas consumers.

The duration of the billing period is established on the basis of the plan for the long-term development of facilities - gas consumers.

3.11 Annual gas consumption for the population (excluding heating), consumer services enterprises, public catering, bread and confectionery enterprises, as well as for health care institutions is recommended to be determined according to the heat consumption rates given in GOST R 51617 (Appendix A).

Gas consumption rates for consumers not listed in Appendix A should be taken according to the consumption rates of other types of fuel or according to the actual consumption of the fuel used, taking into account the efficiency when converting to gas fuel.

3.12 When drawing up draft master plans for cities and other settlements, it is allowed to take enlarged indicators of gas consumption, m3 / year per person, with a gas combustion heat of 34 MJ / m3 (8000 kcal / m3):

- in the presence of centralized hot water supply - 120;

- with hot water supply from gas water heaters - 300;

- in the absence of any types of hot water supply - 180 (220 in rural areas).

3.13 Annual gas consumption for the needs of trade enterprises, consumer services of a non-production nature, etc. can be taken in the amount of up to 5% of the total heat consumption for residential buildings.

3.14 The annual gas consumption for the needs of industrial and agricultural enterprises should be determined according to the fuel consumption data (taking into account the change in efficiency when switching to gas fuel) of these enterprises with the prospect of their development or on the basis of technological norms of fuel (heat) consumption.

3.15 The annual and estimated hourly heat consumption for the needs of heating, ventilation and hot water supply is determined in accordance with the instructions of SNiP 2.04.01, SNiP 2.04.05 and SNiP 2.04.07.

3.16 The annual heat consumption for the preparation of feed and heating the water for animals is recommended to be taken according to Table 1.

Table 1

| Purpose of the consumed gas | Indicator | Heat consumption rates for the needs of one animal, MJ (thousand kcal) |

| Preparation of animal feed, taking into account the steaming of roughage and roots, tubers | Horse | 1700 (400) |

| Cow | 4200 (1000) | |

| Pig | 8400 (2000) | |

| Heating water for drinking and sanitary purposes | One animal | 420 (100) |

DETERMINATION OF DESIGNED GAS FLOWS

3.17 The gas supply system of cities and other settlements should be calculated for the maximum hourly gas consumption.

3.18 The maximum calculated hourly gas consumption Qhd, m3 / h, at 0 ° C and a gas pressure of 0.1 MPa (760 mm Hg) for household and industrial needs should be determined as a fraction of the annual consumption by the formula

(1)

where Khmax is the coefficient of the hourly maximum (the coefficient of transition from the annual flow rate to the maximum hourly gas flow rate);

Qy - annual gas consumption, m3 / year.

The coefficient of the hourly maximum gas consumption should be taken differentially for each separate gas supply zone supplied from one source.

The values of the coefficient of the hourly maximum gas consumption for household needs, depending on the population supplied with gas, are given in the table; for baths, laundries, catering enterprises and enterprises for the production of bread and confectionery - in the table.

table 2

| Number of residents supplied with gas, thousand people | Hourly maximum gas consumption coefficient (without heating) Khmax |

| 1 | 1/1800 |

| 2 | 1/2000 |

| 3 | 1/2050 |

| 5 | 1/2100 |

| 10 | 1/2200 |

| 20 | 1/2300 |

| 30 | 1/2400 |

| 40 | 1/2500 |

| 50 | 1/2600 |

| 100 | 1/2800 |

| 300 | 1/3000 |

| 500 | 1/3300 |

| 750 | 1/3500 |

| 1000 | 1/3700 |

| 2000 and more | 1/4700 |

Table 3

| Enterprises | Hourly maximum gas flow rate coefficient Khmax |

| Baths | 1/2700 |

| Laundries | 1/2900 |

| Catering | 1/2000 |

| For the production of bread, confectionery | 1/6000 |

| Note. For baths and laundries, the values of the coefficient of the hourly maximum gas consumption are given taking into account the gas consumption for the needs of heating and ventilation. | |

3.19 The estimated hourly gas consumption for enterprises of various industries and enterprises of consumer services of a production nature (with the exception of enterprises shown in Table 4) should be determined according to fuel consumption data (taking into account the change in efficiency when switching to gas fuel) or by formula (1) based on the annual gas consumption, taking into account the coefficients of the hourly maximum for the industry, given in table 4.

