Pros and cons of steel radiators

For the manufacture of such units, low-carbon steel is used. The surface of the product must be covered with protective enamel. Good quality steel batteries have high performance properties. They do not rust and tolerate various aggressive influences normally. Tubular and panel steel batteries are commercially available.

Pros and cons of steel radiators

Panel devices are assembled from a certain number of steel plates connected to each other. The finished panels are attached to each other. The features of such an assembly made it possible to achieve the highest possible heat capacity values. Each plate is comparatively thinner. As a result, the finished battery weighs relatively little, which is an additional plus. Various connection options are available.

On average, a standard steel battery is designed to operate at a pressure of 5-10 atmospheres. Experts recommend using such units when arranging autonomous heating systems. In simple city apartments, their use is usually impossible due to the fact that the pressure in the central heating system exceeds the values allowed for batteries of this type.

For the assembly of tubular-type units, steel pipes with a high-quality polymer coating are used. The thickness of the pipes directly depends on what kind of load they can cope with. It is best if the battery is made of stainless steel.

Steel radiator

Also, tubular steel batteries outperform their panel counterparts in terms of service life, which can reach 30 years or more. They are connected in accordance with all existing methods. Working pressure indicators are usually at the level of 7-16 atmospheres, it is additionally recommended to clarify this point in the product passport.

Technical characteristics of aluminum heating radiators

Before buying an aluminum battery, you need to know the set of parameters that characterize it.

- The pressure that an aluminum device can withstand in operating mode can be from 6 to 20 atmospheres. It all depends on the manufacturer. The pressing (limiting) pressure for these products is about 25 atmospheres. For this reason, in houses with central heating, aluminum radiators do not always take root, since there are jumps in the network up to 30 atmospheres.

- The distance between the axles is one of the main dimensions of batteries, which is the distance between the inlet and outlet pipes. For aluminum radiators, this parameter can be from 20 to 80 cm, but more often there are specimens with a distance between the axes of 35 or 50 mm, the height of the battery itself is 10 cm higher. Before buying, it is necessary to measure the space under the windowsill. the radiator must not stand back to back, otherwise circulation will be impeded.

- The battery depth is 8-11 cm.

- Maximum coolant temperature. which heating devices made of aluminum can withstand, can be 110 ° C.

- One of the most advantageous characteristics of aluminum heating devices is the ability to give off heat - the heat transfer coefficient, measured in watts. This thermal parameter is indicated by the manufacturer for one section and can be equal to 80-210 W. Due to the special design and low inertia, the heat transfer of aluminum radiators is quite high, which makes it possible to reduce heating costs by reducing the temperature of the coolant.

- Coolant volume.which will fit in one section, for batteries made of this metal is on average 0.5 liters.

This is what the main technical parameters of the battery look like.

It is also important for the consumer to know how long the radiator will last, how reliable it is.

Operational period

As for the susceptibility to corrosion, this was mentioned above. To extend the service life of the device, it is necessary to carefully select the heat carrier, which cannot be done in a centralized heating environment. A private heating system allows this.

Another factor that can negatively affect the duration of operation is the ability of aluminum to wrinkle easily upon impact.

Manufacturers set the service life for their products - 5-15 years.

This parameter depends on the manufacturing method and how the battery is assembled.

Main features of aluminum batteries

One of the currently most popular types of heating batteries are units made of aluminum. By its properties, it is a very ductile and fairly light metal. Batteries based on it are also lightweight and feature excellent heat dissipation. Consists of several sections. Each such section is assembled from a variety of plates. Such a solution allows you to make heat transfer as efficient as possible and keep heat at the highest level. Aluminum batteries heat up very quickly. However, they practically do not know how to keep warm. When the heating is turned off, such a radiator will cool down very quickly.

Often, aluminum radiators have an original design.

Aluminum is an extremely unstable material to all kinds of chemical influences. In view of this, from the inside, such heating devices are coated with polymers, which provide reliable protection against a variety of chemicals.

Aluminum cannot be called a durable metal either. Therefore, before purchasing and connecting such a heater, it is imperative to clarify the value of the operating pressure in the heating system. The maximum pressure that a particular radiator can withstand is usually indicated in its passport, because for different models, this indicator may also differ slightly.

