The foundation of any building Is the foundation. The integrity and durability of the structure depends on its condition. But just building this part of the house won't be enough.

The foundation needs in mandatory insulation, the best way for which a penoplex foundation is suitable.

Penoplex Foundation - these are expanded polystyrene plates obtained by extrusion. In production, the foamed mass is forced through molding nozzles. As a result, under the influence of temperature and high pressure, the penoplex gets a porous structure with small isolated cells with air.

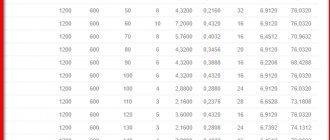

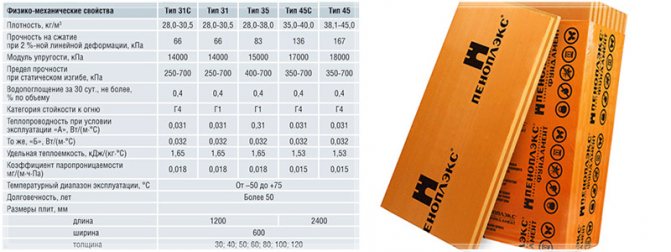

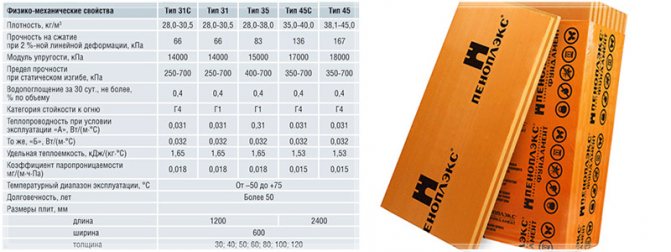

A heater is produced, which has been making PENOPLEX heat-insulating plates from extruded polystyrene foam for more than 18 years. The standard width of the foundation foam slab is 60 cm, and the length is 120. The thickness of the slabs varies from 20 to 150 mm.

What is penoplex and how is it better than analogues

Traditional mineral heaters, rags have gone into the shadows after the appearance on the construction market of extruded polystyrene foam, even despite its high cost. Penoplex is not one material with certain properties, but a line of heaters, a distinctive characteristic of which is the formation of a heat-insulating layer by foaming the original substance at high temperatures. In order for expanded polystyrene to begin to foam, a gas mixture of carbon dioxide and freon (CFH3 and others, CO2) is added to it. The result of the interaction is a high-strength and dense substance with a uniformly distributed structure with granules of Ø 0.1-0.2 mm in the composition. Expanded polystyrene is produced in plates of different sizes and dimensions.

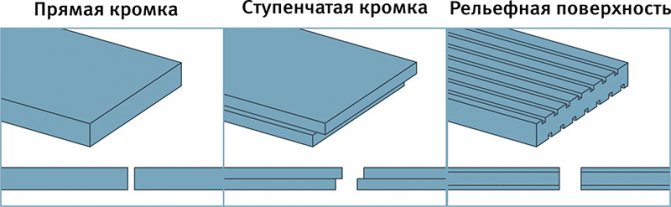

Dimensions and configuration of foam boards

Saying "penoplex", builders mean insulation, but in fact it is a branded Russian trademark of a company that produces extruded polystyrene foam for construction needs - it is insulation of the basement and other surfaces and structures of buildings, and thermal insulation of communication pipes, and protection from frost road cover. Each brand of polyurethane foam is endowed with its own unique characteristics that are optimally suited to the place of use of the insulation. So, the outside insulation of the foundation with Penoplex is carried out mainly by the brands "Penoplex Foundation", "Penoplex Comfort" or "Penoplex 45".

Insulation of the PPU foundation

The advantages of this substance are obvious:

- The minimum thermal conductivity coefficient among analogs: λ = 0.03-0.032 W / (m × K). In practice, this means that expanded polystyrene boards are used much thinner than conventional ones;

- High compressive strength - 27,000 kg / m2;

- Low coefficient of moisture permeability. If you keep such a plate in water for a month, then it will be saturated with moisture only by 0.6%. This indicator is very important, since the basement and foundation of the house are constantly in an environment with high humidity, experiencing the effects of precipitation and groundwater;

- Extruded polystyrene foam can be operated in the temperature range -500C / + 750C;

- The small mass of the slabs makes the installation of the insulation simple and quick, while it is practically not loaded with the additional weight of the material, therefore, the insulation of the foundation with foam is considered the most effective and least consumable;

- PPU does not become infected with fungi, does not decompose under the influence of moisture and an aggressive environment, is non-toxic and is recommended for use in housing and sanitary construction;

- The ease and speed of installation of the slabs is ensured not only by their low weight, but also by the presence of the “groove-tenon” system. Also, the material is easily amenable to any mechanical processing. Including manual;

- The guaranteed service life declared by the manufacturers is at least 50 years.

Penoplex characteristics

Thermal insulation of the basement or foundation from the outside with penoplex is the maximum duration of operation of the building material of the base plus fire safety in group G4. This means that the material can catch fire, but given its constant presence in the ground without air access, plus the protection of the insulation layers with plaster, this is almost impossible. Sizes of expanded polystyrene plates - 600 x 1200 mm, standard plate thickness - from 20 to 100 mm (step by step: 20 mm, 30 mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm).

Do I need to insulate the foundation?

There is a lot of controversy among builders on this topic and some neglect the thermal insulation of the base, considering these works useless, but nevertheless, this is necessary for the following reasons:

- The reinforced concrete structure has excellent thermal conductivity. The floors will be warmer, and heat loss can be reduced by up to 30% as a result of technologically correct thermal insulation.

- Freezing of soils negatively affects the service life of reinforced concrete. Thermal insulation will significantly reduce temperature fluctuations.