Table 4

| Industry | Coefficient of the hourly maximum gas consumption Кhmax | ||

| In general for the enterprise | By boiler rooms | Industrial furnaces | |

| Ferrous metallurgy | 1/6100 | 1/5200 | 1/7500 |

| Shipbuilding | 1/3200 | 1/3100 | 1/3400 |

| Rubber asbestos | 1/5200 | 1/5200 | — |

| Chemical | 1/5900 | 1/5600 | 1/7300 |

| Building materials | 1/5900 | 1/5500 | 1/6200 |

| Radio industry | 1/3600 | 1/3300 | 1/5500 |

| Electrotechnical | 1/3800 | 1/3600 | 1/5500 |

| Non-ferrous metallurgy | 1/3800 | 1/3100 | 1/5400 |

| Machine-tool and instrumental | 1/2700 | 1/2900 | 1/2600 |

| Mechanical engineering | 1/2700 | 1/2600 | 1/3200 |

| Textile | 1/4500 | 1/4500 | — |

| Pulp and paper | 1/6100 | 1/6100 | — |

| Woodworking | 1/5400 | 1/5400 | — |

| Food | 1/5700 | 1/5900 | 1/4500 |

| Brewing | 1/5400 | 1/5200 | 1/6900 |

| Winemaking | 1/5700 | 1/5700 | — |

| Shoe | 1/3500 | 1/3500 | — |

| Porcelain-faience | 1/5200 | 1/3900 | 1/6500 |

| Leather and haberdashery | 1/4800 | 1/4800 | — |

| Polygraphic | 1/4000 | 1/3900 | 1/4200 |

| Sewing | 1/4900 | 1/4900 | — |

| Flour and cereal | 1/3500 | 1/3600 | 1/3200 |

| Tobacco | 1/3850 | 1/3500 | — |

3.20 For individual residential buildings and public buildings, the estimated hourly gas consumption Qhd, m3 / h, should be determined by the sum of the nominal gas consumption of gas appliances, taking into account the coefficient of simultaneity of their action according to the formula

(2)

where is the sum of the products of the quantities Ksim, qnom and ni from i to m;

Ksim - coefficient of simultaneity, taken for residential buildings according to Table 5;

qnom is the nominal gas flow rate by a device or a group of devices, m3 / h, taken according to the passport data or technical characteristics of the devices;

ni is the number of devices of the same type or groups of devices;

t is the number of types of devices or groups of devices.

Table 5

| Number of apartments | Simultaneity coefficient Ksim depending on the installation of gas equipment in residential buildings | |||

| 4-burner hob | 2-configurable stove | 4-burner stove and gas instantaneous water heater | 2-burner stove and gas instantaneous water heater | |

| 1 | 1 | 1 | 0,700 | 0,750 |

| 2 | 0,650 | 0,840 | 0,560 | 0,640 |

| 3 | 0,450 | 0,730 | 0,480 | 0,520 |

| 4 | 0,350 | 0,590 | 0,430 | 0,390 |

| 5 | 0,290 | 0,480 | 0,400 | 0,375 |

| 6 | 0,280 | 0,410 | 0,392 | 0,360 |

| 7 | 0,280 | 0,360 | 0,370 | 0,345 |

| 8 | 0,265 | 0,320 | 0,360 | 0,335 |

| 9 | 0,258 | 0,289 | 0,345 | 0,320 |

| 10 | 0,254 | 0,263 | 0,340 | 0,315 |

| 15 | 0,240 | 0,242 | 0,300 | 0,275 |

| 20 | 0,235 | 0,230 | 0,280 | 0,260 |

| 30 | 0,231 | 0,218 | 0,250 | 0,235 |

| 40 | 0,227 | 0,213 | 0,230 | 0,205 |

| 50 | 0,223 | 0,210 | 0,215 | 0,193 |

| 60 | 0,220 | 0,207 | 0,203 | 0,186 |

| 70 | 0,217 | 0,205 | 0,195 | 0,180 |

| 80 | 0,214 | 0,204 | 0,192 | 0,175 |

| 90 | 0,212 | 0,203 | 0,187 | 0,171 |

| 100 | 0,210 | 0,202 | 0,185 | 0,163 |

| 400 | 0,180 | 0,170 | 0,150 | 0,135 |

Notes: 1.For apartments in which several gas appliances of the same type are installed, the coefficient of simultaneity should be taken as for the same number of apartments with these gas appliances.

