The question arose: is it realistic to create briquettes from sawdust that can be used as fuel, for example, for a greenhouse?

Unnecessary materials can be found at any dacha. It can be:

- sawdust;

- boards;

- wood residues;

- straw;

- branches;

- coal waste;

- dry leaves;

- cardboard;

- paper.

All of these materials burn well, but to use them, you must first grind. To do this, you will need the machines designed for this. You do not need to make them yourself, ready-made devices are offered for sale by specialized stores.

For such work, a rotary machine is suitable, which with the help of knives is able to grind plant material. Its cost is available to any summer resident. This device is indispensable when you need to get fertilizers.

Such a machine can also be used to purchase fuel briquettes. However, they cannot do it alone, you need to have additional equipment.

Technological process

To make briquettes, you will need clay and, of course, sawdust. They are mixed in a ratio of 10: 1, water is added until the consistency of the solution becomes formative. It is very important that the clay, which is the main binding element, evenly occupies the entire volume of the sawdust.

You can mix the mixture by hand, but it is better to use a construction mixer. He will do this job quickly and efficiently.

A variety of materials are suitable for molding briquettes:

- boxes;

- discarded pots;

- any capacity.

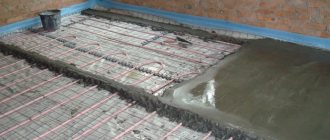

The formation of the future fuel should be carried out by pressing the finished solution.

The last manufacturing step is drying. It's good when there is bright sunny weather outside, because briquettes dry very quickly in such conditions.

Self-production of briquettes

In order to produce DIY briquettes, special equipment is required. It makes sense to purchase an industrial unit if you have:

- desire and ability to organize permanent mass production of eurodrops for their sale;

- steady demand for the product;

- a source of very cheap (better than free) sawdust;

- sufficient amount of funds.

Some models of briquetting machines at an affordable price are presented in clause 2.3 of this article.

If you do not plan to sell euro wood, but you want to make briquettes for yourself, you can use the technology developed by home craftsmen. It is based on the method of gluing sawdust using bonding materials, since it will not be possible to implement the traditional method of separating lignin at home. Let's consider in more detail, how fuel briquettes are made at home.

Features of home technology

Clay is most often used as a binder, but sometimes cardboard soaked in water, cheap wallpaper glue, ordinary starch paste and even PVA glue are used. Sawdust is mixed with a binder in the required proportion (for clay it is 10: 1), with the addition of water to obtain the desired consistency, which is determined empirically.

Mixing must be carried out evenly so that the binder fills the entire volume of the sawdust. The mixture, if possible, is best mixed with a construction mixer. It is best to form briquettes in wooden boxes by pressing the raw materials loaded into them. For this, mechanisms are used, the main unit of which is a press, which creates a lot of pressure on the formed briquette. The final stage in the manufacture of briquettes is their drying.

What machine can be used to make briquettes

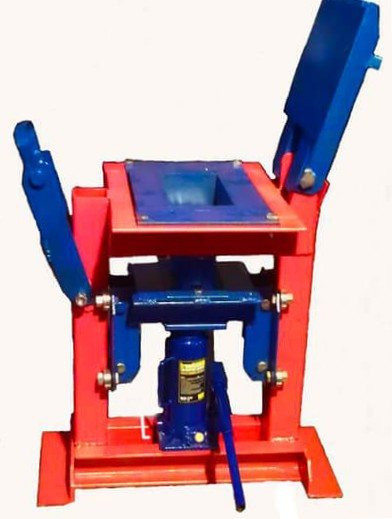

Home craftsmen make such machines with their own hands.Briquettes are made in the form of bricks or round.

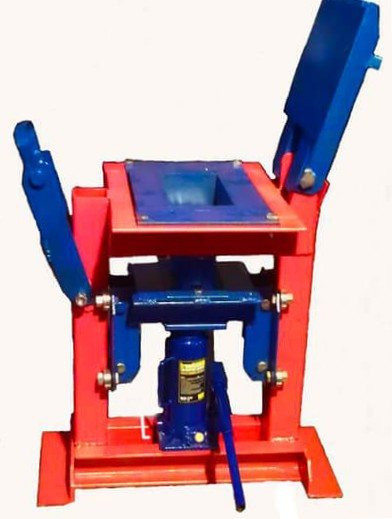

In such machines, the main element is the part that forms the briquette under high pressure.

Such a homemade press can have several types, in which various mechanisms are used:

- manual drive;

- jack;

- hydraulic drive.

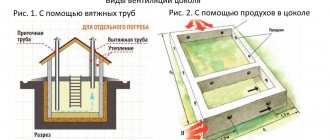

The simplest is the manual mechanism. The welded frame is made of a steel profile tube. It is convenient to fix such a frame on the wall. At the bottom of the frame, a fixed shape is firmly attached, which can have a very different appearance, but more often a rectangular configuration is used. A long arm is attached to the top using a pivot joint. A pressure piece is connected to it, which enters the mold. A small gap is provided for its free movement.

