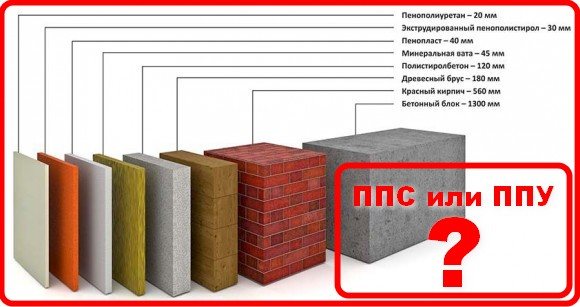

If the question is being decided which is better - expanded polystyrene or polyurethane foam, you should compare properties of these materials. In addition, you need to take into account and terms of Use, because in different rooms it may be preferable to use one or the other option. To conduct a full comparative analysis, the following factors are taken into account: structure, service life, strength and thermal insulation characteristics, hygroscopicity, noise absorption efficiency, density and some other parameters. The cost of the product is also important.

Briefly about 2 materials

Expanded polystyrene (PSP) is a gas-filled, closed-cell material based on polystyrene, its cells contain natural or carbon dioxide, and there is also a vacuum version. There are 2 types:

- foamed;

- extruded (extrusion).

Polyurethane foam (PPU) is a group of gas-filled plastics. The material is based on polyurethane. It can be tough, elastic and self-foaming. If the characteristics of polyurethane foam and expanded polystyrene are considered, you should be aware that both options are similar in most parameters.

Is polyurethane foam (PPU) lighter than extruded polystyrene foam (EPS)?

First of all, hands are itching to destroy the legend that insulated vans filled with polyurethane foam (PPU) are lighter than glued ones with extruded polystyrene foam (EPS). Optimum thermal insulation properties of both materials are achieved at a density of 40 kg / m³. Considering that the heat transfer coefficients of polyurethane foam and EPS are approximately equal, differing only by 2 thousandths of W / m2 * K, it can be argued that both in glued and in jellied sandwiches with the same isothermality (for example, 0.7 W / m2 * K), the thickness of the insulation material should be the same. This means that with the same density of materials, their weight in the composition of vans will be the same. We also note that, for example, for a van measuring 5.3x2.6x2.5 m for 12 euro pallets, an increase of 10 mm in the thickness of the insulation will add only 27 kg of weight.

Comparative table of characteristics of PPU and EPPS

These types of insulation are approximately equally popular due to their properties. If you are interested in the question, polyurethane foam or expanded polystyrene - which is better, it is recommended to compare them according to the main characteristics. The result can be seen in the table:

| Parameters | Polyurethane foam | Expanded polystyrene |

| Density, kg / m³ | 25-750 | 45-150 |

| Thermal conductivity coefficient, W / (m * K) | 0,019-0,028 | 0,04-0,06 |

| Structure | Closed-cell | Closed |

| Operating temperature, ° С | -160…+180 | -100…+60 |

| Environmental friendliness | Polyurethane foam retains its properties and does not emit harmful substances when heated to the maximum value (+ 180 ° C). | Expanded polystyrene at a temperature of + 60 ° C begins to emit a compound dangerous to human health - phenol. |

| Duration of operation, years | With proper installation, the service life is unlimited, in other cases it is 50 years. | 42278 |

| Fire hazard | Incombustible | More susceptible to combustion. In high temperature conditions, burning areas can be separated, which contributes to the spread of fire. |

| Hygroscopicity | Does not absorb moisture. | It is more exposed to liquids and is able to partially absorb them. |

| Appearance | Does not lose its properties throughout the entire period of operation. | Over time, it shrinks, undergoes deformation due to loss of properties. |

Comparison, differences, what is better to choose

Although they have a common scope, the functions and properties are different. The difference between the two is as follows:

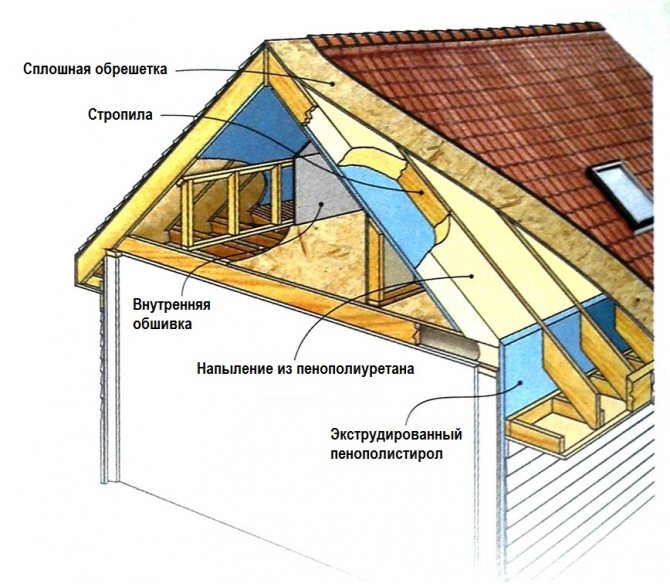

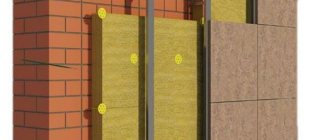

- Thermal conductivity... If we talk about the coefficient of thermal conductivity, then the undoubted leader will be polyurethane foam.Moreover, an important factor is the form of manufacture. Expanded polystyrene is produced only in the form of plates, when installed, gaps are formed that create heat leakage.

- Water tightness... Polyurethane foam is able to repel moisture much better. Fungus does not form on it, which cannot be said about the second material.

- Safety... If applied correctly, polyurethane foam will not do any harm. When the expanded polystyrene is heated, phenol begins to evolve.

- Density... The density coefficient of the first material is much higher, which is its undoubted advantage.

- Installation complexity... The polyurethane foam is endowed with excellent adhesion, which will allow you to quickly finish the job. Expanded polystyrene requires the application of special components.

- Transportation... Since polyurethane foam does not undergo deformation, it is much easier to transport it without fear for its integrity. Expanded polystyrene is a very fragile material, it can be easily damaged.

If we talk about which is better to choose, then, undoubtedly, Polyurethane Foam will win. It has higher strength, long service life, good thermal conductivity, sound insulation, does not heat up, does not emit toxic substances. Therefore, its high price is fully justified. But if you need to insulate a small room, for example a shed or garage, then the choice can be made in favor of cheaper polystyrene foam.

Cost comparison

Surface protection by means of polyurethane foam insulation is a more expensive technology. So, thermal insulation of 1 m² will cost 150-1500 rubles. In this case, the price is formed taking into account the thickness of the material: from 10 to 100 mm. This means that to insulate the surface of 1 m² with a layer of polyurethane foam 50 mm thick, you need to prepare about 850 rubles. The high price of this type of thermal insulation is due not only to the production technology of the material, but also to the high cost of equipment.

If the question is being decided which is better - polyurethane foam or expanded polystyrene, you should know that the latter of the options is offered at a lower cost. For comparison, insulation of an area of 1 m² with EPS boards will cost several times cheaper - 300 rubles, provided that the thickness is 50 mm. Good polystyrene foam boards, characterized by large dimensions and high density, are more expensive.

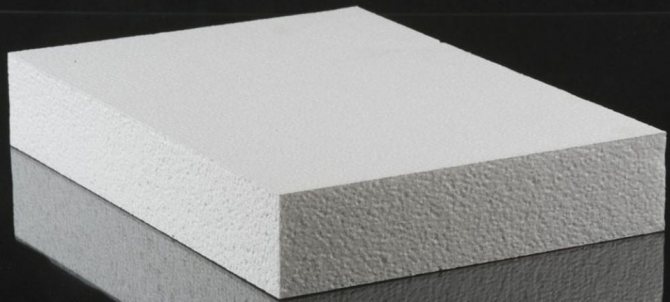

Expanded polystyrene

The heart of the SIP panel is its insulation core. The most common insulation option is expanded polystyrene. It has minimal thermal conductivity, is hygroscopic and cost effective.

You can read more about the reasons for the popularity of polystyrene in our article "The Whole Truth About Polystyrene".

