The supply of vegetables from distant southern countries in the winter provided the counters with tomatoes, cucumbers, herbs, eggplants and other exotic agricultural products. The first euphoria from such an abundance did not last long: buyers quickly realized that they had to pay a high price for the beautiful appearance of vegetables - their health.

Agricultural chemistry and genetic modification make it possible to make products that can withstand long-term transportation and long-term storage, hitting the shelves in perfect condition. More and more buyers are deliberately abandoning overseas products in favor of greenhouse vegetables and fruits.

Greenhouse heating boiler

Greenhouse in our country actively reviving, powerful complexes and numerous private farms appear, which supply quality products to our tables.

The specificity of the country's climate makes

take seriously the heating of greenhouses and greenhouses, must be equipped soil and air heating system maintaining optimal temperatures. For her, it is worth choosing an economical boiler with high efficiency, which will minimize the cost of growing agricultural products in the winter. Do not forget about modern technologies such as gsm moduleswhich will allow using a smartphone to monitor the operation of heating equipment online.

What kind of boiler is needed for a greenhouse?

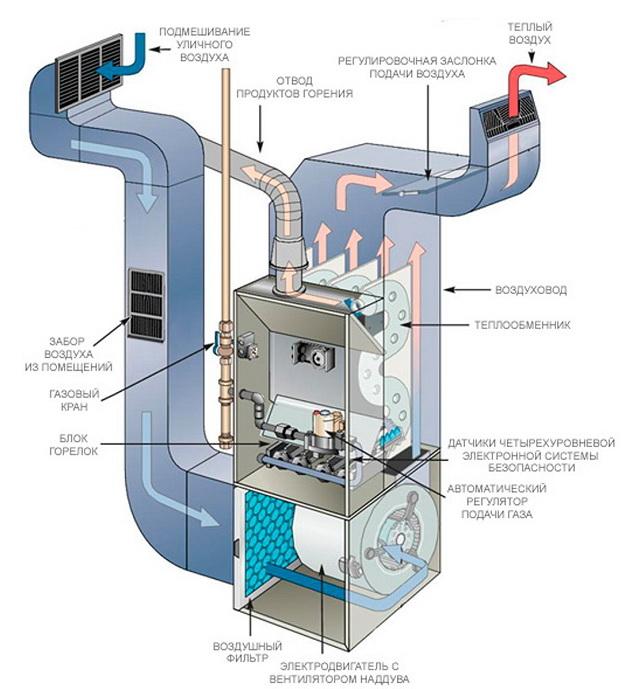

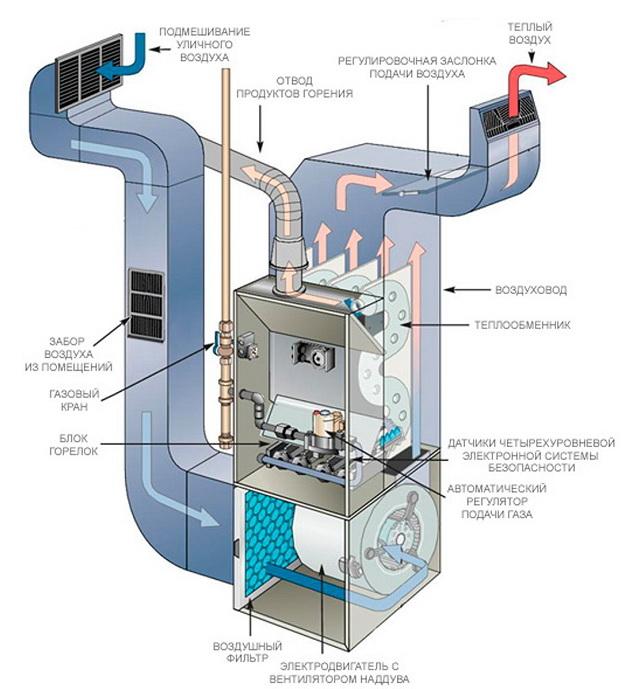

The classic water heating system is perfect for a greenhouse. It allows you to simultaneously heat the soil and air. For this, pipes are laid in the ground, and heating radiators are removed from the outside. The specificity of the operation of this system is a large difference in the temperature of the coolant at the inlet and outlet. After circulation in the system, the water can cool down to 45-50 degrees! Not all heating equipment can cope with such a difference; the most correct solution would be to install a condensing gas boiler. This technique has the following advantages:

- Low fuel cost;

- High efficiency of equipment;

- Use of steam energy;

- Compact dimensions;

- Simple controls.

Condition efficient operation of condensing gas boilers is the low return temperature. Steam condensation occurs when 50 ° C and according to this indicator, the greenhouse water heating system fully meets the requirements of equipment manufacturers. In such conditions Efficiency boilers reaches 107-109%, which provides economical heating of greenhouses of farms.

High technologies do not always contribute to the high quality of greenhouse heating. Solid fuel boilers for long burning and pyrolysis models are popular with fans of autonomous heating due to the availability of fuel and its environmental friendliness. It is not recommended to use this technique for heating the greenhouse, since the low temperature of the coolant in the return will cause condensation to form on the inner walls of the boiler and the heat exchanger. When mixed with combustion products, aggressive solutions are formed that destroy the walls of expensive equipment.

