Boiler structure feature

The requirements for boilers by owners of private houses are simple:

- He must be economical.

- Have a very high level of heat transfer.

- Not expensive.

Taking into account the fact that both gas boilers and the connection of a gas pipeline to a house cost a lot of money, and the subsequent payment for gas will also not bring savings, in many private houses devices that run on wood are installed. The most effective type of heaters is a water boiler, which can not only heat a small country house or summer cottage, but also supply it with hot water.

A home-made boiler made of cast iron batteries is an excellent alternative to industrial units that are expensive and save little.

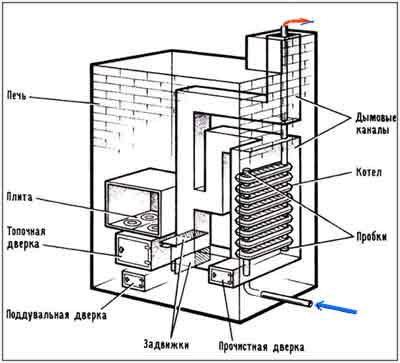

Its structure is such that a water boiler is built into an ordinary stove, which increases its heat transfer many times, thereby reducing waste on firewood, and warming up the room almost instantly.

Criteria for the selection of the required materials

Since a home-made apparatus is assembled from units that have already been used once, it is first of all necessary to assess the condition of the pipes. Particular attention will need to be paid to their walls. Their thickness should be several millimeters. If the appearance of corrosion is observed, then it is undesirable to use such pipes or it is imperative to eliminate all defects before use. All rust will need to be qualitatively removed from the metal with a brush, and then covered with an anti-corrosion compound so that the problem does not arise during operation in the future.

Preparatory work

Finding old Soviet cast iron batteries is not a problem today. Dozens of them are demolished when residents of apartment buildings change their heating to more modern models, or when old buildings are demolished. The best option for the manufacture of the structure will be cast-iron radiators M-140.

One battery section holds up to 1.5 liters of water. The number of sections directly depends on what area the heating boiler should heat from a cast-iron battery. For example, a house with an area of 100 m2 will require 12 sections with a total capacity of 18 liters and a size of 3 m2.

Before proceeding with the manufacture of the boiler, all sections of the radiator must be thoroughly rinsed from scale and dirt accumulated over many years of operation. To do this, you can pour inside a 6% hydrochloric acid solution and hold it there for a while until it eats away all deposits. After that, the solution is drained and each section is thoroughly rinsed with water.

This procedure should be carried out slowly, in compliance with all precautions. Protective gloves should be worn on the hands and a respirator on the face. After all the sections have gone through the cleaning process, you can begin to assemble the boiler from the cast-iron battery with your own hands.

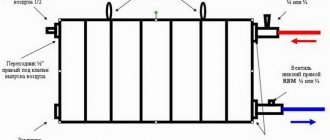

Cast iron radiator heat exchanger

A heat exchanger for a furnace or boiler can also be made with your own hands from sections of cast-iron radiators, even used ones. If sections of the old radiator are used for this, then before assembling them, they must be rinsed from the inside with a weak solution of hydrochloric acid (6-7%), and then with clean warm water to clean their inner surface of all deposits. In addition, using a special key, it is necessary to disassemble the radiator into sections (even a new one) and replace the rubber or cardboard gaskets between them with asbestos threads impregnated with graphite grease. After that, having calculated the required number of sections for the heat exchanger (area of each about 0.25 m2), they are combined into one structure.

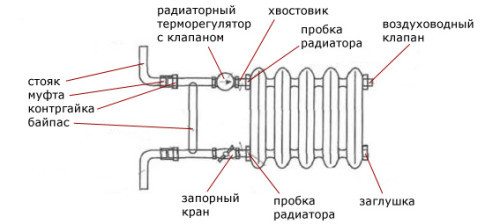

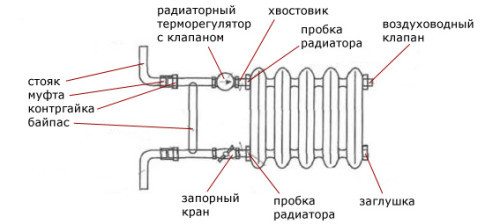

Such a register can consist of one or two rows of sections. The connection of pipes of the heating system to such a structure is carried out using threaded connections and the corresponding adapters, corners and sleeves, as well as when installing cast-iron radiators, but to seal threaded connections that will be exposed to high temperatures, it is also necessary to use asbestos threads, and I don’t put tow as usual.

After the manufacture of such a heat exchanger, even before installation in the furnace, it is necessary to check its tightness, and for this it is necessary to pour water into it and make sure there are no leaks. Such a heat exchanger will have rather large dimensions, so it is better to install the ego not in a firebox, but in a chimney or stove hood. Moreover, cast iron does not tolerate sudden temperature jumps and when exposed to flame on one side and cold water on the other, it can crack.

Related Videos:

Assembling the structure

It is not difficult to assemble radiators together, but first you should purchase new intersectional gaskets or use an asbestos cord impregnated with graphite powder previously diluted in drying oil instead.

Since the temperature inside the boiler can exceed +600 degrees, it is worth taking care of the gaskets in advance. The tightness of the entire structure depends on their quality and strength.

The sequence for assembling radiators is as follows:

- Nipples equipped with right-hand and left-hand threads are screwed into each section.

- Asbestos cords are wound around them.

- The sections are connected in pairs by alternately tightening the nipples. It is important to make the same number of turns with the wrench, so as not to cause distortion.

- All sections of the cast iron radiator are connected in the same way.

- The return and supply pipes should be connected diagonally, closing the unused openings with plugs.

There should be a right-hand thread on one side of the riser, and a left-hand thread on the other. If this does not work out, then you need to screw on the nipple, and on it a coupling with a drive.

Positioning the boiler in the furnace

It is important not only how the radiators will be assembled and connected to the heating system, but also their place in the stove. In order for the device to work for a long time and efficiently, the boiler from a cast-iron heating battery (the video shows how to do this) should be installed not in the firebox, where wood or coal is burning, which means there is an open fire, but behind it in the smoke channel.

