Advantages of a wood-fired boiler

When it comes to using firewood as fuel, we do not mean outdated stove heating, but modern high-quality equipment - solid fuel heating boilers for home use. Such units look beautiful externally, and also have a high efficiency - about 70-90%. This is because their design is based on the latest developments of scientists.

Many countries with cold climates are engaged in the production and sale of wood-fired heating boilers. Research is ongoing to minimize fuel consumption and increase equipment efficiency.

Compared to a gas one, a wood-fired heating boiler has a number of advantages:

- the price of firewood is about 1.5-2.5 times lower than natural gas;

- the installation of wood-fired boilers does not require obtaining permits from the gas service and the fire inspection, as well as notifying neighbors;

- subject to the purchase of a high-quality wood-fired heating boiler, it can also be heated with pellets, wood shavings and even coal;

- the design for wood-burning boilers allows them to work regardless of the connection to the power grid;

- the presence of automation in the wood-burning boiler allows you to reduce fuel consumption by reducing the frequency of downloads;

- often a wood-burning boiler is equipped with a hob that can be used to cook or heat food;

- combined wood-fired equipment allows not only to heat the house, but also to heat the water.

disadvantages

Of course, solid fuel boilers are not without some disadvantages. If you buy cheaper equipment, you will need to throw firewood into it every 2-4 hours. Therefore, you cannot leave him unattended. In addition, you need a place to store fuel, such as woodpiles or special sheds.

Heating wood boilers for the home are sensitive to the quality of the fuel - the wood must be absolutely dry, otherwise the efficiency of the device will almost halve. Of course, high-tech equipment, equipped with automation for fuel delivery and temperature control, can cope with such a problem. However, it is quite expensive.

Let's consider in more detail the main types of wood-burning boilers based on the price factor.

Low price segment of wood-fired heating boilers

First of all, it is worth considering a homemade wood-burning boiler for heating a house. Significant cost savings are achieved by purchasing individual components (sheet metal and pipes) rather than a finished product. Although it will not be so easy to assemble such a unit with your own hands, nevertheless, with proper execution and a successful choice of a model, the efficiency of a homemade wood boiler can reach 70-80%.

The simplest solution would be a standard bottom firing boiler design. It consists of a combustion chamber, an ash pan, a water jacket or register, a draft regulator, and a chimney. If you choose a more complicated design, then it can have all kinds of valves, smoke swirlers or mine combustion chambers. If desired, you can make a boiler even with an upper combustion type.

It is worth noting that the main disadvantage of a home-made boiler for heating a private house on wood is the high rate of fuel combustion. The boiler heats up very quickly, it gets very hot in the house, and after just a few hours the system cools down. To cope with this problem, some masters install a kind of battery - a container with water, in which they store a supply of warm water.It transfers heat evenly to the system and ensures a comfortable temperature for a long time. In some cases, the volume of such a container reaches 2-3 tons.

However, such options are acceptable only for those who like to work with their hands and have enough time for this. All others prefer to buy cheap factory products from domestic producers.

Please note that it is better to purchase a ready-made boiler not from craftsmen, but from trusted manufacturers with high-quality equipment and production facilities. The fact is that in an industrial environment, the quality of the fit of welds is much higher than it is possible to do at home. The method of painting and the quality of paints and varnishes are also important - heat-resistant paints designed for high temperatures are used in production.

As a rule, a cheap wood burning boiler has a simple structure and is made of sheet steel. It is desirable that its thickness is at least 4 mm. As for the power, it can be quite high - it does not affect the price. The disadvantages of equipment from the lower price segment are their service life and fuel consumption. Typically, factory products are designed for 5-10 years of work.

Nevertheless, subject to not very intensive use and free access to lumber, such equipment can be purchased.

Convenient wood boilers for home

Home is a place where it is always cozy and warm. We come here every day after work or school, hoping to have a good rest. Much depends on the atmosphere in the house. But how to create warmth and comfort if the weather is rainy or even frost and cold?

