Today, many heating systems have been developed that are capable of creating comfortable microclimate in premises for various purposes.

However, most of them give the necessary effect only when used at home, since the ability to maintain the required temperature limited area premises.

When applying alternative sources heating in large areas of industrial premises, there is an excessively high level of fuel consumption, or electricity.

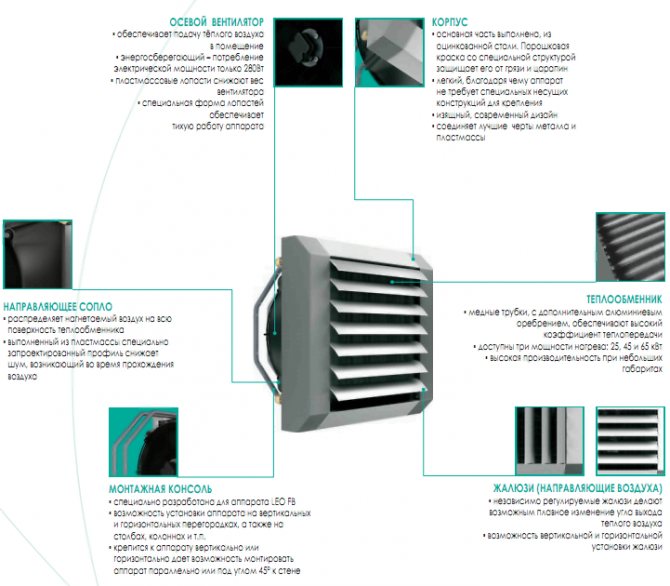

Specially for industrial enterprises original heating systems were developed, called water heaters.

Power cord and poor contact

The first thing to do is to ring and check the integrity of the power cord and all visible contacts. Maybe you will not have to climb far into the insides of the device at all, but the trouble will be on the "surface".

To do this, unscrew and remove the bottom or side cover, depending on your model.

Keep in mind that you should not unscrew the central screws initially, since a motor is attached to them.

Take them away and all the insides will fall apart. It will be better to have the engine itself sitting fixed to one of the covers.

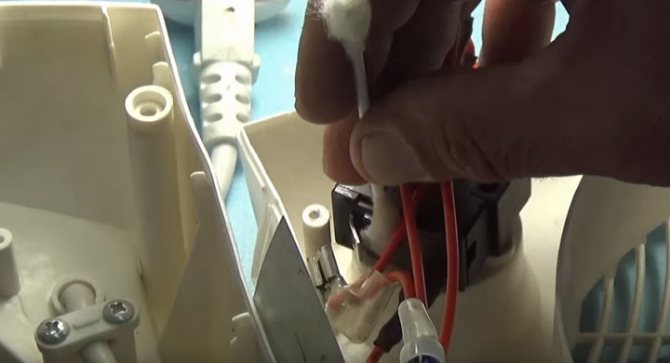

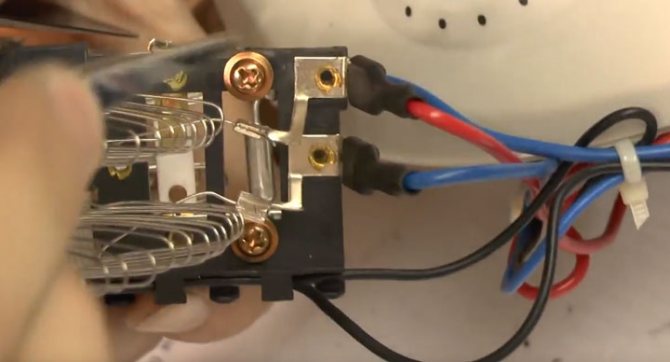

Next, find the contacts where the 220v power wires come. If you're lucky, sometimes without any devices you can immediately see burnt-out wiring.

Put him back in place and all the repairs are over. If the problem is more serious, then just feel and pull all the terminal clamps.

Since the fan vibrates during operation, it is quite possible that some of them have simply moved away from their place. Bad contact on the terminal block can also be detected by the characteristic traces of burning.

Often such defects cause the fan heater to turn on and off spontaneously. Especially when you wiggle it and move it.

If you find this, clean and then wipe the pad with a cotton swab dipped in alcohol.

Next, use pliers to slightly squeeze the terminal and put it back on.

Only after all these manipulations, you can proceed to checking with measuring devices.

Switch the tester to the dialing mode, and with the probes, one by one, check the integrity of the power wires. To do this, touch the input contacts inside the fan and the metal pins on the plug.

If everything is OK, the tester will beep or show zero resistance.