This will save the device and extend its service life, and heating by gases that are formed during fuel combustion is no worse than an open fire.

Cast iron is a rather brittle metal, so it will not withstand shocks, or excess pressure, or too high a temperature. When installing the boiler from the radiator into the furnace, you need to make sure that the pipe at the exit from it was perpendicular to the floor, and the return flow passed under the floor and the foundation of the structure.

After the boiler is installed, you can start laying the walls of the stove, having previously checked it for leaks. To do this, you need to run water through the system under pressure.

Which batteries are better - cast iron or aluminum

Cast iron radiators do not need an introduction, which cannot be said about heaters made of aluminum. To determine which of these types of devices is better, we will describe the advantages and disadvantages of each of them.

The advantages of cast iron batteries include:

- Resistance of the material to corrosion. According to experts, cast iron is not afraid of abrasive substances such as sand and other debris. Also, it is not destroyed by acids;

- Such devices are of low cost, have high thermal efficiency;

- Such products can last up to 50 years.

Modern cast iron radiators

Despite the significant number of advantages, the described devices also have disadvantages.The main disadvantages of cast iron heating devices:

- The possibility of receiving a water hammer and disrupting the operation of the system;

- Insufficient indicators of thermal conductivity of the material;

- Ugly appearance, although modern counterparts are very attractive, but their price is high.

Today, aluminum heating radiators are very popular among consumers. They have small dimensions and weight in comparison with analogues. When using aluminum radiators, it becomes possible to automatically control heating.

Note! Aluminum has a much higher thermal conductivity coefficient than cast iron. This means that such devices will heat up faster and give off heat to the room.

The disadvantages of the described devices include low corrosion resistance, limited product strength. The service life of such devices will depend on the degree of purification of the coolant. The optimum acidity level should be between 7 and 8 pH.

Aluminum heating battery

There is no definite answer to the question of which batteries are better. Here everyone chooses according to personal preference. Recently, more and more users are leaning towards aluminum radiators, because such devices are much lighter and more compact than their counterparts.

When using such devices, it becomes possible to automatically control heating. At the same time, cast-iron batteries have a long service life, suffer less from poor-quality coolant, and are not afraid of corrosion.

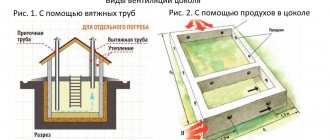

Furnace masonry

The stove can be built independently, following the sequence of actions.

- The first is the laying of the foundation of the structure, made of reinforced concrete.

- For masonry, the best solution would be a mixture of two portions of sand and a portion of clay. To mix them better, experienced builders recommend soaking the materials in water and leaving them overnight. During this period, they will mix well without additional efforts on the part of the owner.

- When the foundation is ready, it should be covered with waterproofing, for which roofing material can be used.

- A layer of mortar is placed on top of the waterproofing, the uniformity of which is best checked with a plumb line.

- The first masonry should form a blower, over which a grate is installed, separating it from the firebox. The grill is attached after 2-3 masonry above the blower.

- In the process of forming the furnace, a place is immediately prepared for the boiler from cast-iron batteries, taking into account the gaps between it and the outer wall of the stove... To do this, a side of bricks is laid around the perimeter, on which the corners are attached. It is on them that the boiler will be installed.

- When laying the masonry, you need to take care of the places where the supply and return pipes will come out in advance.

- The next stage is laying the chimney. During this work, special channels are formed to discharge fumes and combustion waste through them.

After finishing laying the chimney, the entire stove must be checked for the quality of work, for which it is flooded.

It is never necessary to heat the stove if there is no heating medium in the boiler. This could damage the system. You can think over and build a structure that will work both as a heating system and as a stove for cooking.

After completing all the steps step by step, it is quite possible to build a furnace with a water boiler from cast iron batteries with your own hands.

Sooner or later, it may turn out that even a cast-iron battery will require a complete replacement or you will just need to clean it. In both cases, the battery will have to be disassembled. How to disassemble a cast-iron heating battery with your own hands quickly enough and as professionally as possible? The fact is that such radiators are the best option for use in apartment buildings. These heating elements are able to withstand all the vicissitudes of an imperfect heating system.Sometimes, over time, even the cast iron has to be changed, because it has leaked or simply does not fit into the new apartment renovation.

What kind of electric heater can be made by hand

Of all the listed types of self-made heaters available:

- Oil radiator (you need a cast-iron heating battery).

- Infrared heater (we will assemble the film version from scrap materials).

- A fan heater, however, with a very modest power.

Cast iron battery oil cooler

The manufacture of any home-made device begins with the execution of calculation work.

Payment

Ideally, to determine the power of the heater, it is necessary to perform a rather complex calculation of heat loss through the building envelope. But in everyday life, its simplified version is often used: it is believed that 1 kW of heat is required to heat an area of 10 m2 with a ceiling height of 2.5 m. Of course, the result obtained by this method will turn out to be very approximate, but nevertheless, it will help you somehow orient yourself.

In addition to power, you will need to calculate the cross-section of the wires with which the device will be connected. It is known that a current of 17 A can be passed through each 1 mm2 of the copper wire section. The current consumed by the heater is calculated by the formula:

I = W / U, where W is the power (W), U is the voltage.

Thus, to supply the device with a power of, say, 2.2 kW (it can heat a room with an area of 22 m0), a current with a force of I = 2200/220 = 10 A. mm2.

Materials and tools

Here's what to prepare:

- cast iron battery;

- TEN of the required power with built-in overheating protection;

- mineral oil, preferably transformer oil (if the cost does not scare you);

- copper 2-core wire with rated cross-section;

- electrical plug;

- tow;

- steel sleeve;

- steel corners with a shelf 40 or 50 mm wide.

The following tools are needed:

- a welding machine or a drill with drills for metal - depending on whether a welded frame will be used, or assembled on bolts;

- soldering iron;

- adjustable wrench;

- a set of dies and taps for cutting threads on the sleeve (can also be cut on a lathe);

- pliers;

- screwdriver;

- knife.

Manufacturing instruction

The heater is manufactured as follows:

- From a steel corner we make a frame with legs or runners, into which it will be possible to install the battery in an upright position. If you have the skills of welding and the appropriate equipment, we make a welded frame; if not, we drill holes with a drill and assemble the frame with bolts.

