This article on the Mayer (Mayer) cell was the beginning of my research into the possibility of decomposing water into hydrogen and oxygen, for their further use as a fuel gas. For example, instead of gasoline in internal combustion engines, or fuel gas used to heat homes and premises. I am not the author of this article, you can find it on various other sites. It is more informational in nature than scientific and educational, since there is practically no informative material in it. But it was with this article that the research or experiments of many "Kulibins" began. I was also no exception.

Having read the article, a competent engineer will understand the "stupidity" of this article and will want to read anything more intelligent and more like the truth. A fool who is in a hurry to make a hydrogen generator faster and does not want to understand the essence of the issue, will take this article at face value and begin his “anti-scientific” experiments, which will spend even more time and in the end will be disappointed. I am publishing it, without any changes, so that it is clear what is being discussed in my other articles on the Mayer Cell. But I strongly advise against drawing premature conclusions about the possibilities of creating an engine on water based on this article on the Mayer Cell alone. For anyone who really wants to create a hydrogen generator, I advise you to read the rest of the articles on my site devoted to the Mayer Cell, which I personally authored. I think this site visitor will not be disappointed with the material presented in my articles.

About me: I do not wind "bifilar" coils hoping for a miracle, like many other "dunce". I try to substantiate my opinion scientifically, not to believe what is written “on the fence”. Any information must be confirmed by existing physical laws, regulations, or at least be authoritative. I do not believe the "slippery authoritative" scientists, about whose research they write on the Internet, if the scientific nature of their discoveries or observations, except for the article itself without formulations, is not confirmed by anything. For example, I recently received a message on Mile about water activation using MRET technology. I read the article earlier, it did not interest me only because about M.V. Couric, N. D. Devyatkova, V.I. I have not heard Petrosyan before, and the article lacks any substantiation of their observations. Attempts to find something intelligible using MRET technology did not end with anything sensible, pure ADVERTISING, designed to earn money for website authors and filter sellers, nothing more. I will change my opinion about these people and about their work only when I find more or less "worthy" material about it.

This was the introduction, and now the promised article about the Mayer Cell, which is actually called "Water instead of Gasoline" and which became the pretext for my research:

Conventional water electrolysis requires a current measured in amperes, a Mayer cell produces the same effect at milliamperes. What's more, ordinary tap water requires the addition of an electrolyte such as sulfuric acid to increase conductivity, the Mayer cell operates at tremendous capacity with clean water.

According to eyewitnesses, the most striking aspect of Mayer's cage was that it remained cold even after hours of gas production.

Mayer's experiments, which he deemed feasible to submit for patenting, earned a series of US patents, presented under Section 101. Submission of a patent under this section is contingent on the successful demonstration of the invention to the Patent Review Committee.

A Mayer's cell has a lot in common with an electrolytic cell, except that it works better at high potential and low current than other methods. The construction is simple.

Electrodes

- refer those interested to Mayer - made of parallel stainless steel plates, forming either a flat or concentric structure. Gas output depends inversely with the distance between them; the patented distance of 1.5 mm gives a good result.

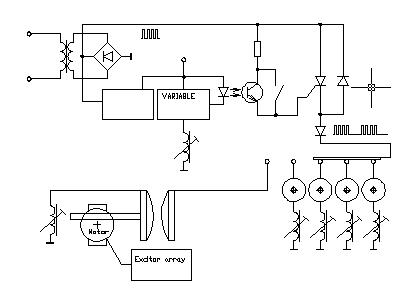

; Significant differences are in the cell nutrition. Mayer uses an external inductance that oscillates with the cell's capacitance - pure water appears to have a dielectric constant of about 5 - to create a parallel resonant circuit.

It is excited by a powerful pulse generator, which, together with the cell capacitance and the rectifier diode, constitutes the pumping circuit. The high pulse frequency produces a stepwise rising potential at the cell electrodes until the point is reached where the water molecule disintegrates and a short current pulse occurs.

