Owners of private country houses, at any given opportunity, do not refuse to build their own baths. The presence of a full-fledged bathroom usually does not affect this decision in any way - you must admit that you cannot even closely compare the usual washing in a bath or shower stall with a full-fledged, one might say, ritual of taking bath procedures in a real steam room. The process of equipping an individual bath in our time is significantly simplified by the fact that a fairly wide range of stoves, heaters, necessary for this purpose, are on sale.

Gas ovens for a bath

However, when choosing a heating unit, sometimes the owners begin to doubt which principle of operation of the furnace will be optimal. Of course, many believe that only firewood should be used for a bath. However, wood-burning stoves are not quite convenient in operation, since they require constant monitoring of combustion and replenishment of the fuel bookmark. Solid fuel stocks must be provided with a place and the required storage conditions, and not in all regions of Russia, firewood can be attributed to publicly available materials. Electricity? - Yes, it is very convenient, but the cost of such an energy source simply scares away many.

Well, gas stoves for a bath can be an excellent alternative. And there is no need to be afraid that gas is not able to create a real "bath atmosphere". The design of modern gas bath stoves is such that it provides the required level of operational safety, fast, complete, uniform, and, importantly, easy-to-control heating of the steam room to the level required by the owner.

What are the advantages of using gas sauna stoves?

Compared to their wood-burning "brethren", gas bath stoves differ in a number of significant advantages:

- Almost all models have a thermostatic control system. And this means that there is no need to be distracted by maintaining the required temperature in the process of adopting bath procedures - to put firewood, change the position of the blowing window, etc. It is enough to set the required heating level in the steam room in advance - everything else will be taken over by the automatic control system.

The thermostatic control system for gas burners allows you to set the desired temperature - and no longer be distracted by this matter while taking bath procedures

- Modern gas ovens are extremely easy to operate. They are equipped with all the necessary levels of control and safety.

- Wood stoves have to be cleaned of accumulated ash literally after each kindling. There is no such problem in gas installations. Prevention is certainly necessary, but its frequency, as a rule, does not exceed twice a year. By the way, this also applies to the chimney for a bath - solid combustion products in smoke from wood - incomparably more than when burning gas.

- When using natural gas network, no questions arise with the organization of fuel storage, with its delivery to the bathhouse. It is enough to turn on the tap and the stove can be ignited. If LPG is used in cylinders, then this is a little more complicated. But for cylinders, too, you can once organize a compact gearbox near the outer wall of the bath, stretch the hoses on an ongoing basis, and in the future not experience any serious problems.

If you plan to use bottled gas, then you can mount a special cabinet near the wall of the bath.

- In terms of the heating rate of a steam room, gas ovens are in no way inferior to wood-burning or electric ones, but at the same time their operation will be much cheaper, due to the quite affordable cost of "blue fuel".

- Modern models of gas bath stoves are distinguished by enviable durability, and the manufacturer gives them a very good factory warranty.

- Many models of gas stoves for a bath have already been given an appropriate appearance in advance, which does not require any modifications. However, there are those that require mandatory bricking or complete closure with a heater on all sides.

- It is also important for traditionally cramped bathing conditions that gas stoves are usually compact.

Gas oven prices

gas oven

Brick cladding technology for a metal furnace

To close the sauna stove with a brick screen or even completely lay it in a similar "case" is a quite feasible task for independent execution. A special article of our portal will tell the reader more about this - "How to brick an iron stove with your own hands".

Essential disadvantage there is only one such stove. As with any other gas equipment, they require the approval of the installation by the appropriate organization and the connection of the main line. This means that you will have to order the preparation of the project, and then deal with its approval by the authorities, which is always accompanied by the loss of time, nerves, and additional material costs. But the advantages of gas ovens still outweigh this "minus".

Furnace gases

Furnace gases are removed into a pipe with a spark arrestor.

| Rotating installation diagram. |

Furnace gases, cooled in the hot chamber to a temperature of 250 - 300 C, are sucked in by the fan 5 through the pipeline 8 and pumped into the cold chamber 3 - the space under the grate.

Furnace gases from apparatus to apparatus in contact ci are moved by means of a compressor. Harmful impurities, no effect

Furnace gases also always contain finely dispersed dust, the amount of which / varies within wide limits - from 5 to 1010 g / nm.

| Basic conditions and indicators of the furnace (average data. |

Furnace gases have similar compositions, and the phosphorus content in the boiler milk for the test coke is slightly increased (Table 6), probably due to the lower temperature of the gases leaving the furnace.

Furnace gases after the second stage of phosphorus condensation are sent (after purification) as fuel for production needs. Due to the lack of data on fine cleaning of furnace gases from traces of phosphorus, their use as raw materials for various syntheses is not yet envisaged.

Furnace gases are treated with carbon to recover sulfur from the gases. In the charge, in the amount of 10 - 12%, coke is given in lumps of 10 - 15 mm in size. The presence of such coke leads to an increase in the surface area and an increase in the interaction of sulfur-containing gases with carbon. Higher sulfides: pyrite FeS2, chalcopyrite CuFeS2, covellite CuS, bornite Cu5FeS4 dissociate to form lower sulfides and vaporous sulfur. Subsequently, sulfides are oxidized to form oxides and sulfur dioxide.

| Jet condenser. |

Furnace gases are cooled in a jet condenser (Fig. 124), in which up to 80% of zinc vapor is condensed. Then the gases are washed in a scrubber, where the pusiera is deposited. The purified gas is used as fuel for heating the initial charge in the tube furnace.

Furnace gases containing 4 - 5% Zn, with a temperature of 950 - 1000 C, are sent to condensers (one or two), directly adjacent to the long sides of a rectangular shaft furnace. Condensers are equipped with rotary stirrers immersed in a bath of molten lead, which removes heat from gases and serves as an absorber of zinc vapors.

| Diagram of a solid waste thermal neutralization unit. |

Furnace gases enter the afterburner, where they are rendered harmless at temperatures above 800 C in the burner flame.

Furnace gases are cleaned of hydrogen chloride, chlorine and fumes. The degree of gas cleaning is determined by gas analyzes before and after gas cleaning.

