Before insulating a wooden house, you will first need to raise it above the ground. This should be done with extreme caution in order for the structure to withstand this test. To do this, using a special technology, the house is strengthened with ropes, corner plates and channels with a board. Then you will need to dig in the walls and level the base horizontally, examine the foundation for decay.

If the rotted area is not so much (less than thirty percent), then it can be cleaned with a metal brush. In the case of large-scale decay, such parts will have to be replaced. After that, with the help of jacks, a very accurate lifting of the house is carried out. When the lift has taken place, wooden posts are substituted in place of the jacks, after which the old foundation is insulated. The foundation is poured and the wooden supports are carefully removed.

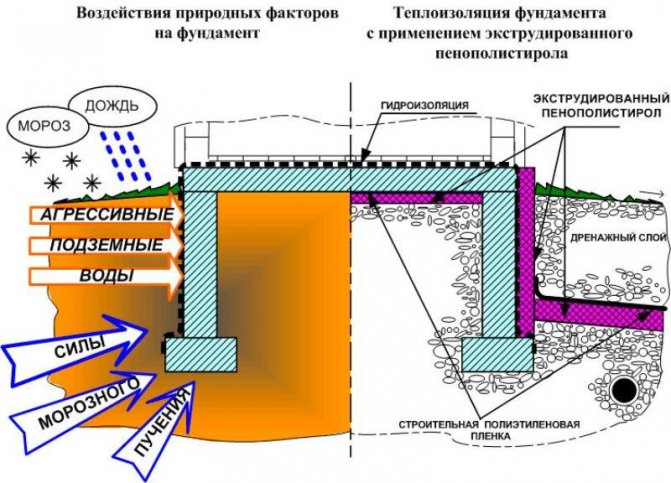

In general, the advantage of insulating the foundation of a wooden house from the outside is that it protects the entire base from freezing, and at the same time does not take away the area that is so necessary for a private house.

In addition, the technology for insulating a private house in this way is much easier to apply than to carry out the process inside. As a result, in addition to the space under the floor, the entire building is also protected from problems associated with soil heaving.

A few words about the strength of the foundation

It is much easier to build a foundation for a house made of wood, because in this case, quite acceptable loads will be placed on the supporting structure.

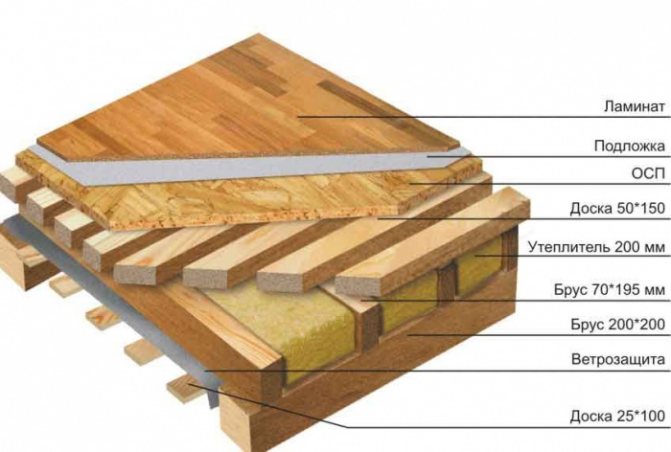

There are a number of requirements for the walls of the base that relate to strength. To meet them, such materials are used that are capable of withstanding high loads. Indeed, during the operation of the structure, the pressure of the structures located above will constantly be exerted on the foundation. For example, floors between floors.

To understand better, imagine a fragile little table. If you put a lot of weight on it, then the tabletop will begin to bend and, in the end, break. With the foundation, everything is about the same. On the base, which is a kind of substrate, pressure is exerted from the side of the structure installed on top. The loads are very significant. This is where the strength requirements follow.