In other versions, mechanized jacks are used, hydraulic drives that replace the lever. Small holes are drilled at the bottom so that the water can freely leave the mold during operation. You can get acquainted with the design in the video:

Applied equipment

Today, there are a lot of trading companies on the market that are engaged in the manufacture of machines for creating fuel briquettes at home.

Most often, such companies are engaged in setting up and installing such equipment. They even teach how to use such devices. You can also purchase equipment from organizations that manufacture pallets, briquettes and production lines.

To make fuel briquettes at home, you need to have:

- waste crusher;

- drying machine;

- press for creating briquettes (screw type, percussion or screw).

It should be noted that you can do without a dryer at home; you can simply dry briquettes outside. And if you are going to use sawdust as a base, you can also neglect the grinder.

For the most skillful residents, we can recommend making a homemade press in your workshop. With sufficient skill, such a machine may not be inferior to industrial counterparts, the drawings of which were developed by a group of engineers.

You may be interested in an article on how to make fuel briquettes from sawdust. You can read about Ruf fuel briquettes in this article.

On the network you can find many schemes for making a homemade press, it is on them that you can carry out its planning and assembly. It is clear that such a machine will have efficiency depending on the type of construction chosen and the quality of its execution.

For those who decided to make such a machine, you need to adhere to one of the found schemes to weld the frame of the structure, install a working element on it, which, unfortunately, cannot be made at home. Next, connect a drive in the form of an electric, diesel or gasoline engine to the working element and add systems for supplying the mass and removing finished briquettes.

Screw Press

It can be called the simplest one made by home craftsmen. The mixture is poured into a perforated molding container, after which it is placed under the bed. Tighten the screw slowly to apply the desired pressure. The principle of operation and the device of such a press are clearly visible in the figure presented.

It is much easier and faster to make "brick" briquettes on a home-made press, which uses a long lever and a system of "pushing" them out of the mold. To make the process faster, some summer residents weld two forms to the frame at once.

Not all craftsmen are satisfied with manual work. There is also improved mechanized equipment. For example, to make a sawdust briquette machine more efficient, you can replace the manual drive with a hydraulic jack. Of course, the assembly of such a unit will require some effort, but the result will increase the efficiency.

Even difficulties in the manufacture of parts do not stop the home craftsmen. They were able to independently make a screw press, on which the briquettes are of very good quality. However, it was costly to make the screw and body using high alloy steels.

For such a machine, an electric drive is required, the power of which must exceed 7 kW, and this is an additional financial investment.

Fuel briquettes at home

It is completely unrealistic to imagine a situation when someone decides to purchase such a powerful unit capable of pressing briquettes at home. Even if finances allow this, and the raw materials will be obtained for free, it will be possible to recoup the purchase only in the case of a large-scale sale of the manufactured fuel.

In other words, it is clear that it will not be possible to implement the traditional technique that would release lignin at home. But numerous home craftsmen have learned through trial and error to use other binding materials.

Raw materials and preparation

- corrugated cardboard, paper;

- the cheapest glue, for example, wallpaper;

- clay.

To make fuel briquettes at home, it is not at all necessary to purchase expensive pressing and drying equipment. At home, they do it differently.

Savvy homeowners have gotten used to pressing heating briquettes from a variety of available materials that can burn:

- from paper,

- leaves,

- straw,

- cardboard,

- husks of seeds and other things.

- Sawdust is placed in water, clay is added there in a ratio of 1 to 10, stirred well, then inexpensive wallpaper glue or soaked cardboard is added to the composition.

- The mixture obtained in this way is placed in a homemade compression mold, and squeezed as tightly as possible with the effort of the hands.

- The formed rectangles are taken out of the mold and laid out to dry outside in a natural way.

Mechanism with a manual screw drive

The simplest press for the production of fuel bars, which you can make yourself, has a manual screw drive.

The design of this mechanism is extremely simple. But the performance of such a screw device is also low - this explains their low popularity.

A special molding container with holes is filled with the ready-made mixture, the screw is tightened tightly, creating an increased pressure.

When using them, a lot of time is spent on filling the container, twisting the mold and removing the formed briquette.

Brick ejection mechanism

It is much easier and much faster to squeeze out the formed briquettes on another press. It is also homemade, but it has a long lever and a special device for pushing out a brick. To speed up the process, some people weld not one shape to the bed, but a pair.

Some craftsmen are able to manufacture other more advanced equipment. How to improve the productivity of a handheld machine? By installing a hydraulic jack instead of a manual drive. Of course, it will take a lot of effort to make such a unit, but the result deserves it.

Note! It will not be possible to create a pressure reaching at least 300 bar in a home-made press, even with the help of a hydraulic jack. It is unlikely that it will be possible to reproduce the factory technology at home without adding water.

Screw press

However, some craftsmen, despite the difficulties with the details, managed to make a screw press. With its help, it is possible to produce heating bricks of a fairly high quality.

Craftsmen write about this on the forums, but at the same time they note the rather high costs of a high-strength steel body and the manufacture of auger parts. Of course, in this case, you cannot do without an electric drive. An engine of at least 7 kW power is required.