The basic device of a gas bath stove

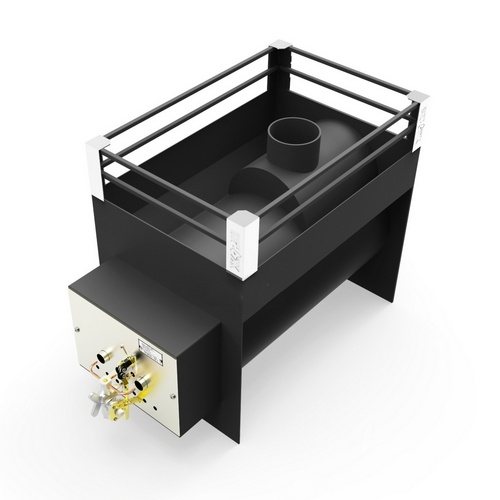

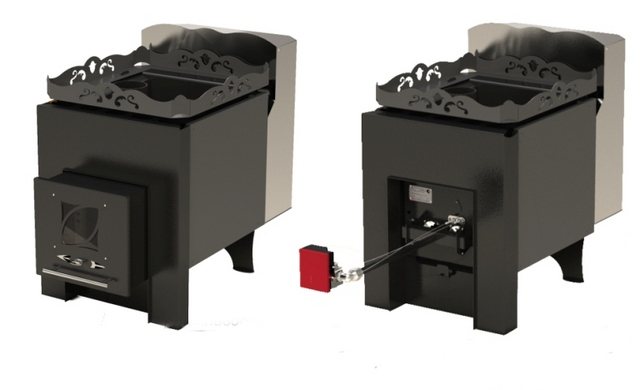

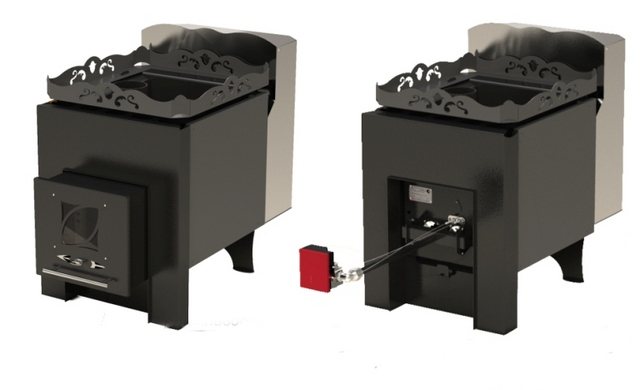

In this regard, there is nothing particularly unusual. Moreover, many models are almost a complete copy of wood-burning stoves, with the only difference being that instead of a window with a door for loading firewood, they have a special panel with a gas burner mounted on it. Some stoves are generally universal - you can purchase for them both a firebox for using firewood, and a unit with a gas burner and a remote control system.

The sauna stove P-2GT, at the request of the consumer, can be equipped with a gas block and / or a fuel receiver for firewood ...

... and, depending on the installed module, becomes either solid fuel or gas

However, there are also completely unique designs of gas baths, one of which will be discussed below.

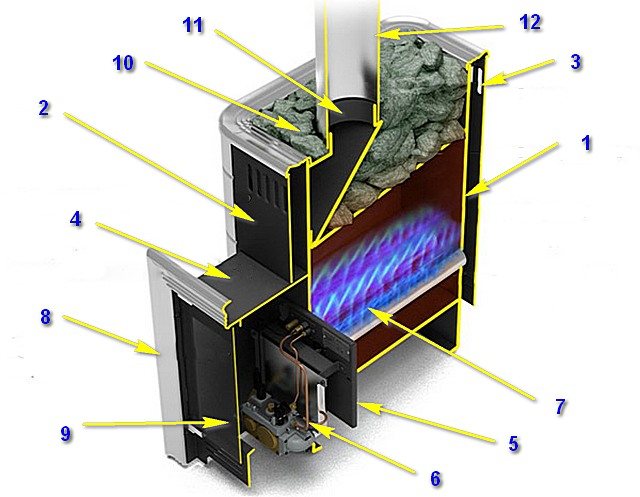

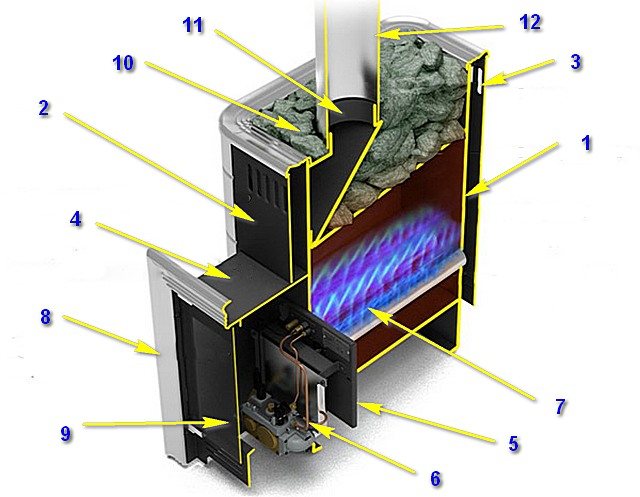

Let's take a look at a typical design of a gas sauna stove using the popular Termofor Urengoy model as an example:

Schematic diagram of a typical gas oven for a bath

The main unit, where, in fact, heat is generated, is the firebox or combustion chamber (pos. 1). Its walls are most often made of high-strength alloy steel with a thickness of at least 4 ÷ 5 mm, which ensures the duration of trouble-free operation of the device.

The outer casing (item 2), also steel, but already with metal about 3 mm thick, is separated from the furnace body by an air gap. Since the air is completely open from below, and there are special slot-like or round windows (item 3) along the perimeter above, this design becomes a very powerful convector, which, due to the directed flows of hot air, provides the fastest possible heating of the entire volume of the steam room.

Find out how to make do-it-yourself sauna stoves with step-by-step instructions from a new article on our portal.

Prices for TMF sauna stoves

Sauna stove TMF

On the side facing the dressing room, the stove usually has an elongated fuel channel (item 4), which allows the loading window and, accordingly, the gas equipment to be removed from the steam room through the wall.

A panel (item 5) is mounted inside the fuel channel, covering it and serving as a basis for attaching the gas block (item 6) from the outside and gas burners (item 7) from the inside.

