The use of combined power plants for heating private households ensures maximum autonomy of the heating system. The originality of the design allows for prompt changeover of the boiler from one type of fuel to another, more affordable in the current circumstances.

An unpredictable rise in the cost of energy resources can make significant adjustments to the well-functioning heating circuit of a private house. Combined boilers for home heating will provide the ability to use the most affordable fuel from a financial point of view.

There are several types of installations that can operate on two or more types of fuel. Below we will consider the main design features of combined boilers and possible combinations of the used energy carriers. In addition, the article evaluates the advantages and disadvantages of the equipment, provides feedback from the owners.

Gas boilers - leaders in heating a private house

The golden rule is: if there is main gas, you need to install a gas boiler... There are no competitors in terms of operating costs for heating main gas. But there are spots on the sun too: the initial investment in the installation of gas equipment is tangible. It will require project development, piping, purchase and installation of heating radiators and the gas boiler itself. Expenses can exceed 350,000 rubles, excluding the cost of connecting to the gas pipeline.

The gas boiler is put on for many years, and not as a temporary solution. Boilers of this type dominate the market and are divided into groups by the type of installation (wall-mounted, floor-standing), by the type of burner (atmospheric, pressurized), by functionality (single-circuit and double-circuit - in addition to the heating system, they also provide hot water supply for hot water supply).

Gas floor-standing single-circuit boiler Beretta Novella Avtonom

They are produced by a large number of companies: BOSCH, BUDERUS, VIESSMANN, DE DIETRICH, CTC, ROCA, PROTHERM, AEG, VAILLANT, HERMANN, BERETTA, BAXI, FEROLLI, DAKON, NAVIEN, TITANIUM. Today a gas boiler of a well-known brand is very reliable, and if installed correctly, it practically does not break. The opinion that only domestic models are fully adapted to our conditions is not entirely correct.

The main difficulties of the Russian heating system of a private house: low gas pressure, power surges (unpredictable long outages) and requirements for the type of coolant.

For example, wall-mounted gas boilers Vaillant AtmoMAX Plus are designed for a nominal main gas pressure of 13-20 mbar (0.013-0.02 kgf / cm²). With a reduced pressure, the automation switches off the unit, and after the resumption of gas supply with the required pressure, it also automatically turns on. The technique is doing just fine, but people run the risk of being left without heat in the winter. In such cases, they install backup heating equipment or select a boiler designed to work with low pressure gas. Currently, such models are easy to find: a Buderus Logano G234WS floor-standing boiler, a Navien Ace wall-mounted boiler and others, designed to operate at a gas pressure of 10 mbar.

Power outages occur even more often than gas interruptions, as a result of which the automation of modern computerized boilers is turned off. For most Russian units with atmospheric burners, this is not scary, they are non-volatile. Operation of imported equipment in this situation is possible in manual mode. An interesting solution was proposed by the specialists VERETTA and DAKON.Electricity for powering the automation is generated by a built-in heat generator.

Another problem in Russian conditions arises due to the fact that many foreign manufacturers remove their equipment from warranty service when using propylene glycol rather than water as a heat carrier. And in summer cottages and cottages of periodic residence, the temperature at the level of 5 ºС at subzero external temperatures is maintained precisely due to the use of glycol antifreeze. And therefore, if you intend to pour antifreeze into the heating system, ask if this is permissible for the boiler of the selected model.

A remote control unit with an information display allows you to easily adjust the mode and control the operation of the boiler

Wall hung gas boilers 1.5-2 times cheaper than floor options, but also with performance, it can be the same. For example, a wall-mounted double-circuit boiler Baxi LUNA-3 Comfort 310 Fi with a capacity of 31 kW costs about 40,000 rubles, and its floor-standing analogue Baxi SLIM 2.300 Fi for 29.7 kW is twice as expensive - 70,000-80000 rubles. But still, do not forget that wall-mounted gas boilers are limited in power (up to 42 kW). They are used for heating and hot water supply of a country house with an area of up to 300 m². An important factor in saving on operating costs is the presence of stepwise or smooth power regulation. The boiler usually operates at full capacity only for one fifth of the heating season. The rest of the time, power reduction results in significant savings.

Wall mounted gas heating boilers:

ARISTON THERMO BS II - double-circuit wall-mounted gas boiler |

BAXI Nuvola - double-circuit wall-mounted gas boiler |

DE DIETRICH Innovens Pro MCA 25 - gas wall-hung condensing boiler |

BAXI Luna 3 - double-circuit wall-hung gas boiler with a closed combustion chamber |

BOSCH Condens 3000 W - gas wall-mounted double-circuit condensing boiler |

VIESSMANN Vitodens 200-W - wall-hung gas double-circuit condensing boiler |

A kind of trump card of pressurized boilers is a replaceable fan burner. It costs a lot and is sold separately. In this case, you can purchase both a "native" burner, and an analogue of a third-party manufacturer (BALTUR, ECOFLAM, WEISHAUPIGIERSH, RIELLO, LAMBORGIANI, BENTONE). The fan burner solves many pressing problems and works for the future.

Firstly, it allows the boiler to function with high efficiency at a reduced gas pressure and to regulate its power. Secondly, a set of replaceable burners provides flexibility in the choice of fuel.