- Insulation on the outside prevents condensation from forming on the inner surface of the structure.

- Polystyrene boards reliably protect the waterproofing layer from mechanical damage.

It is not worth saving at this stage of construction, polystyrene is an affordable material, it can be bought in almost any large construction hypermarket. The insignificant, in comparison with the construction of the whole house, the costs will more than pay off on energy savings in a few years and, most importantly, will ensure the integrity of the foundation structure for decades.

Materials for insulation of the foundation.

There is a huge range of thermal insulation materials on the market. For basement insulation, the leading position is occupied by polystyrene plates of the Penoplex brand. They are used for private housing construction, design institutes lay the slabs of the Penoplex brand to insulate the basement of multi-storey residential buildings.

This material has no equal in characteristics. The base of the house is the most loaded part of the building, subject to aggressive effects of groundwater, frost heaving of soils, as a result of which the outer surface of the structure perceives a significant force. Taking into account all these nuances, special grades of slabs have been developed designed for warming base structures.

This material is a foamed extruded polystyrene foam made from ordinary polystyrene. Thanks to extrusion technology, millions of cells are formed in polystyrene, less than a millimeter in size, which makes the boards excellent thermal insulation.

Penoplex has a number of advantages:

1.Low thermal conductivity;

2.High strength. It is able to withstand the pressure from frost heaving of soils and will not be damaged when backfilling the sinuses when stones are flying onto the slabs. Also, unlike soft insulation, it does not settle or deform over time, thereby preventing the formation of "cold bridges".

3. Ease. There is no additional load on the building.

4. Resistance to aggressive effects of salts and acids contained in groundwater.

5. Minimum water absorption, Penoplex is not afraid of water.

6. Environmentally friendly. Does not emit harmful substances into the soil and does not decompose.

7.Easy installation. Plates are quickly cut, do not crumble during cutting, the low weight of the structure allows one person to install.

8. Service life - 50 years.

The choice of the thickness of the insulation Penoplex.

Depending on the purpose of the building, whether there is a basement or basement in the house, what material of the base structure, where the house is built, the depth of the foundation and a number of other factors, the thickness of the thermal insulation material is chosen.

This calculation is very complicated; to obtain an accurate result, it must be performed by a heating engineer. But you can roughly estimate the thickness of the insulation yourself using the formula:

R = t1 / λ1 + t2 / λ2

R is the required resistance to heat transfer of the structure, determined by table. 3 SP 50.13330.2012 "Thermal protection of buildings" depending on the type of building and the type of enclosing structure.t1, t2 - thickness of the foundation tape and thermal insulation, respectively; λ1, λ2 - Coefficient of thermal conductivity of the material. Indicated in Appendix "T" of the Code of Rules.

Accordingly, the thickness of the insulation remains unknown. Having received the value, we round the value up to the existing thickness of "Penoplex".

Or in any store you can ask the help of our store's expert who knows what thickness should be applied.

Basement insulation options.

How to insulate the base depends on its design.