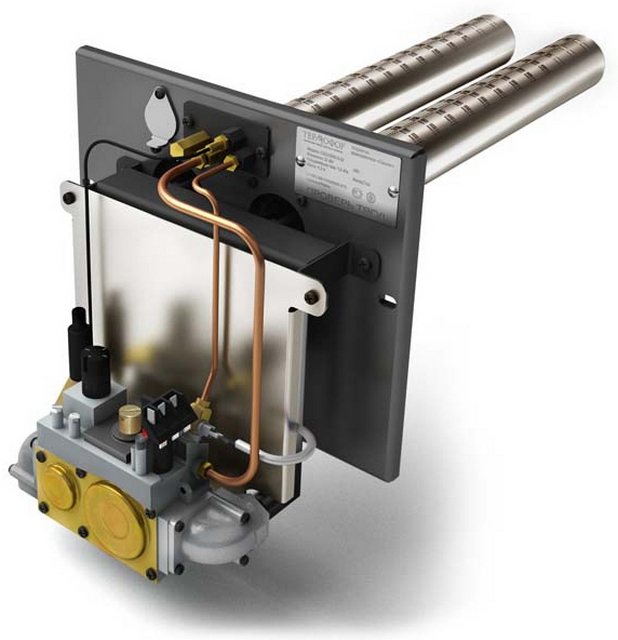

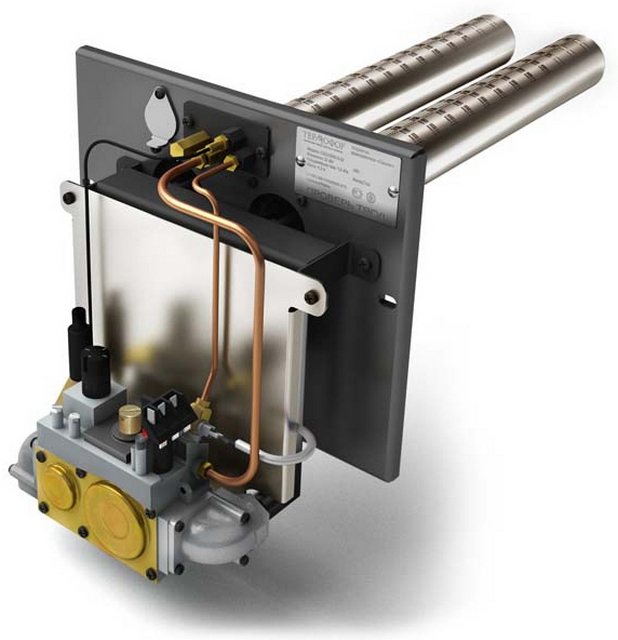

Different models of stoves can assume the installation of different types of gas burners. In this case, the Sakhalin kit with two burners was used.

Domestic gas burner "Sakhalin" based on the famous Italian automatic system. Equipped with an automation unit (can be completely non-volatile), a built-in gearbox, an automatic piezo ignition system.

Burners can differ in terms of the generated heat output, that is, if the internal dimensions of the furnace allow, it is possible to vary this parameter by choosing the appropriate gas block.

So that the gas equipment does not disharmonize with the decoration of the dressing room or the rest room, the window of the fuel channel is framed around the perimeter with a decorative metal trim (pos.

Naturally, any sauna stove requires a heater. The compartment for laying out stones can be located on top, as in the shown model (pos. 10), along the front or side walls, and sometimes even almost completely cover the entire furnace body.

Prices for popular gas ovens

The stove "Siberian cliff", the heater of which covers the entire body of the device and is held in place by a forged grate. A wood-burning option is shown, but the installation of a gas block is not excluded.

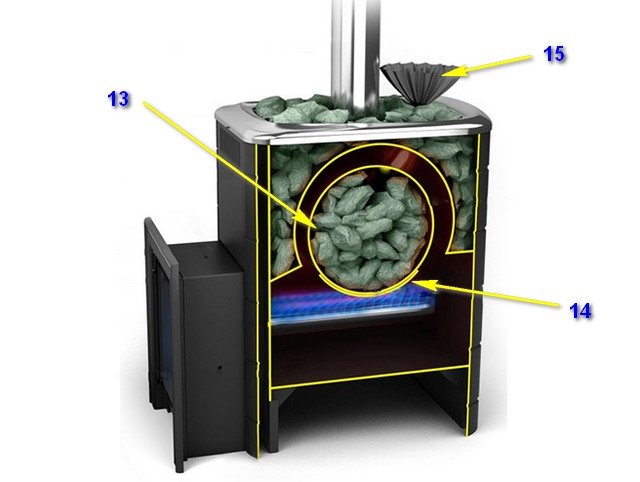

In addition, some types of sauna stoves presuppose the presence of two stoves - an open one and a closed one, to which a channel for pouring water leads for the purpose of a special mode of steam generation.

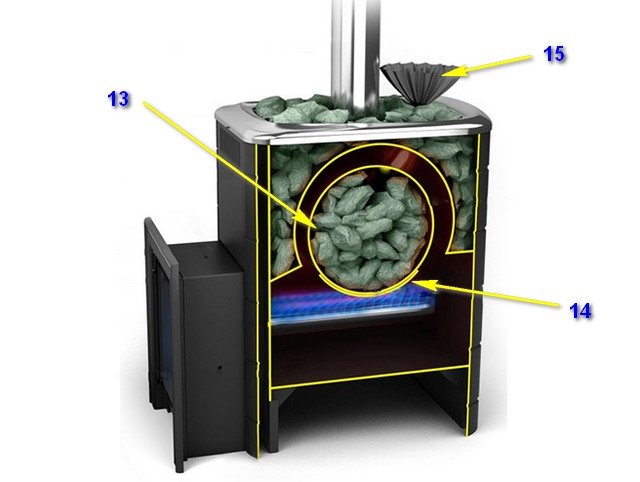

A feature of the gas bath stove "Termofor Taimyr INOX" is the presence of a second, internal heater

The illustration shows a similar model of the stove, but already equipped, in addition to an external one, also with an internal heater (pos. 13). This compartment is in direct contact with the burner flame, therefore it is additionally protected from below by a shield (pos. 14). To create a specific steam generation, closer to the traditional Russian bath, a funnel with a tube (pos. 15) is provided, leading directly to the internal stone laying.

By the way, stones, as a rule, are not included in the oven kit and are purchased separately. The model's passport data usually indicates the required amount of minerals for laying. When choosing stones, a certain amount of caution should be exercised - just boulders picked up on the street may turn out to be unsafe for health - no one except a specialist can predict their exact chemical composition, and how they will behave during high-temperature heating. Therefore, it will be optimal to purchase special minerals - they are sold in stores of bath accessories and equipment. This, for example, can be jadeite, talcochlorite, gabbro-diabase and other stones. However, this is already a topic for a separate conversation.

Like any stove, the sauna heater has a branch pipe for connecting a chimney of a certain diameter (pos. 11). And the initial, necessarily single-walled section of the pipe (pos. 12), is often used to install a tank for heating water.

To heat the water, a tank is used, installed at the initial section of the chimney.

However, the options for heating water may be different. For example, the tank can be hung on the side or rear stack of the oven (if it is not made according to the convection scheme).