In the absence of gas heating, the best choice would be classic solid fuel boiler... He will perfectly cope with the task, but will require increased attention.

If a pyrolysis boiler or a solid fuel model of continuous combustion has already been purchased, then it will be necessary to think over a return heating system to a temperature higher 50 ° C.

Calculation of requirements for technical characteristics, greenhouse heating scheme

The first thing to look out for - this is the area of the greenhouse. Second - the presence or absence of insulation near the heated room. Third - availability of time to control the maintained temperature and load fuel into the boiler. Fourth - budget.

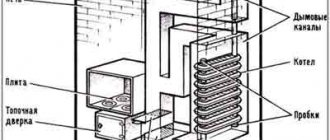

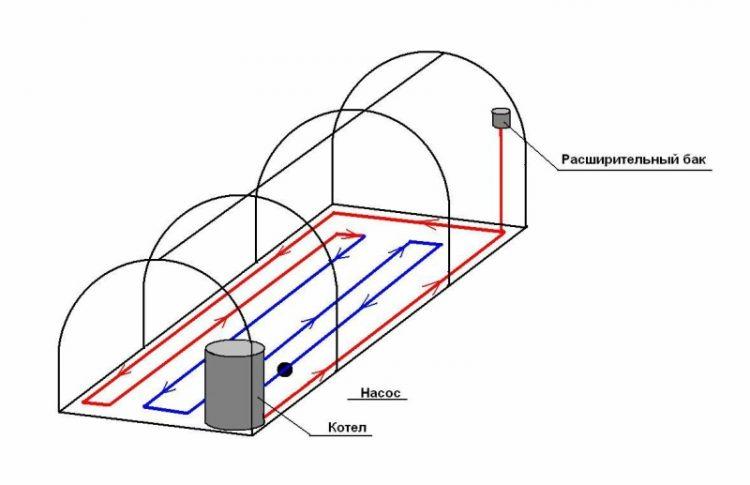

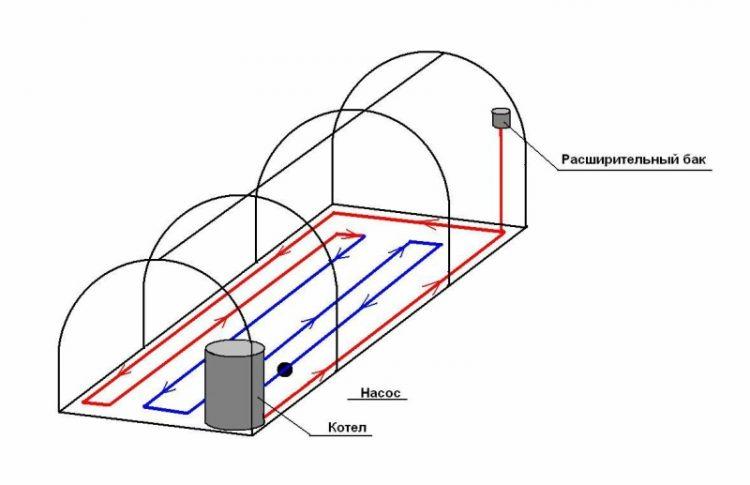

Photo 3. Greenhouse heating scheme using a solid fuel boiler and a water circuit.

Based on these requirements, you need to choose both the device and the fuel for it... With a small budget for a small greenhouse with thermally insulated walls, a direct combustion boiler is quite suitable.

For premises in 100-150 sq. m with insulation, as well as with an average budget, a simple pyrolysis boiler will do.

A long-term burning device is suitable if there is a good initial capital and a large territory (about 400 sq. m.) with insulated walls. In this case, minimal efforts will be sufficient to maintain the temperature regime.

Where to install the heating boiler?

For large greenhouses, you can build a separate boiler room, in medium sized greenhouses it is better to install heating equipment directly at the entrance to the premises... Is it necessary to enclose the boiler? This is not necessary, especially in the case of using gas heating equipment. If preference is given to a solid fuel boiler, then you should make sure that there is a supply of dry fuel next to the boiler. With high air humidity in the greenhouse, it is worth making a separate room for storing fuel.

How to choose a greenhouse boiler: advice from experienced farmers

A greenhouse boiler is the equipment that will allow you to get a good harvest even in severe frosts. Everyone knows how much vegetables cost in winter, so your vegetables during this period are a very profitable solution. But every vegetable grower who decides to start heating the greenhouse may face the difficulty of choosing a boiler, because there are several varieties of them on the market. Which one should you choose for this or that site? Or maybe it will be easier and cheaper to make it yourself from scrap materials?

Pellet boilers

Pellets are a special type of fuel. It is a compressed pellet. They are made from wood, sunflower seed husks, peat, straw, waste from furniture factories.

Accordingly, pellet boilers operate by burning pellets.

The advantages of such boilers for greenhouses:

- high degree of fire safety;

- automated operation of the entire heating system;

- the ability to regulate the intensity of combustion;

- The efficiency can be as high as 94 percent.

The negative aspects of pellet boilers include:

Greenhouse boiler options

At the moment, the following boilers for greenhouses are massively used:

- wood-burning;

- combined (wood-coal);

- pellet;

- gas;

- electrical.