- We make an adapter from a steel sleeve for installing a heating element in a cast-iron radiator. To do this, we cut a thread inside and outside it: the outer one must correspond to the thread in the battery hole, the inner thread - the thread on the heating element shank. Finding a sleeve with suitable dimensions is a great success, more often you have to grind it. Therefore, it is better to order such an adapter from one of the turners.

- From the edge of the adapter, you will need to file off the material to get flat edges for gripping with a wrench.

- Having wrapped the adapter with tow, screw it into the lower hole of the cast-iron battery. In the absence of experience, it can be difficult to select the optimal amount of tow, then instead of it you need to use a fluoroplastic sealant - FUM tape.

- We insert and screw the heating element into the adapter, having previously wrapped its shank with a seal.

- We solder the conductors of the wire to the contacts of the heating element, and at the other end we install an electric plug. It has screw terminals so you don't need to solder anything - you just need a screwdriver.

- All contacts must be reliably isolated.

- We unscrew one of the top plugs of the battery and fill it with transformer or other mineral oil.It should be borne in mind that when heated, its volume will increase, so you need to fill the battery no more than 80–85%.

The heater is ready, you can plug it in. If you need a more powerful device, another heating element can be screwed into the second lower hole, which is connected in parallel with the first.

Video: do-it-yourself electric oil heater from a cast-iron battery

IR heater from scrap materials

It is not possible to calculate this model of a home-made heater, since the main element - a carbon emitter - is applied "by eye". Instead of calculating, the resistance is checked after the fact and if it turns out to be insufficient, adjustments are made.

Materials and tools

The heater will be made from the following materials at hand:

- glass sheet;

- foil;

- paraffin candle;

- wire with an electric plug;

- sealant;

- epoxy glue.

The following tools will be needed:

- multimeter;

- scissors;

- glass cutter.

Manufacturing instruction

Here's what to do:

- Using a glass cutter, cut off two identical rectangular pieces of glass.

- We clean the glass from dust and degrease.

- We light a candle and, holding the glass over it, cover it with soot (both blanks). Soot, as you know, basically consists of carbon, that is, it is analogous to graphite tracks in infrared film heaters. In order for the glass to be smoked evenly, it is advisable to cool it before the operation.

- Having laid one of the glass blanks with the smoked side up, we wash with a cotton swab (it is convenient to use a cotton swab) soot from the very edge around the entire perimeter, so that a clean edging is about 5 mm wide.

- Cut out two strips from the foil, the length of which slightly exceeds the width of the glass rectangle.

- Apply epoxy glue to the cleaned edging, then lay the foil strip on the opposite edges. They need to be positioned so that the edge hangs down on one side only.

- Put the second smoked glass blank on top, so that the layers of soot touch. Pressing the glass sheets together with force, we leave them alone until the glue hardens.

- Using a multimeter, we determine the resistance R of the soot layer by applying the probes to the edges of the foil peeking out from under the glass. Next, we calculate the current strength according to the formula I = U / R, where U = 220 V is the voltage in the mains. The current strength must be within the limits permissible for the wire cross-section. For example, if a copper wire with a cross section of 1 sq. mm, for which the maximum current is 17 A, then the resistance of a home-made heater must be at least R = U / I = 220/17 = 12.94 Ohm.

If the resistance is lower than it should be, the IR heater will have to be redone. In this case, the width of the soot layer will need to be reduced, which will lead to an increase in resistance.

The power of the device is calculated by the formula W = U * I or, if through resistance, W = U ^ 2 /R or W = I ^ 2 * R.

You can get a graphite emitter of infrared waves in another way: you need to grind graphite (from it, for example, brushes are made of current collectors for electric transport) and mix it with a small amount of epoxy glue. Then, instead of glass, it is better to use decorative paper laminated plastic (DBSP), on the rough side of which the resulting graphite paste is applied in the form of a snake. Until the paste has hardened, copper terminals are introduced into it along the edges, after which the entire structure is glued on top with another piece of DBSP (we use the same epoxy glue).

After complete drying (!), We check the resistance of the device and if it is within acceptable limits, we attach the homemade IR-film to the wooden frame and use it.

Video: do-it-yourself infrared heater

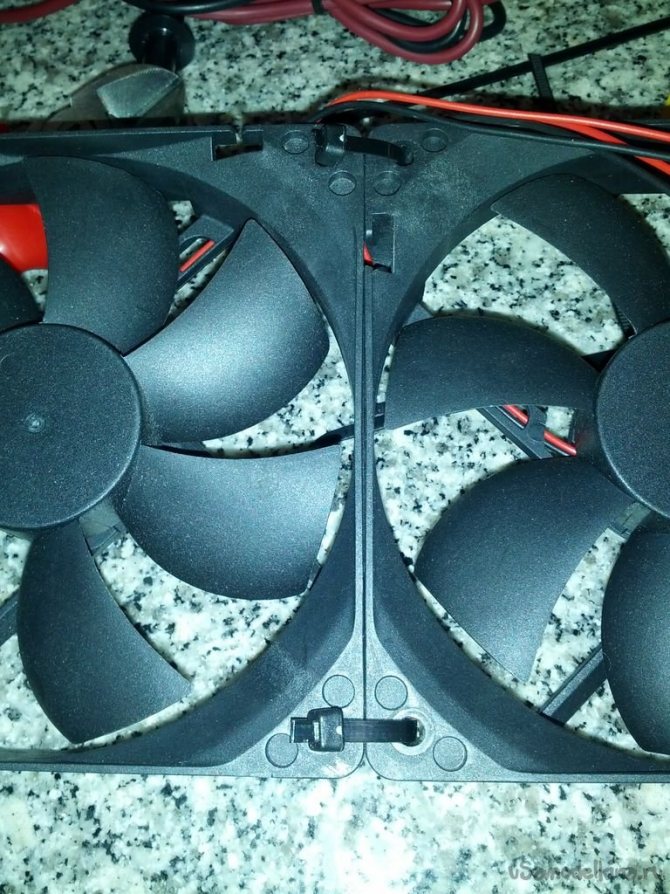

Fan heater 12 V from the power supply

This 12-volt fan heater is primarily useful for motorists.It happens that the standard stove for some reason does not work or the blowing of the rear window does not function effectively enough. In this regard, the resistance of the heating elements and the connection diagram (in parallel or in series) must be selected so that the device consumes a current of no more than 20% of that for which a car electric generator is designed.