Previously, this problem was solved with bulky stoves that provided heating to homes. However, over time and the improvement of technology, new solutions have emerged for this problem. Inconvenient stoves have replaced compact wood boilers that can run on natural fuel and maintain a constant room temperature for a long time. Modern technologies have significantly improved the heating system of homes.

Wood boilers are worth buying, because they:

- save space,

- very convenient to place and use,

- do not require special costs,

- use ordinary wood for space heating,

- equipped with an automatic control system.

Heating in your home will no longer be too expensive. Installing one wood boiler will solve all your problems. However, the choice and operation of such equipment must be approached seriously and responsibly. You should also follow all safety rules when working with the boiler.

Such heating options for your home are budgetary and suitable for anyone who wants to create a cozy atmosphere and maintain a constant comfortable temperature in the house for a long period of time.

What are the boilers?

There is not much difference in which room the boiler is used for. If this is a residential building or a production warehouse, in any case, the temperature will be as you need it. The functionality of the wood boiler should be used correctly and it will last you much longer.

Wood-fired boilers are often chosen. They heat up quickly enough and contribute to the creation of the correct temperature regime in the room. In addition to firewood, you can use other types of solid fuel. But only wood retains heat evenly, without any other chemical additives and increases in boiler output.

The heater is quite simple to use and operate. You can always find fuel for it in stores at a fairly reasonable price. You can also take wood harvested for the boiler yourself.Before heating, it is imperative to check whether the material is dry. Otherwise, the boiler simply will not work or it will fail. To prevent this from happening, it is recommended to worry in advance about the suitability of the materials for kindling.

Wood boilers have only one drawback. Despite their health and performance, they are only able to function for a few hours. After that, you will have to refuel the equipment with wood. The thing is that when the fuel is completely burned out, the system does not automatically renew its reserves. On the other hand, this is a significant plus. After all, you can always regulate the temperature regime as it suits you.

This problem has already been solved in new boiler models that are already on sale. Such boilers are capable of generating heat for up to twelve hours without refueling and performing any other types of settings. This is very convenient, especially if the boiler is installed in a production area.

If you decide to purchase a wood-fired boiler for your own home, then it can be installed directly in the room itself. Sometimes a boiler room is specially built for this. When you do not want to make such a building, then a special separate room will be equipped for the boiler, located in the immediate vicinity of the house itself.

Do not think that once you have installed the boiler, you will no longer need to check it or check its functionality. There is no need to heat the room with a boiler without a person who will control the entire process and refuel the equipment with firewood when the need arises.

What are the features of boilers?

The equipment for heating the living quarters has a special design. Such boilers often differ in some functional features. Boiler bodies and wood combustion chambers can be made from a wide variety of materials. However, the main principle of their work is always the same - to heat the room.

To create all the conditions for the correct storage and distribution of heat, the boiler designers:

- used as the main material for their manufacture, cast iron or steel,

- only dry wood is taken for heating,

- make boiler models practical enough and convenient for further operation.

Each of the materials that become the basis for the boiler has its own advantages and disadvantages. All this must be taken into account when planning and creating equipment of this level of complexity. For example, if the heat exchanger was originally made of cast iron, then such a boiler may well serve you for several years without failures and shortcomings. But this is only if you use the instructions and follow the rules for the correct operation of the boiler.

In addition, the cast iron heat exchanger cools down for a long time. Therefore, if you want to clean the boiler, you will have to wait several hours until the metal finally cools down. Only then will it be possible to start cleaning the chambers and all the grids.

But if we compare cast iron with other metals, then it is better than others capable of ensuring uninterrupted and stable operation of the boiler. When any malfunctions arise in its work, everything can be corrected without the use of expensive repairs. After all, this boiler was cast from durable metal. It is able to withstand small surges in voltage or other kinds of errors in the operation of the heating system.

You can operate a cast iron boiler for about twenty years. And this is a long time, considering how much low-quality equipment made from cheap materials is now on sale. Be sure that it is best to pay for the boiler once by purchasing a high-quality model, than to overpay for its constant repairs later.Therefore, a cast-iron boiler is not always a guarantee that it will simply collapse from sudden changes in temperatures. Sometimes this happens faster than the end of their service life.