They are conventionally classified into two more subspecies. Solid fuel boilers are the above-mentioned first three types. Long-burning boilers are classified in a separate category, since the principle of their operation is not tied to the combustion of materials, but to their smoldering, for which a controlled oxygen (air) supply system is used. They are the most efficient and economical, but they are quite expensive.

The simplest heating boilers for greenhouses are gas and electric. However, it is impossible to call them economical and profitable in the current situation. Gas and electricity are already too expensive for heating, and additional price increases are expected in the future. Therefore, such boilers are used only for an emergency, when other heating options are simply not available for any reason.

You can also cook a wood-burning boiler yourself, but this will turn out to be a banal potbelly stove. Its advantages are cheapness and efficiency, and its disadvantages are the inability to regulate the temperature, the need to constantly add fuel (wood or coal), as well as uneven heating of the greenhouse area. Their use will be justified only if we are talking about a polycarbonate or glass greenhouse with steam heating (or where pipes are laid in the ground at a depth of about 50 centimeters). And such a boiler for heating a greenhouse is suitable only for small areas. If the greenhouse occupies more than 50 square meters, then several "burzhuyki" will be required. Keeping track of them is extremely difficult and troublesome.

But there is also a very big advantage in wood-burning and long-burning boilers for solid fuel greenhouses. The product of their mining is ash and ash, which are extremely useful "ingredients" for growing any vegetable and fruit crops. And in the case of beets, for example, ash allows you to get rid of any insect pests and save a lot of money on the purchase of agricultural chemicals (pesticides and mineral fertilizers). For a vegetable grower, this is far from the last advantage.

Bubafonya stove

The independent manufacture of stoves such as Buleryan and Butakov is an event that is practically impracticable at home. The Bubafon model, if you have the skills of locksmithing and welding and tools, is quite possible to make with your own hands. For heating greenhouse rooms, it is most often just such home-made long-burning units that are used.

Bubafonya is a convection unit, the body of which is made from a gas cylinder or a steel barrel. The design includes a door for loading fuel and an ash pan. Smoldering is provided by pressure, which, by its weight, exerts a metal pancake pressing on the fuel from above. Such a furnace for heating a greenhouse is capable of operating on one tab of fuel for a long period.

Which boiler to choose for a greenhouse

When choosing a boiler for heating greenhouses, you need to take into account both the area of the heated room and your financial capabilities. Ideal - long burning, but they cost an average of 100 thousand rubles. But their consumption is 2 styling for 24 hours. In large greenhouses, they fully pay for themselves in just 1-2 seasons (if firewood or coal is purchased). In small ones, with an area of about 15-20 square meters, the payback will stretch for almost 10 seasons.

For the latter option, simple solid fuel heating boilers or those that run on gas are ideal. The efficiency of the system will be significantly higher if it is supplemented with a pump for pumping water through pipes. This, by the way, will provide even heating of the heated room.

An electric boiler, as practice shows, is a waste of money. They are inefficient, consume too much electricity and only raise the temperature in the upper part of the greenhouse. The volume near the ground remains cold, which leads to freezing of plants.

Combined long-burning boilers are classified as industrial ones.

They should be bought only if the greenhouse is over 100 square meters and those crops are grown in it that react extremely sharply to a change in microclimate.

These are, for example, bell peppers, wild strawberries, strawberries, raspberries, eggplants, carrots, potatoes. They cost, respectively, from 200 thousand rubles. But the savings are huge! And boilers of this type also operate on liquid fuel (meaning processed oil, fuel oil, oil industry waste).

A few words must be said about the pyrolysis boiler, which is conditionally a derivative of solid fuel long burning. Its operating principle is based on burning wood gas. It has a very high heat transfer, since the flame is supplied through the nozzle as from an autogen, thereby quickly heating the water tank.In this case, heat can be dissipated into a steam heating system or by a fan through a radiator. Such a boiler is both efficient and economical, but it takes up a fairly large space (including in height). Not suitable for small greenhouses, as it can burn plants in them. The landing distance from the boiler is at least 50 centimeters.

Emergency heating boilers

An experienced vegetable grower always has at his disposal heating boilers of various types, since one of them may turn off due to an interruption in gas supply, electricity, or simply break down. So for emergency cases, electric ones are ideal, where the heating element is heated, and the heat is dissipated by the cooler. But they should be supplemented with a stand-alone generator.

The most common wood-burning stove is also an excellent solution for emergency heating of the greenhouse volume. But its construction should be done in advance. Smoke can be removed in several ways. But we must not forget that a foul gas for plants is not harmful and reduces thermal conductivity. Thanks to this, the cooling rate of the greenhouse will be significantly reduced.

Every vegetable grower can use a mobile pellet boiler. It is quite easy to transport, but it is useful for burning any solid fuel, including corn cobs. In this case, heating occurs quickly and evenly. The only drawback is the need to have a chimney, and in a strong wind it will blow out from the outside. That is, a large amount of smoke will enter the greenhouse. Plus, pellet boilers are demanding to maintain. They quickly accumulate moisture, which is removed only mechanically. In any case, this is an excellent option for emergency heating, in which fuel can even be combined (for example, kindling with wood, maintaining the temperature with coal or peat).