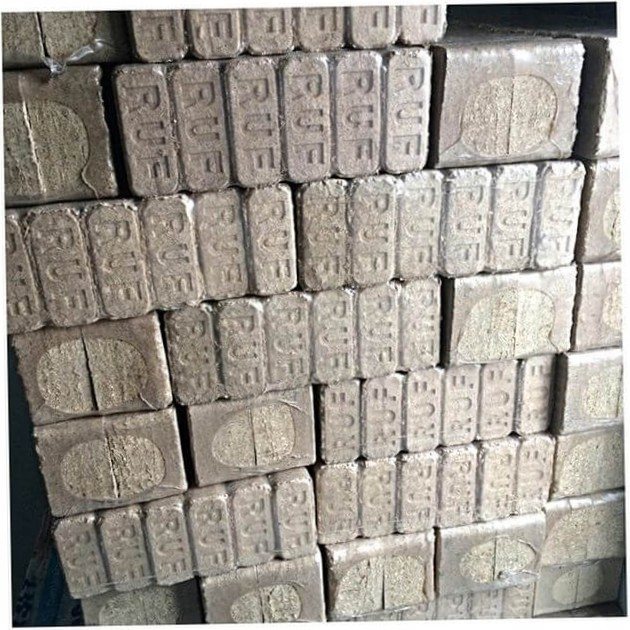

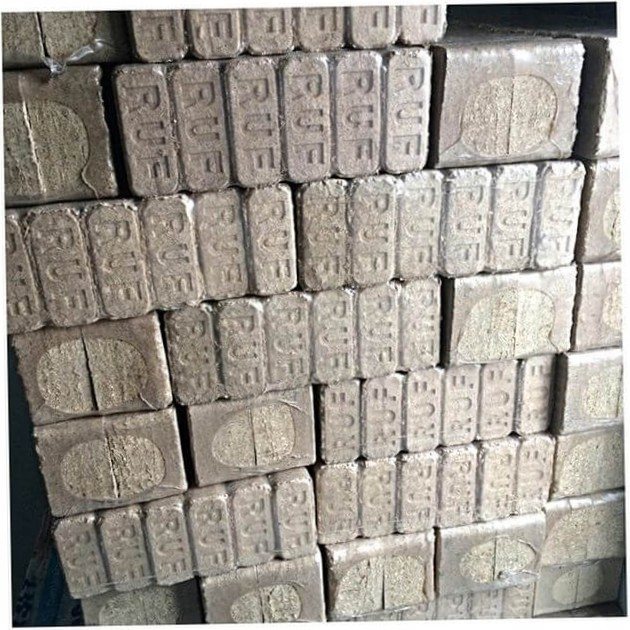

Briquetting press RUF 600

The industry produces a special press RUF 600, which produces briquettes with dimensions of 150x60 mm.

Its application has several advantages :

- Low wear.

- Increased reliability.

- Low electricity consumption.

- High quality and dense briquettes.

- High performance.

- Continuous mode of operation.

The RUF 600 model uses two-time hydraulic pressing. The material is used, the moisture content of which is from 6 to 14% without the addition of binders.

First, a slight pressure is created, due to which the material begins to be pressed due to the existing voids formed between the particles. After this, compaction and subsequent deformation of the particles themselves occur, a powerful cohesion is obtained at the molecular level.

Due to the high pressure that is created at the end of the operation, the elastic deformation becomes plastic. As a result, the structure of the briquette becomes much stronger, the given shape is completely preserved.

Sawdust briquettes machine - YUXI

General information about briquettes

The raw material for this type of biofuel is small wood waste, mainly sawdust. Of course, you can burn them like this, but this is not very convenient, a lot of fuel goes away and it quickly burns out. And all because the density of the wood pulp is low, much more heat will be obtained if the raw material is pre-compressed. This is the technology of briquette production.

In addition to wood, other types of raw materials are used in briquettes, for example, straw or coal. But since the manufacturing technology is somewhat different, its consideration is a question of a separate topic.

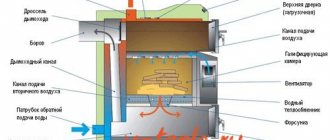

First, sawdust and other waste is processed, crushed and dried. The moisture content of the raw material before pressing should be in the range of 6-16%, which is provided by the drying equipment. Then comes the actual production of fuel, which is done in two ways:

- using a hydraulic press, the raw material is molded into rectangular or cylindrical briquettes. The process takes place at a pressure of 30 to 60 MPa and high temperature;

- by extrusion on a screw press, a 4- or 6-sided briquette is extruded from the finished mixture under a pressure of about 100 MPa. The product is heat treated.

It should be noted that the production of fuel briquettes from sawdust does not provide for the addition of binders to the mixture. Under the influence of high pressure and temperature, the particles stick together with lignin, which is found in any wood. The result is "bricks" or "sausages", whose calorific value is up to 5 kW / kg. The production process is shown in the video:

Note. Pellets have the same heat of combustion, and even some brands of coal. Below is a comparative diagram showing the consumption of different energy carriers for the release of the same amount of heat: