One of the conditions for a comfortable stay is the optimum indoor temperature. But it is impossible to maintain it without efficient heating. Today you can buy boilers that run on different types of fuel. If it is impossible to use gas equipment, an electric boiler will be the best solution. Let's consider what the electric boiler connection diagram should be.

Of all the possible ways of organizing heating in residential buildings, the most convenient, environmentally friendly and effective is the installation of an electric boiler. But in order for the heating equipment to work with maximum efficiency, it is necessary to correctly connect the electric boiler to the heating system. Connection work is the most important stage in the improvement of the building.

Nuances of work

Electric heat generators have high efficiency, which means they are suitable for large areas. The most economical of all are electrode boilers.

All electric boilers are equipped with a regulation system for temperature control and a stabilizer that protects against voltage surges - the devices are almost always sensitive to them. By the way, the main problem of calculating an electric boiler is most often the load on the network, which, as a rule, is more than the norm.

Laying the electrical cable for the heating boiler

The laying of the electrical cable is done according to the wiring regulations in accordance with the design of the house. For a wooden house in pipes or open, for a stone house in boxes or hidden.

The electric boiler is not connected through the socket, the power cable is led into the boiler through the factory connection holes and connected to the circuit breaker or terminals installed on the boiler body in the electrical cabinet.

Important! Any twisting, soldering, welding and other connections not provided for by the boiler design are prohibited.

Components

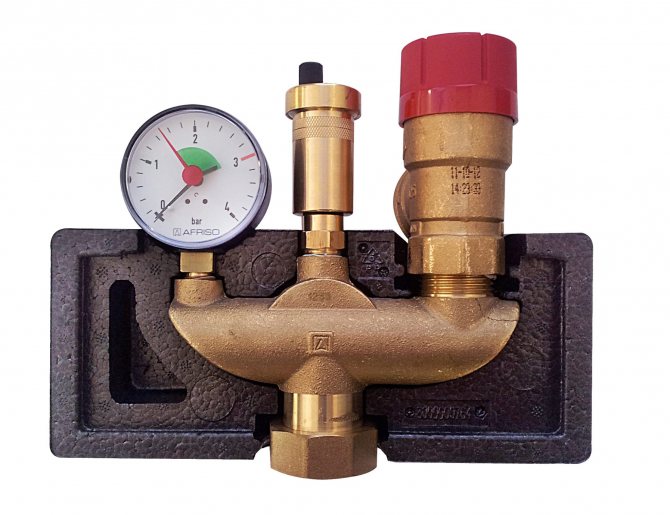

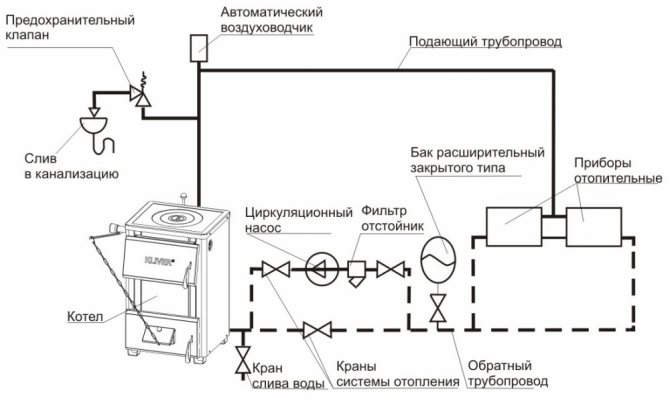

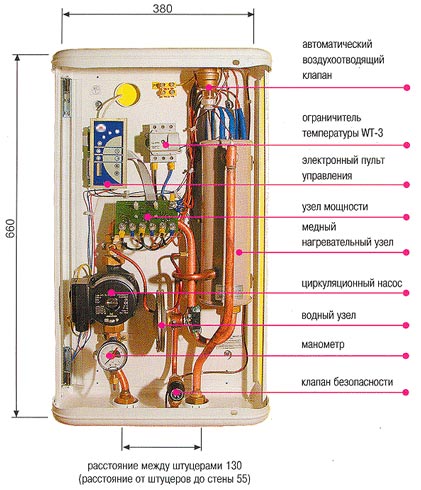

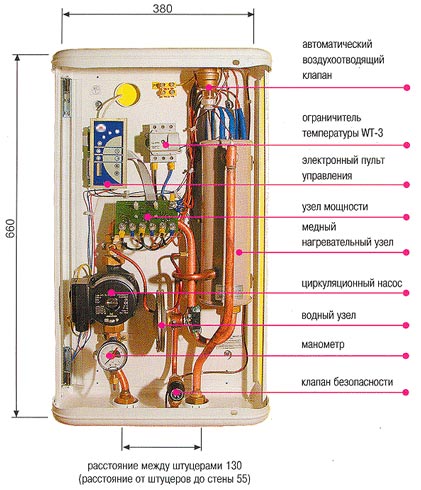

Correct connection of the electric boiler to the heating system ensures further trouble-free operation and efficiency. The electric boiler installation system consists of the following components:

- apparatus;

- temperature sensors;

- radiators;

- drain and shut-off valves;

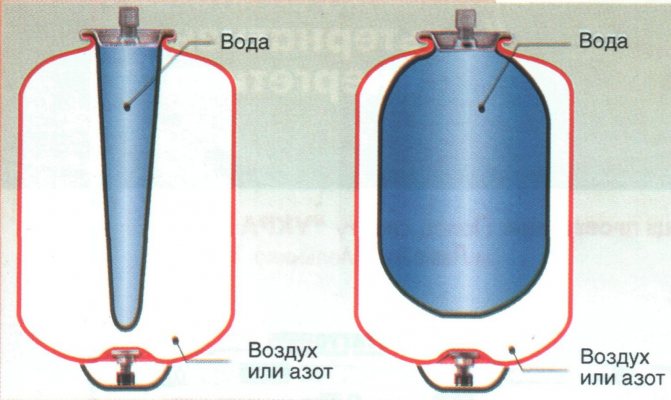

- expansion tank;

- circulation pump and filter.

Prevention and recommendations for use

Compliance with the operating rules, together with the implementation of timely preventive measures, prolongs the period of trouble-free operation of the unit. It is preferable to carry out preventive maintenance during the lowest boiler load, in summer.

During the current heating season, it is advisable to pay attention to malfunctions and deviations that occur during operation. In the warm season, it is recommended to replace all unstable elements and troubleshoot. Then make a preliminary start and check the performance of boiler equipment and systems.

Preventive measures include: cosmetic repairs, cleaning of various kinds of systems and equipment. Particular attention must be paid to fasteners and connecting elements that can significantly affect the functionality of the equipment.

Timely, regular implementation of preventive measures, along with high-quality installation and proper operation, will allow heating equipment to operate reliably for decades.

To extend the service life of the heating unit, it is necessary to descale the heating elements.However, you can prevent the problem by pouring distilled or soft water into the heating system. If before that ordinary water was used, then the heating elements are cleaned with the help of special powders, which are sold in household or car dealerships.

The powder is diluted in water, the resulting mixture is poured into the heating system, which turns on at full capacity. After 30-40 minutes, the entire solution (it will be rusty) is drained into the sewer system. Now you can be sure that the whole system will get its nominal 100% power again. A less efficient option is to install devices for filtering the working fluid.

The reliability of the home electrician is of particular importance. Outdated wiring is one of the most common causes of electrical failure. It is advisable to change the aluminum wire to copper with a cross-sectional margin.

A feature of using this type of equipment is the mandatory control of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomena of electrolysis and breakdown must not be allowed. You can find out how to cook in a Pompeian oven here.

Site selection and rules

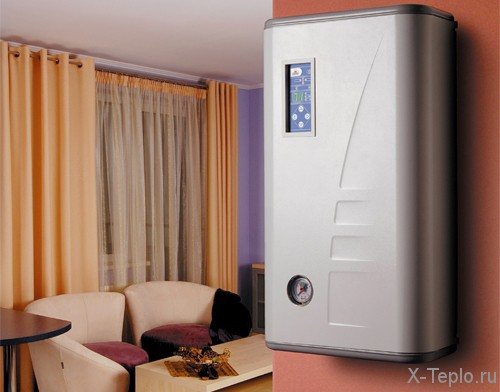

Installation of an electric boiler is possible only on a wall trimmed with non-combustible material and is better in a non-residential area, although a kitchen is also a good fit. It is also necessary to provide for the possibility of water leakage: if such a place is near the boiler, then this creates a risk of short circuit and fire.

Know for safety

According to the established standards, there must be a distance of at least 5 cm from the electric boiler to the walls, the free space in front of it is 70 cm, at the top - at least 80 cm, at the bottom - at least 50 cm.

If the boiler consumes no more than 3.5 kW, then it can be connected to a regular electrical outlet. Boilers with a capacity of 3.5-7 kW are connected directly to the panel with a dedicated cable. They can be powered from 220 V.

