19.09.2014

Burning a wide variety of wood (pressed briquettes, logs, waste), pyrolysis or gas-fired boilers have gained wide popularity for heating domestic and residential premises. They work differently from classic solid models.

However, a design that is more complex at first glance provides a lot of advantages and savings on heating costs. It will be possible to build a simple pyrolysis boiler with your own hands in the shortest possible time.

Pyrolysis boiler test video

- 1 Drawings and diagrams

- 2 Boiler device video

- 3 Required materials

- 4 Putting together a simple pyrolysis boiler 4.1 Other features of the gas generator boiler

- 4.2 Safety precautions

How does a pyrolysis boiler work and work?

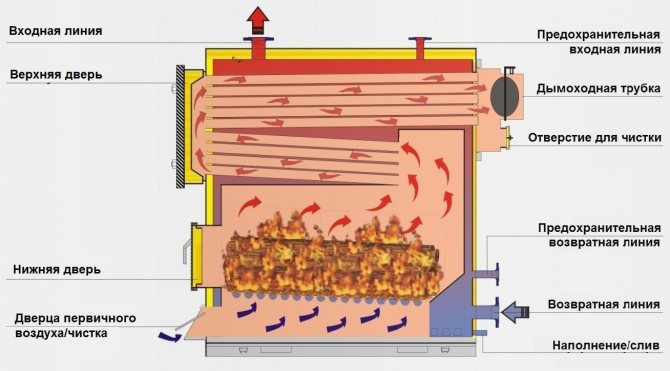

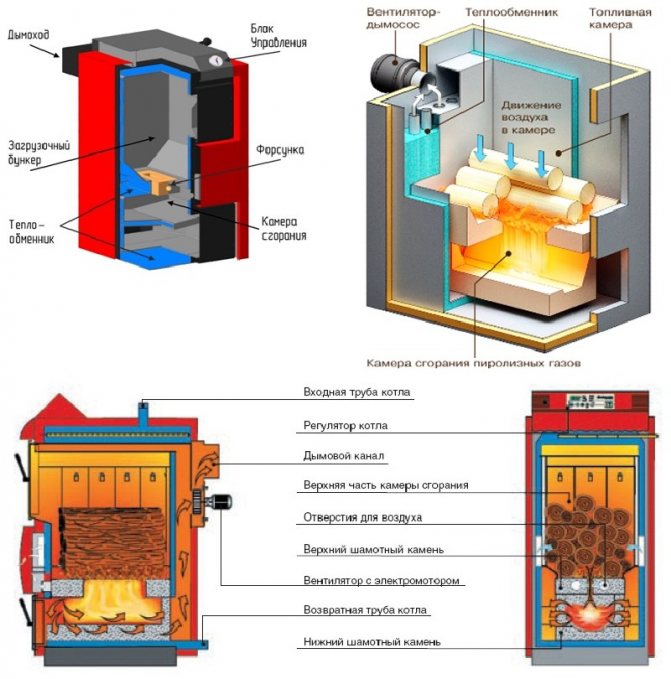

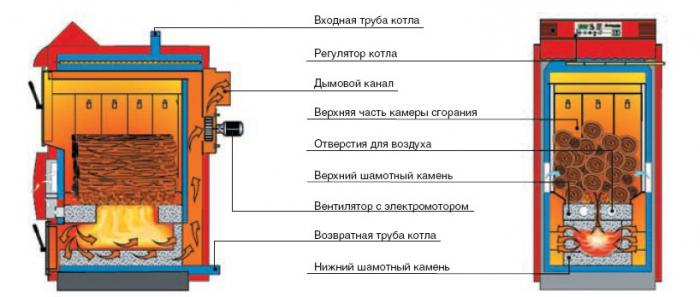

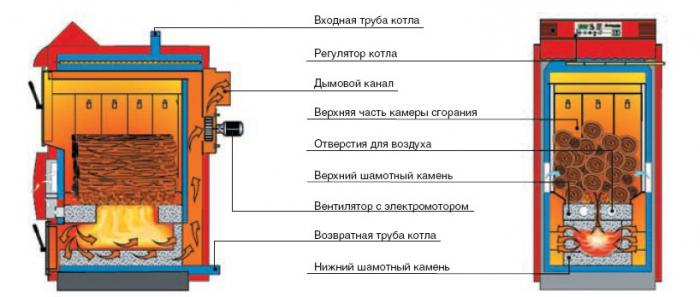

The heart of a gas-fired boiler is a firebox, which is divided into a couple of sections:

- In the first, firewood burns with a lack of oxygen

- In the second, the released gases burn out

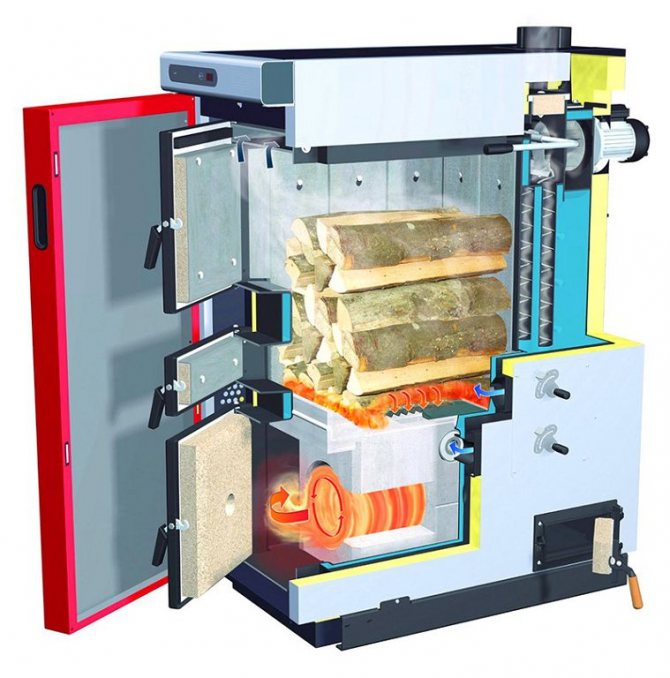

The firebox sections are divided among themselves by a grate. One of the main differences between a pyrolysis boiler and a classic one is the downward movement of air. High aerodynamic resistance does not allow air masses to circulate independently in the desired direction, therefore, forced draft is equipped with a blower or exhaust fan.

The basic principle underlying the operation of installations of this type is the thermal decomposition of wood. Subsequently, it is divided into coal and volatile gaseous mixtures.

The process necessarily takes place in the firewood storage chamber at high temperatures, but oxygen-saturated air should not be enough until full combustion. Volatile gaseous mixtures that enter the second chamber burn out at temperatures over a thousand degrees. Subsequently, carbon monoxide gases are redirected through the convective part into the chimney, giving off their heat.

In order for the wood to burn in ideal conditions, the inner surface is lined with a refractory lining. In this case, both chambers must be veneered.

New in wood heating

The fact that the operation of any home stove, and many modern heating devices, is based on burning fuel, with the obligatory supply of oxygen-enriched air, is known to everyone. But modern gas-generating models of boilers have fundamentally crossed out this principle.

Their operation requires a high temperature with a lack of oxygen, which means that the design of the pyrolysis boiler is fundamentally different from other models. What happens to the wood in this case?

Under the influence of high temperature, they break down into components:

- Solid residues (coal)

- Pyrolysis gas

- Resin

- Methyl alcohol

All the obtained substances are flammable and are burned during the operation of the device, while the more the wood is heated, the more gas will be obtained at the exit. And the operation of the apparatus is based on its combustion, for which they are often called gas generators.

To understand how this process takes place, we will consider what the design of pyrolysis boilers is and what functions each of the units performs.

Fuel used

As fuel, it is necessary to use wood with a diameter of 100-250 mm and a length of 380-450 mm. Fuel briquettes should be 30 × 300 mm in size. In the process of burning firewood, it is allowed to use small sawdust. However, they should be added no more than 30% of the total volume of the loading chamber. Only in this case will the scheme of a homemade pyrolysis boiler be effective. In addition, these devices are capable of burning wet firewood, but provided that their moisture percentage is no more than 40.

To ensure the functioning of such a boiler at maximum power, it is necessary to use only dry fuel. Since the ability of fuel to release energy is determined taking into account the presence of water in the wood.