Sauna stove "Ermak Lux": three walls are made as convectors to provide air heating, and the fourth one is used for direct heat exchange with a suspended water tank

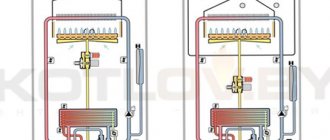

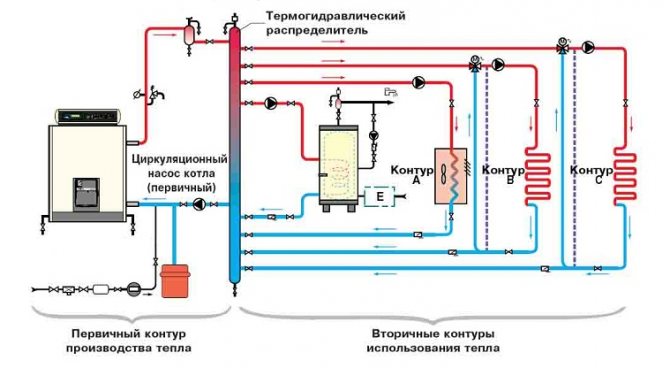

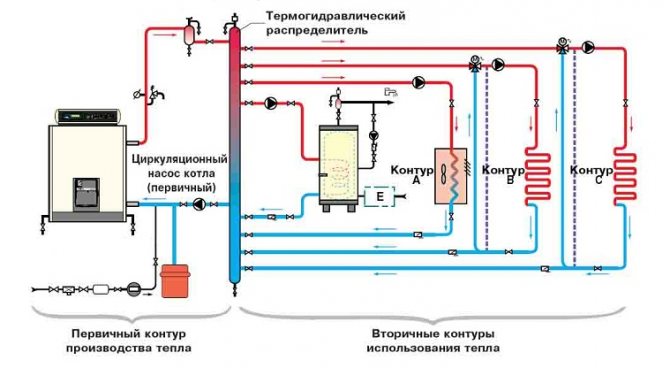

A fundamentally different option is also used. In some models of stoves, a heat exchanger is placed in the fuel combustion zone, which is connected by pipes to a water tank located in the washing compartment.

This is also one of the modifications of the Ermak sauna stoves, but already with a heat exchanger installed inside for heating water

Due to the temperature difference at the inlet and outlet of the heat exchanger, natural circulation is created, and there is always a supply of hot water in the remote tank.

Prices for the oven "Ermak plus"

oven yermak plus

One of the options for organizing water heating for bathing needs is using an internal heat exchanger, a remote tank and the organization of natural circulation

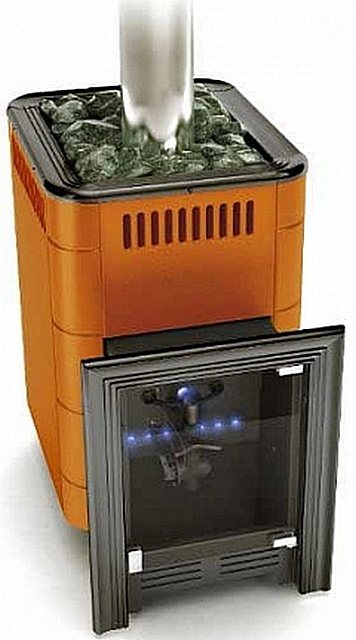

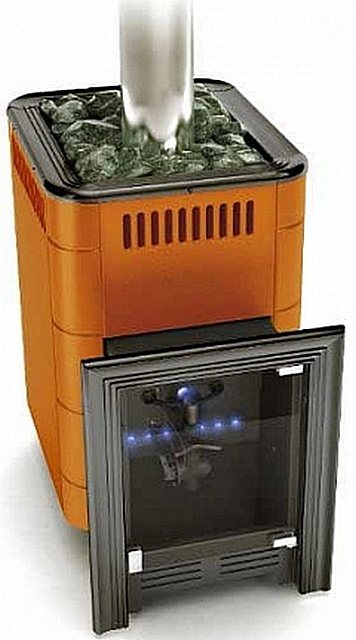

The furnace body can be finished in different ways. Usually this is a metal surface covered with heat-resistant paint, more often black, but sometimes it can also be of various shades, so you can choose a steam room for the overall design.

Stoves are not only black - some models are also given more "fun" shades

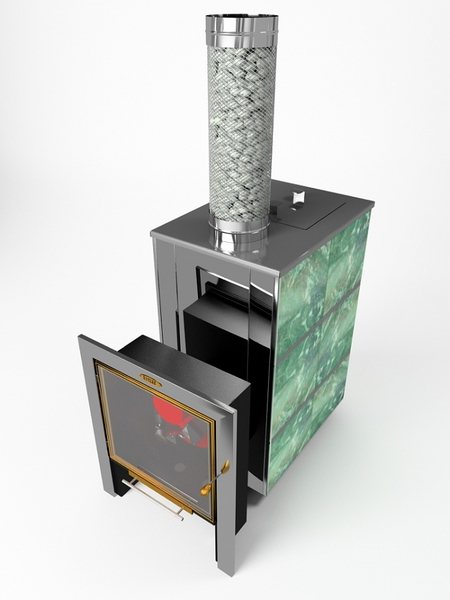

Some stoves are additionally lined with polished natural stone with a beautiful texture. Often, buyers are offered an interesting option - they themselves can order the external finish of the purchased device. Expensive, of course, but worth it.

Gas sauna stove "KUTKIN" with exclusive finishing with natural stone

However, there are also completely “budgetary options, which, in principle, do not provide for any factory finishing at all. A striking example of this is the line of gas ovens of the Zhara brand. Some have the most common cylindrical horizontally located body made of a section of thick-cut pipe, plugged on one side, and on the other there is a rectangular elongated fuel channel in which a gas burner is mounted. A steel grate is welded to the top of the body along the perimeter, which forms a basket for laying stones.

Despite, perhaps, a somewhat rustic appearance, gas ovens "Heat" are fully capable of coping with their direct task

Unassuming, at first glance, appearance does not at all mean low quality. The stove is equipped with a very decent thermostatically controlled burner, but the brick finish, which we have already talked about above, can be done by every owner according to his own understanding.