Heating the soil with electricity

If it is possible to connect powerful electrical equipment, you can also heat the soil with it. For this, you can use the technology "electric warm floors". There are two types of materials for such heating: film or cable. Both options give the desired temperature - up to 40 ° C. They differ only in shape: film is a roll material and it is laid in a continuous sheet, and the cable is "snake" after a certain interval. There are also infrared films, but they are expensive. Cables are several times cheaper, and at the same time have a good warranty period: 10-20 years, depending on the manufacturer.

Electric underfloor heating can be used in a greenhouse

Film underfloor heating in the greenhouse can also be used

Heating with an infrared heater belongs to several categories at once, on the one hand, it is a non-standard technology, but on the other hand, electric energy is required for the operation of the emitters. So the affiliation is controversial. But what is good about this method is that both the earth and the plants themselves are heated, as in the sun. The only thing to consider when using this method is to correctly calculate the distance to the plants: too intense infrared radiation, like the baking sun, can dry out the plants.

Greenhouse heating with infrared radiators is very efficient

Greenhouse heating boiler: wood, electricity and gas

Now we will consider options for boilers for heating a greenhouse and see which one to choose. It can be a wood-fired boiler, gas or electric.

Currently, a healthy lifestyle is massively popularized. The physical condition of a person depends, first of all, on what foods he eats. Therefore, today more and more people are trying to eat right.

As you know, vegetables and fruits that lie on store shelves are stuffed with nitrates and other poisons, so many decide to grow their own food and resort to using greenhouses. In order for plants to grow well, it is necessary to maintain a comfortable temperature in the greenhouse, especially in winter when the air temperature is low.

Moreover, for the normal growth of your vegetation, it is important to heat not only the air, but also the earth. If this is not done, the grown products will simply die. In order to prevent this from happening, it is worth getting a boiler for heating greenhouses. This is the equipment that will act as a source to maintain the desired temperature in your "winter garden".

The main factors that affect the choice of heating method for greenhouses are the cost and stability of the temperature regime. Therefore, it is important to choose a good heating unit.

Greenhouse boilers are:

- solid fuel;

- gas;

- electric.

Possible problems with a homemade device

- The most common problems during the operation of a homemade heating unit are:

- uneven heating of the internal space;

- excessive dryness of the air.

Both factors negatively affect the state of plants in the greenhouse, therefore, you should be especially careful when laying air pipes and provide additional air humidification. Undoubtedly, the selection and installation of technically difficult expensive equipment requires a considerable amount of time and effort to study the issue. Nevertheless, these efforts can be attributed to a prolonged investment in a future rich harvest, which, both morally and materially, will delight you for more than one season.

Solid fuel boilers

Today, wood-fired heating units are the most common and affordable. This is due to their high productivity and efficiency, because ordinary firewood, waste from furniture and woodworking industries, wood scraps, branches cut from trees and even dry garbage act as fuel for them.

You can choose among the following types of solid fuel boilers:

- wood (conventional or pyrolysis);

- coal and wood;

- pellet (work on compressed pellets made of wood, seeds, straw, various waste).

Solid fuel greenhouse boilers have many advantages:

- environmental friendliness;

- cheapness;

- availability;

- safety;

- aesthetics;

- non-explosiveness.

The efficiency of such boilers is in the range of 75–90%.

Using solid fuel boilers as a way to heat the greenhouse, you can be content with fresh vegetables and fruits all year round.

However, such devices also have some disadvantages:

- To store such devices, you need a "solid" area.

- It is necessary to prepare fuel in advance.

- They require regular maintenance (cleaning the boiler furnace from ash, filling fuel).

How to make a greenhouse boiler with your own hands

If you want to save a budget and do not want to buy a ready-made unit, then you can make a solid fuel boiler for heating the greenhouse with your own hands.

To do this, you need to perform a number of actions:

- Get a barrel, the volume of which is 3 cubes.

- Using a drill, drill three holes in it, which will serve for the outlet of the chimney, drain and expansion tank.

- At the next stage, a 5 m high chimney is attached to the barrel. This device will be responsible for removing carbon dioxide from the greenhouse.

- An expansion tank must be attached to the top of the barrel, you can weld it yourself.

- Then you need to lay a heating system around the greenhouse, the best and cheapest way is plastic pipes.

- Using a special soldering iron, you need to weld the pipes together.

Plastic is not subject to rust, corrosion and is able to maintain performance despite temperature changes and high humidity.

Coal-wood boilers

Such boilers for heating greenhouses are considered the most versatile. Firewood, coal, briquettes and various wood and coal waste can be used as fuel. The quality of the fuel does not affect the operation of the unit.

The advantages of coal-wood boilers include:

- independence from electricity;

- large selection of fuel;

- availability;

- ease of maintenance;

Disadvantages of such boilers:

- high fuel consumption during the heating season;

- the need to store fuel;

- the duration of heating without additional fuel loading is no more than 6 hours when using firewood and 8-12 hours when heating coal and briquettes.

Gas devices

Greenhouse gas boilers are a good option. They guarantee uninterrupted operation and heating of the greenhouse at a level suitable for vegetation. The boiler automation ensures its autonomous operation, while human participation in this case is limited.

Using gas heating, you can heat the greenhouse in one of the following ways: air, water, infrared.

Infrared gas heater for greenhouse

Most often, infrared gas heaters are installed on the roof. This is due to the fact that gas infrared heating of the greenhouse in winter has one important advantage: first, the soil is heated, and only after it is the air.

The disadvantage of such heating is the need to install ventilation to remove combustion products.