If something works for you when you turn on the network, for example, a fan is spinning, but the air is cold, then the cord, of course, has nothing to do with it. In this case, its check can be omitted.

In the same way, a microswitch is called, which is sometimes built into the housing.

Switch its key and check that there is a chain.

These things very often fail at high currents. The repair in this case is quite simple. Two wires suitable for it are bite out and connected directly to each other.

The junction is insulated with a protective PPE cap or simple electrical tape.

The only negative - from now on, the fan heater will work immediately after you plugged the plug into the outlet.

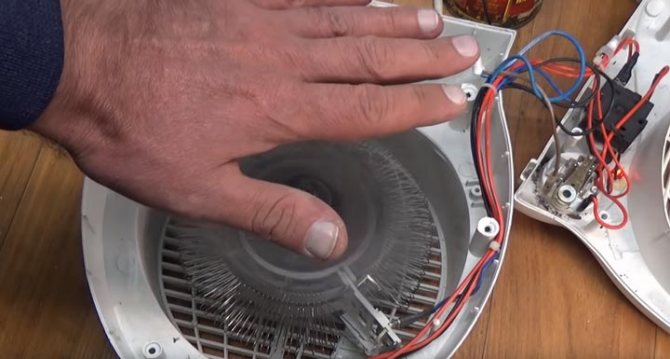

When the switch has nothing to do with it, check the following circuit elements. By the way, don't forget about the mechanical part.

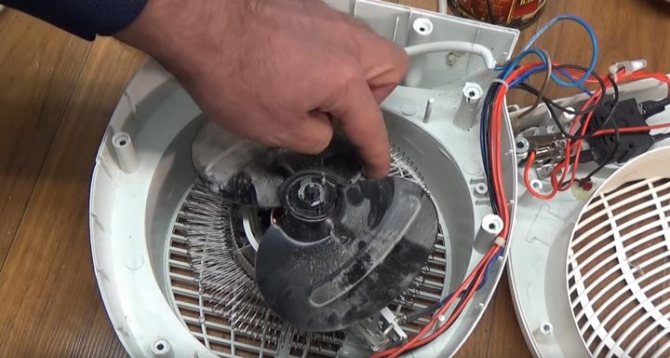

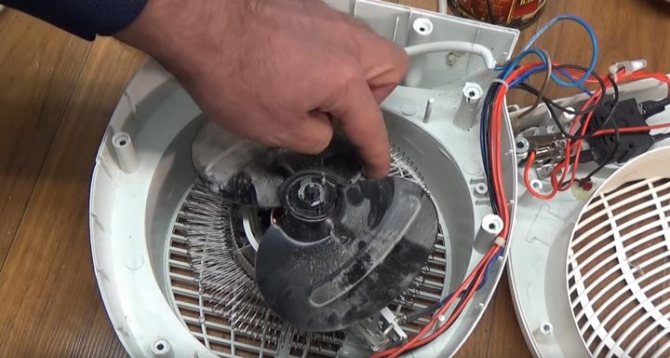

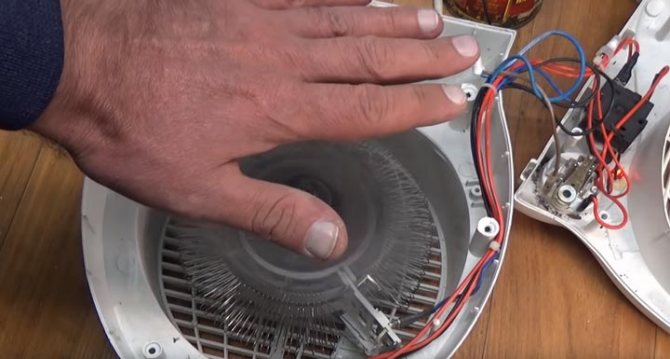

Immediately after opening the case, try to rotate the blades with your hand. They should rotate freely.

Here you need to make sure that nothing is sticking and there are no foreign objects stuck on the shaft.

Fan Heaters Classification

Fan heaters are classified by installation method, area of application and heating element. By the type of regulation, they can be divided into remote and mechanical.

Fan heaters with a remote control are more expensive, but they allow you to control their work without getting up and without removing a warm blanket.

Further, the features of devices in the context of their classification will be analyzed.

By scope

According to the scope of application, fan heaters are divided into:

- industrial;

- household.

Industrial models, unlike household ones, are designed for round-the-clock use without sacrificing durability.

When choosing a home heater, you need to plan its location based on the proximity of the power outlet. Long wires on the floor will not add security to the room.

The capacity of each category also differs due to the capabilities of the household electrical networks.