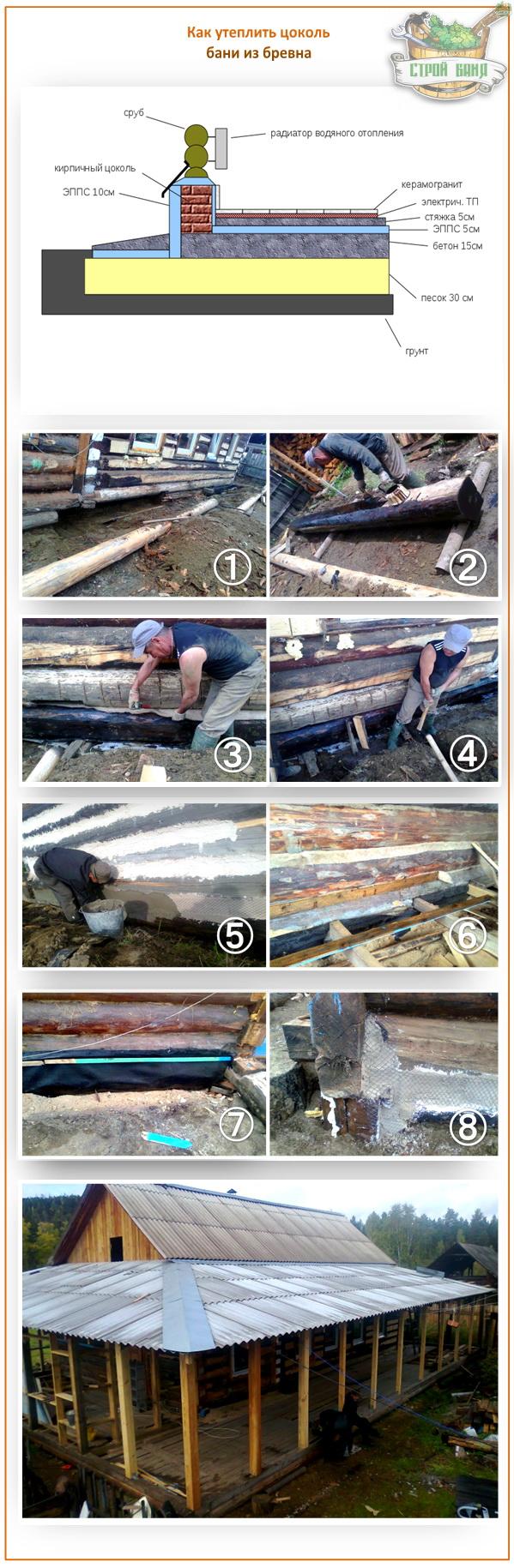

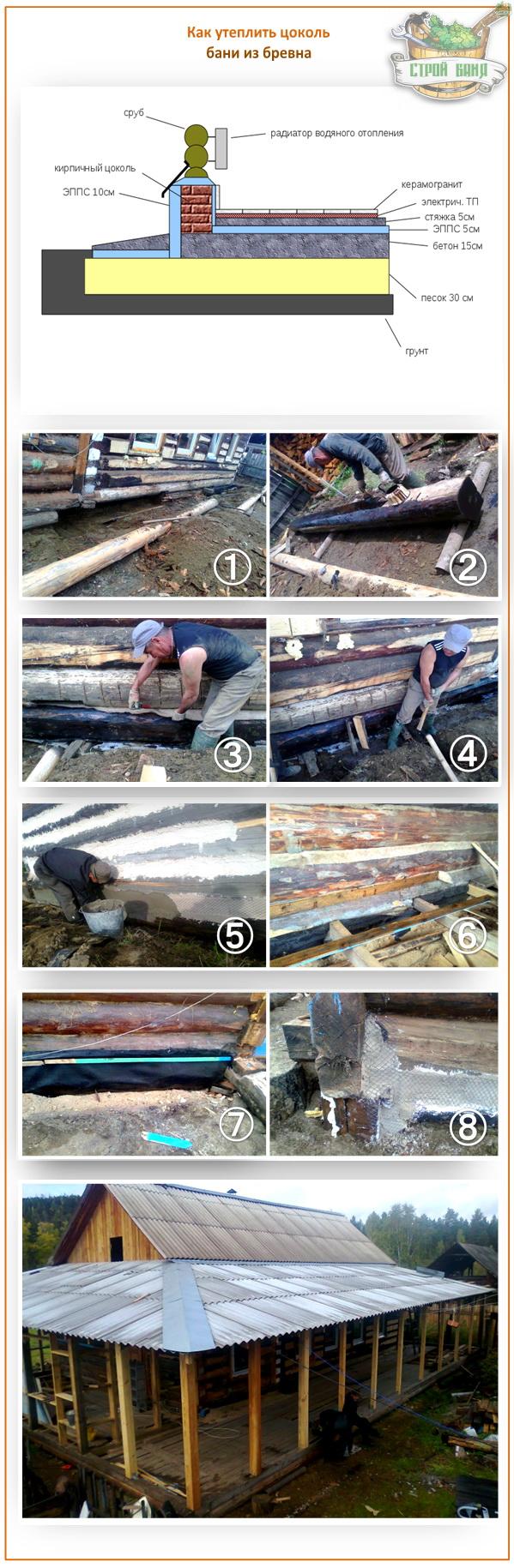

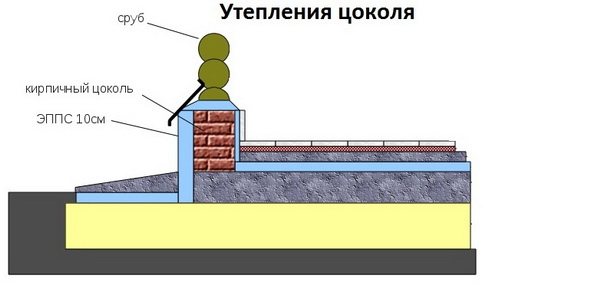

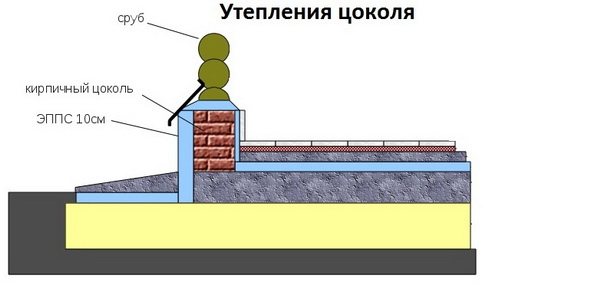

How to insulate the basement of a bathhouse from a log house?

So, if the floor in a chopped bath is always cold and there is even dampness, it's time to qualitatively insulate its base. Here's how to do it:

- Step 1. Dig in the bath around the perimeter 40-50 cm wide and 50 cm below the frame. We throw away all the rotten fragments and replace them with new ones, preferably from larch.

- Step 2. We process the rolled-in logs with the following mixture: linseed oil with working off, heated to 50˚С.

- Step 3. We put the insulating material between the joints - the best of all is "thermojut".