Classic device diagram

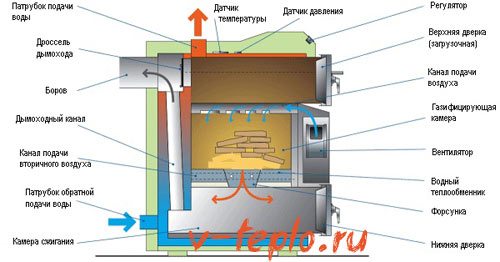

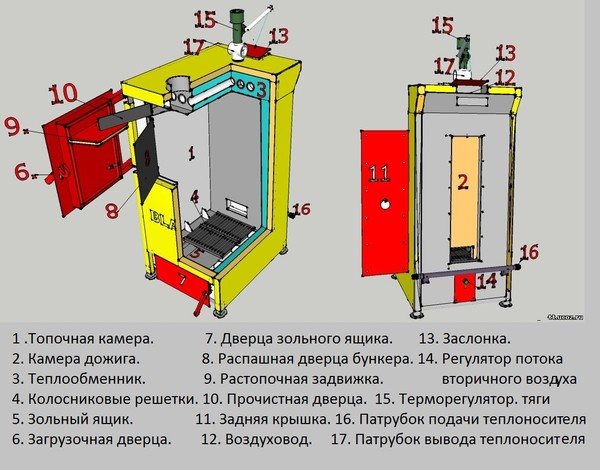

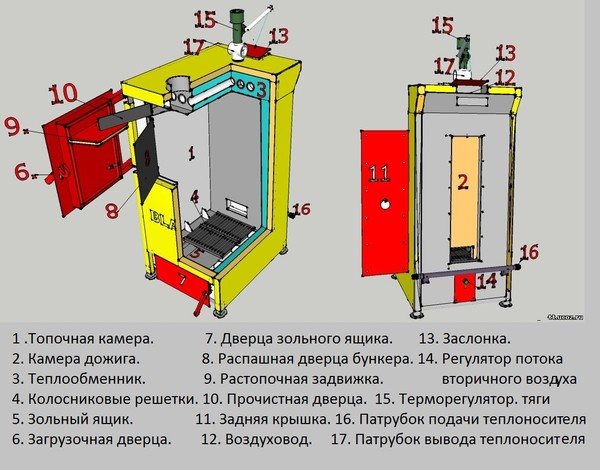

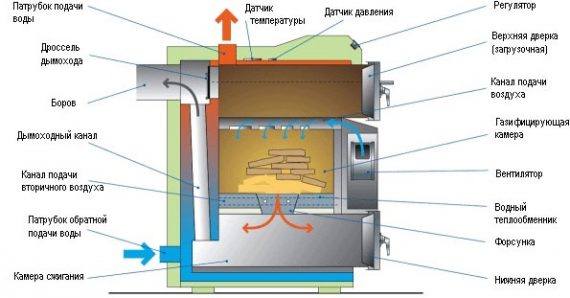

The main elements of the pyrolysis boiler:

- Afterburner and gasification chambers

- Air supply ducts

- Water heat exchanger

- Grate

- Chimney

- Temperature and pressure sensors

- Fan or smoke exhauster

However, in order to have a good idea of the whole process of operation of the heating unit, we will consider the device of pyrolysis boilers, and get acquainted with the purpose of each of the units included in it.

To begin with, any heating device is designed to heat water to the required temperature and supply it to the system. A water heat exchanger is used for this purpose. The coolant enters it through the return line branch pipe, heats up and returns back through the supply line.

The combustion chamber is used for fuel combustion and its decomposition when there is a lack of primary air. The amount of the latter is regulated by an independent thermostat.

The afterburner compartment is necessary for the oxidation of the pyrolysis gas when interacting with secondary air and collecting ash. The flue gas connection and chimney are necessary for the emission of smoke into the atmosphere.

Necessary materials

In order to assemble a pyrolysis boiler with your own hands, you need to prepare a manual working tool, a welding machine, a grinder with cutting wheels and brushes for cleaning. Consumables should be at hand:

- Doors, fasteners and locks for them

- At least one detailed dimensional drawing

- Temperature sensor

- Blower fan

- Pipes for the supply line, hot and cold water supply

- Thick sheet metal

- Fireclay brick

- Grate

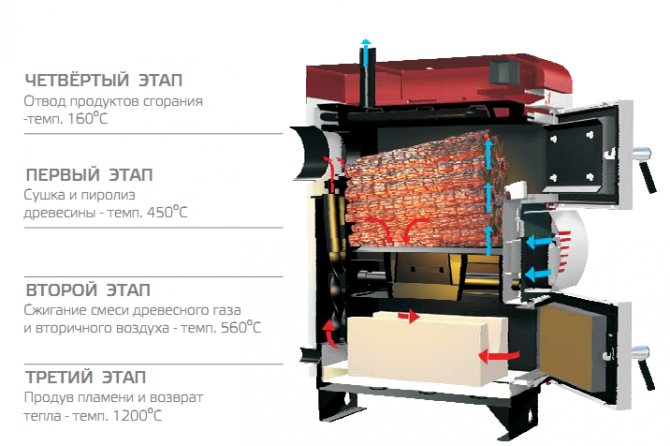

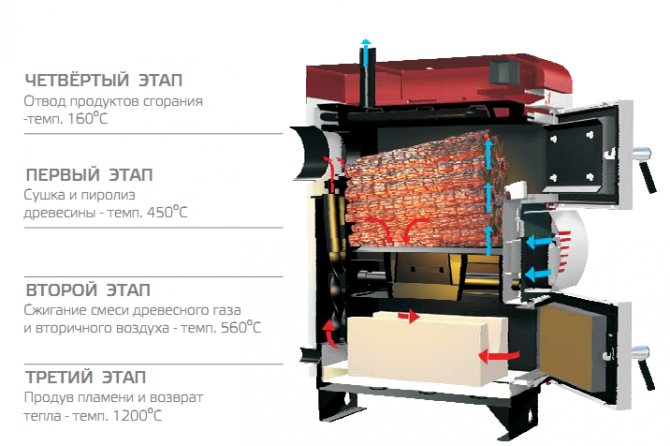

Phased operation of the pyrolysis boiler

In order to have the most complete idea of the design features of the apparatus and the principle of its operation, consider the device of the pyrolysis boiler and its connection diagrams in the photo below.

The chambers are located one above the other and are separated by a grate. Initially, firewood is loaded into the upper part, which is a fuel bunker, and set on fire.

After closing the door and starting the smoke exhauster or fan, the wood is dried. Further, when the temperature rises to 200 degrees or more and there is a lack of oxygen in the chamber, decomposition into a solid residue and wood gas occurs - this is the pyrolysis process.

The lower compartment or combustion chamber is used to burn the pyrolysis gas and collect the remaining ash after combustion. In it, secondary air is added to the released volatile substances and gas combustion occurs, and part of the heat returns to the lower layer of firewood, increasing the temperature and maintaining the pyrolysis process.

In this case, the boiler output is regulated by pressurizing the secondary air through the channels used for its supply.

At the next stage, the heat obtained during the reaction is used to heat water in a heat exchanger, which then enters the heating system.

Boiler according to Belyaev's scheme

We need the following materials:

- About 10 square meters of sheet metal with a thickness of 4-5 mm.

- 8 meters of steel pipe, 57 mm in diameter with 3.5 mm wall thickness.

- One meter of pipes with a diameter of 159 mm and 32 mm.

- 15 pieces of fireclay bricks.

- Blower fan.

Blower fan on a pyrolysis boiler - Steel strips, 20, 30 and 80 mm wide.

Of the basic tools, you will need a grinder, a drill and a welding machine.

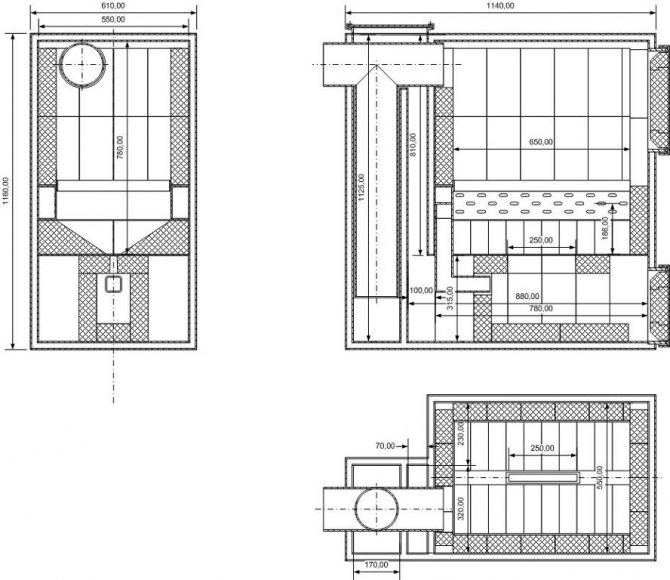

Step-by-step instructions for assembling the pyrolysis chamber:

- Two combustion chambers are assembled.A furnace in which wood and gas will burn, where emitted gases burn.

