What to look for when choosing a boiler

To make the right choice of a heating boiler for a private house, it is worth considering several fundamental points.

First of all, it is worth paying attention to the types of fuel available in a particular region. Both the cost of fuel and the possibility of its unimpeded purchase if necessary will matter.

The next important point is the availability of automation, that is, the ability to work without operator intervention. This condition becomes especially relevant if there is no one in the house during the day, and the equipment must work continuously.

When choosing a heating boiler, you need to take into account how simple and convenient this or that option is in operation, as well as what kind of maintenance it requires. If you do not want to regularly clean the boiler, then it is better to opt for an automated product, although it will cost significantly more.

It should be noted that all solid fuel boilers need periodic cleaning of burners and combustion chambers. Gas and electrical appliances require much less maintenance.

Briefly about the application of the advantages and disadvantages of all these boilers.

Solid fuel

Solid fuel boilers run on wood, coal, fuel briquettes and organic waste. They have the advantage that they can "digest" everything that burns - reliable (no automation), are non-volatile (in terms of electricity).

The disadvantages are: questionable regulation to maintain the set temperature. They also need constant human participation. The maximum possible battery life is 1-2 days (long burning boilers). And of course there is always a mess around, dirt, dust (you need a separate room for them).

Solid fuel pellets

The most complex, expensive ones, take up a huge place in the boiler room. For their combustion, fuel granules (pellets) are needed, which are fed in automatic mode. Due to automatic feeding, relative autonomy of work is achieved. The boiler can start up according to the temperature of the ambient air or heat carrier. It regulates the temperature of the coolant well. You can control it remotely using a smartphone, etc. Due to the large number of automation and complex mechanisms, such boilers are difficult to install, configure and repair.

Gas

An excellent option if the main gas is laid along the border of the site and its connection does not cost exorbitant money. In turn, they are divided into floor-standing, wall-mounted (with an open combustion chamber and with a closed one). Condensing (have a high efficiency with the correct approach to the entire system) and with a conventional combustion chamber.

In the absence of main gas, any boiler is re-equipped with nozzles for liquefied gas. It is only necessary to install a gas tank.

The advantage of gas boilers is a large selection. Various automatics for solving any problems: connecting an indirect heating boiler, underfloor heating, remote control, anti-freezing, etc. Full autonomy of work. Takes up little space (in case of wall mounting).

Among the disadvantages is the connection of gas (main or gas tank, which, in turn, requires periodic refueling). Otherwise, a wall-mounted gas boiler is the best choice for a private house with an area of 100 sq. m.

Diesel

Another type of fuel boilers. They work autonomously. They can be of enormous power. However, in this class there are very expensive models that are not acceptable in terms of economy for a small country house.Such boilers are more suitable for commercial facilities (car services, since waste oil can be poured there, large production facilities ...).

Electrical

Relatively inexpensive boilers. With full functionality and maximum autonomy in work. They require a minimum of attention. Any scheme can be assembled. In terms of initial costs, they are the most budgetary. They have a huge potential and an efficiency of almost 100%. Long lasting. The line of manufacturers has a huge variety of models for any need. They are also in great demand as backup heaters.

The disadvantage may be the lack of sufficient input electrical power. And more in comparison with gas or wood, the cost of kW / h.

Otherwise, they are ideal when choosing a boiler for heating a private house. For the choice of an electric boiler for the home, read here.

Sometimes the cost of connecting the main gas in relation to the cost of heating with electricity does not prioritize gas heating. The payback sometimes reaches 10-15 years.