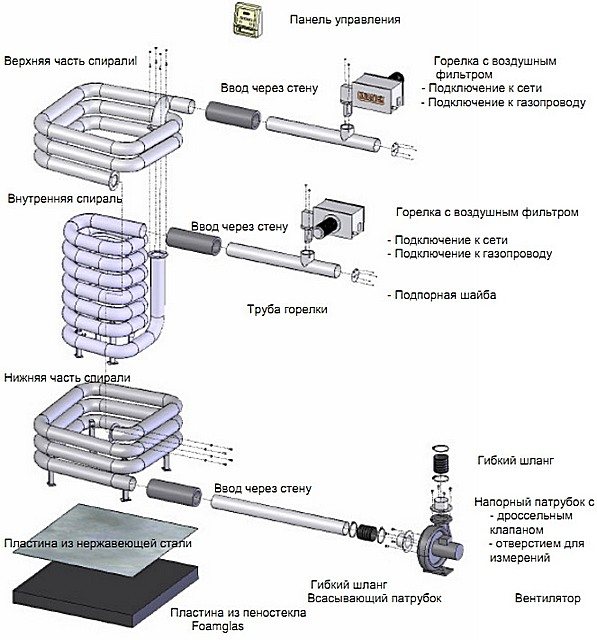

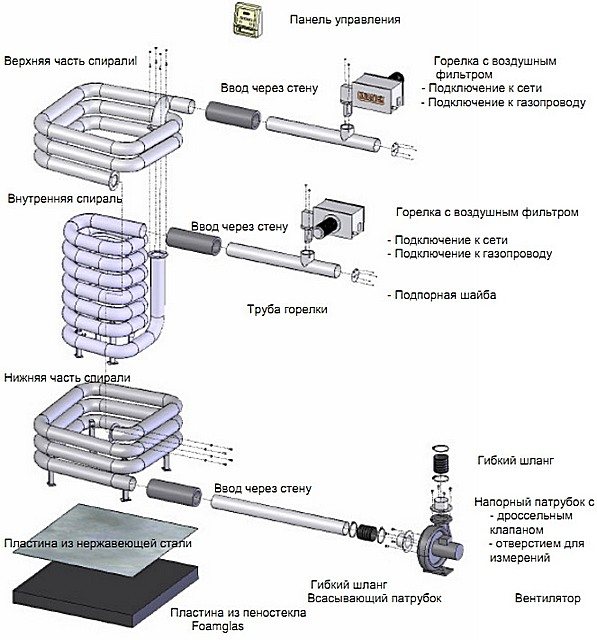

And the bath gas stoves have a completely unusual design. They are a set of specially arranged, spiral-wound alloy steel pipelines through which air is pumped and gas combustion products are removed.

Unlike any other, the design of the Kusatherm gas bath stoves

There may even be several gas burners in such furnaces, as well as individual pipe circuits nested inside one another like a "nesting doll", and the furnace power in the largest models reaches 90 kW! And the "smallest" oven of this type in the line has a power of 10 kW

One of the smallest in its line of gas oven "Kusatherm" after installation (left) and after erection of brick screens

It is clear that such a stove is not left in the "naked" form in the steam room - it must be covered with bricks or covered with some kind of screens. A basket for the heater is provided on top. The stove is distinguished by its high performance, but, unfortunately, the price is too frightening for our consumers, which is even scary to mention.

Which heating method is more appropriate for the home

To begin with, it is advisable to ask for advice from the sellers of stores specializing in gas ovens for home heating, or to study specials. literature. Own houses and summer cottages must be fully heated, because when the weather is cold, there is no comfort without heat. Gas ovens require a special fuel - gas. These systems represent the connections of the chimneys, the body, which stands on the foundation. Usually they have a brick body. This system has components: a heating shield, a fuel combustion chamber (firebox) and a gas burner.

If there is no traditional heating, it is better to place the gas stove inside the building if the number of storeys does not exceed a two-story house. If the building is heated by a gas-fired stove, the mode of its operation can be both permanent and temporary.

Heating scheme with a stove

What to look for when choosing a gas oven for a bath

If it is decided to purchase a gas stove for a bath, you need to focus on several basic selection criteria. And the main, of course, will be the required thermal power.

How to determine the power of a gas bath stove

According to its characteristics, the stove must be able to cope with its direct task - to create and maintain the required temperature in the steam room. That is, we are talking about the thermal power of the purchased unit.

It is usually assumed that one cubic meter of steam room volume requires about one kilowatt of furnace power, regardless of the type of fuel used. It would seem that everything is simple: multiply the linear dimensions of the room by height, length and width - and the desired value is "in your pocket." However, this issue has its own nuances.

This approach justifies itself only if the steam room has a full-fledged, made according to all the rules and on the basis of thermal engineering calculations, thermal insulation, including with the recommended reflective vapor-proof material such as penofol. Then the natural wood lining does not require additional heat.

Warming the steam room is a task of special responsibility!

High-quality thermal insulation of this room is necessary for obvious reasons - it is necessary to maintain a high temperature there, without leading to a senseless excessive consumption of fuel or electricity.In addition, the thermal insulation must be able to withstand the “head” of a high concentration of water vapor. Optimal solution: application foil heaters for a bath - read about it in a special article on our portal.

But in practice, there are sections in the steam room, and sometimes very significant ones, which become "gaps" in the thermal insulation. They must also be taken into account by making the appropriate amendments.

- If there is a window in the steam room, then in any case it contributes to the loss of heat. In this case, it is necessary to add 3 kW (or 3 m³ to the volume of the room, as it is convenient for someone) for each m² of the window, if it has one glass, and 1.5 kW, if the window is with double glazing or double-glazed windows.

The presence of a window in the steam room obliges to increase the power of the sauna stove.

- Brick (stone) sections of the walls, or surfaces tiled with ceramic tiles, have a high heat capacity, and an additional 1.2 kW is added for each m2 of such a section.

- Log walls (or timber walls) have a very high heat capacity, but in order to create and maintain the desired microclimate in the bath, they must be warmed up. If the bathhouse in the log house does not have an internal thermal insulation sheathing, then the conditional volume of the steam room (that is, the power of the furnace) should be increased by one and a half times.

The log walls of the steam room will require a very significant amount of heat to fully warm up

- An uninsulated door (a thin wooden board or even a newfangled glass door) will require an additional 1.5 kW.

- When the fuel window is located in an adjacent room, heat losses through this "bridge" are inevitable as well. Therefore, it is necessary to make an amendment for this circumstance, of the order of an additional 10 percent.

Whether we like it or not, the fuel window of the stove taken out into the next room (in the waiting room) is also a very "effective bridge" of the heat generated by the device.

In total, a very significant increase in volume can be accumulated. And, when choosing a stove, it is recommended to consider such models so that the calculated total value is approximately in the middle of the power range (or steam room volume) indicated in their passport.

And one more nuance: the furnace model can be one, but it can be equipped with burners of different power - this is also worth paying attention to.

Prices for sauna stoves Ermak

Sauna stove Ermak Uralochka

To make it easier for the reader to carry out the necessary calculations, below is an online calculator for calculating the required power of a gas oven for a bath.

Calculator for calculating the power of a gas stove

Go to calculations

Other criteria for choosing a gas oven

- Steam rooms, as a rule, do not differ in a large area. And in order not to reduce the already cramped space, it is worth choosing a stove of commensurate dimensions so that its presence does not hinder the free movement of people.

- The best option would be a furnace with an elongated, remote fuel channel. That is, all control actions will not be carried out in the steam room, gas equipment will not “steal” space, and the safety of operating the stove and taking bath procedures will increase dramatically. Most modern models have just such a layout.

- In the passports of many models, the approximate gas consumption is indicated. Of course, the lower it is, the better, the more efficient the device works, that is, the higher its efficiency.