2. The value of the simultaneity factor for DHW cylinders, heating boilers or heating stoves is recommended to be equal to 0.85, regardless of the number of apartments.

Share link:

Related Topics:

- Determination of estimated gas flow rates (methodology of joint venture ...

- Hydraulic calculation of gas pipelines (method SP 42-101-2003)

- Hydraulic calculation of gas pipelines (method SP 42-101-2003)

How to save on fuel Criteria for choosing heating equipment

Units consuming liquid fuel are designed for both one and two circuits. And it is quite obvious that in the second case, the fuel consumption will be large, because of which the costs will only increase. For this reason, the best option for dual-circuit devices may only be to reduce the consumption of hot water consumed, which will help save on fuel.

Experts advise one more thing. According to them, it is possible to reduce fuel consumption by setting a lower temperature for the heat carrier. And the final point - it is advisable to install a thermostat in the warmest room. If you follow all these recommendations, you will be able to reduce the fuel consumption required for the operation of the boiler, and save a certain amount of money.

On many thematic forms, users are interested in: which units are more economical - diesel or electric? And what is the fuel consumption of a diesel heating boiler? It is rather difficult to unequivocally answer this question, since it depends on a number of points, including:

- the quality of the building's thermal insulation;

- the cost of the fuel used;

- area of the heated room;

- features of a specific climatic zone;

- number of residents in the house.

And if you know about all these factors, then you can roughly calculate the consumption of both fuels by comparing costs. And now - a few more practical tips regarding the choice of a heating unit.

- Heating equipment that consumes diesel fuel, in the presence of a combustion chamber made of steel, will be immune to temperature extremes. At the same time, steel undergoes a rusting process, therefore it does not last as long as, for example, cast iron.

- The higher the cost of a heating boiler, the higher the risk that its maintenance will be very expensive for you (when compared with models that have a lower cost).

- Devices that are equipped with a cast iron furnace chamber can last up to twenty years, but temperature drops affect them, moreover, very significantly. In such heating systems, it is necessary to install valves that will mix the heated liquid into the "return" line. All this is required so that the combustion chamber does not simply split.

Video - Diesel heating boiler - fuel consumption

https://youtube.com/watch?v=ZRj1PzbcBNs

Why Diesel?

When choosing a heating boiler, each user is guided by specific individual requirements. And if, for example, you live in a settlement where there is no centralized gas supply or there are frequent drops in the supply of electricity, then diesel boilers, the consumption of which, as we have already found out, is insignificant, will be the most optimal option.

Moreover, such devices have one more advantage, which we did not talk about - the fuel tank can be installed in any place convenient for you. And this has become a decisive factor for the fact that the popularity of diesel equipment has only increased recently.

Where does diesel heating begin?

Today, diesel heating in a country house is not a problem. After all, you can find many companies that offer diesel boilers.The efficiency of such boilers is 75-85%. It all depends on what design features the boiler has and what kind of appearance it has. Double-circuit boilers can not only heat the house, but also be used to supply hot water.

Boiler room of a private house

Of course, first of all, even when choosing a heating system, all home owners have a question - what will be the consumption of diesel fuel for heating a house? Based on statistics, fuel consumption with constant operation is 0.9 liters per hour. Average rates are 0.5-0.7 liters per hour. However, such indicators can be ensured only if your house is very well insulated.

In this case, you can focus on the requirements for gas boiler houses: area from 4 square meters for each boiler; ceiling height from 2.2 m; doorway from 80 cm; a window of 10 cubic meters by 0.3 square meters of windows; supply ventilation 8 sq. cm per one kW of the rated power of the boiler or 30 sq. cm per 1 kW with air inflow from the internal premises; chimney cross-section not less than the boiler outlet; ground loop bus; channel of natural supply ventilation 30 cm from the ceiling; power supply on a separate machine; diesel fuel for heating - no more than 800 liters in the boiler room.