- The back wall and air outlets from the channel or professional pipes with drilled holes are welded to them.

- A hole is made in the furnace and a branch pipe is welded through which oxygen will flow inside.

- The next is the heat exchanger. To do this, we take two metal plates and drill symmetrical holes in them for a pipe with a cross section of 57 mm.

The pipe is cut into pieces of equal length, and they are welded into the workpieces. Then it is welded to the boiler. - Before making and welding the front wall to the combustion chambers, two holes are made in it. They will be designed for air inlet and outlet pipes.

Pyrolysis boiler diagram - A hog and a cover are welded in front of the damper. It is important to clean all welding seams with a grinder.

- From above, the entire structure is sheathed with a sheet of 4 mm wide with corners. We additionally insulate the upper part. After that, we check the box for leaks. This can be done with water. If there is no tightness, the boiler efficiency will decrease significantly.

- Doors for combustion chambers are made of cast iron plates. The hinges are welded and installed. Latches are placed on top.

- We lay out the lower chamber with bricks, having previously cut them to the required size. Since they will not be visible, it is not necessary to buy new ones. Can be found for free near any destroyed building.

- A blower fan is installed at the outlet of the air pipe.

Also, such a design can be made from a boiler KST, using it as a body.

Wiring diagram in detail

It is not enough to buy a heating device, it is also necessary to install it correctly, as well as connect it to the system.

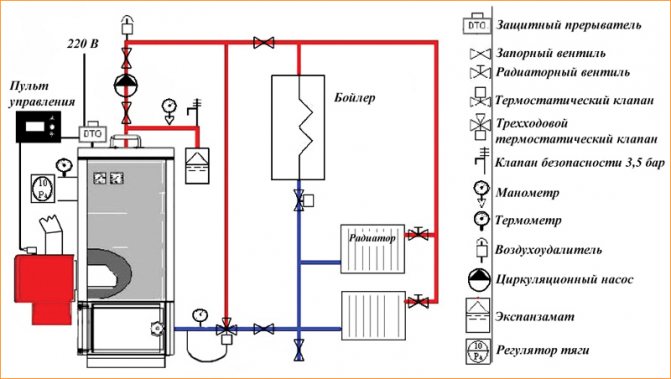

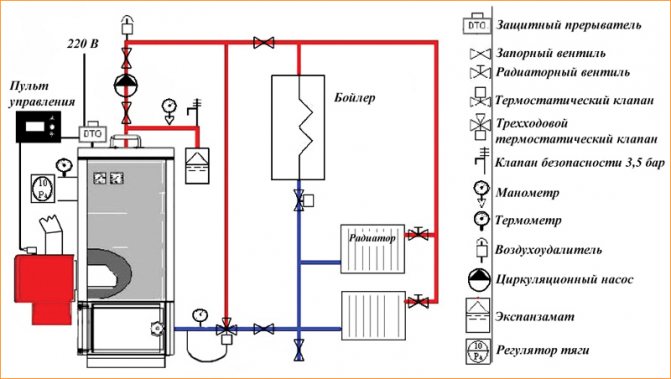

The connection of the pyrolysis boiler can be done in several ways:

- Simple

- With mixing contour

- With a hydraulic arrow

- With storage tank and DHW circuit

The first, in addition to the device itself, includes: a circulation pump, an expansion tank and a security group. With such a connection, a small amount of condensation may occur, but the control unit reacts to its accumulation. In this case, it cuts off the power supply to the pump and thus prevents the formation of a large amount of condensation.

The second scheme for connecting a pyrolysis boiler, in addition to the previously listed nodes, also includes a mixing circuit and taps necessary to adjust the amount of coolant. It is somewhat better than a simple one and completely eliminates the formation of condensate on the walls of the boiler.

The third is most often used for systems with several heating circuits and contains a hydraulic arrow. Its main role is to exclude the hydraulic effect of the pumps among themselves. But it is also capable of degassing the heating system.

And the last one is the scheme of operation of the pyrolysis boiler with Laddomat 21. It includes an accumulation tank and a hot water supply circuit, the ideal operation of which is ensured by an additional unit. The selection of the volume of the container is carried out according to the following indicators: not less than 25 liters per 1 kW of power.

This circuit, due to the presence of the Laddomat 21 block, is able to replace the classic wiring diagram, consisting of separate elements. It works in the following mode. The water is heated to the set value by adjusting its flow from the storage tank using the thermostat valve. It increases or decreases the cross-section of the return line and thereby affects the achievement of the specified parameters by the coolant.