The supply current measurement circuitry detects this surge and shuts off the pulse source for several cycles, allowing the water to recover.

Research chemist Keith Hindley offers the following description of the Mayer cell demonstration: “After a day of presentations, the Griffin committee witnessed a number of important properties of the WFC (water fuel cell, as the inventor called it).

A group of independent scientific observers from the UK have testified that the American inventor, Stanley Mayer, successfully decomposes ordinary tap water into its constituent elements through a combination of high-voltage pulses, with an average current consumption of only milliamperes.

The fixed gas output was sufficient to show a hydrogen-oxygen flame that instantly melted the steel.

Compared with conventional high-current electrolysis, eyewitnesses stated that there was no heating of the cell. Mayer declined to comment on details that would allow scientists to reproduce and evaluate his "water cell." However, he submitted a sufficiently detailed description to the US Patent Office to convince them that he could substantiate his invention application.

One demonstration cell was equipped with two parallel excitation electrodes. After being filled with tap water, the electrodes generated gas at very low current levels - no more than tenths of an ampere, and even milliamperes, as Mayer claims - gas output increased as the electrodes were moved closer and decreased as they moved away. The potential in the pulse reached tens of thousands of volts.

The second cell contained 9 double-tube stainless steel cells and produced much more gas. A series of photographs were taken showing gas production at milliamperes. When the voltage was pushed to the limit, the gas came out in a very impressive amount.

"We noticed that the water at the top of the cell slowly began to turn from a pale cream to dark brown color, we are almost certain about the effect of chlorine in highly chlorinated tap water on the stainless steel tubing used for excitation."

He demonstrated the production of gas at milliamperes and kilovolts.

“The most remarkable observation is that the WFC and all of its metal tubes remained completely cold to the touch, even after more than 20 minutes of operation. The molecule-splitting mechanism develops extremely little heat compared to electrolysis, where the electrolyte heats up quickly. "

The result allows one to consider efficient and controllable gas production that is quick to emerge and is safe to operate. We have clearly seen how capacity increases and decreases are used to drive gas production. We saw how the gas flow stopped and started again, respectively, when the input voltage was turned off and on again. "

“After hours of discussion among ourselves, we concluded that Steve Mayer had come to invent a completely new method for decomposing water, which showed some of the features of classical electrolysis. This is confirmed by the fact that his devices, actually working, taken from his collection, are certified by US patents for various parts of the WFC system.

Since they were submitted under Section 101 of the US Patent Office, the apparatus included in the patents was verified experimentally by experts from the US Patent Office, their second examiners and all applications were established. "

“The main WFC was put on a three-year trial. This raised the granted patents to the level of independent, critical, scientific and engineering evidence that the devices actually work as described. "

The practical demonstration of Mayer's cell is significantly more convincing than the pseudoscientific jargon that is used to explain it. The inventor personally spoke about the distortion and polarization of the water molecule, leading to an independent break of the bond under the influence of the electric field gradient, resonance within the molecule, which enhances the effect.

Apart from the abundant evolution of oxygen and hydrogen and minimal heating of the cell, eyewitnesses also report that the water inside the cell disappears quickly, passing into its constituent parts in the form of an aerosol from a huge number of tiny bubbles covering the surface of the cell.

Mayer stated that he has been operating a hydrogen-oxygen converter for the past 4 years using a chain of 6 cylindrical cells. He also stated that photonic stimulation of the reactor space by laser light through optical fiber increases gas production.

ICE on hydrogen fuel

For several decades, there has been a search for the possibility of adapting internal combustion engines for full or hybrid operation on hydrogen fuel. In Great Britain, back in 1841, an engine running on an air-hydrogen mixture was patented. At the beginning of the 20th century, the Zeppelin concern used internal combustion engines running on hydrogen as the propulsion system for its famous airships.