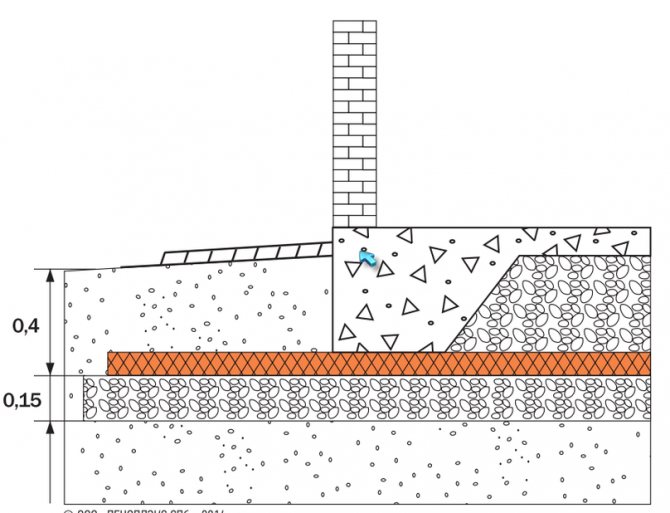

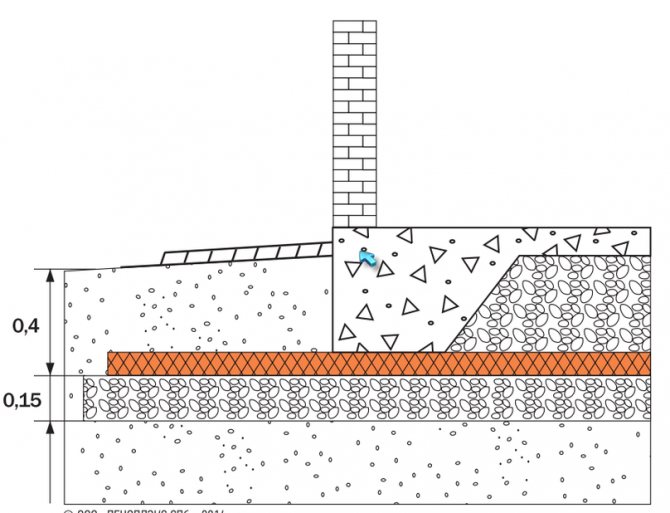

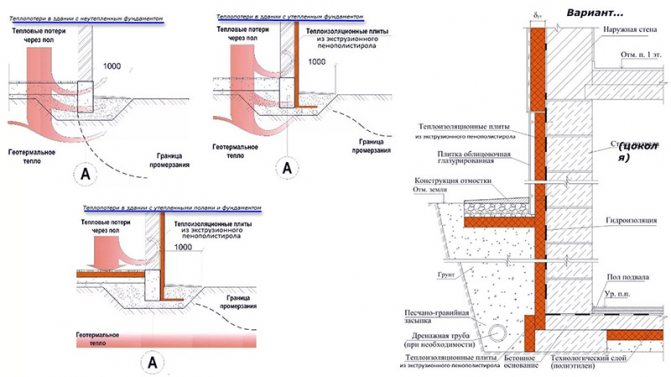

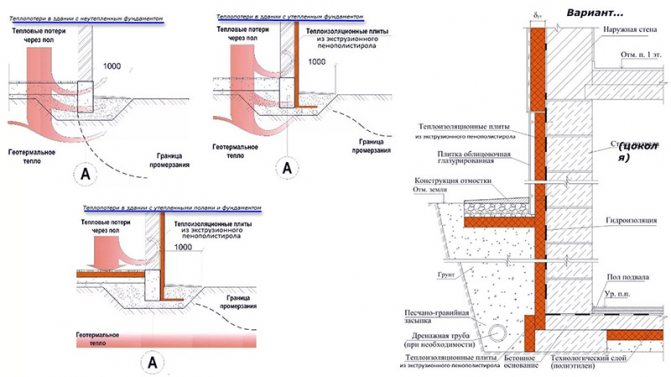

1. The depth of the foundation is below the depth of soil freezing.

The depth of laying should be taken to be 30 cm greater than the depth of soil freezing, which can be determined according to SP 22.13330.2011 "Foundations of buildings and structures", depending on the area of construction. In this case, only the vertical part of the base needs to be protected. The purpose of thermal insulation is to cut off the foundation from the surrounding soil with Penoplex. Therefore, the horizontal part of the pillow should also be covered with slabs and no structures (blind area, masonry) should directly contact the outer surface of the base, otherwise cold will penetrate through these places.