In addition, the presence of a storage tank in it allows the boiler to operate in optimal mode. And in case of a sudden power outage, it allows you to maintain the temperature of the coolant at a given level for two days.

The efficiency of the DHW circuit is achieved by using the energy of the boiler. Getting hot water for household needs is possible due to the release of a part of its heat by the coolant through the walls of the tank.

Which scheme for connecting a pyrolysis boiler, from the ones discussed above, will be optimal, depends on the specifics of the heating system, and in part on the availability of a free amount of money.

But in any case, they must meet the following conditions:

- Meet safety requirements

- Ensure good circulation of the coolant in the system

And do not forget that the better the boiler piping is equipped, the more economical it will be in operation and more convenient to operate and maintain.

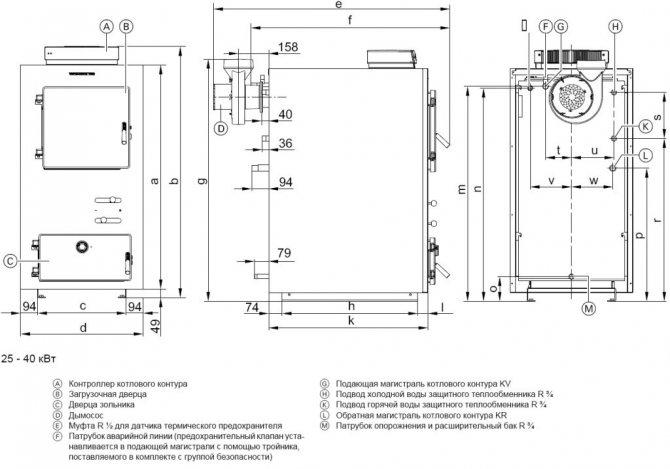

Drawings, diagrams and calculations

Pyrolysis boiler drawing

If you want to understand the principle of the pyrolysis boiler, you need to study its drawings. The device of the unit is not very simple, but there is nothing complicated either. Its body is divided into 2 compartments, where the lower one is a firebox, and the upper one is a chamber where firewood is placed. The same firewood is burned in the firebox. They support the flame, which is transmitted through the lattice partition to the wood lying in the upper chamber. They are the main source of thermal energy and combustible gas. They do not burn in the chamber, but smolder.

As in any other heating unit, the main indicator is the power of the installation. For domestic use, it is better to install boilers with a capacity of 25–40 kW. The higher the power, the larger the overall dimensions of the device. For instance:

- With a power of 20 kW, the boiler height will be 120 cm.

- 40 kW - 150 cm.

All the same can be said about other dimensional indicators. This is why it is so important to accurately determine the power. After all, it is she who will affect the material costs associated with the independent manufacture of a pyrolysis boiler.

What is the most economical heating device?

All boilers are used to heat residential or industrial premises and are divided into three types:

- Gas

- Electro

- Solid fuel, long burning

Each of them operates on a certain type of fuel and has its own advantages and disadvantages. But how do you choose the most reliable and economically profitable sample? To answer this question, it is necessary to consider each of the models produced and, having compared the device of the pyrolysis boiler itself and other types, choose the one that is suitable for specific conditions.

The most common are gas

Let's start with gas equipment, since this type of fuel is considered one of the cheapest, and given the Russian climatic conditions, its consumption in winter will be large. Devices of this type on the market are represented by various manufacturers and a wide range of models, so there is plenty to choose from.

However, it must be borne in mind that gas appliances differ in:

- Installation method (floor or wall)

- Functionality (with one or two circuits - for heating and DHW)

- Burner types (electric or piezo ignition)

- Removal of combustion products (with natural or forced draft)

They have differences in power, and the area of the heated room is directly dependent on its value. Usually, for the calculation, average data are taken, namely, that 1 kW of power is required for 10 m² with a ceiling height of no more than 3 meters.

The advantages of gas equipment include the fact that for devices with forced draft, the equipment of a classic chimney is not required. It usually uses a coaxial pipe that comes with the boiler.

But gas models have drawbacks. The biggest of them is the ability to operate on only one type of fuel and, therefore, the possibility of using such equipment is available only in gasified settlements.

Electric is the simplest and most convenient

Next on our list are electrical appliances. And although this type of equipment is considered one of the most expensive to operate due to the high cost of electricity, you should not completely abandon it.