The development of hydrogen energy was also facilitated by the global energy crisis that erupted in the 70s of the last century. However, with its end, hydrogen generators were quickly forgotten. And this is despite the many advantages over conventional fuel:

- ideal flammability of a fuel mixture based on air and hydrogen, which makes it possible to easily start the engine at any ambient temperature;

- large heat release during gas combustion;

- absolute environmental safety - exhaust gases turn into water;

- 4 times higher combustion rate compared to gasoline mixture;

- the ability of the mixture to work without detonation at a high compression ratio.

The main technical reason, which is an insurmountable obstacle in the use of hydrogen as a fuel for cars, was the inability to fit a sufficient amount of gas on a vehicle. The size of the hydrogen fuel tank will be comparable to that of the vehicle itself.The high explosiveness of the gas must exclude the possibility of the slightest leak. In liquid form, a cryogenic unit is required. This method is also not very feasible in a car.

Take a look around: what can be made from oil

Many of the objects around us are more or less oil. Clothes, a toothbrush, a TV, an electric kettle, a lamp, dishes, toys, and many other items that we use in everyday life are made of plastic, and, therefore, are the result of the chemical industry with the use of oil.

Oil is one of the most valuable and widely used raw materials. The states that own its vast deposits, one might say, control the world economy and processes.

For thousands of years, people have studied natural resources and tried to extract useful qualities from them. Having studied the structure of oil, chemists have found that many useful products can be made from it, and now a person's life is surrounded by many objects, things and means that are made of black gold. Under a certain pressure and temperature, various unnecessary impurities are removed from the oil and pure oil products are created.

Oil objects that surround us:

- Fuel;

- Plastic;

- Polyethylene and plastic;

- Synthetics;

- Cosmetics;

- Medicines;

- Household and household items.

It is almost impossible to list all products that are based on petroleum. The total number can be determined by a figure within 6,000 of such products.

Brown's Gas

Today, hydrogen generators are gaining popularity among motorists. However, this is not exactly what was discussed above. Through electrolysis, water is converted into the so-called Brown's gas, which is added to the fuel mixture. The main task that this gas solves is the complete combustion of the fuel. This serves as an increase in power and a decrease in fuel consumption by a decent percentage. Some mechanics have managed to save up to 40%.

The surface area of the electrodes is of decisive importance in the quantitative gas yield. Under the action of an electric current, a water molecule begins to decompose into two hydrogen atoms and one oxygen. When burned, such a gas mixture releases almost 4 times more energy than when molecular hydrogen burns. Therefore, the use of this gas in internal combustion engines leads to more efficient combustion of the fuel mixture, reduces the amount of harmful emissions into the atmosphere, increases power and reduces the amount of fuel consumed.

Homemade gasoline options

In a similar way, self-made gasoline is obtained from garbage. As the latter, any plastic parts, scraps of polyethylene, polypropylene, PET bottles (ordinary plastic containers), rubber of all grades are used.

Today, handicraft technologies are known for making gasoline with your own hands (it is correct to say - fuel similar to gasoline) from peat, reeds, straw, husks of seeds, corn cobs, leaves, weeds, reeds and other organic and inorganic substances.

Self-made gasoline, few people risk using it for expensive cars, since the technical parameters of this fuel and its effect on fuel equipment are not known. Homemade gasoline remains the result of interesting experiments by competent self-taught techies.

Users have a completely different attitude towards biodiesel or other biofuels obtained by industrial technologies, which have certificates of compliance with the standards in force in the country.

If you liked our article and we somehow were able to answer your questions, then we will be very grateful for a good review about our site!

In the modern world, gasoline prices are steadily going up, despite the fact that the cost of oil is constantly falling.

In this regard, many are beginning to think about whether it is possible to make gasoline at home and how to do it.

Universal Hydrogen Generator Circuit

For those who do not have the ability to design, a hydrogen generator for a car can be bought from craftsmen who put the assembly and installation of such systems on stream. Today there are many such proposals. The cost of the unit and installation is about 40 thousand rubles.