Additional disadvantages of aluminum batteries include not the most reliable threaded connection of the top valve, through which air must escape.

Aluminum is an excellent metal, the characteristics and properties of which make it possible to use it for the manufacture of a wide variety of products, including heating radiators. The low melting point of the material made it possible to significantly expand the range of batteries. Now everyone can choose the battery that will best fit into the interior of his particular home.

Main features of aluminum batteries

Also, among the advantages of aluminum radiators should be attributed to the relatively low cost, especially when compared with the price of bimetallic devices.

How to calculate the number of sections

The easiest way to calculate the number of battery compartments required is to use an online calculator.

But you can do this calculation yourself according to a simplified scheme. This method is suitable for rooms with a standard ceiling height of about 2.5 m, you only need to know the area of the room.

In most zones of Russia, climatic conditions require that the heating power of each square meter be 100 watts. Therefore, you need to multiply the area of the room by 100. And divide the result by the heat output of 1 section of the battery model you have chosen.

For example, there is a room of 20 m 2. It requires 2000 W of thermal energy to heat it. We divide this value by the heat transfer rate of one section of the selected radiator, for example, by 180 W. If you round up, you get 12 sections.

For corner rooms with a balcony, you need to increase the resulting value by 1/5, this also applies to the situation when the battery is planned to be hidden behind the screen. Also, losses during heat transfer can be 20% for one-pipe systems, about 12% for a two-pipe bottom connection, 2% for a cross connection.

There are a few more nuances that you need to know when buying and installing radiators.

What requirements must a chimney for a gas boiler meet? Find out from this article.

General recommendations for the selection of heating radiators

Long gone are the days when people tried to hide unsightly-looking heating radiators with the help of various tricks and third-party devices. Today you can find a battery that will perfectly fit into any interior. Radiators differ from each other in material of manufacture, size, color design and other indicators, so that you can easily choose a battery that can fully satisfy all your needs and fit well into the existing or planned interior.

Today you can find a battery that will perfectly fit into any interior.

Although batteries made in light colors are traditionally installed in residential premises, it is imperative to take into account the fact that a black device, on average, gives off 20-25% more heat solely due to its color. In general, when choosing a battery color, be guided by your own preferences and the overall design of the room.

In living quarters, streamlined batteries look the most organic. It is better to refuse radiators with sharp corners for safety reasons, especially if children live in the apartment or house. Any sharp edges in general are a relic that is recommended to be discarded.

For the manufacture of heating units, materials such as aluminum, cast iron, steel and alloys of various metals (bimetallic radiators) are currently used.

Depending on the material of manufacture, radiators will have different indicators of heat capacity and heat transfer, operating pressure, their resistance to chemical and hydraulic influences and, of course, service life will also differ.

In terms of cost, the most expensive are steel batteries and bimetallic radiators. Cast iron units are relatively inexpensive. The only exceptions are samples using art casting methods and design models of foreign production.

Special attention should be paid to the environmental safety of the material used for the manufacture of heating batteries. The main components of safety for human health are high-quality polymer coating and the absence of formaldehyde in the internal elements.

Panel radiators with bottom connection advantages and disadvantages

To choose radiators for the house, you need to decide what power is needed. To do this, you need to know what water temperature is supplied by central heating. In general, with the help of specialists, you need to calculate the required power of the radiators. To determine which connection is better, side or bottom, you need to think about why the side is worse and why the bottom is better, or vice versa. (See also: How to Calculate Heating Radiators)

Radiators with a bottom connection are more expensive in cost, since at the bottom you can connect pipes that are laid on the floor. If you need a side connection, then you need to select the option of radiators with side connection. It is possible to connect additional pipes from the side. It all depends on the aesthetic characteristics of each person. Tastes and preferences may vary. Each owner of a house and apartment may be preferable and more convenient to one or another connection option to the central heating system.

Radiators with bottom connections are of two types:

- Right-handed

Left-handed

So, for example, panel radiators Purmo, you can choose one or another type of connection.