- Step 4. We jam the rolling logs until they crunch.

- Step 5. Caulk the outer seam of the flap with jute tape and throw it with a solution of gypsum filler with sawdust.

- Step 6. We fix the polymer mesh to the log and once again plaster the seam with cement mortar with a water repellant.

- Step 7. Using a burner, we melt the steloizol to the uppermost third of the covering log.

- Step 8. We fill the trench with sawdust and bark from larch (from freezing the soil).

- Step 9. We build open terraces around the bathhouse and cover them with a roof - if possible.

So - from now on it will always be warm in the steam room.

Why is the supporting structure insulated?

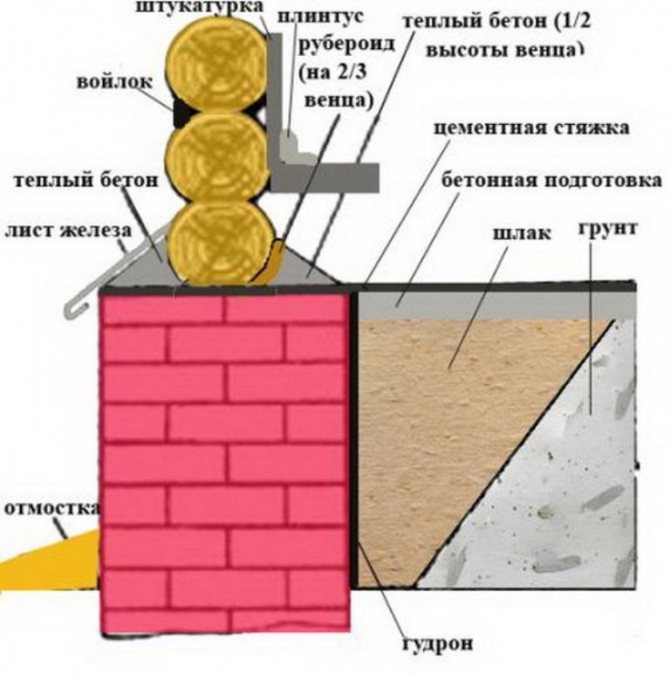

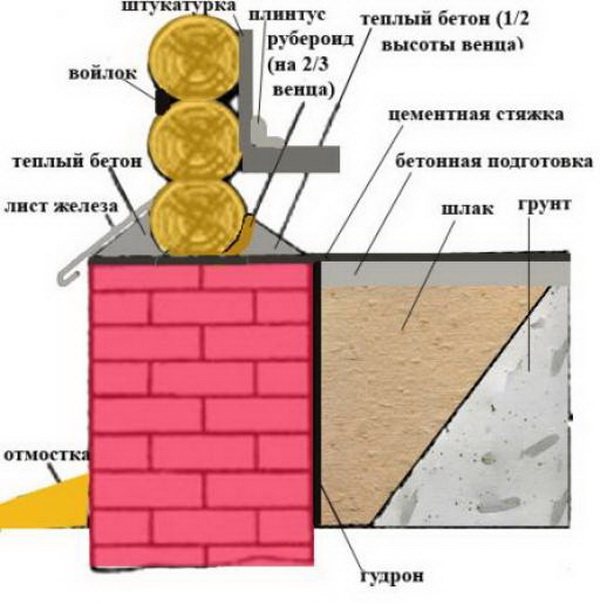

Sectional insulated foundation.