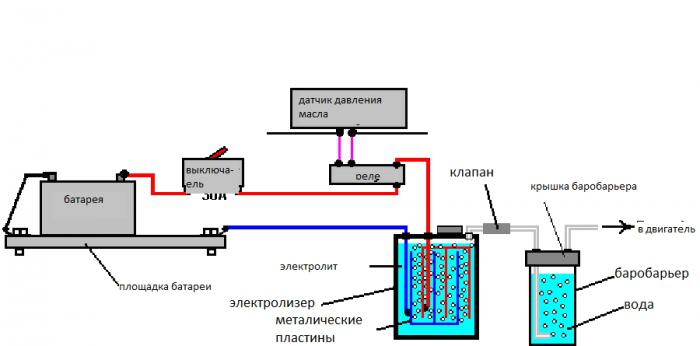

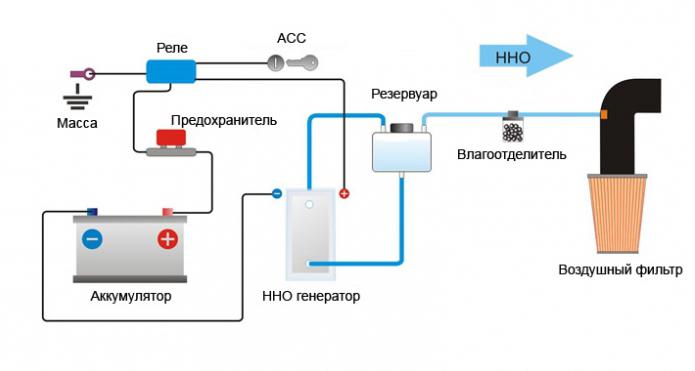

But you can assemble such a system on your own - there is nothing complicated in it. It consists of several simple elements connected into one whole:

- Installations for water electrolysis.

- Storage tank.

- Gas moisture trap.

- Electronic control unit (current modulator).

Below is a diagram by which you can easily assemble a hydrogen generator with your own hands. The drawings of the main plant producing Brown's gas are quite simple and straightforward.

The scheme does not present any engineering complexity; everyone who knows how to work with the tool can repeat it. For cars with an injection fuel supply system, it is also necessary to install a controller that regulates the level of gas supply to the fuel mixture and is connected to the on-board computer of the car.

Alternative ways

Gasoline isn't just made from coal and rubber tires.

It can be obtained from garbage, firewood, pellets, leaves, nut shells, seed husks, corn rods, peat, straw, reeds, weeds, reeds, old sleepers, dry bird and animal manure, plastic bottles, medical waste, etc.

The process of making gasoline at home, discussed above, is not as complicated as it seems at first glance. Terms such as hydrogenation, gasification, etc. can be misleading. But in fact, setting up production and making gasoline with your own hands is not as difficult as it seems.

We bring to your attention an interesting report on how to make gasoline at home:

If we consider the question of what gasoline is made of, then, of course, many can immediately say that it is from oil. This is true, but this is just the tip of the iceberg, and the actual process of fuel production is much more complicated.

Installation types

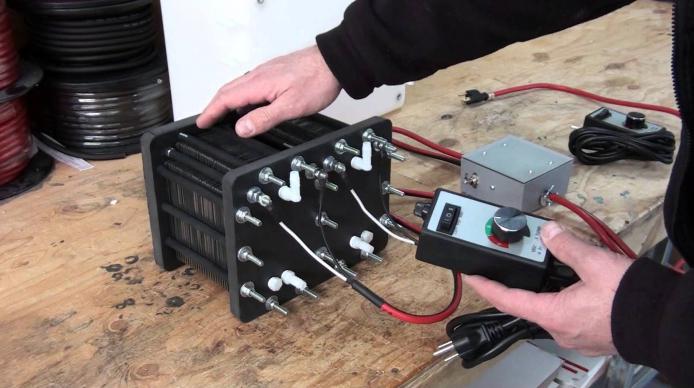

Today, a hydrogen generator for a car can be equipped with three electrolyzers of different type, nature of operation and performance:

- Simple, cylindrical type. Produces 700 milliliters of gas per minute. This performance is sufficient for engines with a displacement of up to 1.4 liters.