With this ratio, it will be possible to avoid overloading the on-board electrical network. Thus, a fan heater for a car of the brand, for example, Daewoo Sens, whose generator is designed for a current of 70 A, must consume a current of no more than 14 A.

When connected in series, the total resistance of the heating elements will be equal to the sum of the resistances of each of them (Rtot = R1 + R2), and in parallel, the total resistance is calculated by the formula: Rtot = (R1 * R2) / (R1 + R2).

Materials and tools

We will assemble this heater from the following components:

- power supply unit from a stationary computer;

- tile;

- bolts and nuts М5, 8 pairs;

- wire with an electric plug;

- nichrome wire.

You will need the following tools:

- hacksaw;

- soldering iron;

- drill;

- spanners;

- crosshead screwdriver;

- pliers.

Manufacturing instruction

The manufacturing procedure looks like this:

- We completely disassemble the power supply: remove the cover, then unscrew the board, and the cooler. You also need to remove the switches and connectors, otherwise the homemade fan heater will smell of burnt plastic during operation.

- We wind nichrome wire on any cylindrical object to get heating coils. The length of the spirals must be selected so that their resistance corresponds to that adopted in the circuit.

- Cut a fragment from the tile with a hacksaw and drill holes in it for installing heating coils.

- We fasten the spirals to the tile and connect them with wires in a parallel or sequential scheme.

- We assemble the fan heater: we install the cooler in its place in the case of the power supply unit and fasten the tile with nichrome spirals in front of it, connect the wires. It is advisable to supplement the circuit with a fuse.

During operation, the fan heater becomes quite hot, therefore, if used in a car, it must be securely fastened. If this is not done, the device may fall while the vehicle is in motion and cause injury to the user or cause a fire.

Video: DIY trash fan heater

Preparatory work

Before proceeding with the replacement or repair of a cast iron radiator, it is necessary to take care not only of the availability of all the tools, but also of the spare parts that may be needed. (See also: Diagram for installing heating radiators with your own hands)

If you decide to completely replace the cast-iron radiator with a similar, only modern model, during the preparatory work it will be advisable to install the brackets on which the battery will subsequently be held.

Water must be shut off and drained before replacement or repair. The following tool is required for dismantling.

Rust removal brush with metal bristles.

Gaskets and tow.

✔ Make your life more comfortable

Does cleaning a radiator make you panic? The screen will be an excellent protection against dust accumulation, and their shape will allow you to playfully cope with wet cleaning. The decorative grille not only protects order, but also serves the safety of children: mobile babies will not bump and cannot get burned from the battery if it is securely hidden.

You will learn more about the advantages of self-produced goods, about our prices and delivery terms from the managers of the company. Enjoy your shopping and always have good weather at home!

Dismantling the cast iron battery

At first glance, disassembling a cast-iron battery with your own hands is quite simple, but it is not. So, first you need to heat the plugs on the battery, for this I use a blowtorch. After the plugs are heated, they can be unscrewed much easier than without heating. (See also: Cast iron heating radiators)

With the help of a grinder, the battery is cut very carefully between the sections. After cutting, the radiator sections are disconnected. In cast iron batteries there is a nipple that must be carefully knocked out of the battery using a chisel. This is required if you decide to clean the radiator or replace a separate section. With a complete replacement of the radiator, it is naturally not necessary to clean anything. It is enough to cut it with a grinder and take it out.

The nipple must be removed so that the thread is not damaged. It is subsequently thoroughly cleaned of rust. Further, the grouping and collection of individual sections is carried out. In order for the battery to have good tightness between the sections, you need to install gaskets and coat all joints with silicone. A little later, when everything is dry, the battery can be gently rinsed using a hose.

Installing a new cast iron battery

Installation is more difficult than dismantling a battery. It is quite possible to do these works yourself. The main thing is to adhere to the rules and follow certain requirements. When installing the battery, be sure to keep its position strictly vertical. Check with a plumb line or level. Otherwise, there is a chance to deal with dismantling again and such a problem as fixing a cast-iron battery. (See also: Which panel radiators are better)

If you have to install several cast-iron batteries in a room, keep in mind that they should all be located only on the same level. That is why, before attaching the brackets that will hold such a heavy structure, it is better to make markings for future holes. This is done using a special template.

As a material for the template, you can use thin plywood, a little larger than the battery itself. On the sample, in the place where the brackets will be located, holes must be drilled. The calculation of the required number of brackets can be performed according to the simple formula 1 bracket per 1 m2 of heating surface. When installing the drilling template, it must be installed using a plumb line.

In place of the marks, holes are drilled using a drill or puncher. The diameter of the holes must be such that the brackets can go inside the wall by at least 12 cm. After the brackets are inserted into the wall, they must be fixed with ordinary cement mortar. You can hang a cast-iron battery on the brackets only after the solution has completely dried. (See also: DIY installation of heating batteries)

Such requirements for securing the brackets must be met. After all, the weight of the edge of a cast-iron battery is about 7 kilograms, and this is still without water. Imagine the weight of an entire structure filled with water.

And the last step is only to connect the radiator to the general heating system. Before this, the plugs are opened. All joints at the joints must be laid with tow or fum tape in order to exclude leaks. In order for the battery to be filled with water, a special tap is opened.

Selection of materials

As is clear from the above, in order to obtain a homemade heater, you will need to get the following components somewhere:

- body;

- butter;

- Heating element;

- mobile stand;

- control and automation devices.

As a body, you can borrow an old radiator from a central heating system, sheet or sectional.An automobile, or any similar product, the design of which will allow the liquid to circulate inside in a natural or artificial (using an electric motor) way, is also quite suitable. You can also make a closed loop of steel pipes with your own hands.

The main thing is not to forget that an indispensable condition for the normal functioning of the system will be to ensure the tightness of the case. If the liquid begins to leak, then such a home-made device is unlikely to bring more benefit than it will cause trouble.