The advantage of such a radiator is largely due to the quality and modern design, which guarantees that the buyer will choose this particular battery manufacturer.

Dia Norm steel panel radiators are specially designed for the tastes of today's youth. All requests and whims are taken into account here. The main thing is that the equipment is designed for an energy-saving heating system. And this question is very relevant today and it is this criterion that the buyer is primarily guided by when choosing radiators.

Steel is the best material for making batteries at this stage of time, it is better than cast iron and aluminum, since cast iron is too rough, in simple terms, and it is also "old", but aluminum is too vulnerable and cannot withstand heavy loads.

How to calculate heat output and determine the number of batteries

After the owner of the home has chosen the desired radiator option, it is necessary to calculate the thermal power, which depends on the following indicators:

- wall material: brick or concrete panels;

- area of the room;

- type of windows: plastic or wooden;

- the number of window openings and external walls of the dwelling.

The choice of one or another type of heating radiators for an apartment, based on the calculation of thermal power, is performed for a conditional room with a ceiling height of up to 3 m and window sizes within 1.5-1.8 m.

A simplified calculation, subject to satisfactory thermal insulation of the outer walls, suggests using one section of the heating battery for 1.5-2 m² of the room.

The types of heating devices on sale are capable of delivering different heat outputs:

- one - 190 W;

- a separate part of the bimetallic battery - 200 W;

- one-piece steel device - 450-5700 W;

- one section of a cast iron radiator - 80-150 W.

As a rule, the manufacturer indicates the power of a solid or sectional heating battery in the passport for its products. The values described above, which determine the amount of thermal energy, are calculated for a heat carrier with a temperature of 70 ° C.

According to experts, regardless of the choice of the unit, when creating a system, it is important to pay special attention to such points as the prestige of the manufacturer of heating devices and the individual characteristics of the heating system. As a rule, the best radiators are made by large rating firms.

How to calculate the number of radiator sections

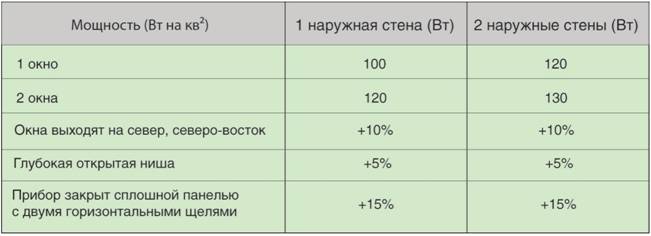

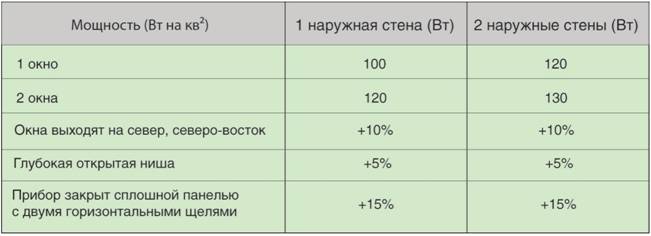

There is a simplified way to do this quickly. To do this, we need the standard power required to heat one square meter of the room. Here are three options.

- If the ceilings in the room are of the usual height (from 2.5 to 2.7 meters), there is one wall outward, and one window. The rated power is 100 watts.

- If the ceilings are the same, there are two walls outward, and one window. The rated power is 120 watts.

- If the height of the ceilings is the same, there are two walls outward, two windows. The rated power is 130 watts.

Now let's multiply two values - the standard power for our version and the area of the room. Having higher ceilings or a larger window (for example, if it has a bay window), we multiply additionally by a correction factor of 1.1. As a result, we get the radiator power (total).

The heat output for one section of the radiator is indicated in the radiator passport. It is necessary to divide the received total power into it. Rounding up the fractional numbers.

For example: The room has an area of 16 square meters, it has one outer wall and one window with a bay window. FARAL Green HP 500 battery (thermal power of the section - 180 watts).

We multiply 100 watts by 16 square meters and by a factor of 1.1.

100 x 16 x 1.1 = 1760 (watt).

To calculate the number of radiator sections, divide this number by 180.

1760/180 = 9.778 (pieces).