The second option is heating the greenhouse with a gas boiler in conjunction with a water system.

Greenhouse gas boiler

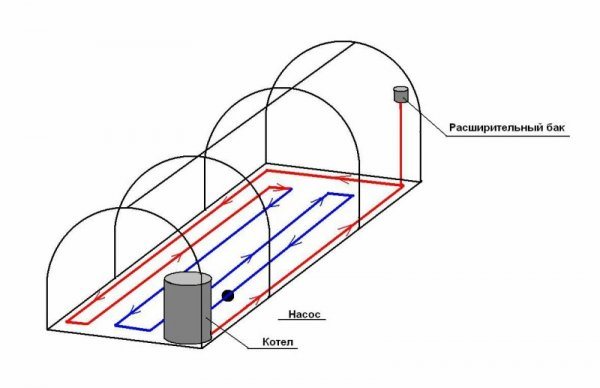

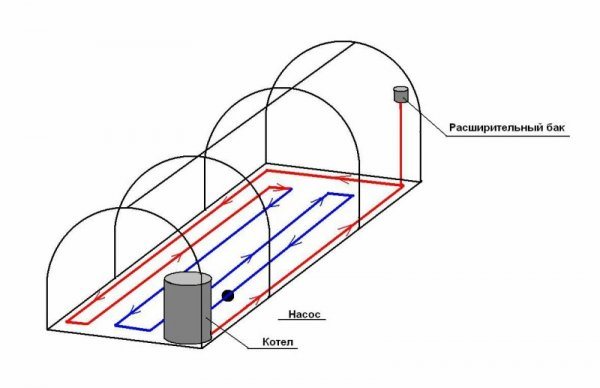

To activate this heating method, it is necessary to perform wiring from smooth pipes with a diameter of no more than 40 mm over the entire area. They should be laid along each bed 20-30 cm above ground level. It is allowed to use the following types of wiring:

- The supply line is along one wall, the return line is near the other. They are interconnected by transverse pipes running between the beds.

- The supply and return are laid along the same wall. Each heating pipe runs along one bed and returns past another.

- The pipe is laid in a snake over the entire area of the greenhouse, forming a single heating circuit.

It is imperative that cut-off valves should be mounted on each branch so that it is possible to turn off the circuit in the event that there is no vegetation in the greenhouse.

In the heating system of a greenhouse using a gas boiler, the main advantages can be noted:

- autonomous operation of the device;

- ease and speed of boiler maintenance;

- high efficiency.

- It is difficult to conduct gas to the greenhouse: a special service must be called.

- The high cost of gas tariffs, especially in the summer.

How to implement polycarbonate greenhouse heating

Before heating a greenhouse, it is worth deciding on several factors: what temperature you are going to maintain inside, how cold outside, how much financial and time costs you can afford.

In practice, there are many ways to heat a polycarbonate greenhouse: from handicraft options to industrial automatic installations that do not require intervention during operation.

Typically, the following types of heating are implemented in greenhouses:

- due to the energy of the sun. The main plus is the minimum cost. But solar energy can only be used in late spring and early autumn. At other times, effective heating cannot be achieved;

- using heaters for solid and liquid fuels. An effective option that allows you to create a full-fledged winter garden from a greenhouse. But it requires constant human participation: add fuel to the furnace, remove non-combustible fractions;

- using electric heaters.It is quite costly to heat a greenhouse with electricity, but it is effective and convenient: heating can be fully automated, achieving and maintaining the temperature with an error of no more than one degree;

- biological heating of the greenhouse made of polycarbonate. Used traditionally in the spring. The most common option is to use cow or horse manure, which at the same time serves as a fairly effective fertilizer.

It is worth choosing a specific type of heating when building a greenhouse - after all, in some cases, serious structural changes are required. And it's better to do everything at the construction stage.

Electric boilers

Electric boilers are easy to use and affordable wherever power lines are established. But if you want to purchase an electric boiler to heat the greenhouse, then you should understand that such equipment is quite expensive, and its use is not always advisable and justified. In addition, power outages often occur now, and during such a period your vegetation may simply simply die.

However, such heating, per unit of heat, is the most expensive. In addition, to connect an electric boiler, a separate line is required, and often not for 220 V, but for 380 V, and the wiring of such a line is a complex, lengthy and expensive process, moreover, this option is not always possible due to the lack of technical capability.

The advantages and disadvantages of an electric greenhouse boiler are as follows.

| Benefits | disadvantages |

| Low cost of equipment. | The need for a permanent connection to the mains. |

| Availability. Can be purchased at any major hardware store. | High energy costs. On average, electricity bills when using such a heat source increase by 10-20%. |

| Convenient control system, so there are no difficulties with operation. | |

| No combustion products, no need to equip the chimney. | |

| Minimal maintenance. The electric heating element does not need to be cleaned of soot or dirt, as, for example, in solid fuel boilers. Maintenance is required approximately every 2-3 years. | |

| They are convenient in location, do not take up much space, most of the devices are wall-mounted. |

A greenhouse is a great opportunity to please yourself and your loved ones with fresh and natural vegetables, greens, not only in the summer, but also in the winter. In order to successfully grow vegetables and ultimately harvest a good harvest, you need to ensure a good temperature in the greenhouse. Boilers for heating greenhouses are assistants in this matter. Each heating method has its pros and cons, therefore, in each case, one or another option may be the most optimal.

