A reliable heating boiler is a guarantee of warmth and comfort in the house

Each consumer solves this problem in his own way, but one thing is safe to say: with an outdated boiler, all energy saving measures will not give a tangible effect. A reliable boiler, regardless of the fuel used, is the heart of any heating system. It is on his work that the warmth in the house depends, which we so need in the cold season. But so that the cost of heat does not ruin the family budget, the old boiler must be replaced with a new, modern and economical one.

The range of boilers is unusually large, and the consumer can choose a model designed both for heating a private house and for organizing autonomous heating in an apartment.

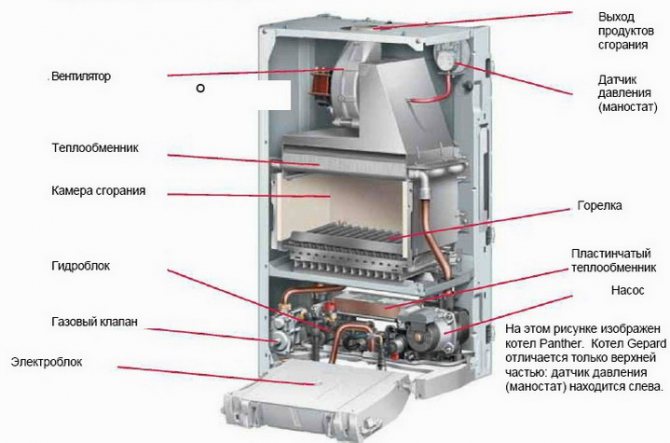

The principle of operation of the turbocharged column

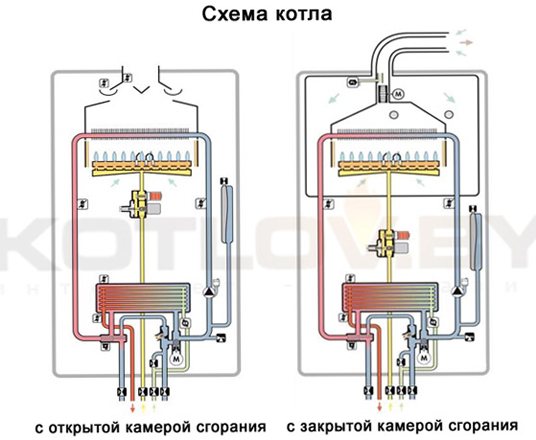

The principle of operation for all water heaters is the same - when you open the hot tap on the mixer in the device, the burner ignites from the pressure of the flow and begins to heat the water in the heat exchanger. The difference between the work of a gas water heater with a closed chamber is as follows:

- when the column is in standby mode, the burner igniter does not burn;

- when the DHW tap is opened, the flow sensor is triggered, the membrane bends and the gas valve opens the flow of fuel to the burner;

- sparking occurs at the command of the controller; after the flame has appeared, the sensor detects its presence, and the sparking stops;

- after the appearance of a flame, a fan turns on, which draws smoke into the chimney;

- the temperature of the coolant is maintained by the column automatics at a given level; so that the liquid does not overheat, the modulating burner reduces the combustion intensity.

Due to the design, the efficiency of devices with a closed chamber is higher than that of analogs with an open firebox. For the first, the indicator is 88-95%, for the second - 80-88%. Efficiency is achieved in the following ways:

- due to precise dosing of the required volume of air and fuel;

- flame modulation maintains the set temperature without consuming excess fuel;

- the air coming from the street to the burner is preheated in the coaxial pipe from the heat of the outgoing smoke.

The use of a coaxial chimney makes it possible to return some of the heat that goes away with the smoke.

Read here how to connect the gas column duct?

…

How to fit a gas water heater into the interior?

What you need to know about the ventilation of the gas column?

The safety system of the device with a closed firebox includes the following elements:

- flame sensor;

- chimney draft sensors;

- temperature sensors;

- automatic gas valve that controls the fuel pressure at the inlet;

- safety water valve that records the working water pressure.

Automation stops the operation of the device in the following situations:

- power outages;

- the pressure in the water supply system exceeds 10 bar;

- the burner has gone out;

- the controller is out of order;

- the boundary temperature of the coolant was exceeded.