Heating system with a diesel fuel boiler

When you equip a diesel boiler room, you need to pay attention to the fact that you do not need to equip a complex special chimney to work with a turbocharged burner. You can just buy a coaxial chimney and draw it out through the wall

Thanks to such a pipe, combustion products will be efficiently removed, and clean air will be taken inside.

Calculation of the consumption of liquefied gas

Gas calculation using propane or butane has its own characteristics, but does not present any particular difficulties. What matters is the density of the combustible substance, which changes with an increase or decrease in temperature and depends on the composition of the gas mixture. Only the weight of the liquefied fuel remains constant.

The volume of gas used differs in winter and summer, so it makes no sense to use units of m³ to determine the consumption of liquefied gas per 1 kW of heat, for designation kilograms are taken, which do not change with the change of seasons.

Calculation for 1 kW of heat

The quantity is calculated for heating the house and heating the water in the system. If food is cooked on gas, this must be taken into account additionally.

The formula is used Q = (169.95 / 12.88) F, where:

- Q is the mass of the fuel;

- 169.95 - the annual amount of kWh for heating 1 m² of the house;

- 12.88 - calorific value of propane;

- F is the square of the structure.

The resulting value is multiplied by the cost of 1 kg of the liquefied mixture to calculate the cost of purchasing the required amount. The price is usually given for 1 kg, and not for 1 m³, which should be taken into account.

Classification

The choice of the model depends on the set of required characteristics: power, heat exchanger material, type of combustion implemented in the boiler, as well as the need for hot water supply.

Power selection

The most important characteristic, on the correct choice of which the heating efficiency and economical fuel consumption depend. The power of diesel heating equipment is measured in kilowatts, it is indicated in the technical documentation for any boiler. For the calculation, there is a special technique that takes into account all the nuances.

It is more convenient for an ordinary consumer to focus on the area of a heated private house - this indicator is also indicated in the main characteristics of any model. As a rule, for a temperate climate, you can use a simple formula: the total area of all rooms in the house is divided by ten, as a result, the required boiler power is obtained. For colder climates, this value should be increased by 20-30%.

A simplified method for calculating power is relevant only for houses with a simple layout with a ceiling height of up to 3 m.For multi-storey buildings with heated staircases, it is better to calculate based on the volume of the premises.

Fuel consumption calculation

The consumption of diesel fuel directly depends on the power of the boiler, on average it is calculated as follows: the power of the boiler in kilowatts is divided by 10, the hourly consumption of diesel fuel in kg is obtained in heating mode. In the mode of maintaining the temperature, the consumption is reduced by 30-70%, depending on the degree of thermal insulation of the house. On average, the consumption of household heating boilers in a medium-sized private house is 0.5-0.9 kg.

Heat exchanger material - what depends on it?

The heat exchanger in diesel boilers can be made of steel or cast iron. Both materials have both advantages and disadvantages:

- boilers with a steel heat exchanger are lighter and cheaper, respond faster to temperature changes, are more resistant to local overheating, but they are highly susceptible to corrosion;

- the stainless steel heat exchanger is durable, is not afraid of the effects of aggressive compounds, has a uniform heat distribution, while the price for them is slightly higher;

- the price of boilers with a cast-iron heat exchanger is higher, they are heavier, they are more fragile and can crack during sudden temperature changes, but they are more resistant to corrosion and durable when used in an aggressive environment;

The combustion of diesel fuel produces large amounts of soot containing sulfur compounds. Combining with condensate, they form weak acids, which leads to rapid corrosion of the boiler elements and its failure.

Condensation can be avoided by using a properly installed return flow system to the boiler, which will be described in the corresponding section.

Single or double circuit?

Diesel boilers for a private house can not only provide heating, but also heat water for domestic needs. Such boilers are called double-circuit. When choosing a double-circuit boiler, it is necessary to increase the design power by 20%, otherwise it may not be enough for efficient heating and water heating.

When buying, you need to evaluate the feasibility of buying a two-circuit model, if the hot water consumption is insignificant, it is better to install a separate water heater and not complicate the heating system.

Heat generation method - which is better?

According to the principle of heating the coolant, diesel boilers are of the traditional type and condensing ones, which additionally use the energy of condensate. They have improved efficiency and lower fuel consumption, but they are more expensive.

Do I need a replacement torch?