You can purchase a steel boiler instead of cast iron equipment. It does not have such a solid lifespan, but there are other advantages to which you should pay attention. Among them, one can especially highlight heat resistance. Unlike a cast iron boiler, it is much higher here. This will ensure that the equipment does not fail at the most inopportune moment.

How does the boiler work?

Practically everyone who has ever encountered the principles of operation of this equipment knows what should be taken into account when working with a boiler. Carbon monoxide should never enter the chimney. If this happens, then it is necessary:

- turn off the equipment,

- leave the room where the boiler is located,

- call the appropriate service so that specialists can adjust the heating system.

All wood boiler owners should know the above steps. After all, carbon monoxide simply cannot come out. It acts as an additional source of heat. Gas in this case is a raw material that maintains an optimal temperature regime in a residential area.

It is necessary so that in the process of special reactions, a combustible gas is formed inside the boiler. This resource development protects the environment. This is especially true, because often the boiler is located indoors, or is located in close proximity to it.

The coolant heats up gradually, but unevenly. Therefore, the entire combustion process and the corresponding temperature regime can be regulated using special functional features of the boiler. The air supply is capable of controlling the combustion rate of the respective natural materials.

When the combustion process itself takes place, a large amount of ash and soot is emitted. It can settle on the walls of the chambers and if the equipment is not properly cleaned, this will lead to its complete clogging and damage.

Despite their seeming harmlessness, combustion products such as soot and ash have their own structure and can affect the quality of operation of many components of the boiler. Therefore, there is a special grate under the wood combustion chamber.

When the fuel is burned, the production wastes immediately fall into a separate compartment. So it is much more convenient and faster to take care of the wood boiler, because in this case it practically does not get dirty. And the resulting production waste can be sent for recycling or appropriately disposed of.

Remember one main rule, without which the installation of the boiler will be simply impossible. A chimney must be located in the room where it will function. Oxygen plays a very important role in the process of temperature regulation inside the boiler itself and throughout the living space.

You should also check the quality of the fuel used for heating the room. Damp wood will only ruin the boiler. Such fuel will be useless, and the logs will not be able to fully burn out inside the boiler chambers. Never try to take such logs for heating. But if the production of this material is important, and you have nothing else to heat the room with, first dry the tree. After that, you can safely load the boiler and make all the necessary adjustments for its further operation.

The boiler must be located in a place where no other equipment will be located. Also, provide an appropriate storage area for fuel. It should not be damp, because if the wood gets damp, it will have to be dried again before using it.

Wood boilers have good efficiency. All adjustments can be made regarding the temperature of the water that will be heated by the combustion of the wood. This is very convenient, because you will always know which temperature mode is optimal for heating your home.

Sometimes, along with wood, you can safely put other types of solid fuel into the boiler. This will increase the heating rate of the water and therefore increase the overall temperature in the living area. There is no need to connect the boiler itself to other communications. It is completely autonomous in its work and does not need additional power supplies.

Choose a wooden boiler for your home and enjoy all its benefits!

The middle price segment of wood-fired heating boilers for a private house

Boilers from domestic manufacturers, as well as products from Germany, Lithuania, Poland, the Czech Republic and Slovakia, are presented to the buyer in the middle price segment. You can purchase a steel boiler for water heating on wood, the efficiency of which will reach 90%. Cast iron boilers are also found in this segment. Typically, their hulls are made up of whole sections, making it easy to assemble equipment on site. This design also simplifies the repair process by simply replacing the section.

Among the advantages of cast iron housings is their resistance to any kind of corrosion, which significantly extends the service life of the equipment. Nevertheless, cast iron is quite fragile - it does not withstand mechanical damage and temperature changes. Therefore, cold firewood cannot be loaded into a cast iron boiler.

As for steel, it is not afraid of mechanical damage and temperature changes. And provided that certain substances are added to the coolant, it will not be afraid of oxidation either. The main disadvantage of a steel boiler is that the steel burns out quickly. When choosing a boiler, make sure that it is made of heat-resistant metal.