Automation on apartment electricity meters is already triggered at long-term loads of 3.5-4 kW, so the power of household fan heaters rarely exceeds 2.5 kW.

Powerful industrial fan heaters often require separate wiring and are also equipped with special switches designed for high currents

Heaters for industrial use are not limited in power consumption and usually have the ability to be connected to a 380 V mains voltage.

High-performance space heating systems are sometimes called heat guns.

By the nature of the installation

According to the method of installation, fan heaters are classified into the following types: stationary and mobile.

Stationary, in turn, are divided into:

- floor;

- wall-mounted;

- ceiling;

- combined.

Mobile devices can be installed anywhere in the room and even hung on hooks. These include desktop heating systems.

Mobile fan heaters are compact, lightweight, and their power is usually limited to 2-2.5 kW.

Image gallery

Photo from

Floor-standing heater without paddles

Wall mounted heater for thermal curtain

Industrial ceiling four-way fan heater

Mobile budget fan heater (duichik)

Floor-standing fan heaters are often in the form of a vertical column. Compared to mobile devices, they produce less noise and are more productive.

Some floor standing models have a movable swivel housing that allows you to direct the flow of warm air in several directions. In the summer they can be used as simple fans.

Wall-mounted fan heaters resemble the external unit of an air conditioner, but they do not supply the air flow to the side, but downward. They are often used for thermal curtains over the entrance doors to the premises. Wall-mounted models are controlled using a control panel and mechanically.

Heat curtains are practically not installed in residential premises. Their installation is relevant above the entrances to shops with high traffic.

Ceiling fan heaters direct streams of warm air in all directions simultaneously, therefore they are recommended for heating large rooms with high walls.

Stationary fan heaters are relevant in rooms with a constant need for heating. And if you need heat for a couple of weeks or just to warm your feet, then the mobile option is the best choice.

By heating element

A heating element in a fan heater can be as follows:

- Heating element;

- spiral;

- ceramic heater;

- water heat exchanger.

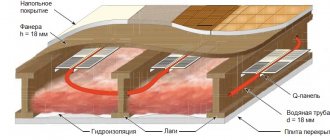

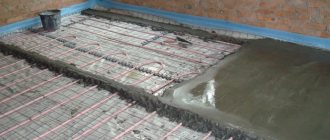

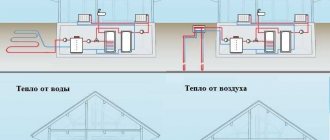

Appliances with a water heat exchanger are usually wall-hung and integrated into the space heating system.Their fan serves to accelerate air circulation in the room when rapid heating is required.

Image gallery

Photo from

Heating element for fan heater

Spiral heater for fan heater

Ceramic plate heating element

Fan heater with water heater

The nichrome wire spiral is the oldest and cheapest heating element that has been used for over 100 years. Its surface heats up to 800 ° C, which leads to burning of dust contained in the air and the appearance of a slight burning smell.

A burnout of the coil can lead to a fire in the device, therefore this type of fan heater is the most fire hazardous.

The heating elements are in the form of a tube that contains a nichrome wire inside and is filled with a heat-conducting substance. Its surface temperature rarely exceeds 450 ° C, so the dust does not burn on contact with the tube.

This makes the heating element more comfortable and safe compared to the spiral, no odors arise during its operation. The cost of fan heaters with heating elements is slightly higher than with spiral heaters.

Ceramic heaters have radiator grilles made of semiconductor material, the surface of which is made of heat-resistant glass-ceramics. These products are obtained by spraying powder onto a metal frame, followed by sintering in an oven.

The surface temperature of ceramic heaters does not exceed 100-150 ° C, and high heat transfer is provided due to the large area of contact of air with the hot coating. These heaters are safe to use, but require regular manual cleaning and are more expensive.

