Polyethylene pipes of different diameters are in demand in the construction of gas pipelines, sewerage networks, water supply and drainage systems. The popularity of HDPE pipes is due to the operational properties, the technical capabilities of the structures being built and the ease of installation.

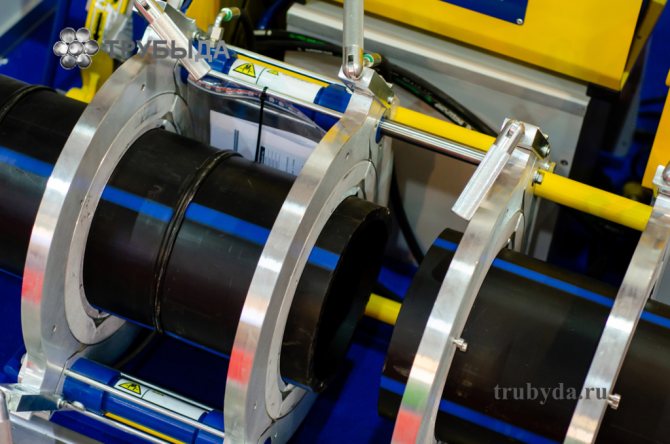

To fix polyethylene pipes, welding is used, which, depending on the conditions and equipment used, can be performed end-to-end or with the help of electrofusion couplings. The use of welding HDPE pipes allows you to obtain strong one-piece connections that are resistant to hydraulic shocks. They are leakproof and able to withstand water hammer.

Preliminary preparation

Before installation, it is necessary to prepare materials and check the welding equipment. For engineering communications, pipes made of low-pressure polyethylene are used, the diameter of which ranges from 20 to 1200 mm. They are cut into pieces of the desired size and the ends are processed. Equipment preparation includes:

- inspection of parts of the welding machine and check of the functioning of drives and grounding;

- removal of polymer residues and treatment of working surfaces of welding equipment with degreasing agents;

- check the oil level in the hydraulic system.

To ensure a certain welding mode, they check the functioning of the control and measuring devices with which the welding machines are equipped.

Electrofusion welding

Electrofusion pipe welding

When working in a confined space, HDPE pipes are fixed by electrofusion welding. It is carried out with the use of electrofusion couplings and allows the construction of branches at functioning pipelines. Thanks to the application of the electrofusion method, joints are obtained that are designed for a load of up to 16 atm.

Output

So, now you know how to connect polyethylene pipes into a single whole. Still have any questions? Ask them in the comments to the text. Also, I recommend watching the video in this article.

July 31, 2020

The proposed videos will clearly demonstrate all types of HDPE pipe welding, as well as acquaint you with the process of assembling a compression fitting and saddle.

Self-installation of polyethylene water pipelines requires some knowledge and skills, but it is quite feasible if the above rules are followed. In the absence of special equipment, it is possible to assemble a water supply system without tools at all, using exclusively compression fittings.

There are many installation options, but you need to use the one that will provide the result with a minimum of financial costs.

Are you determining the best way to weld polyethylene and want to clarify some points? Do not hesitate to ask your questions to our experts - we will try to help you.

Read next: Gas torch for brazing copper pipes - a review of the best