Rounding up - we get 10 sections.

If you notice an error in the text, please select it and press Ctrl + Enter

Popular

Copyright 2020 - SRBU.RU Reprinting of materials is prohibited!

Login to the site using:

Or enter your username and password:

Information about cast iron batteries

Cast iron radiators are the most popular and most familiar option to every inhabitant of the post-Soviet space. It was these batteries that were installed in almost all standard apartments. Old cast iron batteries can hardly be called beautiful and stylish. The new samples look much better, although they are inferior in their aesthetic qualities to devices made of aluminum and steel.

Cast iron radiators

Cast iron is a fairly heavy material. The batteries made from it also weigh a lot, which causes certain difficulties and inconveniences when installing them. Among the undoubted advantages of cast iron radiators, it is necessary to highlight their reliability and durability. High-quality products without any problems serve for 35-40 years, without requiring even minor repairs, which is much higher than that for batteries made on the basis of other materials.

Cast iron heats up relatively slowly and cools down just as slowly. It is characterized by low thermal conductivity, but has a high heat capacity. Heating is carried out by convection.

Such batteries normally "cooperate" even with a low-quality and dirty coolant. The material is resistant to corrosion damage. Directly radiators can have one-, two- and three-channel structure.

Among the additional advantages of such heating units, one can single out a relatively affordable cost. Only imported design models are expensive. Here, everyone must decide for himself what is more important to him: save a certain amount of money or purchase a beautiful unit that will become a worthy addition to the interior.

Thus, batteries of any considered type can be used to heat living quarters. But buying bimetallic batteries in most cases turns out to be unjustified. In terms of their properties, such radiators practically do not differ from their aluminum counterparts, but they are much more expensive. So it is better to leave them to various public and industrial buildings.

Heating radiators which are better

Apartment owners are not recommended to give their choice in favor of aluminum appliances, because pressure surges have a bad effect on this material. The best and proven option for heating city apartments is cast iron appliances. Otherwise, focus on personal preference and available budget. Happy choice!

Advantages and disadvantages of bimetallic radiators

A feature of bimetallic batteries is the use of two different metals for their manufacture: the body is assembled from aluminum, and steel is used to create the core. The rod has a very high strength.

Advantages and disadvantages of bimetallic radiators

The undoubted advantage of such units is their ability to operate at pressures up to 45-50 atmospheres! Steel perfectly tolerates the effects of water with various impurities. The aluminum case will heat up quickly and give off heat to the room to the maximum.

The combination of different metals made it possible to obtain a product that has the advantages of two materials at once. Such batteries have the highest cost among other existing options. Usually they are used when organizing a heating system in various public and industrial buildings, shopping centers and other similar places. They are installed in residential premises relatively rarely, primarily due to their high cost. They last an average of 20 years, which is quite a decent indicator.

Selection rules

It would seem that all radiators on the market are largely identical, but they have many differences.

Before buying a heater, you should pay attention to some of its features.

Observing all the installation rules, you will provide yourself with high-quality heating for a long time.

Number of panels

This is an important indicator that affects the power of the heater. The most common radiators contain:

- 1 slab (their thickness does not exceed 6 cm);

- 2 slabs (from 10 to 14 cm);

- 3 slabs (15-18 cm).

When comparing all types of panels with the same power, single-panel radiators will turn out to be the most effective due to the fact that in such a product both of its surfaces are in contact with air currents. An important plus of these models is their compactness.

Two-panel models are more powerful than single-panel ones, but not significantly. The additional stove has a capacity equal to 70% of the main one.

Three-panel appliances are the most powerful, but also the largest. Due to their size, they are not used in apartments or houses.

In this video, you will learn how to connect the batteries correctly:

Product marking

Having carefully studied the marking, you can find out the main characteristics of the product. The designation is deciphered as follows:

- the first number indicates the number of panels;

- the second indicates the number of planes with edges;

- type of connection to pipes is designated as V - bottom, C - side.

Often, the labeling contains information about the height and width of the panels.