- Be sure to focus on what type of gas is acceptable for the stove to work. The fact is that some gas burners with which the furnaces are equipped are designed exclusively for natural network gas, while others allow the reducer to be reconfigured and the nozzles are changed for a liquefied balloon one. Do not lose sight of this so as not to get into an unpleasant situation.

- As already mentioned, many stoves are versatile - they can also work on wood when changing the fuel block. This can be beneficial in the case when gas has not yet been supplied to the house, but in the near future such a possibility is seen.So that the bath does not stand idle, and in order to prevent unnecessary costs, such a model will become just a godsend - over time, it will be possible to simply install a gas burner instead of the loading window.

- You should probably think over the question of how the water will be heated in the bath in advance, and purchase the appropriate tank that is suitable for the selected model. Well, if you want to save space in the steam room as much as possible, then it is better to take the container to the washing room, and for the steam room to buy, with a little extra payment, a modification of the stove with a built-in heat exchanger.

- It is imperative that you carefully check all the documentation of the purchased stove - the store manager is obliged, upon request, to present certificates of quality and safety, the factory passport of the product with marks on the passage of technical control. If there is some confusion with the documents, or there are none at all, then you should refrain from buying.

- It will never be superfluous to thoroughly examine the device for external damage. Anything can happen during transportation, loading and unloading - but you need a high-quality stove!

- It is important - as a rule, stoves are not equipped with a stone insert, but the passport always says how many stones the baskets are designed for. These are not empty numbers, since the nameplate capacity of the furnace is designed specifically for the specified amount of minerals. And it's not recommended to make your own adjustments to this issue.

- You should not rush to cheap models of completely unfamiliar brands. There are cases that such accessibility is achieved by completely unacceptable economy of unscrupulous manufacturers on high-quality materials. This will then necessarily affect the operation of the device, and in the worst case, the safety of operation.

Prices for the oven "Ermak Uralochka"

Ermak uralochka

It is best to purchase gas ovens from trusted, trusted manufacturers. By the way, this is exactly the case when there is no need to chase imported equipment. Russian companies produce excellent gas ovens - these are the above-mentioned Teplodar, KUTKIN, Ermak more than once. Many of them use components for gas automatics from leading world brands.

European-made gas ovens are also very good, but their cost is usually significantly higher than domestic ones, with, in fact, equal characteristics and functionality.

How to choose a gas stove for your home

The recommendations of professionals will help you choose a high-quality unit for keeping warm in the house.

What to look for:

- Power. The temperature indicator in the house depends on this parameter. The power of the burner, the heated area, the number of windows, doors, wall thickness, and the integrity of the roof are taken into account.

- Equipment. Manufacturers equip systems with adapters, which allows the unit to be connected to multiple fuel sources. But this design is suitable for houses no more than 2 floors in height, otherwise the efficiency of the system decreases.

- Method of generating heat. Furnaces with burners show higher productivity than catalytic ones. The latter are recommended to be installed in houses with a small area, the power of the catalytic furnace is not more than 4.9 kW.

- Burner type. The simplest is a single-stage burner, independent of the power supply, with automatic switching on and off of the device. Two-stage burner - a device operating in 2 modes, makes it possible to save up to 40% of the nominal value. This means that while there are no people in the house, the stove will operate in reduced mode, saving fuel. A continuously adjustable burner is expensive, but it allows you to quickly change the heat supply mode.

- Air supply to the furnace. The atmospheric ventilation of the combustion chamber differs, in which air is supplied in natural mode, the efficiency is 90%. And there can be an inflatable system, where air is forced, the efficiency is 95%.

- Fuel combustion chamber type. A gas stove with an open combustion chamber takes air from the room, but the exhaust gases also go into the room.The stoves are mobile, comfortable, but require good ventilation of the room. A closed chamber is a more practical option in which a chimney is equipped. Furnaces do not burn oxygen, so they are better suited for permanent homes.

If the gas stove in the house is equipped with an additional sensor that detects the level of carbon dioxide, the device will automatically turn off when the dangerous level is exceeded - this is very convenient when there are children in the family. It is strictly forbidden to purchase units that are not intended for installation in residential premises. Before purchasing, you need to request documents for the device, carefully read the instructions from the manufacturer.

A brief overview of popular models of gas stoves for a bath

In order to somewhat expand the information received by the reader, it makes sense to give a brief overview of models of gas bath stoves that are in wide demand among the Russian consumer.

| Model name, illustration | Brief description of the model | Estimated price (summer 2020) |

| Furnace "P-20GT"

| The stove is a typical representative of universal gas-wood-burning appliances for a bath. At the request of the consumer, it is completed with a fuel receiver, or a gas burner of the GGU-20 Spectrum or UGOP-22 type. The gas block can be converted to run on liquefied natural gas (LNG). The heating capacity of the stove is 20 kW - designed for a steam room up to 22 m³. The efficiency when working on gas is 85%. The chimney diameter is 112 mm. Furnace dimensions: 535 (W) × 1200 (D) × 800 (H) mm. Weight without stones - 85 kg. The volume of the stonework is 50 dm³. On request, it can be equipped with a hot water tank suspended on the rear wall. It is possible to purchase a model with a built-in heat exchanger "P-20PG / T". The thickness of the walls of the combustion chamber can vary - 5 or 8 mm. The walls are painted in two layers with black heat-resistant silicone paint. | With a 5 mm wall - 12,000 rubles; - 8 mm - 13 800 rubles. With built-in heat exchanger - 12 400 and 14 200 respectively. GSU Spectr 20 kW with Sigma 840 automation - 16,500 rubles. GSU "UGOP-P-22" - 4,000 rubles. |

| Zhara-Malyutkagaz

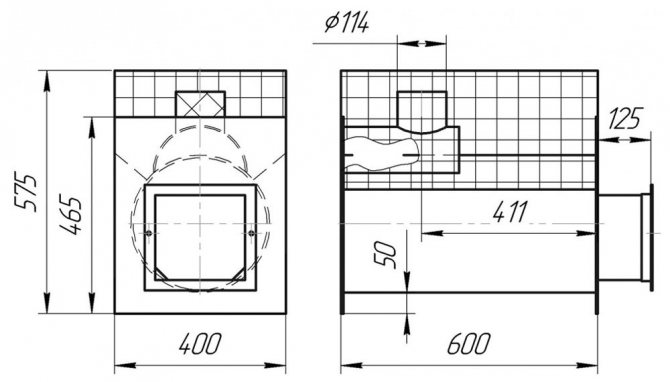

| One of the most compact gas-fired sauna stoves. The power of the GGU-16 gas burner, included in the kit, is 16 kW, and the furnace with it allows heating a steam room with a size of 4 to 12 m². Furnace dimensions - 400 (W) × 725 (D) × 575 (H) mm. The weight without a bookmark is 54 kg, and the weight of the stones to be stacked is 100 kg. Chimney diameter - 114 mm. The thickness of the firebox arch is 6 mm. The firebox can be taken out into the dressing room. At the request of the buyer, it can be equipped with water tanks with a volume of 50, 73 or 90 liters for a fee. | RUB 15,900 |