- With split type cells. It is the most efficient in terms of design and performance. Gas output exceeds 2 liters per minute. This volume allows it to be used in freight transport.

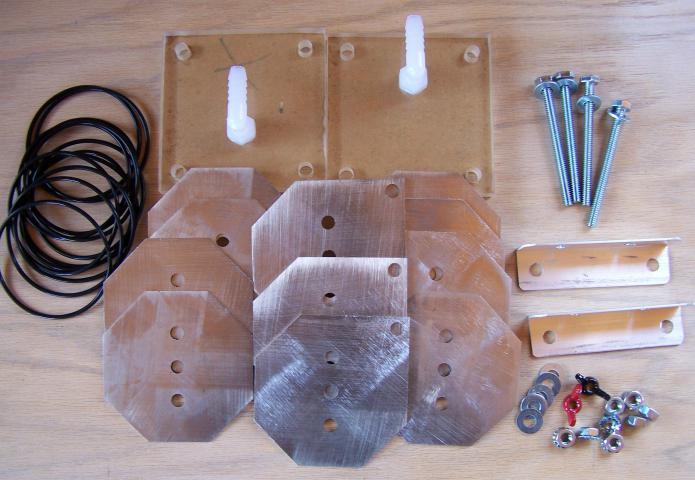

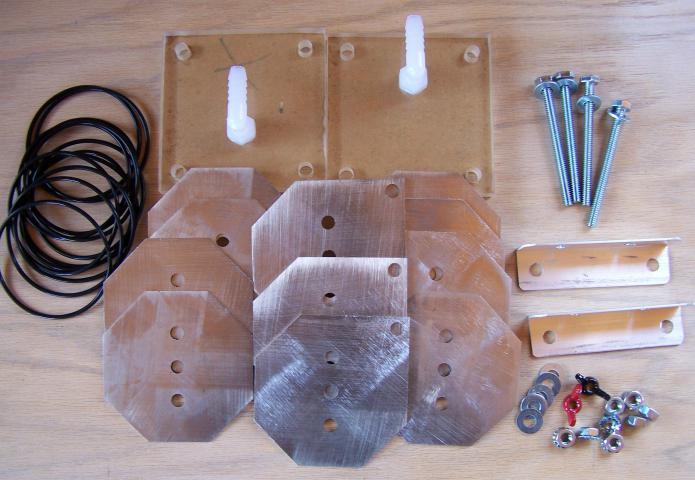

- Electrolyzer with open plates. This design provides additional cooling to the system so that it can be used during long-term operation of the unit. The gas outlet is regulated by the number of reactor plates.

The first type of design is sufficient for a variety of carburetor engines. There is no need to install a complex electronic circuit for the gas performance regulator, and the assembly of such an electrolyzer itself is not difficult.

For more powerful cars, the assembly of the second type of reactor is preferable. And for diesel engines and heavy vehicles, a third type of reactor is used.

How to make gasoline with your own hands?

The greatest yield is obtained when using waste rubber tires, as well as any other rubber products.They need to be crushed by any suitable means to a size that will allow the pieces to be pushed through the feed hole into the reactor - a metal boiler with a hermetically sealed lid with a gas outlet pipe welded into it. A fire is being made under the reactor. The process uses the technology of decomposition of rubber into complex gas components. Rubber sublimes, bypassing the liquid stage, immediately into gas.