Based on your capabilities, you can choose the right option and ensure the fruitful growth of your plants.

Greenhouse heating boilers

Today, many people prefer to eat vegetables and fruits grown in their own garden. Everyone wants to see fresh produce on their table all year round. For some it is proper nutrition, while for others it is a way of earning money.

To achieve the possibility of growing various crops at any time of the year, regardless of weather conditions, it is necessary to properly equip the heating system in the greenhouse.

You can entrust the installation of the greenhouse heating system to professionals, but, having the desire and some knowledge, it is better to do it yourself.

Heating types

There are various ways to heat the greenhouse, and each of them has its own pros and cons.

To find out about the application and types of induction heating boilers, click here.

You can read about the device, the principle of operation and the leading manufacturers of double-circuit electric boilers at the link -

Also read about the types and features of the operation of solid fuel and liquid fuel boilers.

Air heating

The simplest and cheapest type of air heating has the following structure: a three-meter steel pipe is brought into the greenhouse with one edge, while a fire is kindled under the other. As soon as the pipe begins to heat up, hot air enters the inside of the greenhouse, thereby heating it.

This type of air heating is not particularly convenient due to the need to constantly maintain the burning of the fire, therefore it is used only in emergency cases. If instead of a fire there is a modern heating boiler, then the process of heating the greenhouse will become much easier.

With the help of a boiler, the greenhouse heats up quickly and efficiently, but there is also a minus - drying the air in a heated room.

The air in the boiler washes the firebox and heats up, after which it spreads through the greenhouse using air ducts. Lack of moisture can be compensated for by placing buckets of water inside the greenhouse or using modern humidifiers.

The combustion products of the heating boiler have a high temperature, which can be used to heat the soil (through pipes).

Water heating

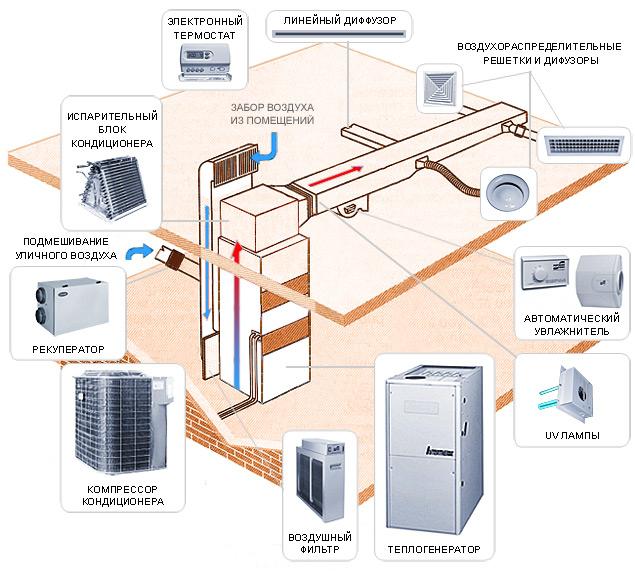

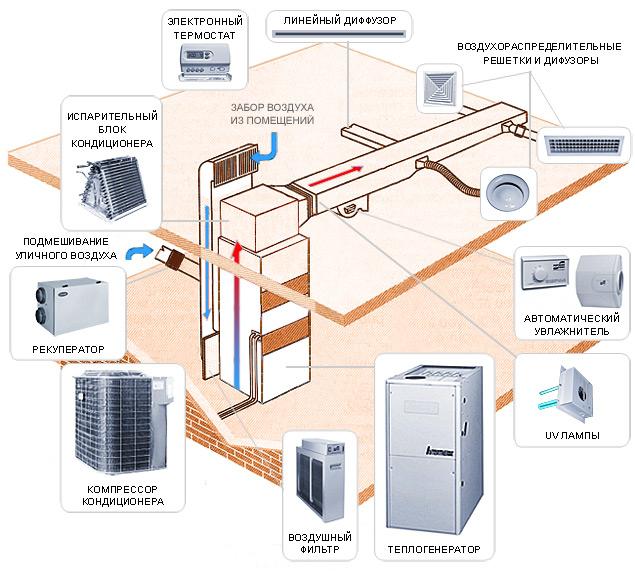

Heating greenhouses with a heating medium is the most common. The main elements of such a heating system are: a boiler, heating circuits (radiators, coils), a circulation pump, pipelines, fittings and protective elements.

For uniform heating of the greenhouse, it is necessary to install several heating circuits at different levels in height and an underground coil of the "warm floor" type. The regulation of the air temperature in the greenhouse can be entrusted to automatic sensors-relays. The temperature will be controlled by decreasing or increasing the intensity of movement of the coolant.

If each heating circuit has its own circulation pump and temperature relay, then an individual operating mode can be set for each circuit.

If we compare the water and air heating systems, then:

- An air heating system heats up the room faster than a water heating.

- Air heating has a simple design and does not require a lot of additional equipment, unlike water heating.

- Water heating has a laborious installation process and requires the installation of additional equipment, but it is more efficient than air heating.

Boiler selection

The choice of a boiler for heating a greenhouse directly depends on the preferred type of fuel, the size of the greenhouse and the outside air.

By type of fuel, the units are:

- Solid fuel burns coal, peat, firewood. They are conventional, long-burning and gas-generating.