Some models are equipped with the function of cooling the heat exchanger with a fan if the maximum possible water temperature is exceeded.

…

Many turbocharged models have an anti-freeze function for the heat exchanger. It works according to the following principle: if the room temperature drops below 0, the automation will turn on the electric heating element, which heats the heat exchanger to prevent water freezing. "Anti-freezing" will prevent damage to expensive equipment in case of shutdown of the heating system in winter.

Classification of boilers and the general principle of their operation

Heating boilers are classified according to several parameters:

- Type of fuel.

- Power.

- The number of contours.

- Installation methods (floor or wall).

- Combustion chamber type (open or closed).

If in an electric heating boiler water is heated directly by TEN, then in gas, solid fuel and diesel boilers, an open flame is used to heat the coolant, which is created by burning fuel in a special chamber. Fuel combustion chambers are open or closed, and the combustion process and temperature regime are controlled by a reliable automation system.

The principle of operation of any heating boiler is simple. The fuel burns out, heats the coolant, which gives off heat to the room through the radiators. In diesel boilers, open chambers are used, and various models of gas and solid fuel boilers can have both open and closed combustion chamber designs. Consider their distinctive characteristics, as well as advantages and disadvantages.

Comparison

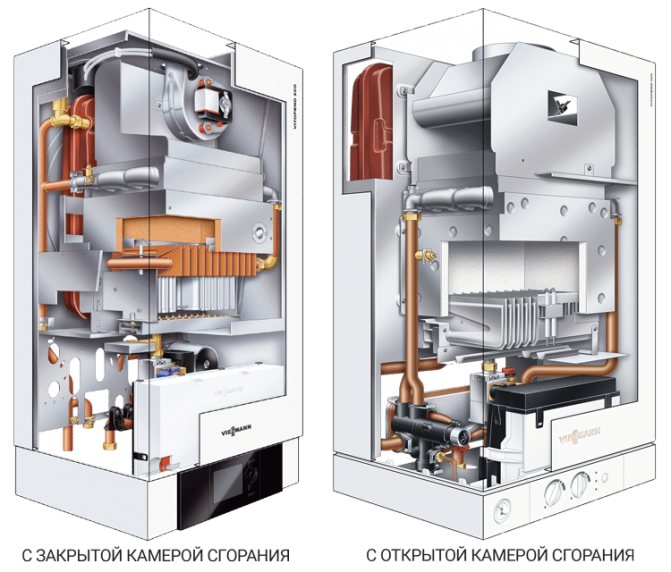

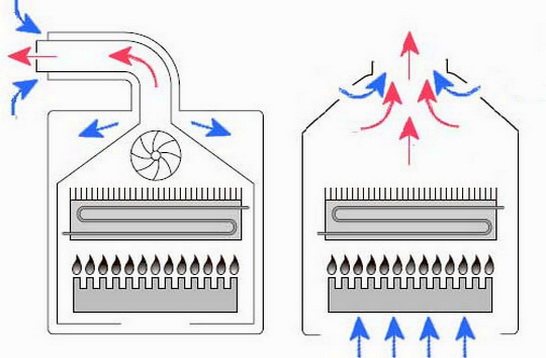

The main difference between an open chamber and a closed one in gas boilers is that the first structural element of the unit operates due to natural draft and involves the removal of combustion products through a traditional chimney installed in a special room. Desirable - located at a distance from living rooms.

The second type of chamber in gas boilers involves directing air from the atmosphere into the unit using a fan, and also provides for the removal of the resulting smoke. As a result, combustion products can be removed by means of a coaxial chimney. It has a less complex design, as a result of which the boiler of the type in question can be installed in residential premises.

Having determined what is the difference between an open and a closed chamber in gas boilers, we will reflect the conclusions in a small table.

Features of an open combustion chamber

An open combustion chamber is a burner that heats a coil, through which thin tubes a coolant (water) flows. As you know, the presence of oxygen is necessary to maintain the combustion process. The design of the open chamber provides for the intake of oxygen from the ambient air through special channels. The exhaust gases are removed naturally through the chimney.