Switches and thermostat

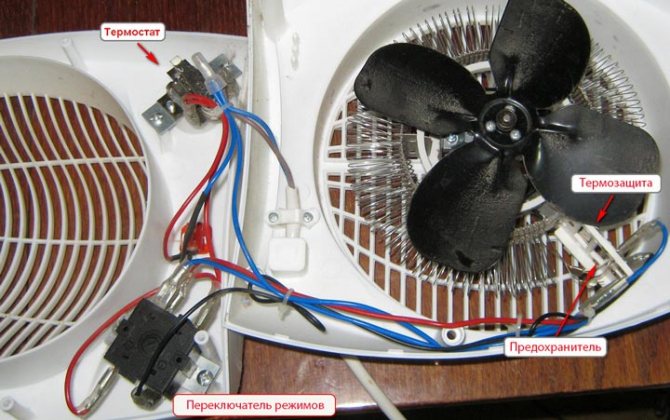

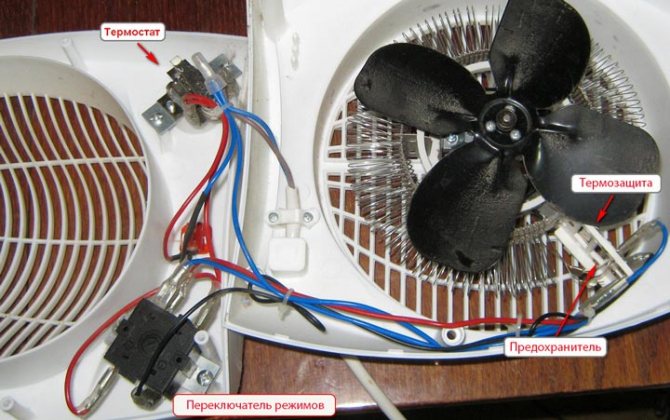

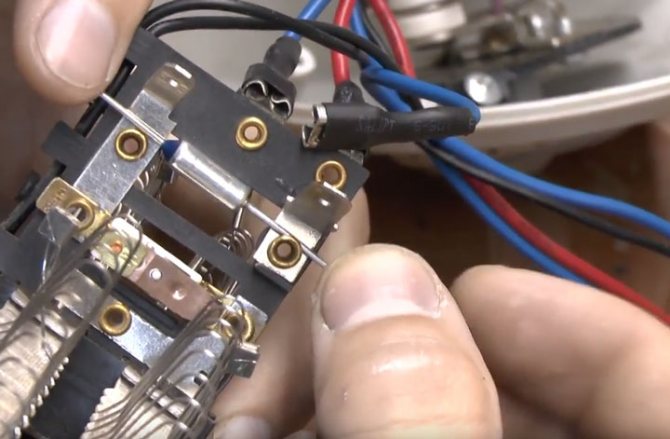

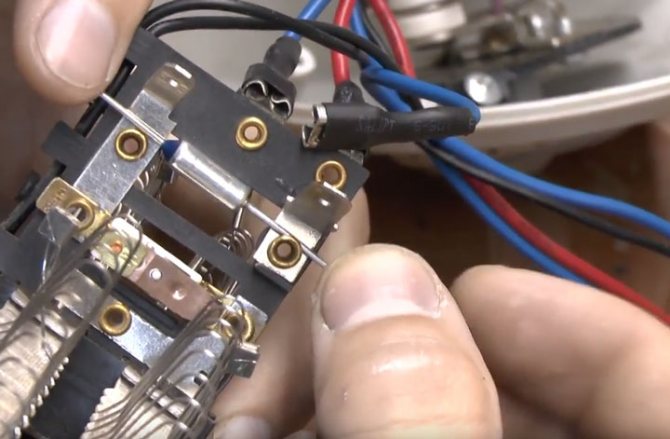

What other electrical components in the circuit can fail? Immediately after the power wires, there is a thermostat and a mode switch.

Outside the case, these are the "handles - wheels" familiar to everyone.

Some people mistake a thermostat for an element that regulates the speed of rotation of the blades. In fact, this is a bimetallic plate, and one of the power wires from the plug comes to it.

When twisting this handle, a barely audible clinking should be heard. This means the thermostat turns on and off. If there is no separate microswitch in the circuit, then it also performs its function.

But his main task lies elsewhere. When the ten and the heater body reach a certain temperature (which you yourself set by turning the knob), the bimetallic plate inside the thermostat bends and snaps off its contacts - the fan turns off completely.

The serviceability of this element is also checked with a multimeter. Bring two probes to the contacts and twist the handle. In the ringing mode, the sound will appear and disappear.

The mode switch is checked in the same way. By turning its knob, you turn on one ten, two, or simply put the duychik in fan mode without heating.

Only when you remove the terminals for dialing, it is better to take a picture of their initial connection to a smartphone in advance, so as not to confuse the contacts later.

The currents in these elements are not weak - about 10A. Therefore, the loss of the chain in them is not so rare. True, the very first check of the thermostat and 4-position switch can be done "by smell".

Burnout of contacts under such a load never goes unnoticed. Such things will definitely smoke and stink.

Assembling

In order to assemble a thermal water fan heater, you will first need to make a markup, and then, using metal scissors or a grinder, cut a strip of metal, which will allow you to get an impromptu frame. The stripe width must be the same as the width of the device body The length of this workpiece is equivalent to four sides of the device. Bend lines should be marked on the strip, and then you can start the process.Opposite sides are connected with rivets or bumpers, for this, a side 2 centimeters wide should be formed. A front panel should be made from the remnants of the material, in which holes for air outlet are made. The element is fixed to the front side of the frame.