Choose panels with the brand of expanded polystyrene PPS14 (PSB-S25) or PPS16 (PSB-S25F)

The grades of expanded polystyrene according to GOST differ from each other primarily in terms of density. The more kg of grain per 1 m3 of sheet, the better such a SIP panel retains heat and the higher loads it can withstand. But the cost of such expanded polystyrene is higher!

A cube of material PPS10 (density 10kg / m3) costs an average of 2000 rubles / m3. And a cube of material PPS16 (not less than 16 kg / m3) is almost 3,000 rubles / m3! But it is not so easy for the customer to distinguish them visually and tactilely.

That is why buyers who are chasing a low price often bring to the facility SIP panels with PPS10 or PPS11 expanded polystyrene with a density of 10 and 11 kg / m3, respectively.

The Ilya-Stroy company decided to be transparent in the issue of the used expanded polystyrene, offering customers 2 prices for SIP panels with PPS14 and PPS16

- The standard version is PPS14 (according to the old GOST PSB-S25) - the density of the insulation is 14 kg / m3. With flame retardants that block self-combustion of the material. The optimal combination of price and physical properties.

- The premium option is PPS16 (according to the old GOST PSB-S25F) - the density of the insulation is from 16 kg / m3. With flame retardants that block self-combustion of the material.

Thermal conductivity of PPS14 - no more than 0.038 W / (m * K).And the thermal conductivity of PPS16 is 0.036 W / (m * K). The difference is only 0.002 W / (m * K). That is why we offer PPS14 as a standard version at a more affordable price. And we make PPS16 to order.

Be careful: unfortunately, many estimates indicate PPS16 (PSB-S25F), but in fact, panels with "lightweight" expanded polystyrene come to the object. Don't skimp on the walls of your future home! Unfortunately, customers don't feel the trick when they meet a suspiciously low price. They tend to believe in luck: "I was lucky, I found a profitable option", "Such a deception will definitely not happen to me." Etc.

The correct foam in SIP panels must contain "Fire retardants"

Choose only PSB-S type expanded polystyrene (self-extinguishing). In the composition of such material - special fire-fighting additives - fire retardants, which block the independent combustion of foam without direct contact with the fire source.

In cheap SIP panels, polystyrene without fire retardants can be used.

It is not recommended to use SIP panels with expanded polystyrene for baths and saunas

The maximum operating temperature of expanded polystyrene is +80 ° C, therefore, this insulation is not recommended for thermal insulation of saunas and baths.

International audits of environmental friendliness of expanded polystyrene

The International Building Code (IRC) classifies expanded polystyrene as one of the most energy efficient and environmentally friendly insulation materials.

The British BRE * rating assigns the highest environmental class A + to expanded polystyrene.

ECOPSE, the French Association of Expanded Polystyrene Producers, encourages manufacturers to improve production technologies by introducing a green label - Uni'vert PSE. The label "Uni 'vert PSE" is awarded based on the results of an eco-audit, subject to the candidate's compliance with strict requirements, every year French manufacturers successfully pass this audit, confirming the safety of expanded polystyrene products.

For what purposes, which is better to use?

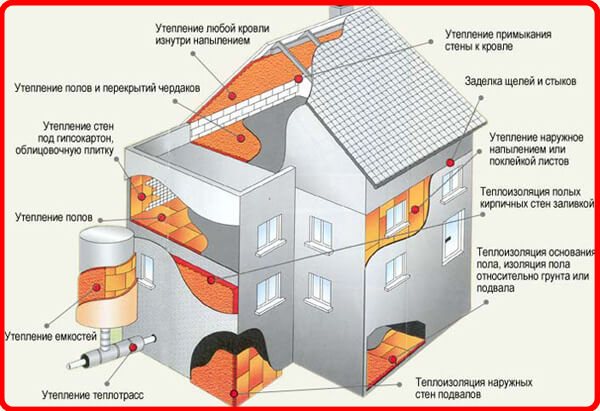

PPU and PPP have their advantages over each other, for this reason, in some conditions, it is preferable to use one or another version of the insulation. For example, it is better to use PPU, if there are such tasks:

- it is necessary to create an effective wind protection;

- you need to implement the requirement of high adhesion;

- creation of a seamless heat-insulating structure;

- short terms of installation.