The branch pipe is connected to the condenser (refrigerator) through a water seal (so that there is no access to the oxygen reactor). This is the simplest coil placed in cold water or a jacket cooled by running water. In it, the gas is partially condensed into a liquid, which, after additional distillation, will become home-grown gasoline. It is periodically drained through a valve installed at the far end of the refrigerator. That part of the gas that has not condensed is directed further into a tube with holes - the burner. It is ignited using the reactor for additional heating.

The resulting liquid is a kind of oil that needs to be distilled in the second cycle. It is loaded into an apparatus similar to the first, which already operates as a distiller with a liquid heating temperature of no more than 200 ºС. If we divide the liquid obtained as a result of distillation into fractions (according to the order of the distillate portions), then when testing them for the intensity of combustion, you will notice that the former burn like gasoline, the next ones - like diesel fuel or kerosene. A liquid similar to gasoline and is used in gasoline engines.

Required performance

In order to really save fuel, a hydrogen generator for a car must produce gas every minute at the rate of 1 liter per 1000 engine displacement. Based on these requirements, the number of plates for the reactor is selected.

To increase the surface of the electrodes, it is necessary to process the surface with emery paper in the perpendicular direction. This treatment is extremely important - it will increase the working area and will avoid the "sticking" of gas bubbles to the surface.

The latter leads to the isolation of the electrode from the liquid and prevents normal electrolysis. Do not forget that the water must be alkaline for the electrolyzer to work properly. Ordinary soda can serve as a catalyst.

Basic properties of gasoline

The main properties of gasoline include such characteristics as its chemical composition, as well as the ability to evaporate, burn, and ignite. In addition, you can also highlight the resistance to detonation and corrosion activity.

It is important to know that all physical and chemical properties of gasoline fuel will change depending on how much hydrocarbon and what kind of hydrocarbons it contains. For a more illustrative example, you can take the freezing point for gasoline as a basis. In normal processing, the freezing rate of this liquid is -60 degrees Celsius. However, with the use of additional components, this figure can reach -71 degrees Celsius. The vaporization temperature of gasoline is 30 degrees. The higher this indicator rises, the faster the evaporation will occur. It is also important to note that the amount of fuel vapors from 74 grams to 123 grams or more per cubic meter will already form an explosive mixture.

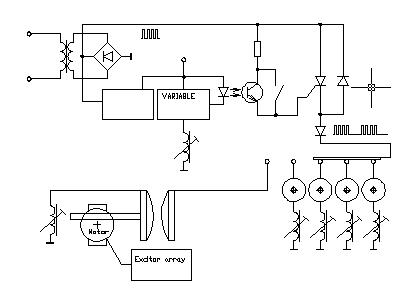

Current regulator

A hydrogen generator on a car increases its productivity during operation. This is due to the release of heat during the electrolysis reaction. The working fluid of the reactor is heated, and the process proceeds much more intensively. A current regulator is used to control the course of the reaction.

If you do not lower it, water may simply boil, and the reactor will stop producing Brown's gas. A special controller that regulates the operation of the reactor allows you to change the capacity with increasing speed.

Carburetor models are equipped with a controller with a conventional switch of two operating modes: "Track" and "City".

Chemical properties

In order to consider the chemical properties and their stability in gasoline, it is necessary to be based on the most important indicator - the time that these properties remain unchanged. This indicator is the most important, since during long-term storage of fuel, the lightest hydrocarbons begin to evaporate, which greatly reduces the performance of the liquid as a whole. According to the state standards of the Russian Federation, it follows that the chemical composition of any brand of gasoline from 92nd to 98th remained unchanged for five years. This period is prescribed taking into account the storage of explosive fuel in accordance with all the rules.

Installation safety

Many craftsmen place plates in plastic containers. Don't skimp on this. A stainless steel tank is needed. If not available, an open plate design can be used. In the latter case, it is necessary to use a high-quality insulator of current and water for reliable operation of the reactor.

It is known that the combustion temperature of hydrogen is 2800. It is the most explosive gas in nature. Brown's gas is nothing more than a "explosive" mixture of hydrogen. Therefore, hydrogen generators in road transport require a high-quality assembly of all system components and the presence of sensors to monitor the process.