When selecting the capacity of the equipment, it is worth leaving a margin of 25-30%. The fact is that the standard power value of 1 kW per 10 m2 is quite approximate and is applicable only for a pre-heated house with good thermal insulation. In addition, if a wood-fired steam heating boiler does not work at the power limit, then it will last much longer.

Features of solid fuel boilers

For the production of boiler equipment, high-strength steel or cast iron is used. The characteristics of the alloys affect the service life, as well as the thermal conductivity and heat capacity of the structure. So boilers made of steel do not lend themselves to deformation as a result of temperature and pressure drops. Cast iron, in turn, is resistant to corrosive processes.

Steel equipment has an affordable cost, attractive appearance and comfortable fuel loading. Cast iron boilers are unpretentious and durable. The latter are more often installed in houses where the owners live permanently, and steel products are more often used to heat temporary dwellings (summer cottages).

Solid fuel boilers share a number of common characteristics:

- the possibility of offline connection;

- operation on different types of fuel and the admissibility of their combination;

- high level of efficiency;

- the need for the mandatory installation of a chimney;

- regulation of the degree of combustion by controlling the air supply;

- the presence of a long-term combustion mode, which makes it possible to use the formed flue gas as a raw material for heating;

- the dependence of the combustion efficiency on the quality of the fuel used (work is significantly impaired if, instead of dry firewood, wet firewood is used).

Please note: improved models of modern boilers are capable of operating on one fuel load for up to 14 hours without a break, however, they require periodic monitoring and testing of equipment.