Heat loss is an inevitable drawback that manifests itself after the construction of absolutely any foundation.Sometimes, during the construction of wooden houses, they do without the construction of a supporting structure. This is due to the lightness of wood compared to stone. However, many wooden houses still have an appropriate foundation. You cannot discount such a procedure as thermal insulation of the foundation, even if wood conducts heat much better than stone.

In cold weather, heat loss will be unreasonably high. And it turns out that due to the properties of wood and special insulation materials, the house will be warm, and the lower part will give off cold. In this case, you will have to spend a lot on utilities so that the house is always warm.

Why is it better to insulate the foundation from the outside

Experts believe that this option is preferable for several reasons.

It is recommended to insulate the foundation from the inside only with good ventilation of the basement. Otherwise, the humidity in the basement will increase, in addition, the inner layer of insulation shifts the dew point, because of this, the entire base gets under the influence of moisture and cold. This reduces its service life, leading to rapid destruction.

Wooden houses are usually placed on a columnar, pile or strip base. These types differ in their structure, which means that their insulation is done in different ways.

For thermal insulation of any type of base, extruded polystyrene foam (EPS, penoplex) is used. It is durable, has a long service life, does not emit toxic substances, is resistant to compression loads, does not allow water to pass through, mold and moss do not start on it. It is easy to use, attached to the foundation with a special glue or with umbrellas, the foam boards have a convenient connection to each other.

How to insulate the base of the house?

According to most experts, polyurethane foam is the best material for insulating the foundations of wooden houses. This material has a very low thermal conductivity, which means that less of it is required for thermal insulation in a wooden house than other heat insulators. The size of the thermal insulation layer depends on the thickness of the base and the thermal insulation material. Usually it is 30, 50 or 100 millimeters.

Of course, polyurethane foam alone is not enough. Insulation is also carried out with foam and expanded clay. However, polyurethane foam copes with the tasks set somewhat more efficiently. He has proven himself to be the best in the construction of many objects. In general, the factors associated with the project directly affect the choice of waterproofing material. Know that polyurethane foam is durable and reliable. But do not give up other materials. Consideration should be given to the requirements of the project. Perhaps foam is the best option for realizing your ideas.

In addition, you can use foam glass, which is also a good heat insulator. It is a foamed glass melt. Silicate glass is heated at a temperature of 1000 degrees, then, while cooling, it acquires excellent mechanical and thermal insulation properties.

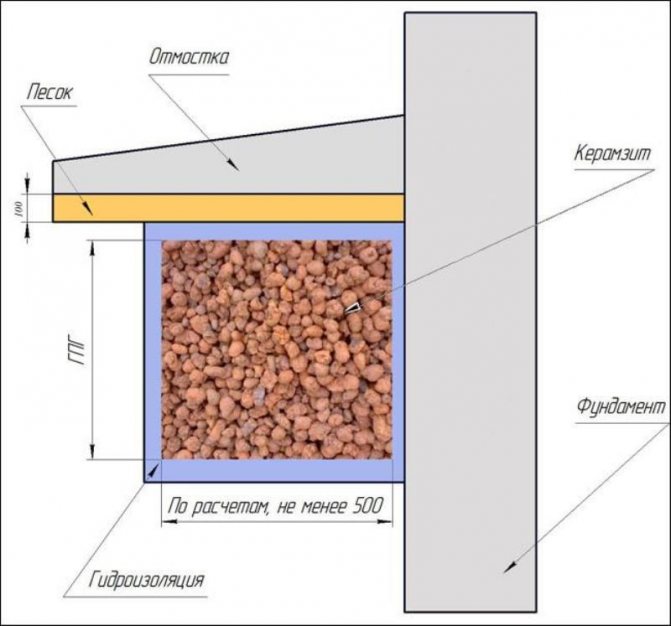

Warming with expanded clay

Another popular material for insulating the foundation of a wooden house outside is expanded clay. For him, a narrow layer will be sufficient, in contrast to the soil. For insulation in this way, formwork is mounted, and then a pre-prepared mixture of expanded clay and concrete is poured. Mineral wool with a waterproofing film is laid on top.

When choosing this method of insulating the foundation of a private house, you need to take into account, however, some disadvantages. Since the mixture is prepared from expanded clay with the addition of concrete, it is he who can become a poor conductor of heat.

Expanded clay is a fragile material that can make itself felt over time.The width of the formwork must be at least 0.5 cm.

Thermal insulation of the supporting structure of the house made of wood with polyurethane foam

There are only two ways - thermal insulation from the inside or outside. The first option means carrying out work in the basement from the inside of the house, the second - on the street. If you have chosen polyurethane foam, then the insulation is reduced to a simple dusting of this material on the base. Spray guns are great for this job. 35 kg / m3 - this should be the indicator of the density of the material.