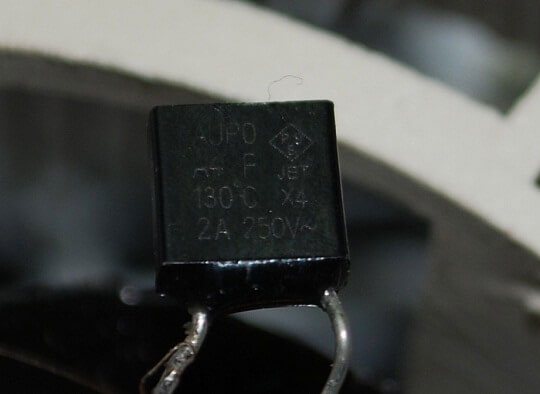

Fan heater thermal protection

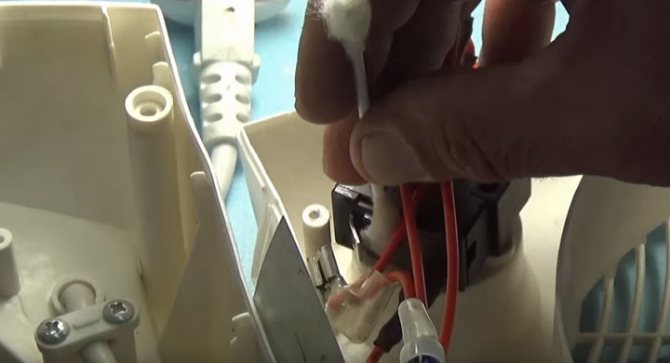

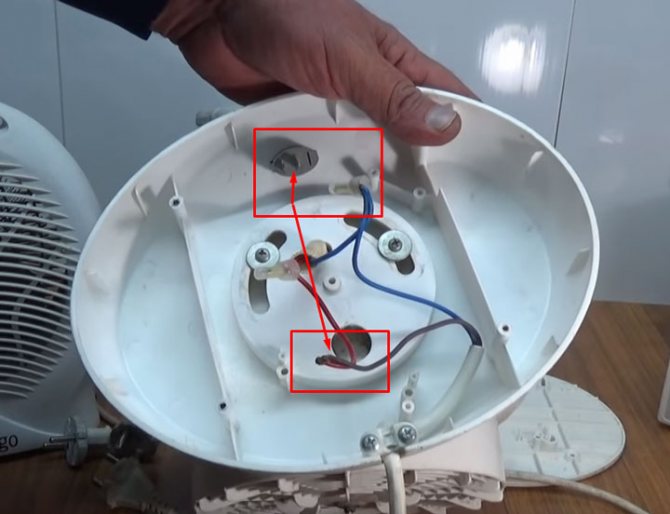

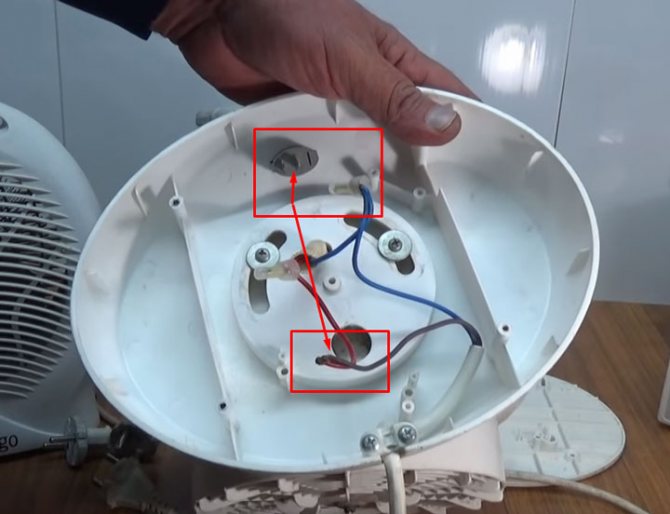

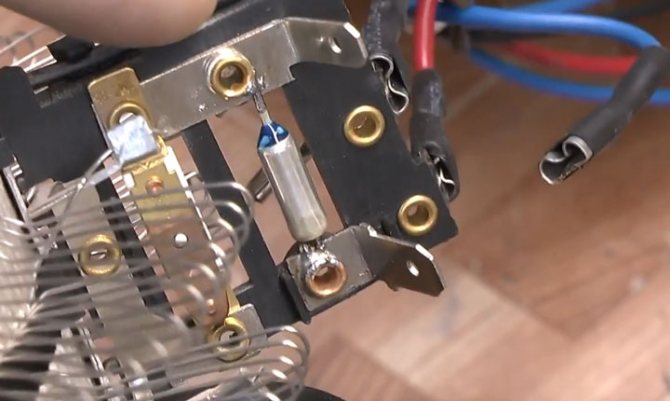

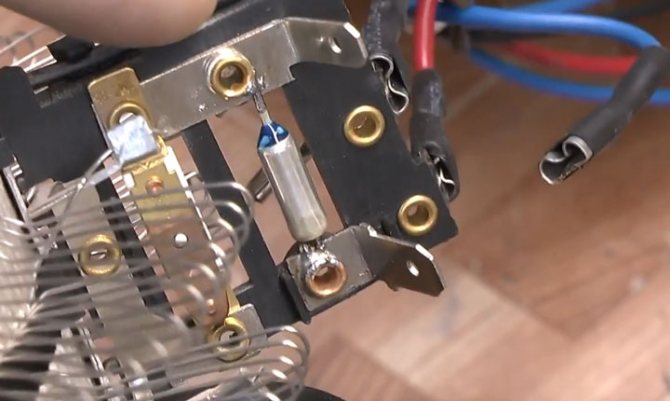

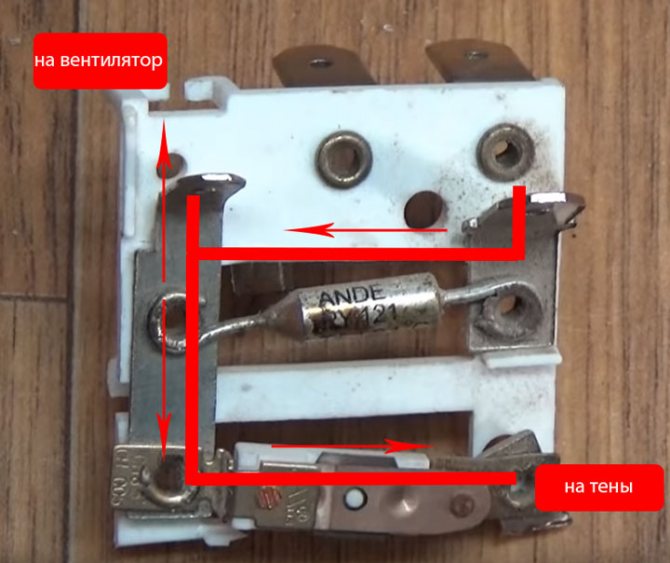

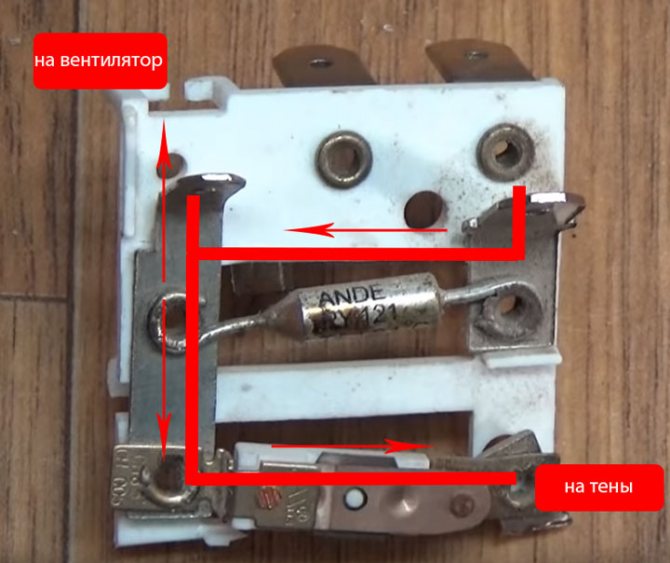

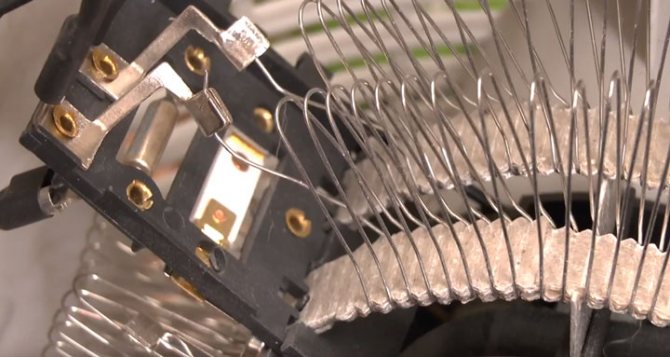

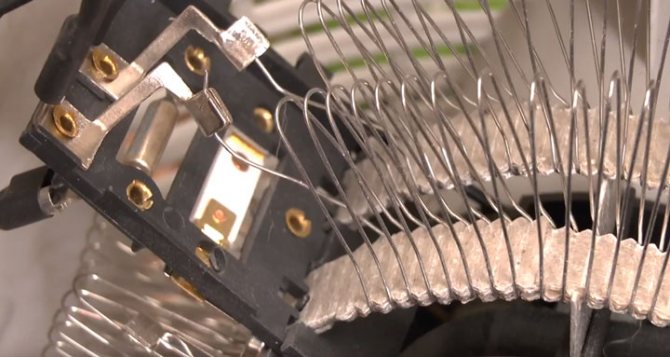

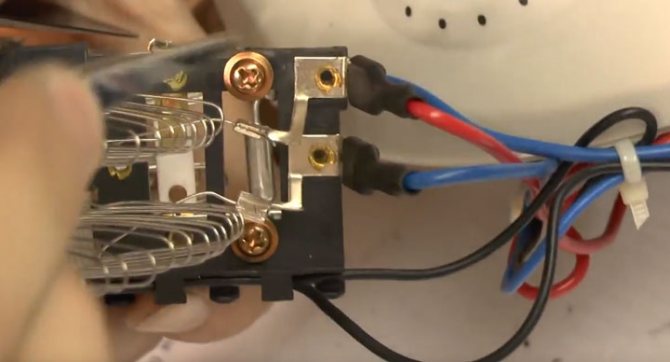

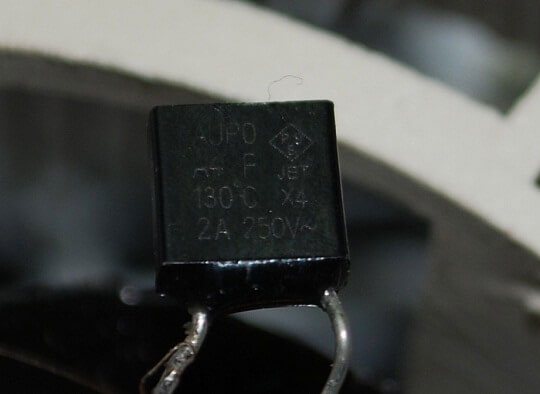

If everything is in order here, let's move on. Two protection systems are located right next to the ten. They consist of a bimetallic plate and a 121 degree thermal fuse.

Both of these elements, in good condition, should give a circuit and make a sound when ringing, i.e. show a short circuit across itself.

Keep in mind that you cannot connect anything directly here! It is this system that provides fire protection.

Remove it, and no UZIS and other devices will save you from sparking.

Power is supplied here to the top right pin. Further, through the fuse, the voltage goes to the left connector.