Diesel burners are very similar in design to gas burners, so there are many models on the market that allow you to use any of these burners in one boiler. Replacing them is so simple that it does not require a call to the wizard - you can do it yourself at a convenient time.

If a diesel boiler is purchased as a temporary source of heating, and it is planned to connect to the gas main in the foreseeable future, it is better to choose a model adapted to replaceable burners.

Determining factors of gas mixture consumption

Heating a house using natural gas is considered the most popular and convenient today. But due to the rise in the price of "blue fuel", the financial costs of homeowners have increased significantly. Therefore, most zealous owners today care about the average gas consumption for heating a house.

The main parameter when calculating the consumption of fuel consumed for heating a country house is the heat loss of the building.

It's good if the owners of the house took care of this even during the design process. But in most cases, in practice, it turns out that only a small part of homeowners know the heat loss of their buildings.

The consumption of the gas mixture directly depends on the efficiency and power of the boiler generator.

Equally influential are:

- climatic conditions of the region;

- design features of the building;

- number and type of installed windows;

- the area and height of the ceilings in the premises;

- thermal conductivity of the applied building materials;

- the quality of insulation of the outer walls of the house.

Please note that the recommended rated power of the installed unit demonstrates its maximum capabilities. It will always be slightly higher than the performance of the unit operating normally when a particular building is heated.

For example, if the rated power of the boiler is 15 kW, then the system will actually function effectively with a thermal power of about 12 kW. A power reserve of about 20% is recommended by specialists in case of accidents and in excess of cold winters.

Therefore, when calculating fuel consumption, you should focus on real data, and not be based on maximum values calculated for a short-term action in an emergency mode.

How to install a diesel fuel boiler in the country

- The boiler is installed in a well-ventilated, heated room with natural light.

- Tanks for diesel fuel are installed in the boiler room (a reserve fuel supply of no more than 3-5 m3 is allowed), or they are mounted in the ground below the freezing point.

- The connection to the mains is carried out by means of a stabilizer and a UPS, with a capacity sufficient to ensure the autonomous operation of the boiler during the day.

Pros and cons of using a diesel boiler in heating a summer cottage

- Speed and low cost of installation. In the Moscow region, just supplying gas to a country house costs 800,000-120000 rubles. For the installation of a boiler house on diesel fuel, no approvals, design documentation, etc. are required. Immediately after purchase, the boiler is mounted and piping is performed. It will take 1-2 days to install.

- Efficiency - for small rooms, it is realistic to select equipment with low diesel consumption. At the same time, mini boilers are small in size, efficiently heat rooms and have a high degree of automation.

- Noise during operation.

- Limitations associated with the characteristics of diesel fuel.

- The need for regular cleaning of the heat exchanger and chimney.

Requirements for a diesel boiler room in the house

Installing a diesel boiler in a house is a complex technical process that requires qualified assistance. When connecting, take into account the current regulatory requirements and fire safety rules. Adjustment and maintenance are carried out using special computer software.

The organization of heating in a private house with a diesel boiler is carried out in compliance with the following conditions:

- The room for the boiler is chosen from technical rooms with a sufficient area, lighting, ventilation.

- The placement of diesel boilers in residential country houses is carried out on a non-combustible base. Wall and floor decoration is carried out using non-combustible building materials: ceramic tiles, plaster.

- Automation - maintaining the temperature in the house, is carried out in automatic mode. Human participation in the work of the heat generator is minimized. It is imperative that a safety automatics be installed that turns off the operation of the boiler in the event of an emergency.

- Ventilation in the boiler room is provided through channels with natural and forced air supply and air extraction. The section of the ventilation duct is calculated based on the triple air exchange within an hour.

- Diesel fuel storage, installed in a detached building. In the boiler room, storage of a reserve tank is allowed, with a maximum capacity of no more than 3-5 m³.

The correct installation of a diesel boiler in a residential private house is based on an understanding of the working processes. The burner device creates strong noise interference, therefore, soundproofing measures are carried out in the boiler room.

Additionally, a UPS and a stabilizer are installed to ensure that the system remains operational, even in the event of power surges or power outages.

Advantages and disadvantages of household diesel boilers

Reviews of diesel heating boilers for private houses and cottages indicate the same problem. A domestic consumer, even if he reads the operating instructions, adjusts the operation of the boiler to his needs, violating the manufacturer's recommendations, which is the main reason for malfunctions.