| "Termofor Urengoy Carbon"

| A popular gas sauna heater with a compact design. Designed for use in steam rooms with a volume of 6 to 12 m³. More suitable for maintaining a Finnish bath in the steam room. It is recommended to install a 26 kW Sakhalin-type gas burner device, although it is possible to use cheaper UGOP-P-22 type gas turbine units. The walls of the oven are arranged according to the convection principle. Material - structural steel. The external color can be given various shades. Furnace dimensions: 645 (L) × 450 (W) × 705 (H) mm with a weight without a bookmark of 44 kg. The weight of the stones to be laid is 30 kg. Chimney diameter - 115 mm. The fuel window is covered with heat-resistant glass that hides the gas burner equipment. | From 14,000 rubles. - depending on the modification. GSU Sakhalin 26 kW - from 13,000 rubles. |

| "Termofor Taimyr INOX"

| In many respects, it is structurally similar to the "Termofor Urengoy Carbon" model described above. Designed for steam rooms with a volume of 8 to 18 m³. The principal difference is the system of double preparation of steam, which includes external and internal heaters. Great for creating a classic Russian bath atmosphere - high relative humidity without overheating the steam room. A tube with a funnel leads to the opened stone bookmark, where water is poured for vaporization.Furnace dimensions: 645 (L) × 450 (W) × 860 (H) mm with a weight without a bookmark of 45.5 kg. | From 19,000 rubles. without GSU |

| "Ermak Uralochka-16"

| Universal gas-wood stove for a bath. In the gas version it is equipped with a UG SABK-TB-16 burner, which allows it to be used in steam rooms with a volume of 8 to 16 m³. Material - structural or stainless steel (in the modification "Uralochka-16N") 4 mm thick, and in the combustion chamber - 6 mm. Central location of the chimney. The removed fuel intake window, which allows you to place it in the dressing room. The buyer can choose from several additional options (for an appropriate payment): a hinged tank for heating water or a built-in heat exchanger, an additional grid for the heater along the stacks of the stove, a convector screen, a steam generator. Furnace dimensions: 550 (L) × 445 (W) × 730 (H) mm, the weight of the basic stone fill is 60 kg. | From 13 900 rub. complete with GSU |

| "KUTKIN Standard G-2.0"

| Quite expensive, compared to others, is a model of a sauna stove. A characteristic feature is a decorative external finish with natural stone - a choice of jadeite, serpentine, or soapstone. The material of the firebox and the body is stainless steel AISI 430. Operating modes - Russian, Finnish or Turkish bath. Recommended GSU - "OHG-2 Olympia" (South Korea). Central location of the chimney with a diameter of 115 mm. Hidden heater in the body, plus located along the chimney. Equipped with an economizer for the chimney is possible. Furnace dimensions: 620 (L) × 450 (W) × 900 (H) mm, weight - 60 kg. The mass of the stone bookmark is 80 ÷ 90 kg. | In the basic configuration, without gas equipment - from 43,000 rubles. |

| "RUS 18 LGDU" | Compact inexpensive gas stove for a bath. Thermal power - 16 kW, designed for steam room volume from 10 to 18 m³. Shortened fuel line, which does not always allow you to take it to the dressing room. When the gas burner is removed, the stove also works fine on solid fuels. Furnace dimensions: 588 (L) × 388 (W) × 816 (H) mm, weight - 49 kg. The mass of the stone bookmark is 90 kg. The chimney with a diameter of 115 mm, central location, usually a hot water tank is put on it (from 55 to 80 liters). If desired, a model with a built-in heat exchanger is purchased. | RUB 15,000 as standard (including gas burner) |

And at the end of the publication - a short video telling in more detail about the Termofor Taimyr INOX gas sauna heater

Prices for ovens "Termofor"

oven thermophor

Furnace features

Do-it-yourself heating and cooking stoves are very simple to build. They are represented by numerous modifications. Each of them performs two main tasks at once:

- Heats the room

- Serves for preparing hearty and tasty food

Depending on the area of the house, the stove can have different dimensions. The same can be said about the variant of the arrangement of the structure: wall-mounted, corner, island or built-in.

The principle of operation of such a seemingly complex structure is very simple:

- In the furnace, gases are formed in the form of smoke, which are in direct contact with the hob and give off their heat

- Heat is also transferred to the side oven

- Steam from the cooker and smoke are removed through vertical channels into the chimney, giving off heat to the room

The flue and heating ducts can be divided among themselves. In the summertime, this will make it possible to heat only the cooking and oven.

Introductory video review of a working stove

https://youtube.com/watch?v=yhh0BIsh_cI

For cooking in a summer cottage, a barbecue oven is also ideal, see the instructions for laying with your own hands

Composition - flue gas

The flue gas composition is calculated based on the combustion reactions of the fuel constituents.

The composition of flue gases is determined using special devices called gas analyzers. These are the main devices that determine the degree of perfection and efficiency of the combustion process, depending on the carbon dioxide content in the exhaust flue gases, the optimal value of which depends on the type of fuel, the type and quality of the combustion device.

The composition of the flue gases at steady state changes in the following way: the content of H2S and S02 is steadily decreasing, 32, CO2 and CO - change insignificantly / During layer-by-layer combustion of oxides, the upper layers of the catalyst are regenerated earlier than the lower ones.A gradual decrease in temperature is observed in the reaction youth, and oxygen appears in the flue gases at the outlet of the reactor.

| Schematic diagram of equipment piping during well development with the use of flue gases. |

The composition of flue gases is controlled by samples.

The composition of the flue gases varies along the length of the torch. It is not possible to take this change into account when calculating radiative heat transfer. Therefore, practical calculations of radiation heat transfer are based on the composition of the flue gases at the end of the chamber. This simplification is to a certain extent justified by the consideration that the combustion process usually proceeds intensively in the initial, not very large part of the chamber, and therefore most of the chamber is occupied by gases whose composition is close to its composition at the end of the chamber. At the end it almost always contains very few products of incomplete combustion.

The composition of the flue gas is determined not only by the water vapor content, but also by the content of other components.