As for the oil, then, firstly, its amount should be based on the calculation

85% of the volume of the case. The rest of the cavity is filled with air. This 15% area is retained so that the oil does not crush the housing due to thermal expansion during operation.

Secondly, the quality characteristics of the liquid must meet at least two criteria: purity and heat resistance. Dirt and impurities will shorten the life of the heating element, causing scale to build up on it. And the decent temperature of the heating element suggests that you should select technical oil of the appropriate brand. A suitable option would be, for example, a transformer.

The number and characteristics of heating elements are selected depending on the required power of the heater (and taking into account the overall dimensions of the case). Conventionally, we can assume that to create a comfortable atmosphere in a room with a normal ceiling height, it is required

1 kW per 10 sq. m. For rooms with high ceilings, poorly insulated, located in cold areas, etc., several times more powerful products are needed.

Of course, the possibilities of the power supply network in the place where it is planned to use a self-made device should also be taken into account.

In terms of durability, it is also important to consider the possible combinations of the heating element and housing metals. For example, it is not recommended to use heaters with a magnesium anode.

combine aluminum and regular steel (not stainless) with copper.

Installation of heating elements in the heater case

Since the structure, in all likelihood, will have an impressive mass, then a mobile platform on wheels, if one is planned to be included in a homemade device, must withstand the load assigned to it. It can be made, for example, from rolled steel - angles, channels, etc. materials.

Switches or rheostat are selected in accordance with the total power load of the device.

A bimetal plate (taken, for example, from an old iron) should be used as a thermostat. When choosing a setting for it with optimal temperature characteristics, one must proceed not only from considerations of saving energy, but also from the fact that excessive heating can provoke an increase in pressure inside the case to a too high level.

For a better guarantee of safety, an additional thermal fuse can be provided. Or a similar switch that operates at a certain pressure.

How to calculate the number of sections

In order to correctly calculate the required number of sections in the battery, you need to know that the thermal indicator in such radiators varies from 80 to 160 W. a few years ago, the calculation of capacity was carried out according to the principle - one section per 2 square meters. Now the calculations are more complicated. But this makes it possible not to overpay extra money and get an optimal thermal result.

In order to correctly calculate the power, a coefficient is required, which is 41 W for block houses and 34 W for high-rise buildings made of bricks, but for modern new buildings in which only modern materials are used as insulation, this coefficient is only 20 W.

An important point, all these coefficients are provided only for rooms in which there are installed double-glazed windows.If you have wooden windows in your apartment, then you need to add 15% to the value.

The power of the device will be equal to the volume of the room multiplied by a factor. In order to find out the number of sections, you just need to divide the result obtained by the thermal power of one section.

Of course, it is better to buy sections with a margin. For example, you have 20 sections, you'd better buy 21. The power of a cast-iron radiator is calculated in a similar way.

I would like to add that today cast iron radiators are still very relevant. There are many types of a wide variety of manufacturers on the market. Czech cast iron batteries have proven themselves quite well. There are quite original designed models.

If you choose among domestic manufacturers, then you can note the Luhansk cast-iron batteries. They have proven themselves well in the consumer market, and have also received many positive reviews.

If you decide to swap out your old cast iron batteries for new lightweight radiators, think carefully. Will it turn out that in winter you will feel somewhat cool in the room? If the main reason for changing heating elements is the appearance of the batteries, then it may just be worth updating them.

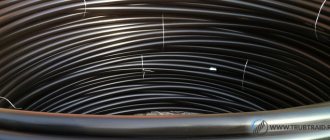

Working with pipes

After the scheme of the oil heater is selected, it is necessary to make its body. We make a drawing, determine the dimensions and start working with a grinder. The pipes are cut to length in the required quantity. After cleaning the ends, they are carefully and thoroughly welded. The operation of the entire heater as a whole will depend on the quality of welding. A leaking seam is not only a nuisance, but also a possible cause of a fire. When welding the ends of the pipes, leave one (on the lowest pipe) free. Subsequently, a heating element will be inserted into it. This means that the stub will have a different configuration.

Finished pipes are tied together. The piping is done with pipes, only of a smaller diameter. On the uppermost pipe, it is necessary to provide a place where the filler plug will be located. Structurally, it can be made in the form of a welded short squeegee with a coupling, one side of which will be welded. Using your plumbing and mechanical experience, the configuration of the heater can be made more aesthetically pleasing than the one in the photo. By the way, the body can be not only tubular. For this purpose, radiators from cars, old cast-iron radiators and other closed containers are well suited.

To increase the safety of work, it is advisable to install a pressure-sensitive safety valve on the upper pipe.

Useful Tips

Interesting fact. Many people do not want to use cast iron radiators solely because of their appearance. But recently, it is the cast-iron retro heating batteries that have become widespread. These are the models that they so diligently left. Fans of retro style often specially order such models in stores. Admirers of more modern design can be offered to decorate cast-iron radiators with special screens.

There is no heat loss from the screens, but the batteries look somehow very simple, but stylish. Those who do not want to change their batteries can simply bring them back to their original beautiful appearance. Batteries can be repainted using modern materials or you can give them a rather unusual look yourself. When choosing materials, be sure to select those that can withstand high temperatures over 80 degrees. It is advisable to consult with sellers about painting materials. There are some paints that can change color when interacting with hot surfaces. In this case, by carefully painting the battery in a snow-white color, you can see a completely non-crystal white version during the heating period.

By the way, there are companies where you can order radiators designed to match the design of your room. This service is still just an innovation on the market. But it is starting to gain momentum. As practice shows, most users of cast iron radiators still prefer to modernize them rather than change them.

As the famous saying goes: "Prepare your cart in winter, and sledges and radiators in summer." Sooner or later, everyone faces the need to change batteries, and, of course, this should be done during the inter-heating season.

Before we proceed with the detailed step-by-step instructions for installing heating radiators with our own hands, let's dwell on the technical characteristics of the main types. After all, the installation process largely depends on the design features. Therefore, it is necessary to choose the right radiator, based on the area of the room, the operational properties of the heating system, SNiPs, norms and regulations for installation, etc.