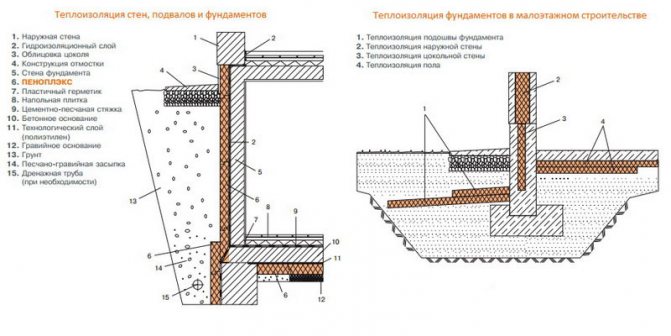

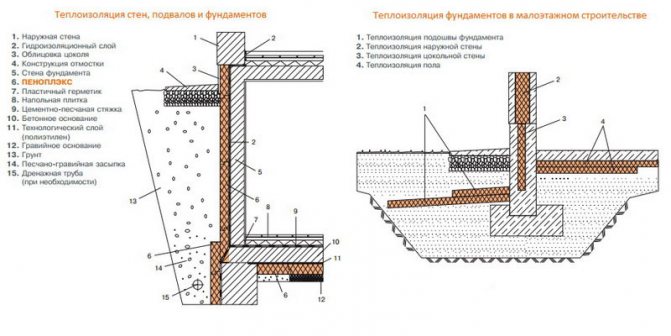

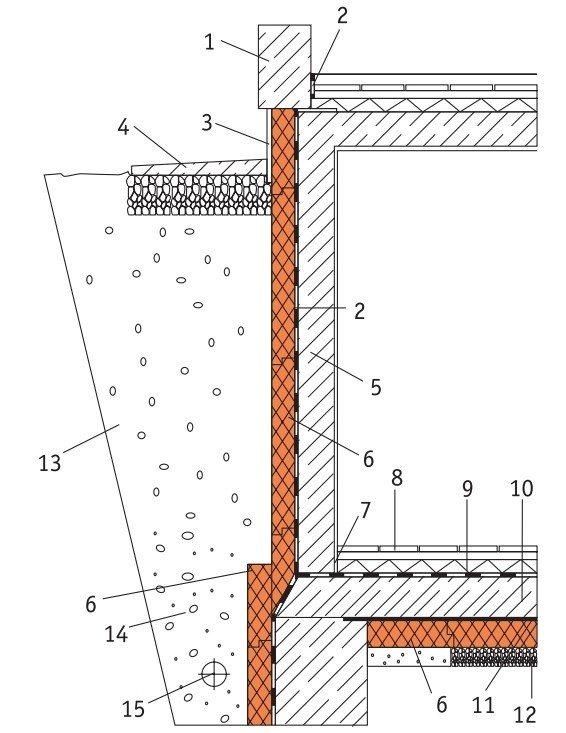

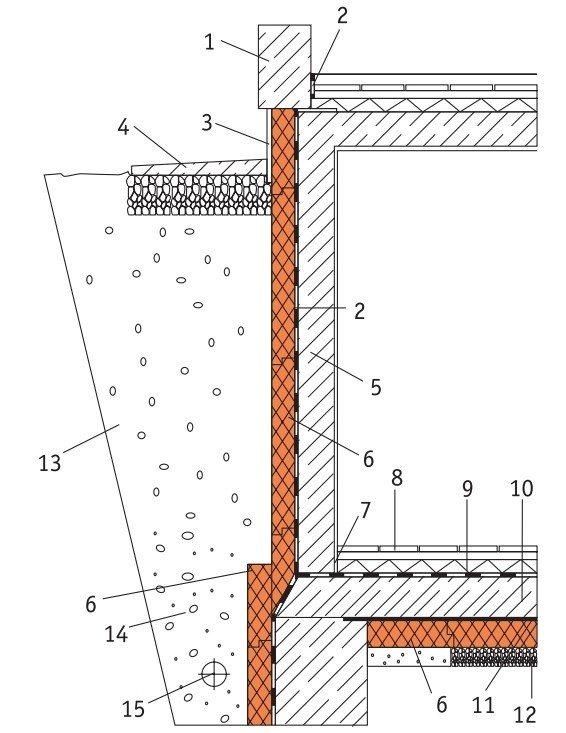

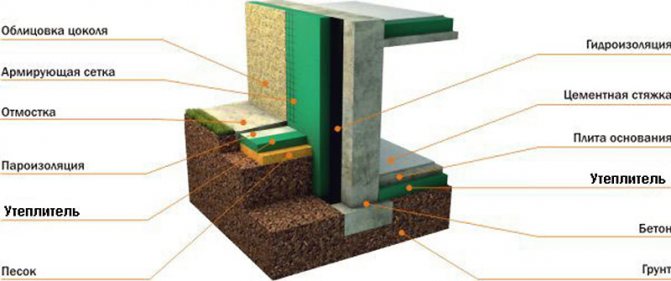

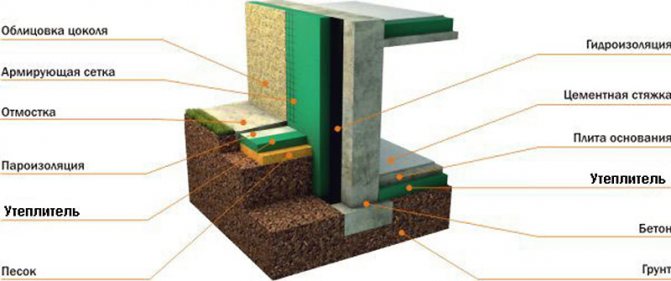

1.Exterior wall 2. Waterproofing layer 3. Plinth facing 4. Blind area design 5. Foundation wall 6. Penoplex 7. Plastic sealant 8. Floor tiles 9. Cement-sand screed 10. Concrete base 11. Technological layer (polyethylene) 12. Gravel base 13. Ground 14. Sand and gravel backfill 15. Drain pipe (if required)

2. The depth of the foundation is higher than the depth of soil freezing.

Recently, many companies have appeared on the market that are engaged in the construction of "light" houses made of wood, vulture panels, panel houses. These structures do not require a massive deep foundation, which can cost up to 30% of the entire construction cost. But on the other hand, it is dangerous not to deepen the base below the level of soil freezing. The frozen ground greatly increases in volume, pushing up the house standing on it. This can lead to severe deformations of the structure.

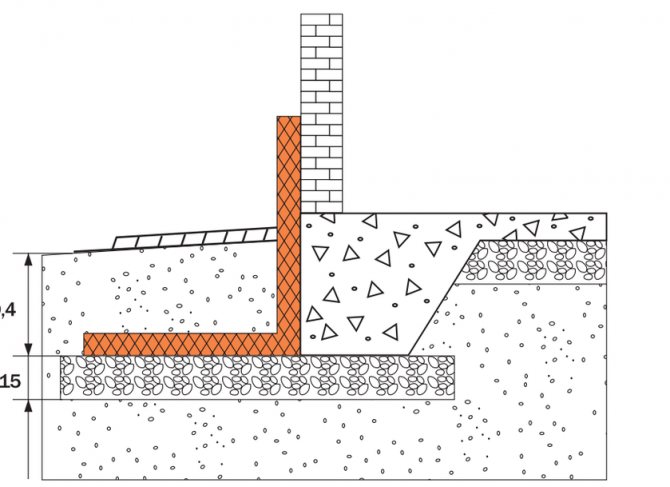

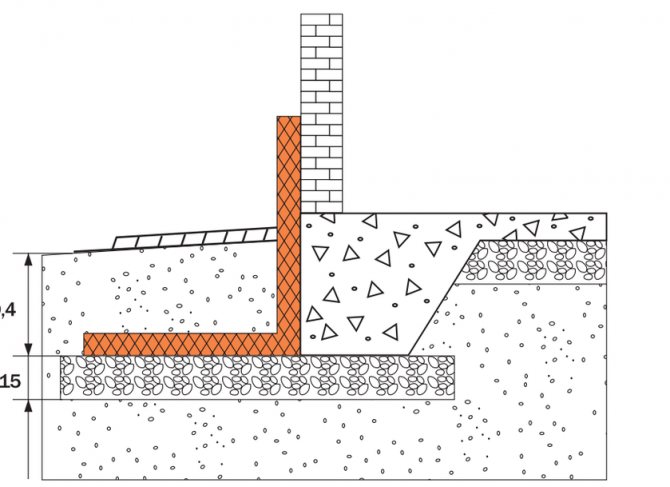

A compromise in this matter is the device of horizontal thermal insulation, which will smooth out the vibrations of the frozen soil and protect the building from deformations. And the cost of Penoplex is significantly lower than the cost of building an unjustifiably deep foundation.

a) in a heated building, the vertical surface of the base is insulated and Penoplex is placed on a gravel-sand mixture by 1.5-2 meters away from the foundation at the level of its cushion.

b) in an unheated house, penoplex is laid horizontally on a cushion of gravel-sand mixture, 15 cm thick under the whole house, 1.5-2 meters wider on each side.