The composition of the flue gases varies along the length of the torch. It is not possible to take this change into account when calculating radiative heat transfer. Therefore, practical calculations of radiation heat transfer are based on the composition of the flue gases at the end of the chamber. This simplification is to a certain extent justified by the consideration that the combustion process usually proceeds intensively in the initial, not very large part of the chamber, and therefore most of the chamber is occupied by gases whose composition is close to its composition at the end of the chamber. At the end it almost always contains very few products of incomplete combustion.

The flue gas composition is calculated based on the combustion reactions of the fuel constituents.

The composition of flue gases during complete combustion of gas from different fields differs slightly.

The composition of flue gases includes: 2 61 kg of СО2; 0 45 kg H2O; 7 34 kg of N2 and 3 81 kg of air per 1 kg of coal. At 870 C the volume of flue gases per 1 kg of coal is 45 m3, and at 16 C it is equal to 11 3 m3; the density of the flue gas mixture is equal to 0 318 kg / l3, which is 1 03 times higher than the density of air at the same temperature.

Calculations of the composition of flue gases, for example, Nazarov coal (SrCp0 8%) show that with such an amount of sulfur, the maximum possible yield of SO3 will be 75 mg / m3, which is equivalent to 90 mg / m3 of sulfuric acid. Similarly, the content of sulfuric anhydride can be estimated for other Kansk-Achinsk coals.

The regulation of the composition of flue gases by the content of free oxygen in them is as follows.

The flue gases of AVT furnaces contain nitrogen oxides, sulfur, oxides and carbon dioxide and products of incomplete combustion of fuel.

To determine the composition of flue gases, there are manual and automatic volumetric gas analyzers; manual ones are used for control measurements, and automatic ones are used for continuous gas analysis.

Alteration of the gas unit

Do-it-yourself wood-fired boilers can be made not only from scratch. In the vast expanses of the Internet, you can find not only diagrams of homemade boilers. If you still have an old gas boiler, do not throw it away or dispose of it.

From this, at first glance, scrap metal, you can make an excellent wood-burning boiler, which will heat both a small house and a garage of any size with high quality.

To do this, the boiler must be disassembled and all elements that must be connected to the gas system be removed from it. Further, it is worth referring to the diagram of a homemade boiler. There is nothing complicated in such a scheme. The converted gas boiler system looks like an old steam locomotive.

Such a boiler consists of a metal barrel that is filled with water. Pipes are laid inside the barrel and taken out. The heated air enters the heating system through these pipes. Air circulation is carried out in two ways: natural and forced. The use of forced air circulation in the garage heating system is irrelevant.Such heating schemes are suitable for two-story residential buildings. For a garage, it is quite enough to perform a simple heating system with natural circulation of the coolant inside the system.

The heating system itself and radiators are mounted to those pipes that extend from the water tank. To heat an ordinary garage, it is enough to equip the heating system with only two radiators of 4 sections. Given the fact that this room will be heated periodically, you should not use water as a heat carrier. The best option for such heating systems is air or antifreeze. Antifreeze is quite expensive, so it is better to stay on the organization of an air heating system.

As fuel in such boilers, you can use any solid fuel, the moisture content of which does not exceed 20%. The most common and inexpensive fuel is wood. At enterprises that are engaged in sawing wood, you can purchase trim boards or formwork at a low price. Thus, an old gas boiler can turn into a rather useful tool for heating a garage space.

Installation rules

The efficiency, reliability and durability of a gas oven directly depends on how responsibly its installation is performed. Naturally, it is most correct to trust such works to specialists. Most often, qualified installation services are offered by companies selling the corresponding equipment.

But in any case, you need to approach carefully and control the following installation steps:

- The walls in the steam room of the bath, where the gas stove will be installed, must be made of non-combustible materials, or this must be their finish. The distance between the wall and the stove should be at least 5 cm, such an air gap will create the safest possible mode of operation of the unit.

- The gas oven is installed on a refractory base, which must necessarily protrude beyond its dimensions (more than 10 cm around the entire perimeter).

- The size of the opening for the burner with a cover: width 51.5-66.5 cm, height 61.5-68 cm. Size of the opening without the cover: width 35-45 cm and height 47-55 cm.

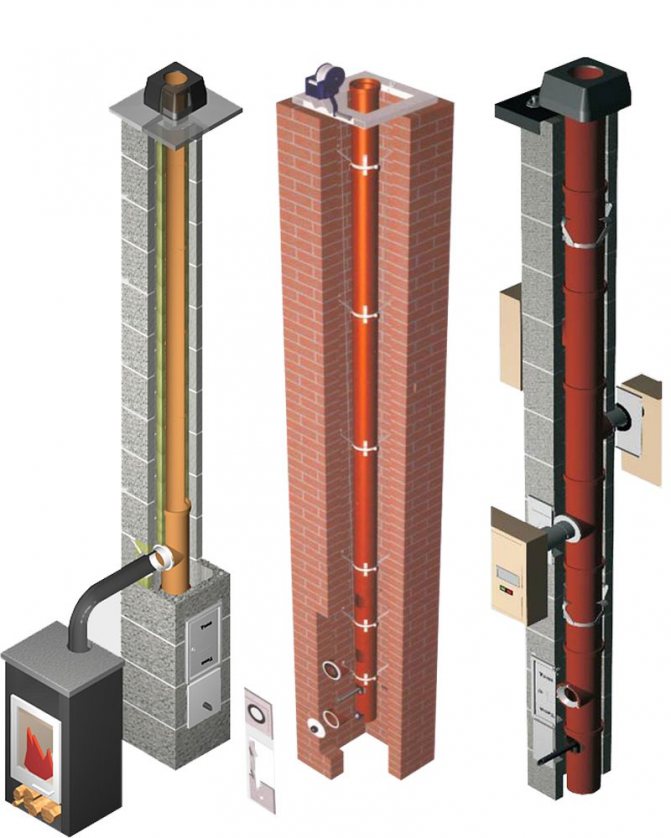

- Stainless steel pipes are used to connect to the chimney. They are mounted in the course of fuel combustion ("through smoke") and inserted into each other at half their own diameter. The height of the chimney from the burner level is at least 5 meters.

- It is necessary to install a gas oven so that its front part goes into the dressing room. It is advisable to make the opening 55-65 cm in height and 40-46 cm in width.

- The stove on the side of the steam room should not have holes that are not hermetically separated from the combustion chamber.

- The dressing room should be equipped with exhaust ventilation and a window with a vent for ventilation. All bath doors must open outward for safety reasons.

- The connection point of the gas oven to the chimney must be absolutely sealed. For this, a heat-resistant silicone sealant is used.

In conclusion, it should be noted that there is no need to doubt the choice of a gas oven for a bath. Such factory units are functional, reliable, easy to operate. At the same time, they belong to environmentally friendly equipment, their purchase and use is beneficial for economic purposes. The period of validity of such products, subject to strict observance of all safety regulations, is more than 25 years.