When polyurethane foam and expanded polystyrene are considered, the comparison is made not only in terms of parameters, it is also necessary to take into account the operating conditions. For example, if it is planned to use PPS, it is necessary to provide high-quality moisture protection, which is facilitated by film materials. Expanded polystyrene and analogs similar in structure (polystyrene) need to create conditions in which the risk of fire will be small.

Installation features

The installation method is exactly what distinguishes polystyrene foam in panels from polyurethane foam. PPU is most often sprayed in the form of a monolithic coating that does not have joints and does not require serious preparation. Check out If you follow the PU foam spraying technology, insulation with this material does not take much time, since there are no additional installation work.

Pro Tip There are two main types of exterior wall cladding with polyurethane foam insulation - siding and plaster. Each method has its own subtleties of applying polyurethane foam, which are important to know in advance for the correct preparation of surfaces and subsequent finishing.

A couple of reviews about EPS

Leonid, 35 years old, Omsk: I used expanded polystyrene for wall insulation in a dacha. The house is small, it is heated in winter, so there were no problems with the appearance of moisture inside the heat-insulating "pie". I carry out repairs every 5-7 years, which means that the insulation during this time will not have time to sink and lose its qualities.

Vitaly, 45 years old, g.Khabarovsk: Expanded polystyrene does not make the structure heavier, retains heat well, so I chose this material. I heard that it is flammable, but the house uses a minimum amount of fire hazardous coatings, mostly concrete, brick, plastic, metal everywhere.

What it is? About production. Manufacturers. Advantages and disadvantages. Application.

Extruded polystyrene foam is a dense, smooth on the outside heat-insulating material, most often orange in color, has gained immense popularity among construction companies and the population, without exaggeration.

Extruded polystyrene foam was developed in the fifties of the twentieth century American. Since its inception, extruded polystyrene foam has spread throughout the planet. Except for the thermal insulation of roofs, foundations, plinths, walls, it is impossible to list all areas of human activity, wherever this high-tech modern bright material is used.

The production process of extruded polystyrene foam is an extrusion process. More precisely, this is the foaming of polymer compositions during the extrusion process. The resulting material is pressed through a specially created high-strength mold, resulting in a strong and reliable sheet of a given thickness and dimensions. Its thermal insulation properties are unique.

The characteristics of extruded polystyrene foam are not the same, and depend on its manufacturer. Here are the main Russian brands:

- Penoplex

- Technoplex

- TechnoNIKOL (XPS Carbon family)

- Ursa

- RavaTherm

- Polispen

Description of PPU properties

In the section Polyurethane foam description, characteristics, we have already described the PU foam in brief. PPU in everyday life is foam rubber, rigid construction marks are used in the insulation of walls, foundations, floors, roofs, balconies.

Save up to 50% on heating

There are two ways to install PPU: sheets and spraying. Better insulation is created by spraying using GRACO high-pressure equipment. Ours uses just such equipment.

The main advantages of polyurethane foam

- thermal conductivity of polyurethane foam 0.02 - 0.03 is lower than that of polystyrene, and 2 times lower than that of mineral wool;

- high moisture resistance, practically does not absorb water;

- PPU use temperature from -70 to +110 degrees;

- the official service life is more than 30 years, cases are known - 60 years, this is 5 times more than that of expanded polystyrene and mineral wool;

- during operation there is no deformation, subsidence;

- he is not afraid of mold and mildew;

- good sound insulation;

- Continuous seamless coating and foam-filled crevices, thanks to the spraying of finely dispersed foam;

- there is no condensation, which means there is no mold;

- good adhesion to any surface;

- there are no installation costs due to the lack of vapor barrier, wind protection, counter-rails, you immediately buy the installation and the insulation itself;

- low load on structures due to low weight;

- flexibility and elasticity under stress;

- the fastest installation in comparison with other heaters and no waste

- our prices include the cost of installation and material. What everyday problems of people the PPU solves, see here.

Disadvantages of polyurethane foam

- higher price, this disadvantage is compensated by savings of up to 50% on heating and cooling of premises, there are no drafts on the floor;

- need protection from the sun, polyurethane foam must be covered with paint or decorative coating, for example, siding.