Connection method, performance and equipment

According to the connection method, the radiator panels are divided into side and bottom. When laying heating pipes along walls, it is recommended to choose models with side connection. The most common panels are with the bottom mounting method. The kit with such a product must include a thermostatic valve and a thermal head.

You can install radiators with your own hands, following the instructions

Any panel heating radiator is, in a sense, a convector, which increases its efficiency. In products with two or more lower panels, there are openings at the bottom through which cold air enters in and out through the top, warming up to the set temperature.

When buying a radiator that will be installed independently, you should consider the need for additional equipment. Probes, pipes, taps, etc. may be needed. Subject to the recommendations for choosing a product, as well as fulfilling all the conditions for correct installation, the heating radiator will last for many years and will not cause any problems.

In this video, you will learn about aluminum and steel heaters:

Analysis of the domestic market for heating radiators

Alexander, tell us about the latest technological methods of increasing the reliability of radiators - protection against leaks, pressure surges ...

Alexander Kvashnin: We are guided by the principle of optimality of simple solutions and the aphorism “the best is the enemy of the good” - a reliable guarantee of the tightness of the heater and its resistance to water hammer is strict compliance with the requirements of the GOST 31311 standard for general technical conditions of production in terms of the minimum permissible wall (pipe) thickness of the heater in contact with water.

Here, we also proceed from a risk-oriented approach - for example, by establishing a unified method for determining the wall thickness of a steel panel radiator during the revision of the GOST R 53583 standard for test methods, the most vulnerable places in terms of corrosion and pressure were identified (along the axis of welded points and on bends) , in which it is necessary to measure such a thickness.

How do manufacturers today achieve an increase in the resistance of radiators to corrosion in the presence of aggressive elements in the coolant?

A.K .: The main mass technical solution to minimize such risks has already been invented - a bimetallic heating radiator with a steel channel for the passage of the coolant, specially invented for operation in Russian conditions of water treatment, has proved its ability to successfully solve safety problems, both at the current moment (the presence of static strength to hydraulic shocks), so and in terms of durability.

Also, Russian and foreign manufacturers are striving to increase corrosion resistance and durability through the use of new materials - low-carbon and even stainless steel alloys, but the breakthrough efficiency of such methods has not yet been sufficiently studied and proven by long-term operation, therefore thickness indicators remain relevant.

In addition to objectively improving products, manufacturers are forced to work with an eye on the needs of consumers. What consumer trends are you seeing today? Interested in the level of buyers' interest in the radiator brand, its energy efficiency, warranty periods, service support options, price, design and other parameters.

A.K .: First of all, the Russian market of heating devices in recent years has been characterized by trends that are key for the industry and trade in general. First, construction markets, including large ones, are gradually disappearing into the past, and the segment of DIY stores, which are network construction hypermarkets, is growing. This contributes to an increased focus on the safety and quality of construction products, including radiators, as retailers value their reputation.

Secondly, the general trend of growth of Internet commerce has developed on the heating appliance market. On the one hand, digitalization makes it possible to speed up, simplify and expand the choice of goods of interest to the consumer, but at the same time, the risks of selling a radiator with characteristics that do not correspond to those indicated on the website increase.

As for consumer preferences, when selling in a retail network for a consumer in the mass segment, the main selection criterion is still the ratio of price and heat transfer. Here, in connection with the introduction of mandatory certification and the transition to work under conditions of open and reliable data on heat transfer, domestic heating devices are becoming more and more competitive in the ideology of “ruble cost per watt of heat transfer”.

In turn, the role of the brand for the consumer increases in direct proportion to the increase in the price of the heater that he intends to purchase. For example, in the most massive economy segment, “white goods” are widespread - heating radiators, designated by the type of heater and technical characteristics without mentioning any brand.

The growth in the volume and share of imports of such "nameless" aluminum and bimetallic radiators to Russia is constantly recorded by APRO - by the end of 2020, the share of no name was 12 percent in the segment of aluminum radiators, and for bimetallic radiators it was even more - 44 percent for the "classic" percent on "black bimetal". It is noteworthy that in the segment of steel panel heating radiators, a similar situation is not observed (only seven percent).