You can watch a video showing how to insulate the foundation of a wooden house, as well as the advantages of insulation by spraying polyurethane foam.

https://www.youtube.com/watch?v=3bP6ksK9MNY

It is best to insulate the foundation from the outside. This will save the base from freezing, which has a positive effect on the entire structure. If the house has a basement, then the microclimate in it will improve.

Protect the polyurethane foam from sunlight if it is decided to use it outside the building. Plastering based on a metal or polymer mesh is fine. However, there is another option - fixing porcelain stoneware or stone with a special glue.

Internal and external thermal insulation are practically the same technologies. If you decide to insulate the house from the inside, then you need to cover all walls with polyurethane foam, from floor to ceiling.

Often, when insulating the foundation of a wooden house, not only the walls are insulated, but also the ceiling with the floor - this also has a beneficial effect on the microclimate. The surface that has been sprayed with polyurethane foam is finished with a standard cladding. You can choose any material you like.

Other materials used in thermal insulation

The installation of other heat-insulating elements directly depends on the type of material itself. For example, foam boards are attached to the surface with glue. Expanded clay is filled up, then a layer of waterproofing is created. As a rule, such work is not particularly difficult, but in terms of the simplicity of work with polyurethane foam, they are incomparable.

To insulate a building with polyurethane foam, you just need to use a spray gun. When performing foam insulation, you need to do much more body movements: treat the plates with glue, attach them to the surface, make sure that the layer is even, etc. To do it right, and even with your own hands, is not so easy.

Materials and technology of external insulation of the foundation of a wooden house

To insulate the foundation of a wooden house outside, the following are most often used:

- Expanded polystyrene, ordinary (foam) or extruded (foam);

- Expanded clay;

- Polyurethane foam.

The choice of the type of material depends on the type and material of the foundation itself, the amount of funds that you can allocate for its insulation, as well as other factors, for example: watering of the soil or the level of groundwater. So the methods of insulating strip and columnar foundations may differ, both in the choice of insulation and in the technology of work.

As for the cost, the most economical option is insulation with plates of ordinary expanded polystyrene (foam), and the most expensive one is polyurethane foam. But, on the other hand, the cheapest option will not always be the most reliable.

Each of the above materials has its own pros and cons, as well as features of the technology of warming the base of a wooden house. In order to choose the best option, we will consider them in more detail using the example of insulation of a strip foundation.

Warming with expanded polystyrene

Insulation of the strip foundation of a wooden house from the outside with expanded polystyrene plates is currently one of the most popular solutions. This is explained both by the relatively low cost of the insulation itself, as well as by the simplicity and convenience of working with it.Expanded polystyrene or polystyrene is an elastic synthetic material in the form of plates of different thicknesses (1-10 cm), having a granular structure. It is air and moisture permeable, easily breaks and crumbles. Moreover, the lower its density, the more pronounced are these features.

For insulation of the foundation, it is best to choose a denser foam (density 25-35). The dimensions of expanded polystyrene plates are usually 50x100 cm.

Polyfoam is combustible (except for some of its varieties, which include flame retardant additives) and although this is not a special drawback for warming the foundation, this feature must be taken into account when warming the basement of the foundation. It is best if such a heater is insulated from the lower crown with a layer of 10-15 cm of non-combustible heat-insulating material (for example, mineral wool).

External insulation of the foundation with foam during the construction of a house