A cooler and sometimes a neon indicator are connected from this connector on top. And from below, through the thermoplate, power goes to two ten.

That is, when this main fuse burns out, both the fan and the heating stop working. When the bimetallic plate is triggered, only the heating is turned off, the fan continues to rotate as before, cooling the spiral.

On the reverse side of this double protection, on the opposite contacts of the heating element, the wiring from the mode switch is suitable.

Turning it on, we connect either one ten in the chain, or we use two spirals at once. It turns out that a phase is supplied to the fuse, and zero is applied to the contacts on the reverse side through the switch. Or vice versa, depending on how you plugged the plug into the outlet.

Typical wiring diagrams for heaters heaters are as follows:

Very often in this chain, it is the thermal fuse that is the main reason for the inoperability of the entire device.

At the same time, its replacement is not as simple as it seems at first glance. It is not for nothing that the plant uses rivets here, not soldering.

Power

The main question to be solved is: what kind of wind turbine is needed. After all, a device with a lower performance will not be able to effectively heat the home. And if you buy a device with high performance, then electricity consumption will increase.

Old aluminum wiring often fails and is flammable. Most of the sockets are designed for a maximum current of 16A: this corresponds to an equipment power of 3.5 kW.

The calculation is considered classic when 10 sq. m of the room requires 1 kW. It is also desirable to add a margin of 10-15%.

Apparatus for a small room or an addition to the heating system, 1-1.5 kW will be quite enough.

To calculate the power for heating only with an electric fan, you need to take into account many parameters - the number of windows, orientation to the cardinal points, the quality of double-glazed windows, climate, etc. It is better to entrust the calculation to a specialist, but you can do it yourself using a special calculator (available on the Internet).