A separate cable is not a whim of the manufacturer: the safety instructions limit the maximum current at the outlet to 16 A. But boilers with an electric power of 7 kW or more are powered only from 380 V.

Advantage and scope of electric boilers

Most often, electric boilers are used when installing heating in the country and in a private house. This is due to the fact that this equipment has a low cost and at the same time you can install it yourself, without calling the wizard.

Among the main advantages of electric boilers are:

- the equipment is safe (the design does not include an open flame or the presence of flammable fuel sources);

- water heaters can be off for up to six months, while without harm to their performance (relevant for summer cottages and country houses that are rarely visited);

- dimensions are relatively small, so it can be placed in any room;

- today there is a huge variety of electric boilers, different in power, installation method and principle of operation;

- when water is heated, soot does not appear, which is dangerous for both humans and the environment.

Useful features and disadvantages

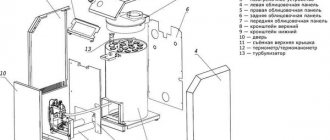

It is also worth considering installing a universal solid fuel boiler with built-in electric heating elements. Some models even have a hob, which does not require additional external finishing.

Electric boilers can easily tolerate power outages for up to 6 months. This makes them a good option in case of irregular use of the system or in case of interruptions in the supply of electricity needed to heat a private house.

The disadvantage of using an electric boiler is the need for powerful supply cables with a large cross section.

Which boiler to choose

On the market you can find different types of boilers for heating an apartment or a private house. In order not to get confused, you must have a minimum of knowledge about each of them:

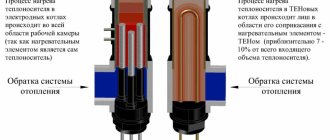

Electrode boilers. The liquid is heated by an alternating current that passes through it. This type of electric boilers is considered the most convenient. The efficiency of an electric boiler is not lower than 98% - this is what the manufacturers say.

IMPORTANT: distilled water is not suitable as a heating medium. Compositions are included with the unit, their task is to increase the indicator of the electrical conductivity of the liquid

Compositions are included with the unit, their task is to increase the indicator of the electrical conductivity of the liquid.

As you can see, the connection diagram is quite simple for both single-phase and three-phase boiler modifications.

Heating elements boilers are the most common devices, heating elements in them perform a heating function. The units have an efficiency of at least 93%. Despite the low cost, heating elements boilers have a serious drawback: if the water is too hard, then scale appears on the heating elements, as a result, the power of the boiler decreases.

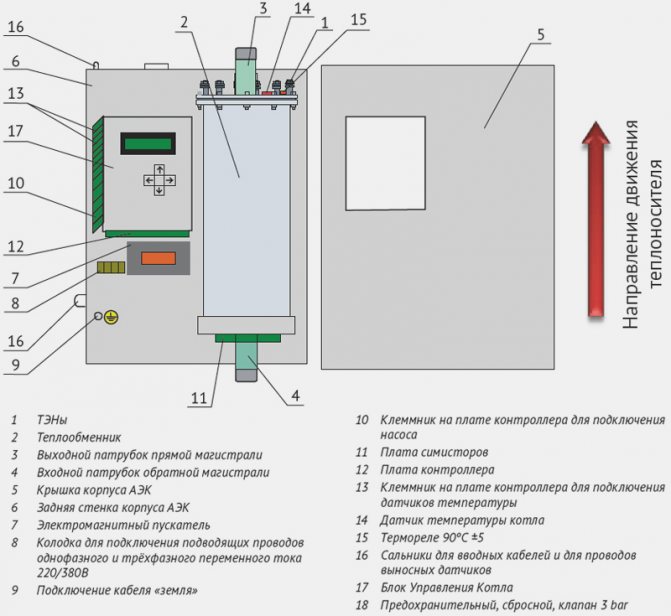

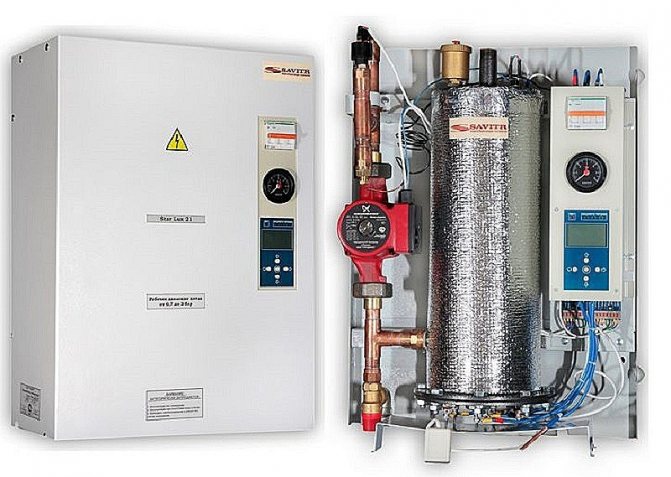

This is what a standard heating element boiler looks like.