Fig. 1 External insulation of the foundation during its construction

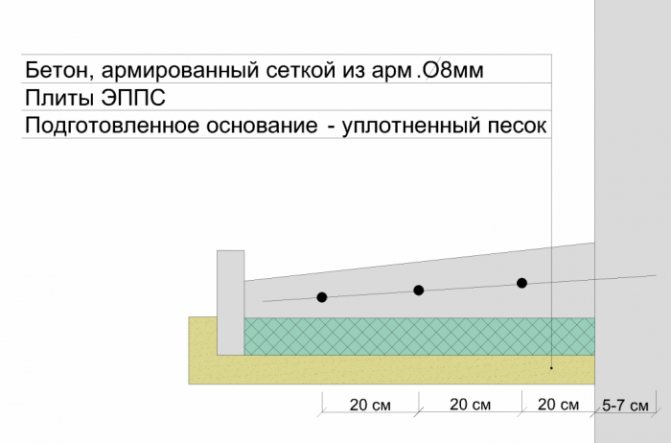

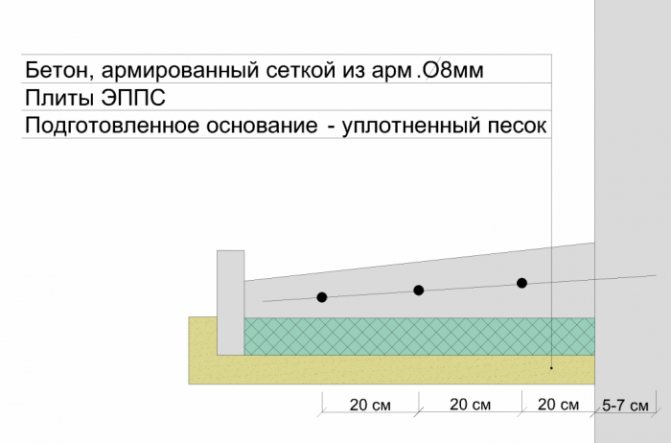

The technology of insulating the foundation of a wooden house outside with foam is quite simple. If the house is just being built, then this work can be done simultaneously with the pouring of the foundation. To do this, the width of the formwork is made larger, taking into account the thickness of the insulation, which is calculated and selected depending on the construction area and most often is 3-5 cm. Before pouring the concrete, the foam plates are installed inside the formwork, on a sand and gravel cushion, along the outer perimeter of the foundation.

In order for the insulation plates to be reliably fixed in concrete, it is necessary to first install plastic dowels-umbrellas in them (along the edges and in the center). Thus, after the concrete has hardened and the outer formwork has been removed, the insulation will be securely fixed and no additional fastening is required. In the corners of the foam board, it is best to connect using polyurethane foam.

With this method of insulation, a layer of insulation will have to be waterproofed, since ordinary polystyrene foam allows moisture to pass through.

Figure 1: 1 - formwork; 2 - polystyrene; 3 - plastic dowels; 4 - concrete; 5 - waterproofing; 6 - sand and gravel "pillow".

External insulation of the finished foundation

But it often happens that it is necessary to insulate the foundation of an already finished wooden house. In this case, it is necessary to dig a trench outside along it, about 0.5 m wide and a depth corresponding to the height of the underground part of the foundation. If it is laid too deep, then the depth of the trench may be less, but at least 10-20 cm more than the depth of soil freezing in this area.

Fig. 2 Insulation of the finished foundation of a wooden house outside with expanded polystyrene

The outer surface of the base of the house is cleaned of dirt and dust, and, if necessary, repaired and leveled. After that, the side surface must be covered with a layer of waterproofing (if this was not done during the construction phase). For this, you can use liquid formulations or roll materials. Installation of roll materials should be carried out using burners. In any case, the waterproofing layer must be securely fixed to the surface of the foundation.

Before the installation of expanded polystyrene plates, a sand and gravel cushion (with a rammer) with a height of 10-15 cm is arranged at the bottom of the trench. The plates are fixed with polystyrene glue or other adhesives that do not contain acetone or gasoline. The glue is applied dotted or dotted on the board itself or in a continuous layer on the base. Rows of slabs are mounted starting from the corner, with a gap in the joints.

Figure 2: 1 - wall; 2 - polystyrene; 3 - external finishing of the base; 4 - waterproofing; 5 - blind area; 6 - foundation; 7 - crushed stone, gravel, sand or their mixture; 8 - "pillow".

The fixed foam is preferably covered with a layer of waterproofing. Especially, that part of it, which is below ground level. After that, the trench is covered with crushed stone, sand or their mixture, and a blind area is arranged on top of it.

Use for thermal insulation of plates of extruded polystyrene foam

Extruded polystyrene foam is a more expensive insulation, but it is more dense and practically does not absorb and does not allow moisture to pass through. When using it, there is no need for additional waterproofing. In addition, it can withstand greater ground pressure without deformation. Plates of this insulation usually have dimensions of 60x120 cm and a thickness of 1-5 cm. They can have a smooth or corrugated surface, butt-joint or have special grooves.

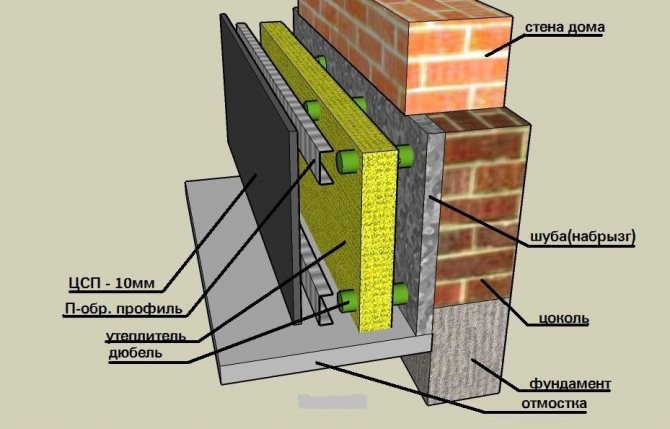

Preparation of the base and fixing of extruded polystyrene foam boards is carried out in almost the same way as in the previous case. If the boards are joined end-to-end, without grooves, then glue should also be applied to their ends. When insulating the basement, in addition to adhesive mixtures, for fastening the plates, you can additionally use plastic dowels-umbrellas.