Gas boiler options

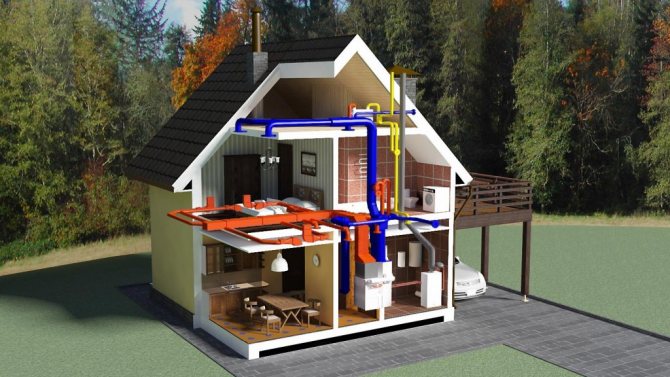

All gas heaters differ primarily in the type of installation - they can be floor-standing or wall-mounted. Wall-hung boilers are designed for a maximum power of 60 kW, but floor-standing appliances are produced with a capacity of 100 kW or more. Some boiler models are designed to work in a cascade. It should be noted that one of the advantages of wall-mounted boilers is their compactness - they are easy to fit into the kitchen interior.

If you plan to install a floor-type boiler with a capacity of more than 60 kW, you will have to allocate a separate room for it. It can be placed both in the house itself, and be attached to it and have a separate entrance.

It is far from always possible to connect directly to the main gas pipeline, however, this is not a reason to refuse to install a gas boiler. In this case, you can choose a gas boiler according to the parameters of your home, equipping it with a special burner for working with liquefied gas. How economically profitable such a solution will be can be determined only after preliminary calculations. To do this, you need to calculate how much 1 kW of heat will cost if you use several alternative fuels available.

The minimum required boiler power for a house is 100 sq. m.

The power requirements depend on the heat loss of the house, the boiler simply has to replenish them. For an average house in the climatic zone of the Moscow region with 2 brick masonry and a ceiling height of 2.7 m, the heating capacity is calculated from the rule: 1 kW of power for every 10 m2 of heated area. We also recommend setting a power reserve of 10-30%, depending on the type of fuel used.

For example, the minimum required boiler power for a house with an area of 100 sq. m. = 10 kW * 1.2 = 12 kW.

Often, manufacturers do not produce 12 kW versions, limiting themselves to 10 and 15 kW boilers, so you can choose a 14 or 15 kW model, but no more. A boiler with too large capacity will cycle more often (on / off), which reduces its resource.

Standard simplified calculations are sufficient for more than 95% of cases. If the house is well insulated, located in the extreme southern or northern point of the country, has high ceilings or a large glazing area, more accurate calculations are made. You can do them using the calculator below.

Calculator for accurate calculations

The heating boiler must provide the total power of the radiators (boiler power ≥ the total power of the radiators), therefore, first, you need to use a calculator to calculate the power of the radiators for each room separately. Summing up all the values obtained, you will receive the minimum required boiler power.

Varieties of burners

There are two main types of burners - open (or atmospheric) and closed (turbocharged). Atmospheric burners require a chimney with good draft, and turbo burners are connected to a coaxial chimney that passes through the wall near the boiler.

When choosing a gas boiler by parameters, you should pay attention to the combustion chambers for different burners. They differ in the way they draw in air. The open-type burner draws in air directly from the combustion room, and therefore it is necessary to install powerful supply ventilation. But for turbocharged burners, the fuel chamber is supplied with one of the pipes of the coaxial chimney. In this case, there are no strict requirements for ventilation.

It is worth noting that one of the disadvantages of boilers with a turbocharged burner is the sensitivity of the chimney to atmospheric manifestations - frost or heavy snowfall. In this case, the boiler simply will not turn on.

Another fundamental point is that it is advisable to select a gas boiler according to the parameters of the burner, that is, how many modes it is designed for.

There are three options:

- Single stage... Such a boiler has only two modes of operation - on at full power and off. This is the cheapest type of burner that consumes too much gas. This type of boilers cannot be called energy efficient.

- Two-stage... The burner can be set to work at 50% and 100% power. The third mode is a complete shutdown. This is a more economical option for boilers that allow you to maintain the temperature in the room to some extent.

- Modulated... The most effective, but also expensive option. Smooth regulation of the power level allows the boiler to turn on both 10% and 100%.