I would like to draw your attention to such an indicative trend from the point of view of the development of import substitution as the beginning of the placement by the largest chain retailers and dealers, who previously considered only foreign manufacturers as OEM partners, orders for contract production of heating radiators under their own brands at leading domestic factories. Also, manufacturers quite widely use an indication on the packaging of a large amount as a tool for market positioning, for which the consumer is insured against damage associated with the operation of the heater.

For its part, APRO, together with the National Association of Builders (NOSTROY) and APIK, in 2020 successfully implemented a voluntary verification project in order to identify safe, high-quality and energy-efficient models of heating devices and their positioning in front of organizations in the construction sector. We are also promoting an initiative to test heating radiators in 2020 within the Roskachestvo system, the results of which will be widely covered in the media.

Now I propose to move from consumer to marketing trends. In particular, it is very interesting what you associate with the persistent tendency over the past few years of a decrease in both physical and value volumes of imports of aluminum and bimetallic heating radiators in the Russian Federation and a simultaneous (2016-2017) growth in imports of "black bimetal", as well as a significant increase in imports of steel panel radiators? What other trends in the field of import and production do you consider significant?

A.K .: This is directly related to the results of the work of our Association - several years ago we managed to achieve increased control over the import of aluminum and bimetallic heating radiators into Russia. Due to this, it was possible to almost completely suppress the facts of a significant underestimation of their customs value. Accordingly, the economic motivation to receive superprofits from their import has also dropped. Actually, the same desire to increase marginality is also due to the growth of import volumes of "black bimetal" - this practice allows you to save one and a half percent of the cost when paying customs duties. The introduction of compulsory certification partly solves the problem of "black bimetal" - with honest data on heat transfer, the market attractiveness of such heating devices decreases very significantly.

As for the growth of the segment of steel panel radiators in the Russian market, this is a pan-European trend, which in the Russian Federation is characterized by far not so much an increase in imports as the implementation of large projects to create new and significantly expand the production capacities of existing domestic factories specializing in steel "panels" ...

Among other main trends, it would indicate a significant decrease in the volume of imports of aluminum and bimetallic heating radiators from Italy, due to the replacement of their market niche by leading Russian manufacturers that provide comparable quality at a lower price.

I would also like to say that on August 20, 2020, the decision of the Board of the Eurasian Economic Commission came into force on the allocation of separate codes in the Commodity Nomenclature of Foreign Economic Activity of the Eurasian Economic Union (TN VED EAEU) for aluminum and bimetallic radiators and their parts, which will allow clear official data on imports, and customs will make it possible to automatically identify aluminum and bimetallic radiators to control the fact of passing mandatory certification.

What about the "dark force" of the market for heating radiators - counterfeit? To what extent do manufacturers face it today, what methods of struggle do they use, and how radically does the introduction of mandatory certification affect this situation and will affect it in the short and long term?

A.K .: If we talk about counterfeit goods, which are understood as goods produced and sold in violation of intellectual property laws, then such a problem is practically irrelevant for the heating appliance market. It is also impossible to talk about the presence on the market of heating devices as such falsified products - there are cases of "handicraft-garage" production of steel convectors from improper materials, but they are of a local nature.

For the Russian market of heating devices, the most urgent problem is when not the product itself is falsified, but the data about it on the packaging and in the accompanying documentation: the indicators of heat transfer, operating pressure, and weight are unreasonably overestimated.

There are also cases when, for positioning in a higher price segment, Chinese-made heating radiators are issued as products from Italy or Germany by using the colors of the corresponding national flags on the packaging. In our market, this unhealthy phenomenon was designated by the word "China Italy".

At the same time, all the above issues can be effectively resolved by the tool for mandatory certification of heating radiators and convectors, in which all parameters of heating devices, as well as information about the country of origin and the manufacturer, must be reliable.

Is the introduction of compulsory certification of radiators positively positive? To whom does certification promise losses, change of plans and for what reason?

A.K .: Mandatory certification of radiators and convectors was introduced in Russia from June 27, 2020. Let's see what we have today? All major brands and models of heating devices of various types are certified. At the same time, the costs of passing this procedure and conducting tests did not have any tangible effect on the cost of heating devices and their final price on the market. But in order for the introduction of mandatory certification to go as smoothly as possible, APRO carried out a large-scale preparatory work.