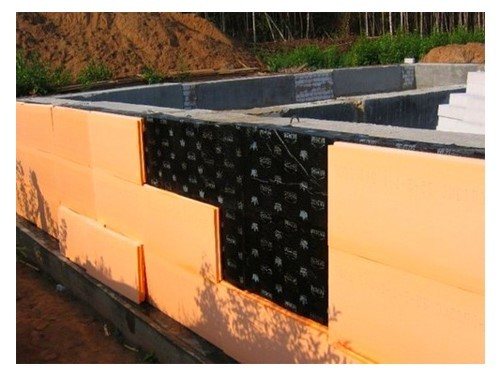

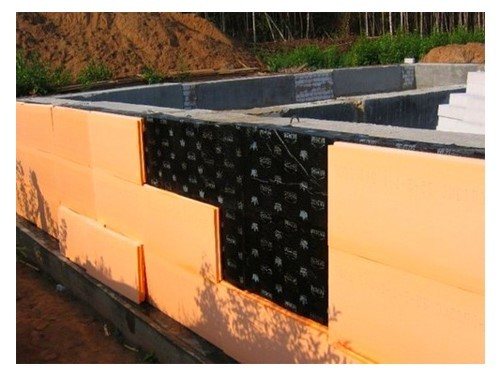

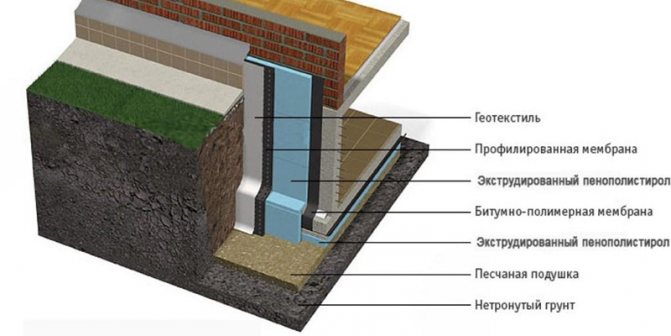

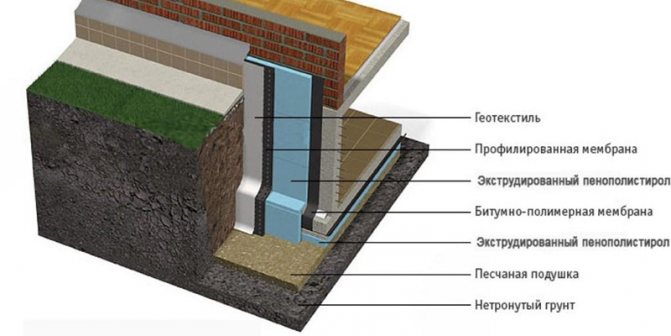

"Penoplex" slabs laying technology.

First you need to perform a coating or roll waterproofing. Bitumen-based coating waterproofing is the most common. The surface is pre-treated with a primer. Then a coating waterproofing is applied. The boards are glued directly onto it. The bitumen is heated at 6 points until it starts to melt, and Penoplex is pressed tightly against it.Under the ground, no additional fasteners are needed, but above the ground, the slabs should still be fixed with dowels (4 pieces per slab).

Roll-up waterproofing is melted onto the base previously treated with a bitumen primer. The surface is heated with a gas burner and the expanded polystyrene is glued to the foundation. Waterproofing is laid with an overlap, after the first layer is completed, the second is often fused to avoid the slightest gaps. Further, sheets of expanded polystyrene are mounted on a special glue or bitumen mastic.

If the required thickness of the insulation is large and the insulation must be done in 2 layers, then the installation is carried out with a displacement of the joints. When the work is over, it is recommended to protect the insulation itself from moisture, chemical compounds in the soil, and physical impact. There are special membranes for this. A good, albeit less effective, protection will be an ordinary roofing felt. An additional layer will increase the warranty period of the slabs and will be a good barrier to water ingress into the material cells. After all work is completed, backfilling is performed.

Buy penoplex foundation on the official website

Which is better - external or internal insulation of the foundation

When insulating a strip foundation or any other type of base, you should choose the place of its installation - from the inside or outside. To maximize the protection of the foundation material from the negative effects of natural factors, it is necessary to use external insulation, and this process is easier to organize during the construction of a house, and not later. And the powerful insulation of the foundation of the house from the inside additionally insulates the basement and basement rooms and communications. At the same time, the foundation itself remains practically unprotected from negative influences - it is damaged by moisture, negative temperatures and soil movements.

Foundation insulation methods

Advantages of external insulation:

- Protection against subzero temperatures and its effect on moisture in concrete;

- Creation of an insulation barrier for groundwater and atmospheric precipitation;

- With insulation in the basement and basement rooms, a constant and optimal microclimate (humidity and temperature) will be maintained;

- The dew point moves closer to the outer walls of the foundation.

How to calculate the foam layer for basement insulation

Insulation of the foundation from the inside with penoplex

When insulating your house, in particular, the foundation, first of all, you should calculate the thickness of the material and its properties for the correct choice of the brand of insulation, and you can make fairly accurate calculations on your own. The formula looks like this:

R = h1 / λ1 + h2 / λ2;

Where:

- R is the resistance to heat transfer in the region;

- h1 - base wall thickness, mm;

- λ1 - thermal conductivity of the base building material;

- h2 - thickness of the expanded polystyrene plate;

- λ2 - thermal conductivity of polystyrene foam.

Example: when insulating a reinforced concrete foundation with characteristics λ = 1.69 W / m K and a wall thickness of 400 mm, the calculations will look like this:

- 3.2 = 0.4 / 1.69 + H2 / 0.032;

- 3.2 = 0.24 + H2 / 0.032;

- 2.96 = H2 / 0.032;

- H2 = 0.0947 m, or ≈95 mm.

Result: With a foundation wall thickness of 400 mm, it is necessary to purchase 100 mm thick foam panels. When calculating, rounding should be done upward, providing a margin.