Of course, when making a selection of a heating boiler according to the type of burner, it is most reasonable to stop at a modulated version. Excessive purchase costs will quickly pay off during operation.

How to choose a boiler for heating a private house

Floor-standing or wall-mounted

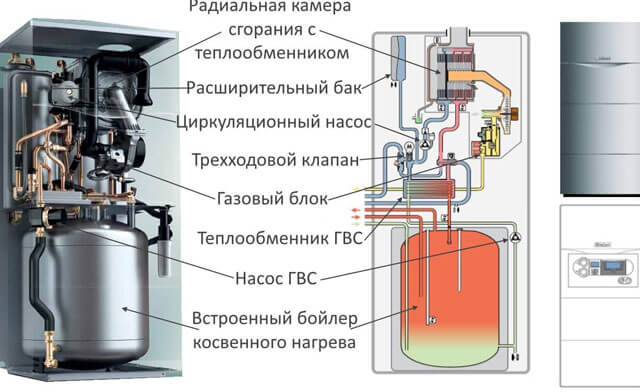

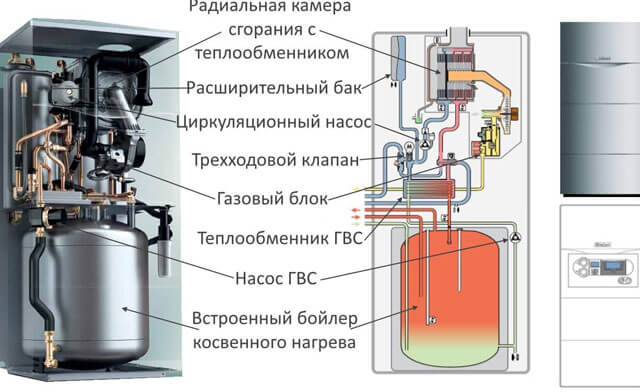

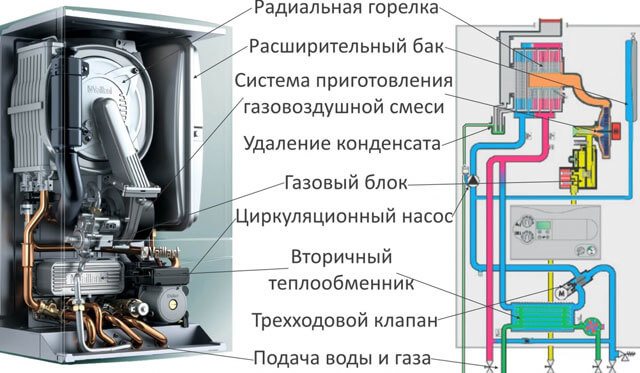

Gas wall-mounted Vaillant with the necessary elements and units of the heating system built into the body.

Floor-standing models are more resourceful and versatile, most of them are non-volatile, i.e. not requiring connection to the mains (except for electric boilers). Wall-mounted models are more compact, while in their case already from the factory they contain an expansion tank, a circulation pump, a safety valve, an air vent and other elements of the heating system.

Light steel or copper heat exchangers are installed in wall-mounted models, which, even in spite of special coatings, are subject to corrosion and serve no more than 12-16 years. Floor-standing models are not limited in weight, therefore heavy cast iron heat exchangers with thick walls are often installed in them, cast iron is practically not subject to corrosion, and the service life of such heat exchangers is more than 25-30 years.

Please note that solid fuel and liquid fuel models, due to technical features, are presented only in the form of floor models.