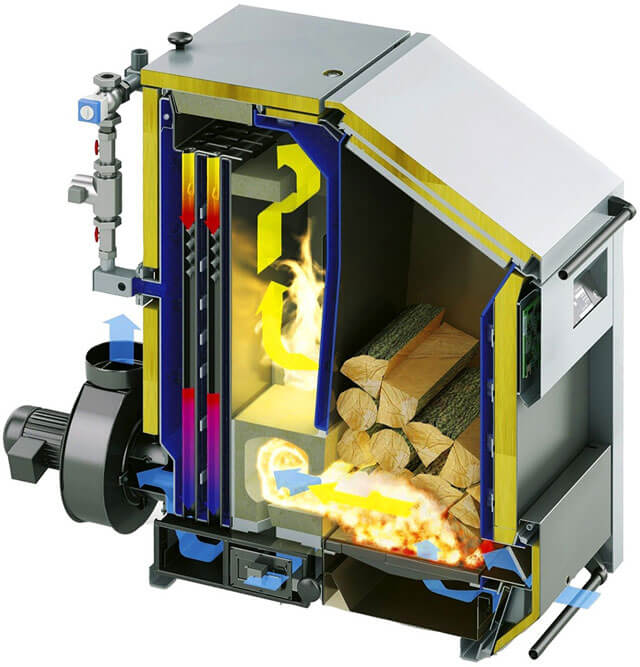

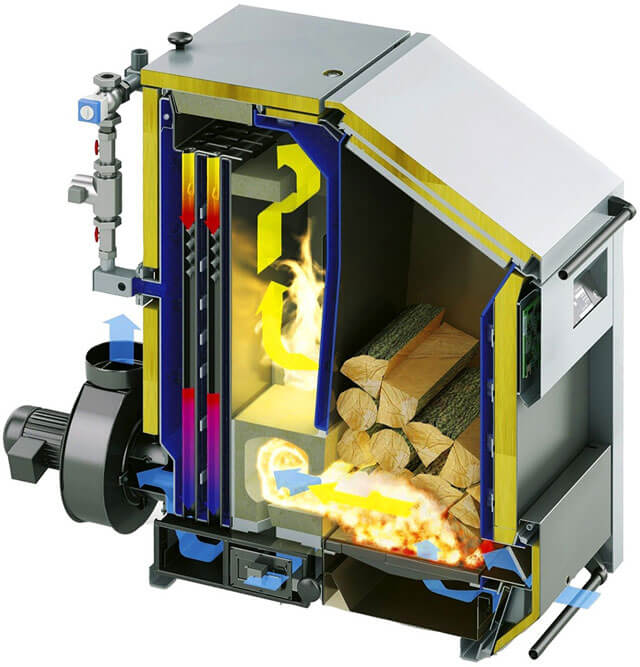

Long burning boilers

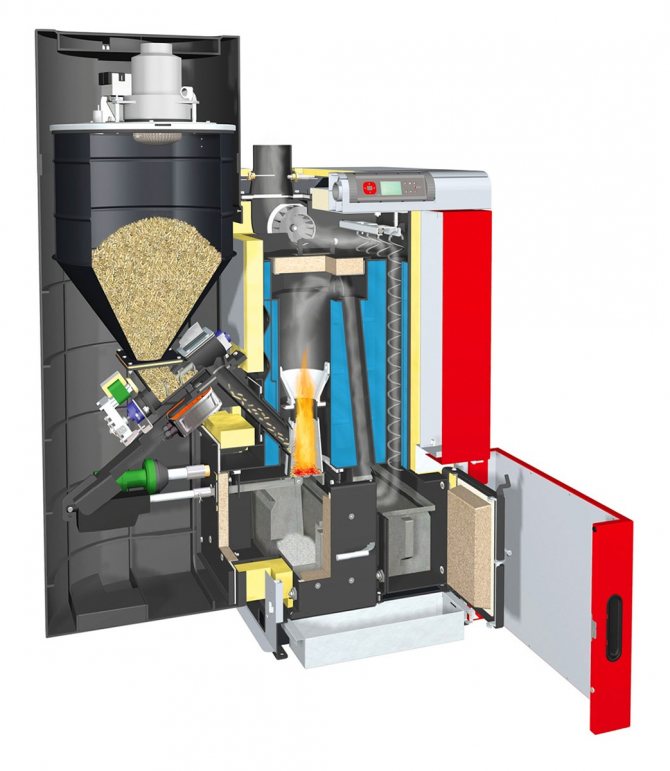

This category includes the most modern and economical units - boilers with a pyrolysis type of combustion. On one load of firewood, they can work up to 40 hours, and if coal is used, up to 5 days. The most reputable manufacturer of such devices is the Lithuanian one. Their boilers look beautiful externally, have an elongated shape and do not clutter up the room. The price of such equipment depends on the capacity.

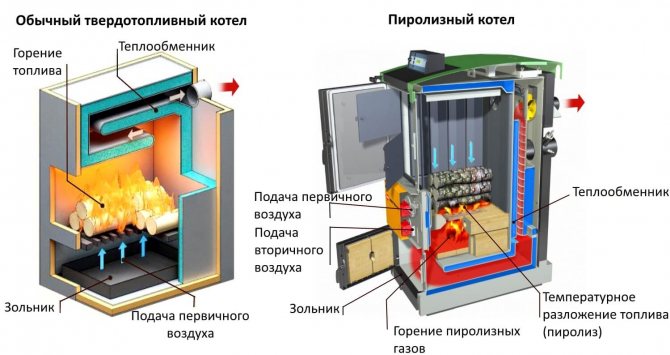

The peculiarity of pyrolysis boilers is that in the process of burning wood, pyrolysis gas is generated, which enters a separate chamber. Burning out, it generates a large amount of thermal energy. Only after this does the solid fuel burn out. Thanks to this mechanism, pyrolysis boilers are the most economical and consume 1.5 times less fuel. Provided that very dry wood is used, the boiler can work without additional loading for up to 12 hours.

Pyrolysis boilers

If a household heating boiler in a private house is supposed to be fired with coal or wood fuel, it is better to give preference to a pyrolysis or, which is the same thing, a gas generator model. Such equipment is also called long-burning boilers. Pyrolysis is the process of formation of combustible gas when coal or wood fuel smolders. without oxygen. It takes place in a special boiler chamber and is accompanied by the release of a significant amount of heat. Wood gas, which consists mainly of ethylene and propylene, is fed through a ceramic nozzle into a second chamber, where air is injected and burned. Solid fuel pyrolysis boilers for the home are very profitable, since they have increased efficiency, moreover, much less effort is required to clean them, because there is not much ash left after pyrolysis.