External insulation with expanded clay

Expanded clay is a lightweight porous material in the form of pellets (granules) obtained by firing clay. Due to its porous structure, its thermal conductivity coefficient is quite low (0.07-0.18 W / m ºС), which makes it a completely effective insulation. In this capacity, this material has been used for more than one decade. With the help of this material, only a part of the foundation that is below ground level can be insulated.

Fig. 3 Insulation of the foundation of the house outside with expanded clay

Its main disadvantage is that it can absorb moisture, resulting in a decrease in its thermal insulation properties. In order to prevent this from happening, when using expanded clay to insulate the foundation of a wooden house from the outside, it is necessary to thoroughly waterproof it. In addition, it is not advisable to use this insulation for external insulation with a high level of groundwater.

To insulate the foundation with expanded clay from the outside, as in previous cases, it is necessary to dig a trench 0.5-0.6 m wide along the foundation to its entire depth and waterproof it. Cover the bottom of the trench and walls with waterproofing material and fill in expanded clay to ground level. From above, the trench with expanded clay is covered with a blind area, at least 0.7 m wide, arranged along a layer of waterproofing. The ground part of the foundation (basement) is insulated from the outside with slab insulation.

Figure 3: 1 - waterproofing layer; 2 - expanded clay; 3 - blind area; 4 - finishing of the base; 5 - wall; 6 - slab insulation; 7 - the foundation of the house; 8 - sand and gravel "pillow".

Spraying polyurethane foam

Another modern option for insulating the foundation of a wooden house from the outside can be spraying polyurethane foam on its surface. This insulation is applied in liquid form (in the form of foam) and, after hardening, forms a continuous coating that repeats the shape of the base, with characteristics close to extruded polystyrene foam. This method allows you to perform the insulation work as quickly as possible. At the same time, the configuration of the foundation can be almost any. But the application of such a heater requires the use of special equipment and cannot be done by hand. And the cost of such an option for thermal insulation will be higher than with independent insulation in other ways.

How to insulate a house on a columnar foundation

Another option for insulation in the context.

Thermal insulation of a pillar foundation is a process that constantly raises many questions. The pick-up device is the most acceptable option when insulating a columnar foundation.

A pick-up is a kind of partition that fills the space between the foundation piles. It can be made from a variety of building materials. Let's consider them.

- Wooden pick-up. In this case, the pick-up can be made of timber, boards or logs.A trench 30-40 centimeters deep is dug between the pillars. Then a pillow of sand and gravel is placed there, and bars with grooves are attached to the posts, into which 4-6 cm boards are inserted and wooden shields are obtained. After that, the lower part of the filling is covered with expanded clay.

- Brick filling. In this case, a trench is also dug up and the pillow is filled up. Bricks are placed in a row one or two at a time.

- Pick-up from insulation sheets. This method is used when insulating a private house, the length of the foundation pillars of which reaches 0.8 meters. Steel lathing is attached to the posts. Insulation (polystyrene, expanded polystyrene) is attached to it from the inside. Outside - sheets of corrugated board. The space between the insulation and the ground is covered with expanded clay.

For aesthetic beauty, blind areas can be made, which are a waterproof coating (asphalt or concrete strip) that runs along the entire perimeter of the building from the outside. Blind areas will protect the building from flooding and precipitation.

Strip foundation

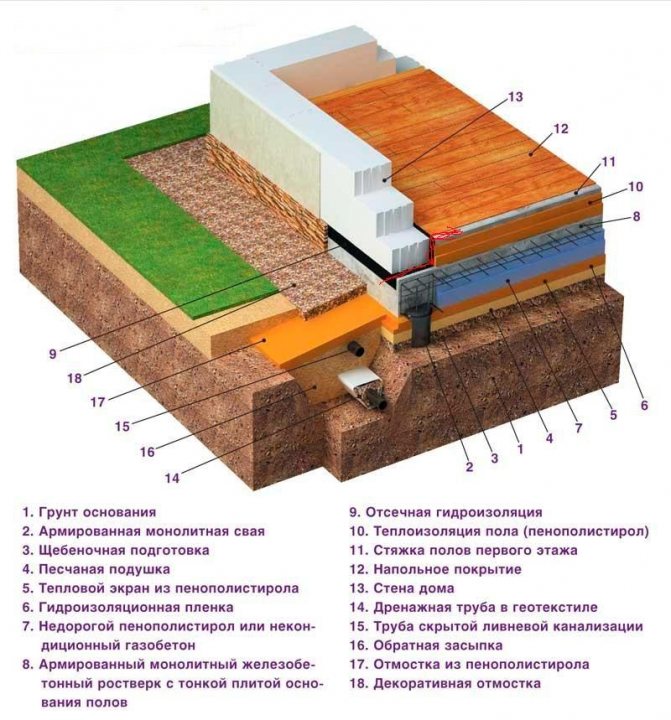

First, dig a trench to the very bottom of the foundation. Its width is 80-100 cm, since the insulation of the blind area is also carried out at the same time. If the foundation is of a buried type, then the first 40 cm in depth, the trench is dug to the width of the blind area, and then, to save energy, you can make it 50 cm wide.