- Oil fired boilers burn diesel fuel or kerosene.

- Combined boilers can operate on various types of fuel.

- Gas boilers run on natural gas or propane-butane mixture.

- Electric boilers do not burn fuel. Heating of the coolant is carried out with the help of heating elements.

In terms of power, the unit is selected in accordance with the calculation of the heat losses of the greenhouse and its dimensions.

Wood-fired hot water boilers

Air heating units that burn wood are able to quickly heat the air in the greenhouse, while the installation of the boiler is not a laborious process.

The principle of operation of an air-heating boiler is based on the creation of natural air circulation in the greenhouse: the air heated in the boiler is sent to the greenhouse room, thereby displacing the cold air back into the boiler and this cycle is constantly repeated.

Air-heating pyrolysis (gas generating) boilers are a conventional solid fuel boiler, but with an additional firebox. It is needed to burn combustible gas that is released when burning wood with an oxygen deficiency.

Pyrolysis boiler furnaces are located one above the other. Firewood is loaded into the lower one and ignition is performed. In the process of combustion, pyrolysis gas is released, which accumulates in the upper furnace and ignites there, releasing heat.

Advantages of pyrolysis boilers:

- High coefficient of performance (COP).

- Relative cheapness in comparison with analogues.

- Ease of installation.

- Rapid warming up of the room.

- Long service life (from 20 years).

Disadvantages of pyrolysis boilers:

- The need for the preparation and storage of fuel.

- The need for constant ash removal and chimney cleaning.

- When the boiler is in operation, a burning smell can be emitted.

Read about household floor-standing double-circuit gas heating boilers in the article.

You can read the link about automatic boilers for long burning on wood materials -

Infrared heating

Infrared heating of the greenhouse, in addition to its direct purpose, also favorably contributes to the growth of plants, and also does not harm human health.

The air is heated using a special infrared thermal film, which is completely safe, easy to install and connect. Film heating is controlled by an automatic system and reaches 20-500C.

Principle of operation

Infrared film has instructions for its installation. This process does not require special skills, you just need to deepen it into the ground to the specified depth. Next, you need to connect to the mains. It is necessary to set the desired temperature and the heating of the greenhouse will begin in automatic mode.

When installing several temperature controls, it becomes possible to configure an individual mode for each bed.

The efficiency of infrared film is 95%. In this case, all the heat is used gradually and for its intended purpose - the soil warms up, and then the air heats up.

Electricity consumption

The average electricity consumption is 60 W / h per 1 m2 of infrared film. The maximum power consumption is 240 W / h per m2. Such consumption occurs only when the film is heated from a cold state. Further operation of the heating proceeds more economically - the lower the maintained temperature, the less electricity consumption.

Greenhouse heating can be arranged in various ways, the choice of equipment is very rich, so choosing the right one is not difficult.

Comparison of ovens and traditional heat generators

Most heating devices work on the principle of fast fuel combustion. It is set on fire from below, and the fire goes up. In this case, oxygen access to the combustion zone is open. The disadvantage of such a system is that the temperature constantly jumps. The fuel resource is not completely consumed, and as a result of combustion, soot and soot are formed. Throughout the operation of the unit, it is necessary to constantly adjust the thrust and frequently add fuel.

As for long-term combustion units, their principle of operation is somewhat different from heat generators. In this case, the fire moves in the opposite direction: from top to bottom. This makes it possible to fully load the firebox to the maximum. The fuel burns out gradually. Oxygen is fed directly to the fire itself. Combustion is slow. In this case, less heat is generated. This makes it possible to create a comfortable temperature that is optimal for greenhouses.

Among the most efficient units, it is worth highlighting gas generating or pyrolysis furnaces. Their peculiarity lies in the fact that during the slow combustion of fuel, flammable vapors are formed, which later also enter the combustion process. This increases the efficiency of the unit and reduces fuel costs. The disadvantage is that condensation forms in the chimney when gases are removed. Therefore, the pipe must be insulated.

The gas boiler has the following advantages:

- Economical and high efficiency. Fuel is relatively inexpensive. At the same time, it is possible to use wood and more. Such units are relatively inexpensive. The efficiency of the unit is close to 85%.

- Easy to maintain. During the day, it is enough to do just a few downloads. When the required temperature is reached, the operation of the unit is controlled by the draft of the combustion chamber.

- High functionality. The stoves are ideal for the construction of various types of heating systems, as well as hot water supply.

Modern units can be built independently or purchased ready-made. To make the right choice, it is worth considering the main characteristics of existing models.

Boilers run on different fuels

We make boilers for greenhouses

In recent years, more and more people are thinking about a healthy diet without nitrates and other poisons present in purchased vegetables, fruits, greens. And many decide to grow their own food using greenhouses. For some, it becomes a lucrative business that brings pleasure and tangible income.

Greenhouse boilers

But it is not enough to install a greenhouse, you also need to heat it on cool days in order to get early vegetables. The heating issue can be solved in different ways. How to heat a greenhouse efficiently and inexpensively? What fuel should be used to heat it? Can you do it yourself? Answers to these pressing questions can be found in this article.

Features of heating greenhouse rooms

The main factor in choosing a method for heating greenhouses is the price of maintaining the temperature. After all, most greenhouses have a colossal loss of heat. Ideally, for good plant growth, the greenhouse should be built of metal profiles and plastic, with hermetically sealed glass windows.