Single-circuit or double-circuit

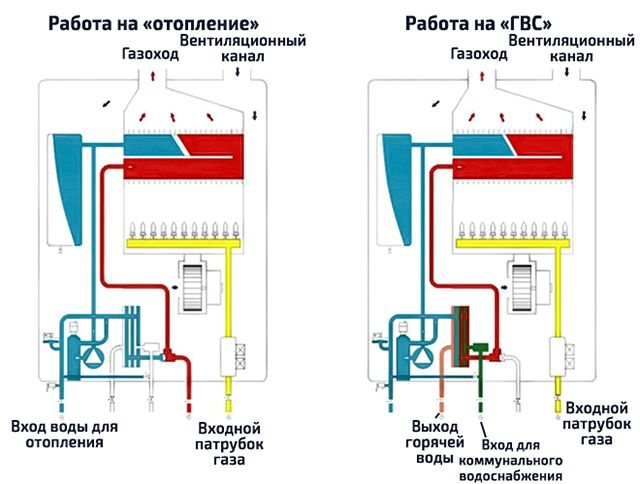

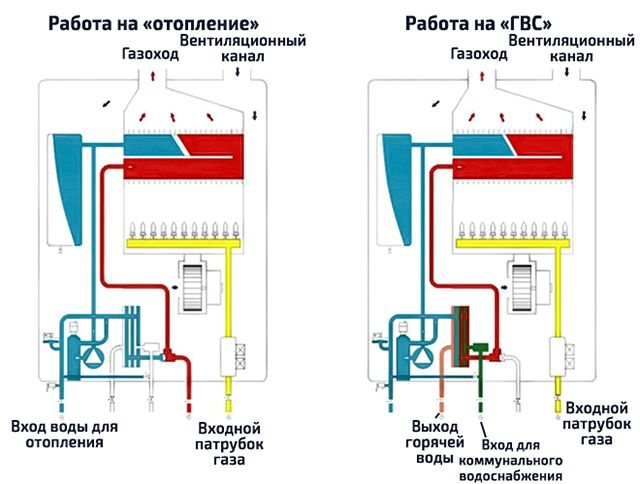

A clear principle of operation of double-circuit boilers with the priority of hot water supply (DHW).

Single-circuit boilers are designed exclusively for heating. Two-circuit models are equipped with an additional heat exchanger, with the help of which they also heat sanitary water for hot water supply to the house. Sanitary water from the DHW circuit does not mix with technical water from the heating circuit.

The cost of double-circuit boilers is only 10-20% more expensive than single-circuit versions, so this is the most profitable way to solve the issue of hot water supply.

Heat exchanger material

The heat exchanger that transfers the thermal energy of combustion to the heat carrier can be made of:

- become - the lightest and most inexpensive option to manufacture, it is used mainly in wall-mounted models, boilers of the low and middle price segment. Steel heat exchangers have thin walls and are susceptible to corrosion, therefore, their resource is limited by physical properties, service life is 12-14 years;

- copper - more resistant to corrosion, more heat-conducting, but also more expensive metal. Copper heat exchangers are used in models of the middle and high price segments, their service life is about 13-17 years;

- cast iron - resistant to corrosion, retaining heat for a long time, but heavy and brittle. The service life of cast iron heat exchangers is at least 25-30 years.

How to choose a room thermostat and save up to 30% per month on heating

Combustion chamber device and types of smoke removal

There are several options for organizing fuel combustion:

- open combustion chamber and natural draft through a vertical chimney - the standard version used in floor-standing models, when the air for fuel combustion is taken from the room, and the combustion products are naturally discharged into the vertical chimney. For fuel combustion, proper ventilation must be provided in the boiler room;

- closed combustion chamber and forced draft through a coaxial chimney - an easier-to-organize option, used in wall-mounted and some floor-standing models. Air intake and exhaust of combustion products is carried out through a compact coaxial (side) chimney. The chimney itself comes complete with a boiler.

Electric boilers do not need air intake and removal of combustion products, and, accordingly, a chimney.

Types of gas burners for flame regulation

The criterion applies exclusively to gas boilers, in which there can be 3 types of burners:

- single stage - works in on / off mode;

- two-stage - works in off, 50 and 100% power modes. This reduces the load, increases fuel economy;

- modulated - smoothly regulates power in the range of 10-100%. This is the best, but also more expensive type of burner, since the boiler automation can achieve the most economical and gentle burner operation - continuous combustion at the lowest possible power.