Improving a homemade heater

If a similar design of an oil heater is planned to be used in another place, for example, in a country house, then some changes will have to be made to it. They will only touch the electrical part. The fact is that you are in the garage temporarily, but in the country, in comparison with the garage, you are permanently. Therefore, the requirements for the room temperature will be different.

In order to achieve comfortable heating conditions for the country house, the wiring diagram of the heater must be slightly changed. For this, a relay is introduced into the heating element circuit, which will control the heating of the element, maintain the specified temperature of the coolant. And again, the old electric iron, or rather its bimetallic plate, can play its positive role. In the iron, it served as a regulator of its heating, here its purpose will be the same - to maintain the given oil temperature. In addition to the direct, there will be an additional effect - energy savings. The dependence is direct - the lower the temperature, the less electricity is consumed.

Bimetal Iron Plate

If a large volume of heating is planned (for example, a greenhouse), then several heating elements can be built into the device.

A home-made designed oil heater completely replaces the purchased one, and even surpasses it in some parameters. This is, firstly, the manufacture of the required dimensions. Secondly, tangible savings in material resources. Of no less importance will be the fact that the garage will be a little cleared of unnecessary trash (pipes, trimming a corner, profile), from which a useful and necessary thing will be made.

The video shows the manufacture of a slightly different model of an oil heater.

Radiator heater is one of the most popular types of devices that are used to heat a room. In this segment, a wide variety of equipment is presented, and it differs not only in functional parameters (power, heat transfer, etc.), but also in the principle of operation.

In our article we will tell you which radiators can be used for heating, how to select and install them correctly.

To keep the house warm, you need to choose and install the right batteries

Types of radiators:

- Cast iron.

- Steel.

- Aluminum.

- Bimetallic.

Cast iron radiators

Heating radiator installed in the apartment

Cast iron radiators, perhaps, are the real "long-livers" on the market. A few decades ago, such batteries were in almost every house and apartment. But even today, despite the technical progress and the emergence of newer modern radiators, cast iron products are very popular among our compatriots. Why are they so good?

It should be noted right away that today these heating systems have been significantly modified and technically improved.Therefore, speaking about the advantages and disadvantages, we will focus on those radiators that are currently on the market. One of the main advantages of these batteries is their long service life. Manufacturers give a guarantee of at least 50 years, but with proper care, this period can be doubled or even tripled. Of course, during this time, the aesthetic appearance of a heating radiator may become morally obsolete, but a purely technical possibility of operation for such a long time is there!

Due to the massiveness and high heat capacity of cast iron, these radiators are able to maintain a high temperature for a long time after turning off the coolant. They are quite resistant to pressure drops and aggressive environments. But due to its massiveness and heavy weight, the installation of cast iron batteries is a rather long and laborious process. In addition, they are not very beautiful in appearance, unless, of course, the cast-iron structure is a "highlight" of the style concept of the interior.

Steel radiators

Steel radiator in the apartment - photo

These products belong to new generation batteries and are of two types: panel tubular.

Steel radiators are distinguished by high heat transfer, increased energy saving, and high efficiency. The structure consists of two steel plates welded together. These products are manufactured with two types of connection: side and bottom. The choice depends on the initial position of the heating circuit. Their high popularity in the market is due to their light weight, ease of installation and attractive appearance. When buying, be sure to carefully study the coverage, as this affects further operation.

Tubular radiators are a structure consisting of several sections, fastened together by welding. Depending on the area of the room and the heating effect, it is necessary to calculate the output of the finished module and select the optimal size. Tubular steel batteries are characterized by excellent heat transfer, high level of performance and low price.

One of the advantages of these radiators is also their most important disadvantage, if you turn off the heating system - steel radiators very quickly lose their heat and vice versa "help" the ambient temperature to cool the temperature of the liquid in the system. If cast iron radiators are warm for a few more hours, then their steel counterparts will become cold in 15-20 minutes.

Aluminum radiators

10-section aluminum battery

They are made of aluminum alloy and painted with powder enamel. Due to their high heat transfer capacity, such batteries quickly and efficiently warm up the room. Smooth, aesthetically pleasing and lightweight. They are very popular in the market today, but they also have a number of disadvantages.

The connection of individual sections is made using a threaded coupling method, which allows for a fairly quick installation of the battery. High tightness of aluminum batteries is achieved through the casting method. Each section is molded in a separate mold, after which it is combined into one overall structure.

Due to the chemical properties of the metal, aluminum radiators are not able to withstand the high pressure that is often created in central heating systems. Therefore, for installation in an apartment with a central heating system, it is better not to use these thin batteries. They are more suitable for a private house with an independently adjustable water pressure level in the system.

Bimetallic radiators

Bimetallic radiator device

These products today occupy one of the leading positions in the market. Made from high quality alloys, they feature a double construction.The outer layer of the panel is made of aluminum, which provides lightness, great appearance and high heat transfer. And the core of the structure is made of an alloy of metals that are resistant to corrosion and high pressure drops.

Thus, bimetallic batteries combine the best technical solutions from steel and aluminum radiators. The only drawback of these products is their high cost, which, however, is justified by the duration of operation and an excellent energy-saving factor.

High technical properties and attractive appearance make it possible to use them as an easily controlled and efficient heating system for an apartment.

Another indisputable advantage is the ability to independently determine the number of sections. Based on your needs, the area of the room and the required volume of heated air, you can personally assemble a radiator consisting of at least three or even thirty-three sections, which, of course, is not available when choosing cast iron or aluminum counterparts.

Types of heat exchangers

The most famous type of heat exchanger is the coil. But this form is not a dogma and is not suitable for all ovens. Therefore, in each case, the design and shape of the heat exchange unit can be decided in different ways.

To make the right decision, you need to consider three main factors:

- The heat exchanger should not interfere with the loading of fuel into the furnace and should not impede its combustion.

- Among the geometric dimensions of the unit, two are important: the dimensions of the heat exchanger must correspond to the dimensions of the furnace; the maximum difference between the inlet of the cold water heat exchanger and the outlet of hot water must not be exceeded, otherwise it will work ineffectively.

- Maximum surface area of the heat exchanger.