Electric models have some advantages over other models.

Firstly, they are irreplaceable in suburban settlements, to which the gas main is not connected.

Secondly, they are cheaper than liquid or solid fuel models and are very easy to install, which means they will not require additional costs, except for their own cost.

Thirdly, they can be installed in any room, have small dimensions and weight, and surpass other types of equipment in these indicators.

Their design is very simple and includes:

- Control block

- Heat exchanger (consisting of a tank and heating elements)

Thanks to this, they are very easy to use, do not require preventive maintenance and cleaning. But their most important advantage is environmental friendliness.

They do not burn oxygen in the room, do not emit harmful substances into the atmosphere and are very easy to adjust.

A wide range of capacities allows the use of such equipment not only for heating private houses and apartments, but also for large industrial premises, and even those in which other boilers are prohibited.

In addition, they are fully automated. This allows you to specify the desired temperature, which in the future the device maintains on its own.

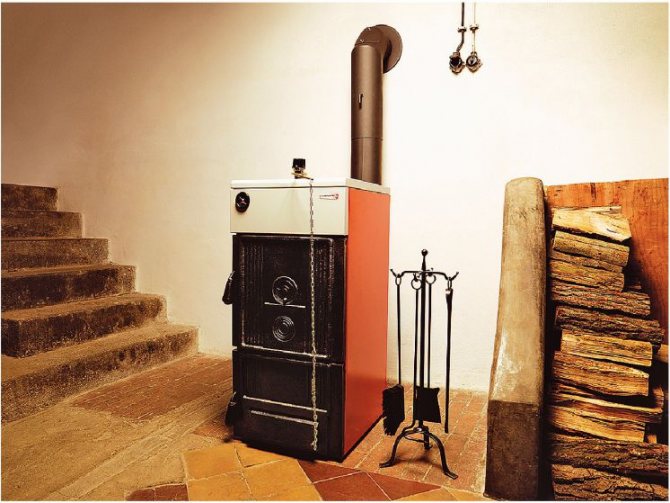

Progressive - pyrolysis

Last on our list are solid fuel boilers for long burning. They also have another name - gas generators. Their principle of operation is based on the combustion of firewood or waste from wood processing, and in some models, coal. At the same time, they have the ability to use fuel as efficiently as possible, and thereby increase efficiency.

They can be used both for space heating and hot water preparation. Modern models are equipped with automation that simplifies their operation. The advantages include the cost of fuel, it is one of the cheapest and most affordable in any locality.

Unlike gas models, they do not require approval for installation, and also surpass them in fire safety, the scheme of the pyrolysis boilers themselves is very simple and allows you to install them yourself.

But their most important advantage is complete autonomy. Even in the absence of gas and electricity in the house, they will be able to provide you with warmth and hot water.

User's manual

Air supply can be done in two main ways: by injection method or by exhaust method (using a smoke exhauster). The use of the injection version allows you to regulate the flow rate, which allows you to control the intensity of combustion, the process of transition from smoldering to the delivery of maximum power in a short period of time.

As for smoke exhausters, today they are producing such designs that can provide vacuum draft, capable of carrying out the pyrolysis process without heat loss.

The most economical mode of operation of the boiler is when the water is heated to 60 ° C. If all the conditions are met, then this temperature is reached after 30-40 minutes.

The normal functioning of the heating system directly depends on the moisture content of the wood. It is not recommended to use wood with a moisture content above 50%. The most optimal is the moisture content of the firewood, equal to 25-30%. In order to achieve such a percentage of moisture, it is necessary to dry the wood for a long period in ventilated areas, in special woodsheds, sheds (depending on the initial moisture and wood species).

When using firewood with a moisture content of 15-20%, compared to 50% moisture, the power increases by about 2 times. However, in natural conditions, it is rather difficult to obtain such moisture. It will take approximately 1.5-2 years. Therefore, immediately after the end of the heating season, it is necessary to start harvesting firewood.

Range

The products are widely represented, since the extraction of pyrolysis gas has been known for a long time and the technology has been tested in the chemical industry. As a rule, most large manufacturers of boiler equipment have, among other things, a line of long-burning boilers.In the table below, we have indicated the most demanded heating equipment from Russian, Ukrainian and German manufacturers. Before considering a specific model, it is highly recommended to calculate the boiler capacity using our small online calculator.