Efficiency

The coefficient of performance (COP) is the ratio of the volume of fuel consumed by the boiler to the volume of heat generated, i.e. efficiency. Average normal values:

- for gas - 88-94%;

- for solid fuel - 82-89%;

- for liquid fuel - 86-91%;

- for electricity - 99%.

Accordingly, the lower the efficiency, the less thermal energy is accumulated by the coolant. If for liquid fuel boilers during mining this is an insignificant indicator in view of the symbolic cost of fuel, then for gas boilers each additional% efficiency contributes to tangible savings.

Additional criteria

Having decided on the main selection criteria one by one, you can turn to additional ones:

- flue gas condensation - used in gas and solid fuel boilers for long burning, when an additional heat exchanger accumulates the residual heat of combustion products. Thus, a significant part of the heat does not "fly into the pipe";

- automation functionality - modern models can be equipped with a programmer that allows you to set the boiler operating mode for the next day or week, for example, setting the temperature to 15 ° C during working hours when the owners are not at home, which will significantly reduce fuel consumption. Also important is the possibility of connecting a room thermostat, the presence of protection against overheating and stopping the circulation pump, the anti-freeze mode. Solid fuel boilers, as a rule, are not equipped with functional automation;

- the presence of heat and sound insulation - a layer of thermal insulation reduces heat loss through the boiler itself, and the sound insulation used in gas, diesel and electric models makes their work practically silent.

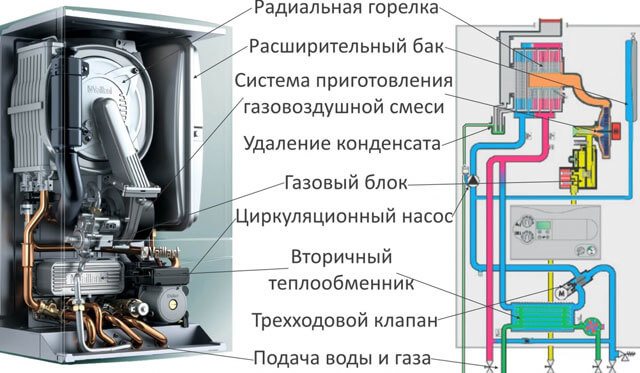

Condensing gas boilers

The gas boilers described above refer to high-temperature appliances, the temperature of the coolant at the outlet of which is 45-50 ℃ and even more. They are ideal for installing radiators.

A feature of condensing boilers is that they can effectively operate with temperatures not exceeding 40 ℃ in the return pipe. In this case, an economical consumption of gas is achieved, since heat is transferred to the coolant due to the condensation of hot steam contained in the flue gases.

This type of boiler is ideal for heating a house with a warm water floor. As a rule, at the outlet of the boiler, the temperature of the coolant is 35 ℃, and in the return circuit - about 30 ℃. This type of operation makes the boiler economical and energy efficient.

Note that condensing boilers also have some disadvantages. First of all, it is a very corrosive condensate. In this regard, a very high quality stainless steel chimney is required. In addition, if you make a selection of a boiler according to power parameters, then the price of condensing devices will be much higher than that of similar devices of the traditional type. The higher cost is due to a rather complex scheme of work, as well as the use of high-quality, condensate-resistant materials.

How to choose a floor standing gas boiler?

Installation of a floor-standing gas boiler is based on the possibility of installing it in rooms in which the area allows. Floor-standing gas boilers, as a rule, come in different capacities and, accordingly, unlike wall-mounted models, they can heat rooms that are large in volume and area.

Such boiler units have a built-in heat exchanger, which can be cast iron or steel. But the units themselves can be cast iron and steel. Cast iron is a brittle material and microcracks may appear on it due to overheating. A steel boiler is not afraid of impacts and overheating, but if it is not properly operated, it will corrode. All floor-standing units, by the type of burner device, are divided into two types, these are with forced draft burners and atmospheric ones. Burners of the atmospheric type have a more simplified design and have less noise. Units equipped with inflatable burners are more expensive, but their efficiency is higher and the power can be several times higher. Floor standing boilers can be completely independent of electricity, so if there are interruptions, then you need to select just such an apparatus.