First, the Association developed a national standard GOST R 58065–2018 for the rules for certification of heating radiators and convectors, which made this procedure clear and transparent. The possibility of using the serial production certification scheme provided by this standard turned out to be optimal for both domestic and foreign manufacturers.

Secondly, on controversial issues, it was possible to obtain official clarifications from the Ministry of Industry and Trade of Russia, Rosaccreditation and Rosstandart, which made it possible to ensure a “smooth entry” of the industry into the new regulatory regime, as well as to avoid excessive costs of market participants for certification tests.

Thirdly, within the framework of the activities of a working group specially created at the suggestion of the Committee of the Federation Council of the Russian Federation on Economic Policy, the formation of the necessary base of conformity assessment bodies was ensured, thanks to which it was possible to avoid a shortage in the sector of certification and laboratory services.

Of course, small importers of these products have suffered from the introduction of mandatory certification, for whom it is difficult to overcome the administrative costs of going through this procedure and for whom the amount of testing costs is significant, given the impossibility of taking advantage of the effect of "economies of scale".

But in the future, even they can find their niche in the market if they can find a legal way to pass certification using cooperative mechanisms.

I think, in particular, certification will greatly improve the market. Alexander, tell me, what achievements of the Association of Manufacturers of Heating Radiators in the matter of increasing the civilization of the domestic market of heating radiators do you consider to be key and why?

A.K .: Let's start with the fact that our Association unites Russian manufacturers of both radiators and convectors. Therefore, the main indicators of the effectiveness of the association are the growth of domestic production and the share of import substitution in the domestic market for the consumption of heating devices.

In 2020, when the association was just created, the share of Russian products was about 20 percent, and by the end of 2018 we expect to reach 45 percent, and maybe even 50 percent, that is, to record an increase in the share of import substitution by more than two times. in just three years.

I will name one record - in the past 2020, in the segment of aluminum and bimetallic heating radiators in Russia, 20 million sections were produced for the first time, an increase in volumes by five times in ten years. In another mass segment - the production of steel panel radiators - over ten years the volume of domestic production has more than quadrupled and has also come close to the record - one million pieces per year.

The introduction of compulsory certification has become an additional impetus for the development of investment activity in the industry, and also stimulated many leading European manufacturers to create localized industries in our country.

A few years ago, heat transfer and operating pressure were overestimated by 20-30 percent. Now the maximum overestimation of heat transfer that market participants can "afford" is four percent, that is, within the permissible deviations established by GOST 31311.

The main thing is that a culture of intolerant attitude towards misleading consumers is gradually coming to all participants in the Russian heating appliance market, and APRO has managed to create equal and fair conditions for everyone and fair competition in the industry.

How to choose the right heating radiator for your home

Before choosing a heating radiator, you should pay attention to the thermal conductivity of the material from which it is made. The coefficient of thermal conductivity shows the intensity of heat transfer through the material.

The higher the indicator, the smaller the heating devices can be, and the less space they will take under the window.

Another point that should not be forgotten when describing heating radiators is the smooth start of the system with a gradual increase in pressure. Failure to comply with this requirement leads to water hammer, from which the radiator can fail.

The principle of heating a room with a radiator is convection and radiation. Warm air rises where it mixes with cold air. Traditionally, radiators are placed under the window - the main source of cold air intake in winter. It should be borne in mind that the battery also heats up the outer wall, so some of the heat is lost. To reduce heat loss, you can use a heat-insulating layer with aluminum foil on top. Foil reflects heat radiation, and thermal insulation does not allow heat to pass out.

Currently, there are models on the market equipped with a room temperature controller. In order for the air to circulate normally, the distance between the battery and the surface of the wall or insulation should be 3-4 cm. The window sill located above the radiator creates an obstacle to the movement of warm air upwards. Therefore, it is necessary to leave a gap of at least 8 cm, and the radiator must be raised at least 10 cm from the floor. Decorative screens reduce the radiator's heat emission. If, nevertheless, it is decided to install them, you should raise the screen at a distance of 10 cm from the floor and make holes in the windowsill for more active air circulation.