But most vegetable growers and farmers cannot afford this method of construction, so most of the domestic greenhouses are covered with polyethylene or polycarbonate. These materials are transparent to sunlight, but they also give off a large percentage of heat to the surrounding space, so the heating of the room must be well thought out and powerful.

Greenhouse boilers

After building the greenhouse, it is necessary to start creating a heating system, the central element of which will be the boiler. The most commonly used:

- Electric - simple, easy to use and available wherever power lines are installed. But the use of such a boiler for heating the greenhouse will cost a pretty penny, besides, fan or emergency blackouts are now common, and then young plants can die from the cold.

- Gas - a stable supply of natural gas ensures good heating of the room, but the price of this energy resource is also quite high. Although many farmers use gas boilers for heating greenhouses because of the ease and speed of caring for them, it is enough to just put gas into the greenhouse and connect the boiler once - and the problems are solved. It is easy and simple to regulate and maintain the desired temperature, and the efficiency of gas heating has been proven over the years. Often, greenhouses are heated with gas by those who have this room next to a gasified house.

Gas boilers are available, and a conventional indoor floor standing version of suitable capacity is suitable for the greenhouse. The combustion products do not need to be removed outside the greenhouse, because all carbon dioxide is processed by plants during photosynthesis. And automation allows a person not to think about maintaining the temperature in the room.

But there are also disadvantages:

- The supply of gas to the greenhouse is rather complicated and requires the participation of special services, which will result in significant financial costs.

- During peak hours, the gas pressure may decrease, which sometimes causes the boiler to go out, and this is dangerous for the normal development of plants.

- In the winter months, gas tariffs increase with an excess of its consumption, and in order to save money, it is necessary to reduce the temperature in the greenhouse, which can negatively affect the growth of vegetables and fruits.

- Solid fuel boilers, or as they are also called, pyrolysis boilers, are used very widely, including in heating greenhouses. This is explained by their high productivity and efficiency, because firewood, wood scraps, waste from furniture factories, branches cut from the garden area and even dry garbage can be used for heating. These fuels are cheap and readily available, which makes these boilers attractive to greenhouse owners, since the savings in heating costs make it much cheaper to grow plants. Indeed, when heating with electric boilers, you can get golden vegetables and herbs, the costs of growing them significantly exceed the price of their sale. And solid fuel boilers are not only economical, but also easy to use. Most modern models are fully automated and only require fuel loading twice a day.

Heating greenhouses with solid fuel boilers

Heating greenhouses with solid fuel boilers makes it possible to grow plants all year round, creating your own profitable and stable business.

Solid fuel boilers are divided into:

- wood (conventional or pyrolysis);

- coal and wood;

- pellet (work on compressed pellets made of wood, seeds, straw, various waste).

Advantages of solid fuel boilers:

- environmentally friendly;

- cheap;

- aesthetic;

- available;

- safe;

- after their work, ash remains, which is an excellent fertilizer and pest control agent.

- large areas are required to store fuel;

- requires preliminary preparation of fuel;

- regular maintenance (fuel filling, ash cleaning).

Specificity of maintaining temperature

Heat escapes from the greenhouse through the ceiling and walls, as well as through the intake of fresh air through the ventilation openings. To compensate for such heat loss, it is necessary to organize an efficient heating system. Before starting any installation work, experts recommend insulating the structure. It is also important to minimize the intake of outside air.

Important attention should be paid not only to the material with which the structure frame is sheathed, but also to the features of its installation. The greenhouse should be as close to the ground as possible. The best option would be to build a foundation, which is laid at a shallow depth. It is additionally insulated. At the same time, the strength of the base is important, which ensures reliable installation of the structure.

The depth of the foundation should be 30 cm. Such conditions apply even to structures that are being built in regions with harsh climatic conditions. Heat escapes in a very small amount through the soil inside the greenhouse. As for heat loss around the perimeter, it can be reduced using ordinary snow, which is a natural seasonal insulation.

Solid fuel boilers - ideal for greenhouses

To ensure the normal growth of plants, it is necessary to establish an optimal temperature regime, as well as ventilation of the structure. If all systems are properly organized, the soil temperature will be the same as in the summer.

The depth of soil freezing depends on the geographic characteristics of the region. To get around any natural limitations, it is necessary to create optimal conditions for plant growth. Thermal energy can be directed both into the surrounding air and into the soil itself. In the latter case, the optimal condition is the installation of an underground pipeline.

Heating a greenhouse entails not small material costs, which depend on the following factors:

- The area of the walls as well as the roof of the structure. The smaller the surfaces, the lower the heat loss.In this regard, experts recommend using semicircular or rectangular frames for the construction of a greenhouse.

- Thermal conductivity of the material. If the coefficient is low, then the material will retain heat well.

- The difference between outside and inside temperature. With a significant temperature difference, heat loss is significantly high.

- The presence of cracks and places of loose fit of the finishing material to the frame of the greenhouse. Through them, cold air will enter the structure, which will lead to a decrease in temperature.

There is a large selection of greenhouses on the modern market. Therefore, there is no single system for organizing the heating of the structure. In each case, you have to develop an individual project.

The unit can be built by hand or purchased ready-made