Induction boilers are durable and economical units that have an efficiency of 98%. The design resembles a transformer. Minus - they cannot give out more power for heating.

Induction boilers are great for an apartment or a small private house.

Installation procedures

To suspend the device, you need a mounting plate, which is included in the delivery set: it is fixed to the wall with four dowels or anchor bolts with obligatory horizontal and vertical alignment. If this is a floor-standing boiler, then it is installed on a special support.

The device must be grounded, inspected and make sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected.

Electric heating units must be connected with a wire, the cross-section of which is specified in the equipment documentation. The wires are led in special protective boxes.

Scheme options

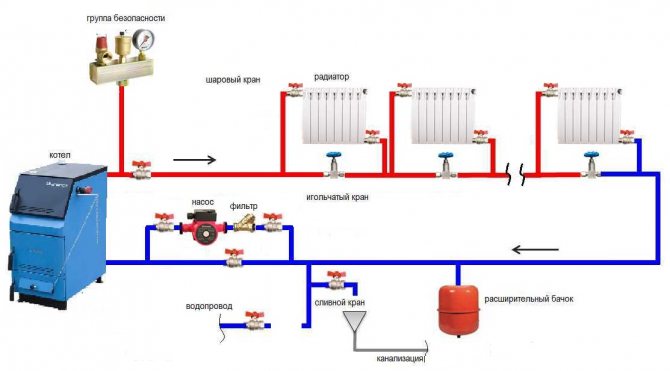

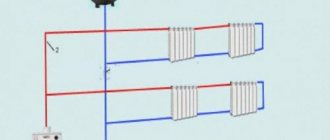

There are various schemes: a diagram for connecting an electric boiler with heating radiators, schemes with the possibility of installing a cascade. The latter option is used if it is necessary to heat large areas. For the operation of devices in a cascade, the terminals of the control unit are connected to the terminals of the controlled one. If the plant system is controlled by a room regulator, then its control contacts are connected to the terminals of the master equipment.

Heating device piping

Strapping can be carried out in a straight and mixing pattern. The direct scheme assumes temperature control with a burner, mixing - with a mixer with a servo drive. The strapping is carried out as follows. A boiler collector is installed, a pipe of the required diameter is connected to the boiler.

A three-way mixing valve is installed at the inlet, which will regulate the temperature. A circulation pump is installed on the return line and a control unit is mounted. After piping, you can fill the system with a coolant and test the operation of the equipment for correctness.

Do not underestimate this stage: in reality, it is not as simple and insignificant as it might seem. Normal strapping allows the equipment to be used without an automation system, and this greatly reduces costs. Therefore, it must be performed at a professional level and taking into account the design features of the system and the boiler.

The piping of the electric boiler must be done by a specialist. If you still have to do it yourself, then you need already assembled distribution units. General scheme for the implementation of the heating system in the house.

Features of the electric boiler piping

When installing and piping this electrical device, one should not forget about some points that directly affect the reliable operation of heating equipment, which will help to avoid frequent breakdowns during its operation.

Tying an electric boiler is called its connection to the heating system using special elements. When connecting an electric boiler to the heating system, one of two ways of transporting the coolant through the pipeline is taken into account - with forced or natural circulation.

In this case, the connection diagram of an electric heating boiler provides that the device must be installed at the lowest point of the structure to ensure the greatest heating of the radiators. The delivery pipe should be located above the radiators at the minimum permissible height.

In the process of installing an electric boiler, one must not forget about the arrangement of grounding. According to safety rules, it is allowed to connect it directly to the switchboard, while it is not allowed to use a zero phase for wiring. After studying the rules for installing a heating boiler, it is necessary to familiarize yourself with how the piping of the boiler and the entire heat supply system is performed.

In addition to the electric boiler (as it looks like in the photo), you need to purchase pipes and other components for arranging heating the room. Correctly made piping of an electric heating boiler allows you to ensure the same temperature at the points of entry and exit of the coolant. The heater should be connected in such a way that after reaching a certain temperature mark in the small circuit, water enters the large circuit (it is entrusted with the task of heating the premises), and there it gives off heat to the batteries.