According to the power level, three groups are distinguished, these are single-stage, two-stage and with the possibility of modulation. Two-stage have great possibilities, especially for use with boilers, and only power modulation can give the greatest savings.

The selection of the required boiler unit must be carried out in terms of heat output and its capacity, which must fully cover all total heat loads for hot water supply, heating and ventilation throughout the building as a whole.

Thermal heating loads for a building are determined based on its volume and temperature parameters using various coefficients. The DHW load is determined based on the norm, if necessary when the unit is double-circuit. In addition, it is possible to determine the load empirically, assuming that there is one kilowatt per 10 square meters. And with the expectation of the DHW system, another 25 percent is added.

Varieties of electric boilers

When selecting the power of the heating boiler by the area of the house, it is worth understanding the main types of such devices:

- Heating elements... This is the traditional and most common type of electric boilers.Multistage units are considered more economical, since they are capable of operating in several modes. Among the disadvantages can be called low efficiency due to heat loss for heating the heating elements. But the advantages include low prices for consumables (heating elements) and easy-to-perform repairs.

- Induction... In such equipment, the heating agent is heated at the moment the water passes through the inductive coil. It is believed that induction boilers are more economical in comparison with heating elements, they have no heat loss and practically no inertia. In addition, such boilers are very compact - they look like a piece of pipe from 35 cm to 1 m long. Among the disadvantages is the need for constant circulation of the coolant, otherwise, the boilers overheat and burn out quickly.

- Electrode... Many buyers, when they want to choose a boiler according to the parameters, stop at this type of equipment less often. Although they are considered the most economical, in most cases consumers are stopped by the need to circulate electrolyte through the pipes as a heat carrier, that is, water with certain additives. This requirement is due to the fact that heating of the coolant occurs due to the passage of current between the electrodes. When operating boilers of this type, it is necessary to monitor the condition of the electrodes and electrolyte. In addition, the entire installation works under voltage - this also frightens consumers a little.

Thus, if you do not know how to choose a boiler by the area of the house and which option to stay on, then pay attention to induction and heating elements.

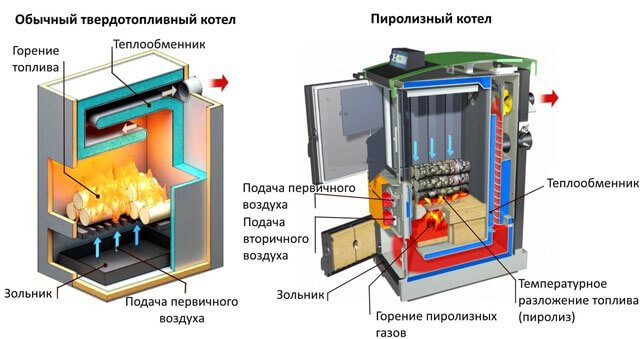

Solid fuel boilers

Often, during the selection of a heating boiler by area, consumers stop at solid fuel equipment. Although it has a number of disadvantages, it is still the most in demand.

As a rule, coal and firewood are used for kindling solid fuel boilers. The final choice depends on which raw materials are more readily available in a given region. It is worth noting that coal and wood boilers are different from each other. Wood-fired boilers have a large loading chamber that can hold a lot of firewood. Coal chambers have a smaller combustion chamber with thicker walls to withstand high combustion temperatures.

The advantages of solid fuel boilers are:

- savings on heating costs;

- the reliability and the prostate of the structure;

- the ability to work regardless of the availability of electricity.

It is worth mentioning significant disadvantages:

- Due to the cyclical operation of the boilers, the air temperature in the house is unstable, it becomes either cold or hot. To solve this problem, heat accumulators are installed, that is, containers with water that allow you to maintain an optimal microclimate constantly - during the combustion process, heat accumulates, which is then consumed to warm up the house.

- The need for service. Any solid fuel will first have to be loaded, set on fire, control the intensity of its combustion, and upon completion of the process, clean the furnace and re-ignite the boiler.

- The system cannot work offline. As it burns out, it is necessary to periodically add a new portion of fuel so that the system does not freeze.

- Since a lot of dirt is formed in the process of filling fuel and cleaning the boiler, it is advisable to install the boiler as close to the inlet as possible so as not to spread it everywhere.

In general, a solid fuel boiler in the heating system of a private house does not seem very convenient. Although the fuel for them is easy to obtain and is relatively cheap, it takes a long time to ignite, so the savings are not always justified.

Long burning heaters

Long burning boilers have been designed to maximize combustion efficiency and load spacing.

There are two variants of such equipment.

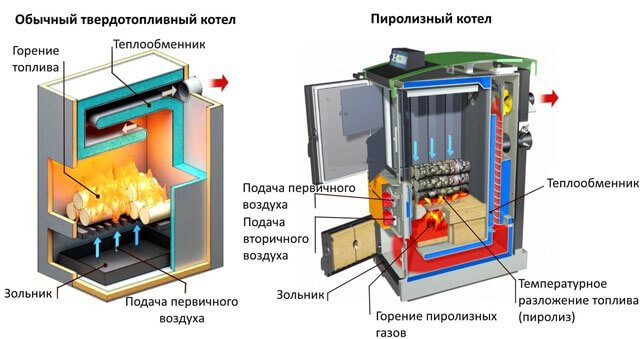

- Pyrolysis boilers... Such devices have two or even three combustion chambers. In this case, fuel combustion occurs with a lack of oxygen. As a result, a large volume of flue gases are emitted, most of them highly flammable. These gases enter the next chamber, into which air is supplied. As a result of mixing with oxygen, the combustible gases ignite again and generate even more heat than the solid fuel itself.

- Upper combustion appliances... In conventional solid fuel boilers, combustion spreads from bottom to top, that is, most of the load is burned at the same time. Due to too intense combustion, the system quickly overheats, which is not very efficient and uncomfortable for residents. If the principle of top combustion is applied, then ignition is carried out only in the upper part of the loaded fuel. At the same time, only a small part of them ignites, which significantly extends the fuel burning period. Thus, the room temperature is equalized.

The efficiency of long-burning solid fuel boilers is quite high - various wood-fired designs are capable of operating from 6-8 hours to a day on one tab, and on coal - from 10-12 hours to several days. However, such results can only be achieved with very high quality fuel materials. The main thing is that they are dry. Wet coal or firewood cannot even smolder, that is, such a boiler will not warm up. It is advisable to equip a barn for storing coal or a woodshed with a margin of 2-3 years. In this case, a long burning solid fuel boiler will be a really worthy choice.

How to read power correctly

First, it is worth mentioning that all our home heating efforts are aimed at heating indoor air to a comfortable temperature.

If we talk about the indicators of a comfortable temperature, then for each specific person they are different.

Someone feels great at a temperature of + 19C, and someone gets cold already at + 22C.

Nevertheless, + 19C is considered the most "healthy" temperature for indoor living quarters.

So, our heat generator heats the coolant, which, through the pipes of the warm floor or through the radiators, gives this heat to the air in the premises of the house.

The higher the boiler power, the more the heat carrier is heated and the more the air in the rooms heats up.

In this case, heat loss occurs - the air of the interior gives off heat through doors, windows, walls and ceilings. Warm air also escapes through the ventilation system.

Liquid fuel equipment

It is worth noting that when selecting a boiler by area, liquid fuel equipment is rarely preferred.

The low popularity of such boilers is due to the following factors:

- high fuel prices;

- the need for a place for storing diesel fuel, that is, a large capacity located close to the house;

- the need to ensure heating of the tank so that diesel fuel at low temperatures does not thicken and clog the burner;

- Since the operation of the equipment is accompanied by a high level of noise and an unpleasant odor, it must be installed either in a well-ventilated annex or in a separate boiler room.

In this regard, it is advisable to install an oil-fired boiler only if you have constant access to cheap fuel.