In country houses, the pressure in heating devices is lower than in city apartments. In a country house, the pressure should be no more than 3 atm, so most of the presented radiators can be installed in them.

Speaking about which heating radiator to choose, in addition to the operating pressure, the gas formation factor in the radiators should also be taken into account.

How to choose and install an aluminum radiator

- if you decide to install an aluminum battery in a house with centralized heating. then it is better to dwell on reinforced products designed for a pressure of at least 16 atmospheres;

- for private houses, radiators of a standard (European) type are quite suitable.

It is also necessary to take into account a number of other nuances:

What is the temperature of the coolant.

Pipeline connection method. which can be one-way or two-way. In the first case, the number of battery sections should not exceed 8-10 pieces. Otherwise, the distant compartments simply will not warm up. In order to achieve optimal performance of the heater, the minimum distances to obstacles must be observed. 3 cm from the wall, 10 cm from the floor and from the windowsill. At the point of entry and exit of the pipeline, it is worthwhile to install shut-off valves. including thermostats

It is also important to install a vent valve. In no case should copper piping be used. Regarding the boiler with a copper heat exchanger, it is believed that it is located far from the battery, therefore it should not lead to corrosion.

In systems with high pressure, pipes are recommended to be used from metal

but aluminum cannot come into contact with cast iron and steel surfaces without processing.

Before installation, you need not only to purchase a radiator and all additional elements, depending on the configuration of the heater, but also to prepare the necessary tools:

- pliers;

- screwdriver;

- hammer drill;

- hydro level.

After all the preparatory work, you can install the batteries in stages:

- collect sections into a single radiator;

- connect shut-off and control valves to it, as well as air valves;

- drain the coolant from the system;

- install the brackets for the battery on the wall and fix the heater to them;

- connect the radiator with pipelines according to the selected heating scheme;

- check the heating system.

The video shows the process of assembling an aluminum radiator with your own hands:

If you have doubts about your abilities, then it is better to entrust the installation to professionals. Only with proper installation will it be possible to fully appreciate all the positive qualities of aluminum radiators.

You should also refuse to purchase and install if you live in an apartment building and are not sure about such indicators as the operating and pressure test pressure in the heating system and the quality of the coolant.

With this article also read

- Choosing a quality electric oil heating radiator

- How to bleed air from a heating radiator: remove air plugs correctly

- Bimetallic heating radiators: types of batteries, which ones are better to choose?

- Decorative screens for radiators: how to choose and install

- How to calculate the number of sections of bimetallic heating radiators for a home

- Calculation table for heat transfer from heating radiators

- What radiators to choose for heating a private house: we take into account every little thing

- Do-it-yourself septic tank from concrete rings: volume calculations and a simple assembly scheme

Pros and cons

Panel radiators have become popular due to their many advantages.

Panel radiators will perfectly fit into any interior

The most significant advantages:

- Multifunctionality. Modern batteries are a convector and a radiator in one device. When using them, no additional devices are required: they are capable of fully heating the room.

- Profitability. When comparing a ribbed battery and a panel radiator, it becomes clear that much less coolant circulates in the first product, but its power is quite high.

- Possibility of temperature regulation. Panels can be equipped with additional devices that allow to regulate the temperature mechanically or automatically.

- High heat dissipation. The radiator panel, due to its area, is more in contact with the environment than ribbed models. It uses the principle of convection, its efficiency reaches 90%. Therefore, such a device can warm up even the largest room.

- A wide assortment and affordable cost make the panels incredibly popular.Steel models are much cheaper than copper, bimetallic or aluminum ones, but they are several times more expensive than cast iron ones.

Panel radiators overview:

All the advantages of panel radiators are significant. But devices, like any product, have their drawbacks:

- The radiator cannot be left without a coolant for a long time, as this will lead to metal corrosion.

- Do not use a coolant with the wrong acidity. The optimal indicator should be in the range from 8 to 9.5 pH, otherwise rust will actively develop inside the panel.

- It is not recommended to install them in a central heating system, as water hammer can affect the reliability of the product.