Popular models of pyrolysis boilers for private houses

| Boiler name | Short description | Model | Power / approximate heated area, kW / m2 | Approximate price, rub. |

| Atom, Motor Sich | Ukrainian, for firewood (380-1000) × (100-410) mm and humidity up to 50%. Walls made of 6-10 mm steel, protected with ceramic concrete | MS-16 | 8–19/80–190 | 120 000 |

| MS-25 | 13–30/130–300 | 138 000 | ||

| MS-32 | 16–38/160–380 | 162 000 | ||

| Teplogarant, Bourgeois K | Russian single-circuit boilers are distinguished by their low cost | Standard T-10 | 10/100 | 40 000 |

| Standard T-20 | 20/200 | 56 000 | ||

| Standard T-30 | 30/300 | 69 000 | ||

| Atmos | Czech equipment made of steel with a thickness of 3–8 mm, individual elements of which are protected by ceramic blocks | DC 15E | 10–15/100–150 | 72 000 |

| DC 18S | 14–20/140–200 | 81 000 | ||

| DC 22S | 15–22/150–220 | 94 000 | ||

| DC 25S | 17–25/170–250 | 96 000 | ||

| Volcano | Ukrainian single-circuit made of steel 5 mm thick. Nozzle and ash pan made of high-strength heat-resistant concrete | ECO 15 | 15/80–100 | 81 000 |

| ECO 20 | 20/150–200 | 85 000 | ||

| ECO 25 | 25/200–250 | 87 000 | ||

| ECO 30 | 30/250–300 | 91 000 | ||

| Divo | Russian pyrolysis boilers, can be equipped with an electric heating element, automatic or manual draft regulator | 10 | 8–12/100 | With manual draft control: with heating element - 55,000, without heating element - 49,000.With automatic draft control: with heating element - 66,000, without heating element - 59,000 |

| 18 | 12–18/185 | With manual draft control: with heating element - 65,000, without heating elements - 59,000.With automatic draft control: with heating elements - 76,000, without heating elements - 69,000 | ||

| 30 | 18–30/300 | With manual draft control: with heating element - 82,000, without heating element - 75,000.With automatic draft control: with heating element - 91,000, without heating element - 84,000 | ||

| Trajan (some write Trojan) | Russian long-burning boilers with the ability to connect an electric heating element | T10 | 10/90 | 47 000 |

| T15 | 15/120 | 51 000 | ||

| T20 | 20/120–220 | 56 000 | ||

| T30 | 30/240–330 | 70 000 | ||

| Buderus (Buderus) | German single-circuit boilers | Logano S121-2 21 | 21/210 | 163 000 |

| Logano S121-2 26 | 26/260 | 166 000 | ||

| gano S121-2 32 | 32/320 | 177 000 | ||

| Viessmann | Another award-winning German manufacturer of boilers made of steel with a thickness of at least 8 mm | Vitoligno 100-S VL1A024 | 25/250 | 170 000 |

| Vitoligno 100-S VL1A025 | 30/300 | 220 000 | ||

| Geyser | Russian single-circuit (PK) or double-circuit (PK2) boilers for long burning | PK-10 (PK2-10) | 10/100 | 48 000 (51 000) |

| PK-15 (PK2-15) | 15/150 | 53 000 (56 000) | ||

| PK-20 (PK2-20) | 20/200 | 59 000 (61 000) | ||

| PK-30 (PK2-30) | 30/300 | 72 000 (76 000) | ||

| BTS | Ukrainian boilers made of steel with a thickness of 5 mm (standard class) and 6 mm (premium class). Ceramic lining | BTS-15 | 15/180 | 117 000 |

| BTS-20 | 20/230 | 121 000 | ||

| BTS-25 | 25/280 | 139 000 |

We invite you to watch a short video about the work of the Trajan boilers.

A little visualization of the operation of Buderus pyrolysis boilers is on the video below.

And more about the rather popular boilers from TeploGarant - Bourgeois K.

By the way, there are models that are designed to work with different fuels. It can be coal, peat and even pellets. The use of pellet boilers makes it possible to automate the process of fuel supply to a large extent.

Testimonials

Among the sea of custom reviews, it is very difficult to find opinions that are truly unbiased and based on real impressions. What users usually complain about:

- abundant formation of tar due to the fact that the required high temperature is not maintained in the combustion chamber;

- the need to install an additional buffer tank with water, which will accumulate excess heat;

- small thickness of steel, which leads to a change in the geometry of the body and the burnout of its individual parts.