Thermal insulation of the foundation - general insulation scheme

In order to prevent the appearance of "cold bridges", "dew points", and to bury all cracks, cracks and joints, it is recommended to fix the external foam in two layers in a checkerboard pattern. That is, with a design thickness of a heat insulator of 100 mm, two layers of plates with a thickness of 50 mm can be used. It is not difficult to calculate the total number of plates: in one package - 8 units.

General requirements for insulation

The foundations of buildings are regularly exposed to moisture, temperature changes with possible freezing, they are subject to constant soil pressure, both in the transverse and longitudinal directions. How to insulate the foundation of the house outside? First of all, the selected insulation must have:

- low thermal conductivity;

- resistance to temperature extremes in the range from -40 ° C to + 20 ° C;

- resistance to moisture, be impervious to it;

- good strength while maintaining structure under pressure on the surface;

- unattractive to mice and insects.

The flammability of the material for external insulation of the foundation located below ground level does not matter, since the likelihood of exposure to a flame is extremely low. There are also no special conditions for vapor permeability, although water resistance already implies the presence of this parameter.

Thermal insulation technology

When insulating the foundation with penoplex, the technology must be strictly observed, taking into account the cost of the material. - a very technological material. If the foundation tape is insulated from the inside out, then the installation sequence will be as follows:

- Foundation;

- Waterproofing layer;

- A layer of foam boards;

- A layer of cement-based plaster;

- Ground pillow;

- Again a layer of foam boards - under the blind area;

- The blind area itself.

The scheme of insulation of a concrete foundation with penoplex

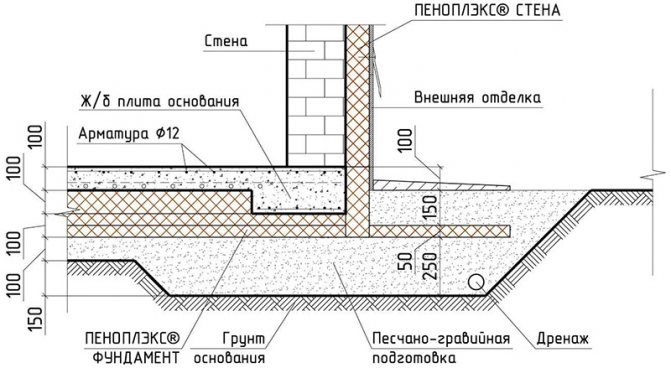

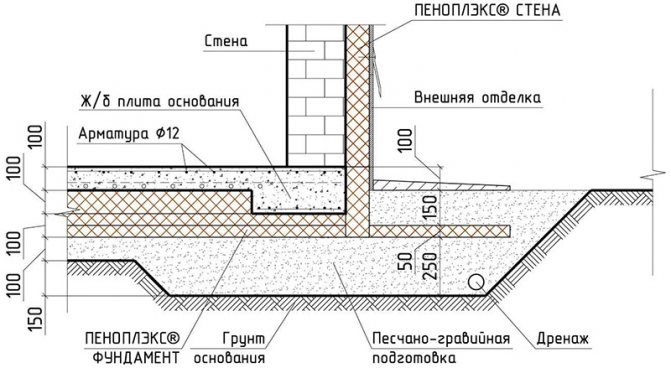

When insulating from bottom to top, the following sequence is used:

- Sand pillow;

- A layer of foam boards;

- Foundation;

- Waterproofing layer;

- Sub-floor concrete screed;

- A layer of waterproofing material along the end of the foundation wall;

- A layer of foam boards at the end of a part of the foundation slab. The slabs are laid from the beginning of the sand cushion and above the level of the soil surface by 0.4-0.5 m;

- A layer of foam boards under the blind area;

- The blind area itself.

Carrying out insulation measures during construction

The procedure for warming the foundation with expanded polystyrene must be carried out at the initial stage of construction work. Developers should strictly follow the technology:

- First of all, a pit is dug, in which a monolithic slab of concrete will be created. Its depth should be 1 meter. Depressions are made at the bottom, into which drainage pipes are laid, the functions of which are to divert surface water into specially created wells. Such measures will protect not only the foundation, but also the walls of the building from getting wet.

- After laying the drainage pipes, the bottom of the trench is leveled and a special material is rolled out on its surface - geotextile. It will prevent the germination of rhizomes of trees and shrubs, which can destroy the integrity of the supporting structure.

- A layer of sand and gravel is laid on top of the geotextile. Thus, at the bottom of the pit, a sand-crushed stone cushion is created (approximately 30-40 cm thick).

- Utilities are being laid, for example, water and sewer pipes. After laying, the surface is sprinkled with sand and leveled.

- Formwork is being constructed along the perimeter of the prepared pit. For these purposes, it is customary to use boards or sheets of moisture-resistant plywood. Outside, the formwork must be supported with jibs or stops so that the wooden structure can withstand the load that the concrete solution will exert on it.

- A small amount of concrete is poured into the bottom of the pit, which will create the first foundation layer. After it has solidified, the developer must proceed with waterproofing and thermal insulation measures.

- Due to the fact that a monolithic concrete slab will constantly be in the ground and in contact with a humid environment, the developer must perform its high-quality waterproofing. For these purposes, in the construction industry, it is customary to use roll material or coating. The concrete base must be thoroughly cleaned of debris and then dedusted. To increase its adhesive properties, it is recommended to carry out treatment with diluted kerosene or solvent. After that, roofing material is rolled out on the prepared concrete base, the canvases of which should overlap. All joints should be treated with mastic, after which experts recommend laying another layer of waterproofing.If the developer decides to use liquid insulation, then he needs to apply it several times to the surface of the concrete base and, after complete drying, continue construction work.

- At the next stage, the slab is insulated. For these purposes, most developers use sheets of extruded polystyrene foam (15 cm thick). Such material is laid, as a rule, in two layers. Make sure that the top sheets overlap the joints of the bottom panels.

- Reinforcement of the foundation structure is carried out, due to which its strength and bearing characteristics will increase.

- The concrete solution is poured in several stages. After pouring the first batch, the developer must use a deep vibrator to remove air and eliminate the resulting voids. After that, the remaining solution is poured out.

The advantages of insulating a slab base

When erecting residential and non-residential buildings, various types of foundations are used. The choice is based on the type of buildings and the soil below them. For unstable soils with a high occurrence of water, a monolithic base is suitable that can withstand significant external influences. The slab foundation consists of several layers:

- sandy, overlapped by strips of geotextile. The joints are glued with construction tape;

- the second layer is crushed stone, at least 15 cm thick;

- a layer of cement mortar 10 cm thick;

- a layer of material to protect the entire structure from moisture;

- thermal insulation;

- overlapped polyethylene film;

- reinforcing mesh;

- concrete pouring.

What does a monolithic foundation look like?

Monolithic foundations, in comparison with strip and columnar, have a lot of positive qualities:

- serve as a floor for the first floor;

- suitable for the construction of buildings on floating grounds, ensuring their safety during the movement of the soil;

- suitable for construction in peat bogs and swampy areas;

- reinforced concrete base plate is not subject to shrinkage;

- suitable for the construction of buildings up to 3 floors.

But not everything is as good as it seems at first glance. A monolithic foundation is not a cheap pleasure. For its construction, serious financial investments will be required for the purchase of materials and the rental of large construction equipment. In addition, the arrangement of a monolithic foundation requires certain knowledge of technology. It cannot be built on slopes. That is why the slab foundation is chosen only when there is no other option.

Horizontal insulation of the slab

High-quality insulation of the foundation monolithic slab guarantees the durability of the building and long-term operation without the need for unplanned repairs. It is especially important to insulate the foundation slab under residential buildings, when it is possible to avoid significant heat loss on the first floors of the house.

Insulation of the foundation slab must be performed for the following reasons:

- Providing increased waterproofing of the foundation.

- Significant reduction in heat loss.

- Saving money for heating a residential building, real heat saving mode.

- Prevention of the formation of condensation that could destroy the building structure.

- Improving the comfort of living.

- Temperature stabilization in the interior of an operated residential building.

The choice of materials for insulating a slab base depends on a number of specific conditions, first of all - on the possibility of attracting special equipment (insulation with polyurethane must be performed using a special polyurethane foam installation for spraying insulation), the availability of a sufficient amount of free funds for the purchase of insulating materials.

One of the best insulation materials is polystyrene.

- Polyurethane foam is a type of foamed plastic that is permeated with pores with air bubbles.The composition for insulating polyurethane foam is made directly at the construction site, for which two compositions are mixed, which, as a result of a chemical reaction, form a strong hardened foam. Different ratios when mixing the original ones make it possible to obtain insulating compounds with different qualities, suitable for warming bases made of different materials (including reinforced concrete). PPU has unique qualities: it helps to preserve heat in the room; reduces noise; improves sound insulation; does not decompose under the influence of excessive moisture; resistant to a range of chemical fluids. The material is highly resistant to inflammation (some brands of polyurethane foam are not flammable, they belong to the group of hardly combustible materials).

- Foam - the structure of the material consists of a foamed substance containing pores filled with air. Polyfoam is used to insulate building structures, including foundations, but the surface of such insulation requires additional surface protection due to the low mechanical strength of the material.

- Extruded polystyrene foam - produced in the form of rectangular sheets with a fine-mesh structure. The material has unique properties - the ability to withstand high compressive loads without changing the geometric dimensions and internal structure. Extruded polystyrene foam is widely used to provide thermal insulation for foundation slabs without additional protection. It is very important when using material for insulating foundation slabs to provide special holes for the free release of soil moisture.

Indications and benefits of insulation

Insulation of the slab foundation is carried out to meet certain needs. With it you can:

- prevent the destruction of the structure from temperature differences;

- make the floor on the ground floor warmer;

- save on future heating of the building;

- reduce soil swelling under the building.

Various materials are used as a heat-insulating layer, except for mineral wool. The peculiarity of the insulation technology is that the concrete structure is erected on a layer of heat-saving material. Thanks to this, the soil under the house does not freeze. Heaters allow you to increase the efficiency of the warm floor.

Base slab insulation technology

Insulation of the slab foundation of a building requires certain knowledge and the study of step-by-step technology. Much depends on the choice of materials, the installation methods of which may differ. Installation is carried out both from the inside and from the outside. If penoplex is used for outdoor work, then this will protect not only the plates, but also the walls from freezing. Arrangement of the inner part of the base will improve the indoor climate, but will not protect the walls from severe frosts.

What is the conclusion from this? External insulation of the foundation with foam is an excellent option for any buildings. Its use is possible only at the initial stages of construction. Otherwise, it will be possible to carry out insulation only from the inside.

It is necessary to insulate the base of the building in advance, in the warm season, when the weather is dry. This is especially true for regions with a cold climate, where a cold snap sets in much earlier, and the soil freezes to a great depth. During construction in winter, additional costs will be required for heating concrete and maintaining the desired temperature on the site.

In the insulation of slab facades, each process is of great importance. Compliance with the phasing and technology will allow you to achieve high-quality robots, reduce heat loss of the entire future building and maintain its durability.

Plate materials for insulation are used more often than others. This is polystyrene, expanded polystyrene, sometimes mineral wool. A layer of 5-10 cm will be enough.If mineral wool is used, then the surface of the base will not need to be leveled beforehand.

The board material can be mounted in one of two ways: on glue or on self-tapping screws. The process is carried out as follows.

- If self-tapping screws are used, the insulation sheet is attached to the surface of the foundation slab. For each square. m. it is necessary to prepare 8-10 consumables.