By location, all heat exchange devices can be divided into two types:

- External heat exchanger - located near the chimney and most often it is a sealed container, "encircling" the chimney. Heating of the liquid occurs due to the heat of the removed combustion products.

- Internal heat exchanger - a container located directly in the furnace chamber or located in the immediate vicinity of it.

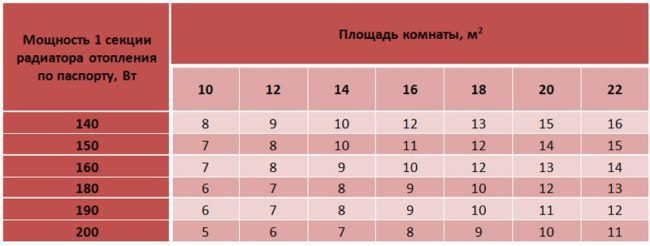

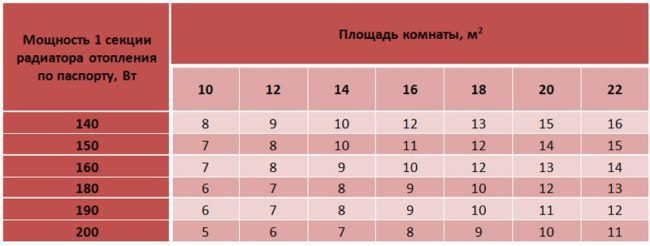

Calculation of the required number of sections

Table for calculating the number of battery sections.

After you have decided on the choice of a radiator, you need to correctly calculate its size. After all, even the most efficient radiator will not provide warmth in a room if its dimensions are not capable of heating the room.

The basic value for calculating the size of the radiator and the number of sections is the area of the room. We offer a simplified (everyday) option for calculating the number of radiator sections.

As a standard, to provide the necessary heat in the room, 100 W is enough per 1 square meter of area. We calculate in a simple mathematical way:

Q is the required heat transfer from the radiator.

S is the area of the room.

This formula will tell you what power of the radiator to take to heat the room if the radiator is a one-piece non-separable structure. If its scheme involves building up additional sections, then add one more parameter to these calculations:

N is the required number of radiator sections.

Qs - specific thermal power of one section.

To make the calculations correctly, you do not need a higher technical education. It is enough to pick up a tape measure and measure the area of the room.

Pay attention, this formula is suitable for a standard apartment with a ceiling height of 2.7 meters, if the height of your ceilings is much higher - we recommend doubling the required number of sections!

Where are we going to post?

Typically, radiators are placed where the greatest heat loss in the apartment is expected. As a rule, this is a zone under window or from the side of the corner wall of the house.Even if the apartment is located in a well-insulated building and is equipped with double-glazed windows, the window is the place where the lowest air temperature will be during the cold season.

Choosing the best place for the radiator

If you do not put the radiator under the window, then the cold air entering from the outside will gradually sink down and spread along the floor. We know from physics lessons that warm air moves upward. This means that, moving away from the battery and rising to the ceiling, it will create a kind of barrier for the cold stream from the street. According to the SNiP recommendations, the size of the battery should occupy at least 70% of the window, otherwise the warm air will not create the necessary barrier.

If the batteries are too short, a situation may occur where cold zones will form on the sides. As a result, the room temperature will be low even with a powerful radiator. As you can see, not always only the power of the battery provides a comfortable microclimate in the apartment.

Using radiators

Heat transfer selection

So that the radiators do their job, i.e. provided a comfortable microclimate, we need to purchase a sufficient number of such devices for one room.

And here you can not do without calculations, the instructions for which are given below:

The number of heating points must correspond to the volume of the room

- The power consumption depends on how much volume needs to be heated. Therefore, we need to multiply the area of the room by its height (in meters). So, for a room with an area of 25 m 2 with ceilings of 3 m, the required value will be 75 m 3.

- Further, we multiply the volume by the standard indicator of 41 W / m 3. This value determines the heat consumption per cubic meter of living space for central Russia. In our case, the total heat volume will be 75 * 41 = 3075 W.

Note! For the northern and southern territories, other regulations apply, which you can find in the reference literature.

- Next, we need to find out the number of batteries or individual sections we need (if a prefabricated system will be used for heating). For this, the volume of consumed heat is divided by the standard heat transfer of one element.

For cast iron models, heat transfer is calculated per section

Important! As a rule, manufacturers indicate for what temperature of the coolant the heat transfer of the radiator section is calculated. To make the necessary amendments, it is worth knowing in advance the heat supply parameters of your home's network - you may have to purchase a radiator with a performance margin.

System installation

Do-it-yourself installation of radiators for heating is a rather complicated process, but this task is still feasible for most craftsmen.

Let's start the description of the algorithms with the instructions for installing electrical models:

Electric radiator under the windowsill

- As a rule, stationary electric heaters are mounted on the wall. In this case, for connection, either a socket located in the immediate vicinity of the device is used, or hidden wiring for a fixed connection.

Note! In any case, the circuit to which the electric radiator will be connected must be connected to the switchboard through an RCD.

- In order for heat flows to be evenly distributed in the room, the battery must be placed according to certain rules. It is extremely important to observe the size of the gaps: from the floor - about 100 mm, from the windowsill - 80 - 100 mm, from the wall to the back surface of the battery - 30 - 60 mm.

- If the radiator is completely covered by a window sill, then it is advisable to make holes in it for the exit of warm air, covered with plastic grilles. Otherwise, the bottom of the window pane will continually accumulate condensation as the coldest area in the room.

- The installation of an electric radiator itself is not difficult.It is enough for us to install the mounting brackets on the wall and hang the battery on them.