Conclusions.

How to choose a boiler for heating a private house of 100 square meters and conduct the heating correctly? To decide on the choice of a boiler, you need to take into account the following factors.

The presence of main gas immediately puts gas heating in the first place. For such an area, a wall-mounted boiler will not take up much space and the choice in favor of it will be the most optimal. You decide on one or two circuits based on your budget.Also, there is no great need to purchase an expensive condensing boiler if you plan to heat the house only with radiators (without using low-temperature heating such as underfloor heating). There is a separate article on its use. A floor-standing gas boiler is reliable, but inappropriate for such an area for obvious reasons. It takes up a lot of space and requires the construction of a separate chimney.

In the absence of main gas or significant costs for its connection, it is worth considering electric boilers or gas autonomous heating on liquefied gas. There are also two options here. If there is an input electric power of at least 15 kW, preference is given to electric heating. More expensive in kWh, but cheaper at the initial stage. Payback in comparison with a gas tank will be 5-7 years. Both options are convenient in everyday use and reliable in operation. If the electricity is on one phase and the power is limited to 7-10 kW. That autonomous gas heating is predominantly more profitable.

Well, for special masochists, solid fuel, pellet boilers remain. If, of course, you have a country house in the taiga, and you do not buy firewood, you have electricity from a diesel generator. The choice is obvious.

Home pellet boilers

Due to the design features of pellet boilers, they belong to a separate class. Sawdust compressed into granules serves as fuel for such devices. As a rule, a special shed or bunker near the boiler is taken away for storage of pellets. The period of independent operation of the equipment depends on the size of such a bunker. Usually about two buckets of pellets are required per day of work.

A special burner is installed in the pellet boiler, which allows you to burn the fuel almost completely. If the granules are of high quality, then as a result of combustion, about 3-5% of ash is formed. Therefore, cleaning the firebox is required only once a week or even several weeks. Thanks to the automation of the equipment, it can work autonomously for several weeks.

Among the disadvantages of modern pellet boilers are the high price and sensitivity to fuel quality. Pellets must be strong, not crumble or break, have low ash content and good calorific value.

In general, when choosing a boiler for the area of the house, a pellet appliance can be a good option if there is enough fuel for it.

Combined devices

Before choosing the boiler power for your home, you should pay attention to one more type of boilers - combined ones. This refers to devices that can work with several fuel options. Most often, consumers purchase solid fuel boilers with built-in heating elements. At the moment of burning coal or firewood, the system warms up in the same way as when using a conventional solid fuel boiler. When the fuel burns out and the boiler starts to cool down, electric heating elements are switched on to maintain the temperature in the house. By themselves, they are not able to fully heat the house, but they can maintain the temperature and prevent the system from freezing.

Combined boilers with oil burners are in fairly high demand. Such devices are equipped with two separate combustion chambers - for solid fuel and for liquid.

Despite all the advantages of such devices, they also have disadvantages. First of all, it is a high price. In addition, the efficiency of each of the boiler sections is average. Thus, it is difficult to unambiguously assess the feasibility of this type of boilers.

We select a heating boiler

Given the wide variety of heating devices on the market, many consumers do not know how to choose the power of the heating boiler and which of the varieties to choose.

Here are the basic requirements for such devices:

- Saving money... The best fuels are wood, coal and natural gas. The next step in terms of cost is pellets, liquid fuel and electricity. Nevertheless, it is worth considering the specific situation in each of the regions and the availability of a particular type of fuel.

- Autonomy... Gas, pellet and electric boilers can work without operator intervention. Such devices do not need constant supervision. Some control is needed over oil boilers. But solid fuel ones are distinguished by a minimum level of automation.

- Easy to connect... The most problematic is the process of registration and connection of a gas boiler to the main pipeline. In the presence of an electric boiler, a powerful line for heating should be allocated at the substation if they have a reserve. All other equipment is connected much easier, but with the observance of safety measures.

Thus, taking into account these factors, it will be much easier for you to determine the type and power of the boiler for your private house.