- In the second version, a special adhesive solution is used.

There are general rules for each type of fastening. Insulation material is mounted horizontally, starting from the bottom corner. Each subsequent sheet is applied to the side of the previous one. The rows of insulation are set so that the seams between the sheets are slightly offset and do not form a continuous gap.

After curing, the liquid polyurethane foam provides excellent thermal insulation and additional protection against moisture. Only 5 cm of the cellular structure of the material can be compared in density with a meter thickness of expanded polystyrene. This means that there is no need for additional insulation inside the building.

The technology for warming sprayed insulation is as follows.

- By mixing the components immediately before work, the necessary insulation is obtained.

- Using a special technique, the material is sprayed onto the surface of the foundation.

- After hardening, the foam turns into a durable layer of insulating spray.

We suggest that you familiarize yourself with Painting a gas stove with your own hands

The method of thermal insulation with polyurethane foam has a number of advantages:

- saves time. In one work shift, several hundred square meters of the base can be insulated;

- before installation, the surface to be coated does not need to be leveled;

- creates a continuous layer on the foundation without seams and joints;

- is the warmest of all existing heaters;

- has good adhesion to the concrete surface of the base;

- eliminates the need for additional waterproofing;

- the service life of the material is more than 35 years;

- environmentally friendly and does not create harmful emissions into the atmosphere.

Liquid polyurethane foam is often used to insulate a monolithic foundation

With so many advantages, polyurethane foam is not without its disadvantages. Its cost is several times higher, for example, of the same foam or mineral wool. Special equipment is required to work with the material. It is not resistant to sunlight, therefore it needs a protective lining.

The use of bulk material such as expanded clay is one of the simplest ways to insulate a monolithic slab. To do this, you will need a wider trench, into which a layer of 50-70 cm will be poured. If the thickness is less, then the material will not be able to perform the functions assigned to it. The installation technology is as follows.

- The wall is additionally waterproofed with a primer, plaster, mastic, etc.

- The bottom of the trench is lined with foil or geotextile. If ordinary polyethylene is used, then at least two layers are made.

- The next layer is crushed stone, about 15-20 cm.

- A drainage pipe is laid in the crushed stone to drain water.

- Further, the trench is covered with expanded clay.

It is also recommended to make a partition of bricks, slate, plastic or metal panels, and pour expanded clay between it and the foundation. This will be a kind of barrier that prevents moisture from entering the insulation.

The final stage in the insulation of a monolithic foundation slab will be the protection of thermal insulation. This will protect the material from deformation and moisture. A layer of foam will protect the brickwork. For polyurethane foam and sheet materials, a crate is made of wooden beams or metal profiles. The frame is attached to the foundation, and a layer of insulation is mounted between it and the wall. On top of the frame, on self-tapping screws, any protective layer is attached. If it is metal, then either stainless steel or galvanized sheets should be used.

The technology of warming the foundation will seem complicated only in the first stages.If you deal with its nuances and do everything according to the rules, then the result will exceed all expectations. Do-it-yourself work allows you to save on specialists and the installation of thermal insulation will not result in a pretty penny.

When insulating a foundation slab, horizontal and vertical insulation is used, in which a layer of insulation is laid under the slab base or along the side walls of the foundation structure. Expanded polystyrene or polystyrene is most often used as an insulating material. Watch a video on how to insulate a foundation slab with expanded polystyrene.

Insulation is laid during the installation of the foundation according to the following technology for performing insulation (consider the option of warming the foundation with expanded polystyrene):

- To begin with, on the building site, the place of the foundation for the building is marked.

- The top layer of continental soil must be removed to the depth of the foundation slab, the bottom of the excavation must be as even as possible.

- The prepared area is covered with coarse sand, which needs to be tamped using vibratory rammers. A small layer of concrete is poured over a layer of sand, for which temporary formwork is exposed.

- After the concrete screed has hardened, the insulation is laid out of expanded polystyrene plates, making sure that the mounting grooves coincide as much as possible. Large gaps between the insulation plates must not be allowed.

- On top of the laid polystyrene plates, a layer of polyethylene film is laid, which is glued with a special adhesive tape.

- A construction formwork is being erected for pouring a slab base into which a spatial frame made of reinforcement with a diameter of 10 mm or more is mounted. The concrete is poured from the corner of the slab foundation, evenly leveled and compacted with a vibrator.

- The foundation slab gains strength for about 28 days, the formwork can be dismantled two weeks after the structure is poured - by this time the foundation is gaining up to 70% strength.

- The side walls of the foundation slab are additionally insulated with expanded polystyrene plates.

The insulated monolithic slab will last for many years without damage to structures from adverse factors.

Insulation materials

The table shows the materials used to insulate the foundation slab and their characteristics:

| № | Heat insulating material | Characteristics |

| 1 | Styrofoam | Consists of air-filled cells. It is produced in the form of sheets, has insufficient density, so its surface needs additional protection. |

| 2 | Extruded polystyrene foam | It is able to withstand significant compressive loads without changing its size and structure. It is produced in the form of rectangular sheets with small cells filled with air. Lay the sheets in 1 or 2 layers. The second layer must be spread out so that the seams of the sheets of the first and second rows do not intersect. During installation, provide for the presence of holes for moisture drainage. |

| 3 | Polyurethane foam | It is a type of foamed plastic with many pores filled with air bubbles. The composition is prepared directly at the construction site. The two components are mixed, the result is a dense, solid foam that is applied to the surface. The plate insulated with polyurethane foam has high performance in heat and sound insulation, withstands the effects of moisture. Refers to low-combustible materials, and some brands are hardly combustible. |

Most often, extruded polystyrene foam is used as a heater under the foundation slab.