Water heating systems

With water heating it is much more difficult:

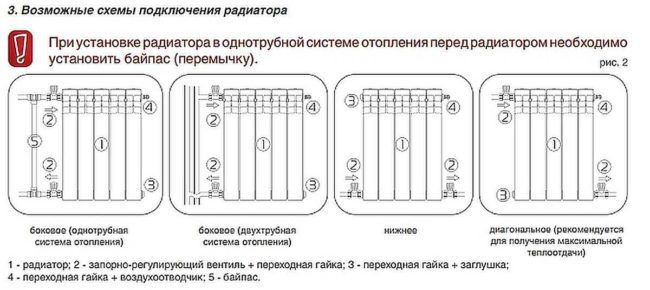

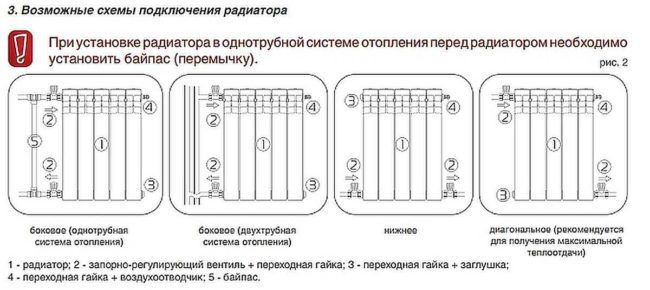

- First, you need to choose a connection scheme. It depends on how efficiently the heat redistribution will take place. Possible schemes are presented in the images in our article, therefore, during installation, it is imperative to keep this information in mind.

Connection diagrams and heat loss during their implementation

- Secondly, we need to lay heating pipes. As a rule, steel or polymer products with good heat resistance are used for this purpose.

- After that, we carry out the installation of the radiator itself on wall or floor brackets. The heaviest are cast iron batteries, therefore, the most powerful fasteners are used to secure them.

- Finally, you need to attach the radiator to the pipes. Most often, threaded connections are used here, which must be as reliable and tight as possible.

Fittings for connection

After completing the installation work, it is worth testing the system. If you have not done this, then it is important to follow the announcements of the beginning of the heating season: only the first launch of a test portion of the coolant will finally demonstrate how high-quality the installation was.

Installation features: deciding on the wiring system

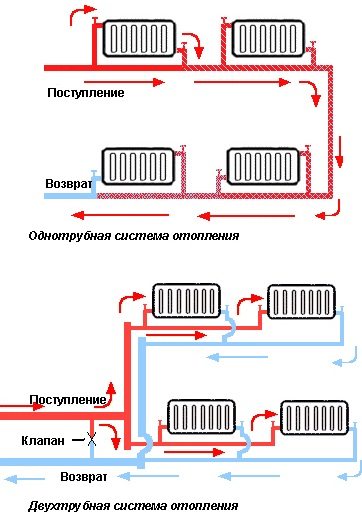

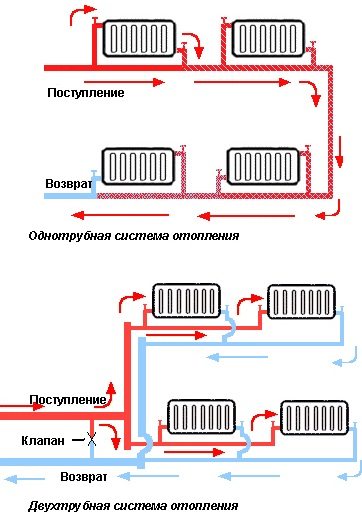

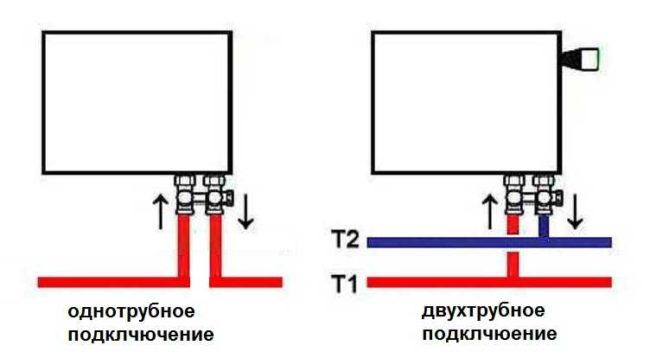

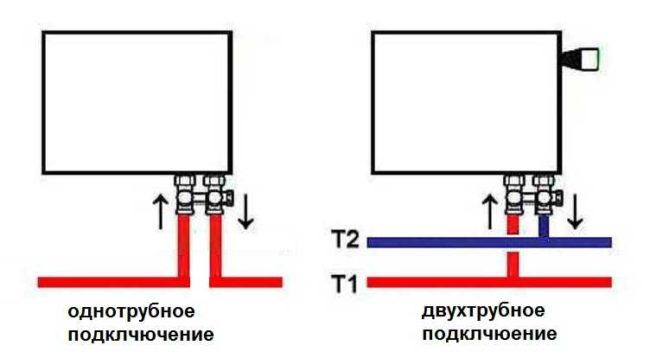

First you need to decide on the wiring system of the heating system in the apartment: one-pipe or two-pipe.

Heating system layout

One-pipe sequential scheme. This is the simplest option that will allow you to quickly figure out the radiator connection diagram. The coolant sequentially flows through the pipe, passes through the structure of the radiator, and then returns back to the pipe.

The two-pipe version is also popularly called the "return". This is a parallel connection, when the coolant passes through one pipe and returns, already cooled, back. Although this option will cause some difficulties for beginners, it has a lot of advantages:

- the room warms up evenly;

- you can use the thermostat to set the required temperature for each individual radiator.

Choosing the right connection type

The type of connection is of no less importance: side, bottom or diagonally.

Battery Wiring Diagrams

Usually, the type of connection is selected depending on the layout and characteristics of the apartment.

Side battery connection

When the choice is made, and you have decided on the type of radiator and the type of its connection, you can proceed to the installation work.

Today, the most popular among heating devices for apartments with a central heating system are cast-iron and bimetallic batteries.

We suggest that you familiarize yourself with the instructions for each of these options, which have a number of technical features.

Before starting the installation for apartments with a central heating system, it is necessary to obtain permission from the relevant authority to carry out installation work. You will have to drain the water from the batteries, which means that you must first turn off the entire riser. This is a prerequisite, failure to comply with which can lead to a serious administrative fine. After you fill out all the documents, a locksmith will come to you at the appointed time to drain the water to the desired floor. Of course, the dismantling and installation of the batteries must be carried out during the inter-heating season.

Damage to the tightness of the heating system in an apartment during the heating season can lead to an accident, for which you will be charged an impressive fine. In addition, you will leave the whole house without heating for a long time!