Open chamber boiler

The room where the boiler is installed must have opening window, which provides a natural flow of fresh air and eliminates high concentrations of carbon monoxide. The design of an open combustion chamber is quite simple, and the maintenance of such boilers consists of the following activities:

- Cleaning the burner.

- Descaling the coil.

- Chimney cleaning.

- Control of the operation of automation devices.

It should be borne in mind that with all the advantages and disadvantages of open combustion chambers, the price of such boilers is an order of magnitude lower than the cost of boilers with a closed chamber, which is often the main criterion for choosing heating equipment. And tangible fuel savings can be achieved only with the installation of a water pump, as well as careful insulation of the chimney and walls of the house.

Differences between gas boilers with open and closed burners - which is better

Choosing a gas boiler, we consistently answer several questions, for example, what power do we need, do we have a special boiler room for heating equipment…. You may have to choose - a closed or open combustion chamber in a gas boiler is needed.

The question of the combustion chamber relates to the design of the boiler; it is impossible to answer it without knowing some of the nuances. At the same time, due to the characteristics of the gas burner, the most significant differences between the boilers follow, which determine their areas of application.

Let's take a closer look at this technical issue - choose an open or closed gas burner, what features they have, and why this choice is so important.

Open (atmospheric) burner

An open burner, or in other words, an open combustion chamber works according to the usual scheme for everyone. The draft is created by a high chimney, combustion air is taken from the room where the unit is installed.

Two features follow from this:

- the room for such a boiler must be non-residential and specially equipped, in accordance with the standards;

- the boiler needs a chimney with a height of at least 6 meters that meets the requirements for straightness, etc., its operation is allowed by gas services.

When we talk about an open combustion chamber, we are talking about large-sized stationary equipment, which is practically impossible to install in an apartment, and in private houses it is installed only in separate non-residential specially made premises.

Advantages and disadvantages

We can say that installation restrictions are the main disadvantage of boilers with an open combustion chamber.

For the boiler, you need to select a boiler room and equip it according to the requirements, in any case, ventilation with 3 times air exchange per hour, etc.

What are the advantages of an open (atmospheric) burner, why does it exist on an equal footing with other designs. It turns out the following:

- Boilers with an atmospheric burner can be with a cast iron heat exchanger, which means the most durable, as well as very powerful.

- Units may not depend on electricity at all, even when running on gas.

- The price for high power is moderate or low.

Such features of an open burner also determine the characteristics of the entire gas boiler - a powerful, reliable and durable option.

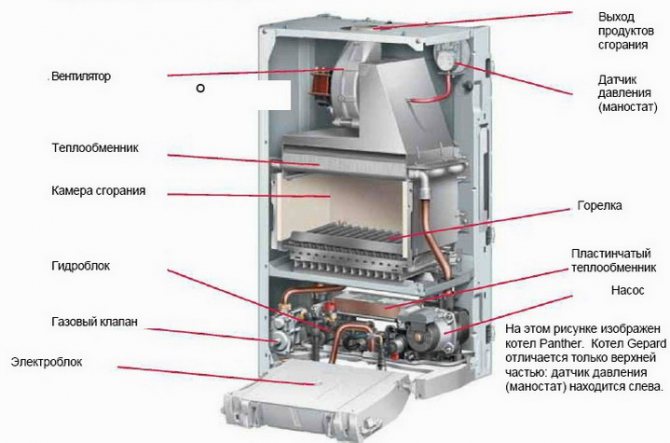

Closed burner with forced ventilation

A closed burner in a gas boiler can only be operated under automatic control. It is ventilated by a permanently operating fan. This means that the presence of electricity is mandatory, such a boiler cannot work without power supply.

Closed combustion chambers are made of copper, steel, much less power than open ones. Durability is also less.

The advantages of units with a closed combustion chamber in compactness and the possibility of installation in utility rooms, including in the kitchen, (except for the bathroom, toilet and living rooms), according to the project.

The boiler does not need air from the room, it takes it from the outside through the chimney pipe (pipe in pipe). And, by the way, this boiler does not need a high chimney, since the combustion chamber (burner) is blown out by a fan. A horizontal chimney is used, led out through the wall.