The efficiency of boiler equipment depends on correct operation, starting with precisely adjusted settings and ending with the need for regular maintenance. If the house is properly heated with a diesel boiler, high efficiency and heat transfer rates are observed. Any violations lead to excessive consumption of fuel.

The disadvantages of heaters are:

- Noisy boilers - as a rule, the noise is not audible if the passage to the boiler room is closed by a door. It is not recommended to install a diesel boiler in a kitchen or any room adjacent to living rooms.

- Maintenance cost - you will need to regularly clean the heat exchanger and chimney from accumulated soot. When switching to another type of liquid fuel, as well as before the start of the heating season, the burner needs to be adjusted. The optimal solution that allows you to save money is the conclusion of a contract for continuous maintenance.

The advantages of boilers are low installation costs, quick commissioning, no need for permits and approvals.

The most economical boiler is one installed and operating in accordance with the manufacturer's recommendations. After installation and connection, a company representative will instruct you on how to use the heat generator.

Operating experience shows that following the recommendations is the best way to extend the life of the boiler, to ensure maximum heat transfer and comfortable heating of living quarters.

Calculation of the power and temperature of a warm water floor

Diesel heating boiler fuel consumption

When deciding to install a diesel heating boiler in your house, fuel consumption is the paramount issue that will naturally concern you.

Moreover, during operation, how to save on diesel fuel. And at the acquisition stage, what power diesel boiler is needed for your particular cottage and how much fuel it will need for the entire heating season, where and how to store it. All this needs to be solved before organizing the heating of the house with a diesel boiler.

The choice in favor of a diesel boiler is based mainly on its ease of operation, complete autonomy and the absence of the need for any permits during installation. The main problem is to find the correct volume of the fuel tank. In remote areas, you will have to have a large container available, which is filled in advance and then diesel fuel is consumed from it throughout the winter.

For simplicity of calculations, it is conventionally considered - for every 10 m2, about 1 kW of boiler power is needed to maintain a comfortable temperature inside the living quarters. That is, for a cottage of 250 squares, you will need to buy a boiler of at least 25 kW. This figure is also multiplied by a correction factor from 0.6 to 2. Calculated based on the lowest possible levels of winter temperatures and depending on the climatic zone of residence. A decreasing 0.6 for the regions of the south, and an increasing 2 for the far north.

After, based on the area of the house, you have chosen and installed a diesel heating boiler, fuel consumption can be reduced due to additional insulation of the home. But experts recommend focusing precisely on 10: 1 based on the area of the house. Pick up a boiler with a lower power, and even with rare frosts, you can freeze. A small power reserve will not hurt.

The amount of gas required to create and maintain an artificial cavitation flow, characterized by a dimensionless flow rate:

,

(7.126)

Where Q

Is the volumetric flow rate of the blowing gas, reduced to the pressure in the cavity, [

m3 / s

];

dн

- the diameter of the nozzle, [

m

]; Is the speed of the incoming flow, [

m / s

].

Two modes of gas entrainment are possible: along longitudinal vortices and in the form of periodically detached portions. Portions sometimes take a toroidal form, and therefore the second regime of gas entrainment is called entrainment along annular vortices.

Dimensional theory can be used to write

(7.127)

and further

, (7.128)

where the standard definitions of similarity criteria are adopted. Index "n

»Means that the diameter of the cavitator is taken as the linear dimension.

The Reynolds and Weber numbers are practically uncontrollable during the experiment. Their influence has not yet been fully studied. Therefore, for simplicity of analysis, we will discard them from consideration. In relation (7.128), the influence of the free surface, which could be reflected by the immersion depth of the cavitator, is discarded. So,

. (7.129)

The first regime of gas entrainment is observed only during artificial cavitation and is typical for regimes of strong influence of gravity (). When Fr

=

const

longitudinal vortices are formed at lower cavitation numbers. The second mode exists at higher cavitation numbers. It is characterized by great nonstationarity. The cavern is periodically filled with foam. Then, under the influence of the return stream, large gas-liquid formations detach from the cavity. The cavity regains its size, and then the process of destruction of the cavity is repeated.