If the house was built some time ago, then cracks may appear on the concrete. They are covered with a mixture of cement with construction glue, if the cracks are small. Larger damage is repaired with cement mortar.

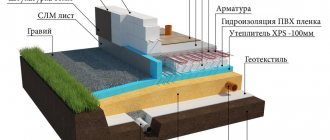

The next step is waterproofing. For this, the surface of the foundation tape is covered with bitumen mastic, on which roofing material is glued. The sheets are glued with an overlap, the seams are additionally coated with mastic. More modern roll materials are also used, such as self-adhesive roll waterproofing.

After that, the insulation is glued. Although penoplex is often attached to dowels, it is still better to give preference to glue or liquid nails - they do not violate the integrity of the sheets. How to insulate a strip foundation with expanded polystyrene, see the video:

The joints between the sheets are foamed with liquid foam.

After installing the insulation, geotextiles are glued to it. It will reduce the effect of soil heaving on the heat-insulating layer.

Next, the trench is filled up to the level of the blind area. Sand and fine gravel are poured under the blind area with a layer of 0.15-0.2 m, the pillow is carefully tamped. This layer will protect the blind area from the loads arising from the movement of the soil. A layer of dense insulation is placed on top. The same penoplex is suitable due to its resistance to compressive loads. Concrete is poured from above, in addition it can be reinforced with a mesh.

Attention! To reduce the effect of frost heaving, a layer of insulation is placed at the level of the basement sole. The most effective combination of foam insulation to the level of the walls in combination with insulation of the blind area at the level of the sole.

Foam insulation - quickly and economically

With foam, the bath base will turn out to be protruding - and well protected from moisture and cold. It is better to take material for this with a density of at least 25 kg / cubic meter, and any thickness, unless the basement protrudes more than 40 cm.

Stage I. Marking a new base

Polyfoam will slightly increase the base in volume, and therefore it must be marked in advance. To do this, pull the lace just above the waterproofing and draw a horizontal line on the wall.

Stage II. Preparing the surface

We clean the surface of the dirt and prime it with a deep penetration compound.

Stage III. Fastening the foam

We start glueing the foam from the corner - for this we make markings with a marker and cut off a couple of pieces with a knife. Now we apply glue to the wall with a notched trowel, apply foam plates and lubricate the ends. So, after gluing several plates, we make holes with a drill, fix the sheets and hammer in nails.

Stage IV. Reinforcement

Now the foam needs to be treated with soil. Next, with the help of cement glue, glue a metal sloping corner around the perimeter and corners. We also glue the reinforcing mesh on the foam, having previously cut it into the same pieces as the foam.

Here's how to fix it: apply glue to the foam, spread it with a wide spatula, apply a mesh and go over it again with a spatula.

Stage V. Finishing the base

After the glue has dried, proceed to finishing the base. Apply the putty solution with a wide spatula, over the glue-cement. On dried putty - already primer and can be painted. And you need to paint the base with a special acrylic facade paint.

Natural and artificial stones are also excellent for cladding the basement of the bath - they can be fixed with ordinary glue for installation work. And this finish looks just gorgeous!

Insulation of the basement: why you need to do it

The question of why insulate the basement of the house can be answered in two ways. On the one hand, these technologies ensure the preservation of heat in the basement, which is important if it will be used as residential and even auxiliary heated premises. If you have no desire to "bury" a huge amount of heat energy into the ground, leaving through the walls into the ground, and pay more for the consumed energy resources than is necessary, then you should not refuse to insulate the basement and foundation of the house.

On the other hand, a decrease in the thermal conductivity of the basement ensures the safety of the foundation for many years. There are regions in which the depth of soil freezing is quite significant, which leads to large-scale heaving of the soil during its freezing and thawing. The soil, frozen to the foundation, will certainly pull the base of the structure along with it in the process of heaving - for a start, microcracks will appear, which will not affect the house in any way. Over time, these cracks will begin to widen, the house will begin to sink - in general, many problems can arise, especially if the house was built on its own, and little attention was paid to the calculations of the supporting base.

Do-it-yourself basement insulation photo

In either case, the insulation of the basement and the blind area with foam or some other material plays a very important role and affects both the operational characteristics of the structure and its service life as a whole.

Insulation of the basement outside photo