Simplified formula looks like this:

W = S x W beats / 10, where

W is the required power;

S - heated area;

W beats - specific power required for heating 10 sq. m in your climatic zone.

| Climatic zone of Russia | W beats, kW |

| Southern regions | 0,7-0,9 |

| Middle lane | 1-1,2 |

| Northern regions | 1,5-2 |

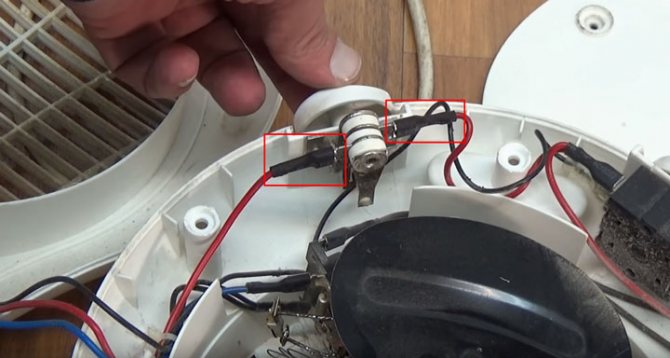

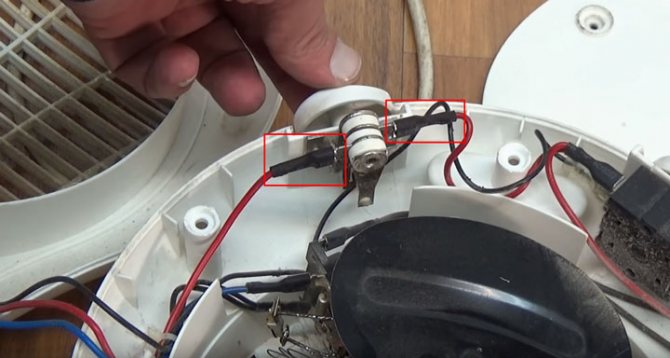

How to replace a thermal fuse

Soldering is not recommended here, since during the soldering process the temperature rises above the calculated 121 degrees. But if you have no choice, you will have to use a good heat sink.

Bite out an unsuitable fuse and flux the brass holes in the rivets.

The thermal fuse itself, namely the wiring suitable for it, is tightly squeezed with tweezers or curved long-nose pliers. Thus, when soldering, the heat will, as it were, be removed through them, without reaching the body itself.

Of course, you will not achieve 100% heat dissipation, but still most of it will go through the wide jaws of the instrument.

If you don't want to solder at all, you can use screws. The main thing is to have bends of sufficient length.

Bend them with a ring, and put small screws in the places of the rivets. Use these screws to secure the fuse to your seat.

You can select and order the required thermal fuse for any temperature and current from here.

If you have not found exactly the same in degrees, choose models with temperatures from 110 to 140C, no more.

What to consider when choosing

In addition to the basic technical and operational qualities of the equipment, you should pay attention to the nature and conditions of use. This applies to both external threats and the way of maintenance

Especially in industry, in production engineering equipment is often exposed to aggressive environments. On the other hand, many enterprises tend to place water heaters as high as possible (technically permissible height - 10-15 m), which further complicates maintenance and repair work. These and other nuances should be taken into account in the selection of the optimal design, not forgetting about the protective properties of the case, the fastening hardware included in the kit and the strapping fittings. For example, some models do not provide for a connection to local communications at all, which makes it possible to count on the complete autonomy of the equipment operation.

Thermal relay

Another fuse, or rather a thermal safety relay that protects the engine itself, is hidden quite far away. It is designed to protect the windings from overheating.

Conventional floor fans are provided with the same protection. Details about the specifics of their verification and replacement can be found in the article at the link below.

Usually it is self-healing, that is, after some time after the windings have cooled down, the duychik can be restarted without any problems. It looks like this.

You turn on the cold fan heater to the network, it works for a while, after which the blades stop rotating spontaneously. The heating elements are still heating at first, and then they are also cut down.

After cooling, as if nothing had happened, the whole cycle is repeated over again. If your device has similar symptoms, and the thermostat has nothing to do with it, then look in the direction of this particular winding protection.

By the way, when the thermal fuse burns out at 121 degrees, take a closer look at the bimetallic plate after it. Most likely, there is also something wrong with her.

In theory, it should work earlier. Otherwise, the fuse will blow again shortly. Therefore, if there is any suspicion, it is better to replace both parts at once.

After repair, be sure to collect all the wires with zip ties in one bundle and hide away from the blades. Otherwise, they can easily be cut with a screw.