The working fluid temperature sensor, pressure and ammeter will not be superfluous in the design of the installation. Particular attention should be paid to the water seal at the outlet of the reactor. It is vital. If the mixture ignites, such a valve will prevent the flame from spreading into the reactor.

A hydrogen generator for heating residential and industrial premises, operating on the same principles, is distinguished by several times higher reactor performance. In such installations, the absence of a water seal is a lethal danger. In order to ensure the safe and reliable operation of the system, it is also recommended to equip hydrogen generators on cars with such a check valve.

Octane number

If the question of what gasoline is made of has become more or less clear, then very few know what the octane number is. Everyone knows that the name of each brand of gasoline contains an alphabetic as well as a numerical designation. Letters such as A or AI indicate the method for determining the octane number. A - motor process, AI - research. But the numbers that follow, and show the quantitative content of the octane number in the fuel.

Everyone knows that both oil and gasoline are explosive substances. Since gasoline is obtained from oil by refining it, this property does not disappear anywhere. The octane number indicates the knock resistance of the fuel. In other words, the higher it is, the higher the safety of the fuel grade. However, it should be understood that this indicator is relative, and any spark will still cause an explosion.

A little about gullibility and naivety

Some enterprising businessmen offer for sale a hydrogen generator for cars. They talk about the laser processing of the surface of electrodes or about the unique secret alloys from which they are made, special water catalysts developed in scientific laboratories around the world.

It all depends on the ability of the thought of such entrepreneurs to fly scientific fantasy. Gullibility can make you, for your own money (sometimes not even small), the owner of the installation, in which the contact plates will collapse after two months of operation.

If you have already decided to save money in this way, then it is better to assemble the installation yourself. At least there will be no one to blame.

Manufacturing process

If you answer the question of what gasoline is made of with a simple answer - from oil, then this is not quite a true statement, since there are some impurities in this fuel, but more on that later.

To obtain fuel in its primary form, it is necessary to subject the raw material to primary processing. This treatment is understood as the purification of oil from salts, as well as water impurities. These processes are carried out under the influence of an electric field. The result of this procedure is the separation of water from oil, as well as desalination to the required level. After completing this procedure, they proceed to the thermal treatment of the oil. It is after such procedures that such fuel is obtained - gasoline, gas, diesel.

This is followed by a catalytic reforming procedure. During this very procedure, the resulting gasoline after primary processing is converted into a fuel characterized by a high octane number. However, such as 92nd or 95th, are obtained by mixing different components that have been obtained as a result of different processing of crude oil.

Mini refinery

Currently, the issue with the production and purchase of fuel is quite acute, since resources are depleted, and because of this, the price of this product is constantly increasing. In light of these events, the question arises as to what is more profitable to buy - gasoline and other fuel - or to produce it yourself. It is important to understand that for most businesses and companies, fuel costs are the most extensive. It is in this situation that many come to consider the idea of a mini-refinery. This option doesn't seem so bad, especially when you consider the cost of fuel and the cost of a mini refinery. Practically every major entrepreneur can purchase such a mini-plant, which can already be said about, say, a region of an entire country.

Refinery types

Currently, you can buy a mini-refinery for oil refining of almost any type on the market. This is the most important criterion, since these industrial facilities have to be operated in a wide variety of climatic conditions. For this reason, the market is saturated with a variety of types of refineries. There are any specimens, ranging from heat-resistant and corrosion-resistant, to "arctic" installations. A wide range of mini-refineries allows you to process the crude product in almost any conditions.

It is worth noting that they themselves can also operate on different fuels. For their operation, you can use natural or liquefied gas, diesel fuel, fuel oil, crude oil. Such a choice of fuel for the operation of the factory itself provides a wide range of possibilities for the operation of the facility, and also allows you to satisfy any individual preferences for the choice of a working fuel product.