It has not been possible to create a unified theory of gas entrainment from the cavity, which would make it possible to calculate in all flow regimes. Individual flow regimes lend themselves to an approximate assessment.

The case of gas entrainment along longitudinal vortices, which is characteristic of small Froude numbers and, accordingly, large Euler numbers, turns out to be simpler for analysis.

Epstein's theory. Suppose that as the body moves, more and more sections of the vortex tubes are formed. The pressure in the cavity and in the pipes is the same. Therefore, the gas is at rest relative to the liquid particles. Let the rate of tube formation be equal to the speed of the incident flow, then the volumetric gas flow rate in the vortex tubes will be equal to

(7.130)

or in dimensionless form

. (7.131)

Let us express the square of the ratio of the diameter of the vortex tubes to the diameter of the cavitator from the Bernoulli equation. In this case, we will take into account that the distance between the vortices "b

»Is much larger than the diameter of the vortices. Let be

h

- the height of the end of the cavity, which is determined by the formula (7.116). Then

,

and further

. (7.132)

Remembering now the meaning for D

(7.111), we get

. (7.133)

Here S *

- the area of the vertical projection of the cavity. Let us take it to be equal to the area of an ellipse corresponding to a cavity in a weightless liquid, and the value

h

we obtain from (7.112). Then we obtain the final Epstein formula:

. (7.134)

It is easy to see that if you enter instead of dH

new characteristic linear dimension, then

CQ

will not depend on

.

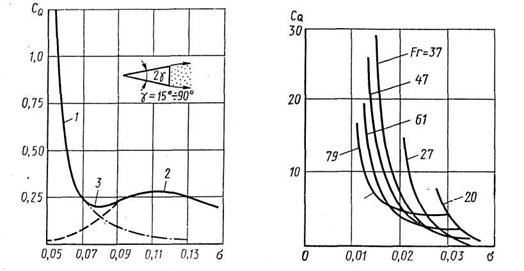

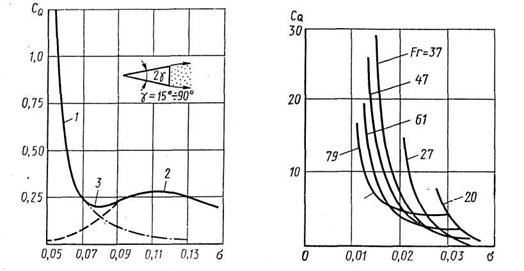

A generalized experimental curve of this type for a fixed value of the number

FrH

for a family of cones with opening angles

2=30°… 180°

is shown in Fig. 7.18. As you can see,

Fig. 7.18 Fig. 7.19

both types of gas entrainment exist. The left branch of curve 1 corresponds to gas entrainment along longitudinal vortices, the right branch 2 - along annular vortices, the middle part 3 corresponds to an intermediate regime, in which both forms of gas entrainment can sometimes be observed simultaneously. The left branch 1 is well described by formula (7.134). The family of experimental curves in Fig. 7.19 gives an idea of the influence of large Froude numbers on the flow rate of the blowing gas during cavitation flow around the disk.

Epstein's formula does not reflect the influence of the Euler number. Meanwhile, it is clear that for small Euler numbers Eu = p∞ / ρV∞2 / 2,

comparable to the number of natural cavitation

συ = (p∞-pυ) ρV∞2 / 2,

the ventilated cavity will differ little from the natural one, and the blowing gas flow rate will tend to zero. With this consideration in mind, another formula is proposed for calculating the flow rate of the boost gas:

, (7.135)

Where Q

- volumetric flow rate related to ambient pressure; - coefficient determined experimentally.

The last formula can be given a different look:

, (7.136)

as .

From formula (7.13) it is seen that ,

if the denominator goes to zero. At a fixed Froude number, this is achieved at a certain minimum cavitation number

. (7.137)

In the case of a disc

. (7.138)

Hence it follows that no increase in gas consumption results in a decrease in the number of cavitation below a certain minimum value

.

Fig. 7.20

In some modes, the walls of the cavity acquire wave-like deformations and then they speak of pulsating cavities (Fig. 7.20). One, two ... five waves can be located along the length of the cavity. Sometimes the cavity loses its general stability and it abruptly changes its volume (portioned separation of the cavity).