Thus, all wall-mounted compact boilers for private houses and apartments are with a closed combustion chamber, consume air from the outside and are controlled by automation.

Features of work

When operating a boiler with a closed combustion chamber, the following is obtained:

- The operating mode of the combustion chamber is verified by the amount of supplied air, the efficiency specified by the manufacturer is higher - up to 93% (condensate boilers that appear use additional energy release during condensation of water vapor and develop all 109% efficiency, if calculated according to the classical method and compared with the tabular heat of combustion of fuel Read more About condensing economical boilers).

- The safety of the chimney is higher, since the gases are removed through the inner pipe of the chimney, while being cooled by the air flowing towards it. The incoming air heats up and thus increases the efficiency.

But automated devices with a closed burner, at a lower power, are more expensive than with an open chamber.

Some conclusions

But the consumer has a simple question - which gas boiler to choose, with a closed or open combustion chamber? The answer lies on the surface - sellers in specialized organizations will easily prompt you to choose the type of gas burner.

Powerful heat generators with an open burner are used less often, but for heating large houses, as well as where electricity is not reliable (options without power supply).

And boilers with a closed burner will be in demand in most cases, for heating houses and apartments, as a convenient mini-boiler room in the size of one cabinet suspended on the wall.

For more information on gas boilers, see the article Creating the most economical heating based on a gas boiler

Features of a closed combustion chamber

A closed combustion chamber is a closed zone with a burner, where air is injected through a coaxial chimney, which is a pipe in a pipe, and combustion products are removed. Forced air circulation is provided through the use of an electric fan, which makes the heating system dependent on the availability of electricity, and also increases the noise level in the room.

The forced air is heated by the exhaust gases, which contributes to complete combustion of fuel... This, in turn, increases the efficiency of closed chamber boilers and improves their environmental safety. Boilers with a closed chamber are easy to install, they do not need bulky chimneys, and they are perfect for organizing autonomous heating in apartments.

Among the disadvantages are regular maintenance, significant power consumption and the danger of freezing the combustion area due to the short length of the coaxial chimney. The fuel savings that sealed chamber boilers provide are usually offset by the cost of electricity, maintenance and the purchase of spare parts needed in the event of a repair.

Renovation and construction

Cons of devices

Due to the need for constant draft, drafts occur. In addition, its strength depends on weather conditions (temperature, wind). And also the work of the hood in the kitchen affects the craving. There are other downsides as well.

Expensive installation

Open chamber boilers dangerous to install in residential areas.

It is desirable for them to equip separate boiler room, the dimensions of which depend on the power of the device. The furnace is thought over at the design stage of the house.

In it there must be windows... You will also need a reliable system for forced ventilation of the room. This increases the overall installation cost significantly.

Important! Wall-mounted models of gas boilers are allowed to be installed in the kitchen, if its volume more than 7.5 m3, and the ceilings above 2 meters. Window area required not less than 0.6 m2.

Sometimes to increase reliability to gas boilers add sensorsthat monitor undesirable phenomena that interfere with work (for example, weakening of thrust). The boiler switches off automatically if necessary. Such a system also requires additional costs.

The presence of a vertical chimney

A vertical type chimney is required to remove exhaust gases. Certain requirements are imposed on it:

- Pipe section not less than the diameter of the branch pipe for smoke evacuation.

- Height to first turn - not less than 0.5 meters and two pipe diameters.

- Certain pipe height above the roof.

Photo 3. Wall mounted gas boiler with an open combustion chamber. A chimney made of steel pipes is equipped for it.

It is determined by the location on the roof:

- no more than 1.5 meters from a ridge or on a flat roof - 0.5 m;

- from 1.5 to 3 meters to the ridge - not lower than its height;

- beyond 3 meters from the ridge - not lower than a conditional line drawn from the ridge at an angle of 10 ° to the horizon.

Attention! Used as material steel or special polymer materials... A brick pipe will not work. It will quickly collapse under the influence of condensation.

Arrangement of a suitable chimney to the gas boiler pretty hard... In addition, it is associated with certain material costs.