One and the same pressurized boiler will run on gas or diesel thanks to the replacement of a single unit - the burner. It is practical if the main gas is only included in the development plans of the settlement. For the first time, they purchase a supercharged unit, a diesel burner and heat the house with liquid fuel (as an alternative, you can use an electric boiler). When the long-awaited gasification becomes a reality, all you need to do is change the burner. The cost of a two-stage gas burner Baltur BTG 6 R (30.6-56.3 kW) is about 26,000 rubles, a diesel Baltur BTL 6 P (31.9-74.3 kW) is 24,000 rubles, a multi-fuel burner (gas / diesel ) Baltur Comist 26 SP (130-340 kW) - over 100,000 rubles.

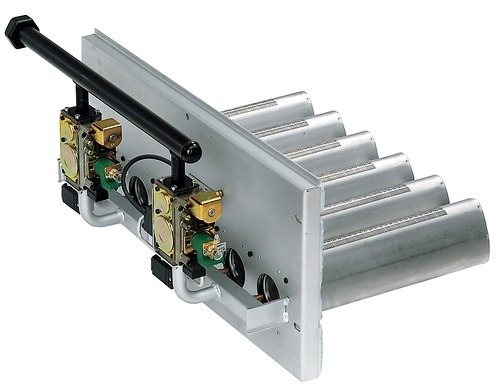

Types of burners for boilers:

Atmospheric gas burner works on the principle of a conventional gas stove, they differ only in the form and method of ignition |

In condensing boiler burners, a special design allows surface combustion rather than flare combustion. |

Blowing gas burner - air for the mixture is supplied by a fan |

Combination (universal) or dual-fuel burners |

The vanguard of gas boilers are gas condensing boilers. Such units are produced by many companies, for example: BUDERUS, VIESSMANN, VAILLANT, BOSCH, etc. The heat exchanger uses the heat of the burnt fuel to the maximum, as a result of which the efficiency increases by 10-15% compared to traditional models (with atmospheric or fan burners). This results in fuel savings, but the operational advantages require significant initial investments: a Viessmann Vitodens 300-W-26 boiler with a capacity of 26 kW costs about 120,000 rubles.In the middle lane and in the northern latitudes, condensing gas boilers do not always show maximum performance. An economical mode of operation is ensured only when a heat carrier with a temperature of 40-50 ° C is supplied to the heating circuit, and Russian conditions may require a higher temperature.

Viessmann Vitocrossal 300 - floor standing gas condensing boiler |

BAXI POWER HT - floor standing condensing gas boiler |

Today, gas condensing boilers are becoming more and more popular, which provide a more efficient process for converting energy when burning gas. Their energy conversion factor reaches 109%. The principle of utilization of the latent heat of vaporization helps to significantly reduce the consumption of gas fuel for the same power of heat supplied to the consumer. Among other things, the operation of a condensing boiler, unlike a traditional one, does not have a negative impact on the environment. The modern design of devices allows you to switch from natural gas to liquefied gas without replacing nozzles and associated service operations. In addition, models of boilers using biogas are already beginning to appear - a gas obtained by fermentation and disposal of natural waste and animal waste products, for example, on a farm.

Comparison of fuel costs per year depending on the boiler efficiency (heating area 200 m²):

| Fuel type | Efficiency 80% | Efficiency 95% | Difference per year |

| Natural gas | RUB 26,000 | RUB 20,000 | 6000 rbl |

| Electricity | RUB 195,000 | RUB 150,000 | RUB 45,000 |

Fuel combination options

There are currently four main combinations on the market.

Combined boilers - "Gas and electricity"

The considered modification is characterized by high performance and economy. The product is equipped with a gas combustion chamber equipped with a special burner and a heating element located directly in the heat exchanger circuit.

Bottled or main gas is used as the main fuel, since its cost is much less than electricity prices. An electric heating element can be used for operational heating of the coolant or in the absence of gas.

Gas-electric installations can have an additional circuit to provide hot water supply. In addition, the design provides for the possibility of connecting a storage boiler. Most models are equipped with an automatic control system that allows electricity to be used as needed.

The advantages of gas-electric combined heating boilers include:

- compact overall dimensions;

- high efficiency;

- simplicity of design;

- affordable price.

If the amount of heat released during the combustion of natural gas is sufficient to maintain a given temperature regime, the ACS turns off the heating element.

Combined boilers - "Gas and firewood"

Most boilers of this type allow using not only wood, but also other types of solid fuel. Typically, such installations have two combustion chambers and a common heat exchanger. Some models have separate heating and DHW circuits.

Self-made combined boilers with one combustion chamber are not uncommon. The essence of the "invention" boils down to the following: an additional burner is installed in the factory solid fuel system. When using firewood or other solid fuel, the gas equipment is dismantled.

Before embarking on such a modernization, you should know that the use of a gas burner leads to a significant increase in temperature in the combustion chamber, which can cause its premature destruction.

Electricity and firewood

A distinctive feature of such combined heating boilers is the simplicity of the design.To increase the intensity of heating or separate use, an electric heating element of the corresponding power is additionally installed in the heat exchanger of a solid fuel boiler.

Most factory wood and solid fuel boilers have a special port for installing heating elements and are equipped with special nozzles for connecting a storage boiler or a DHW circuit. Combined devices operating on solid fuel and electricity are equipped with special heating elements.

Another advantage of such installations is the ease of maintenance and repair. In case of failure of the electrical component of the heater, the repair, as a rule, consists in replacing the heating element.

Multi-fuel combined boilers

Some manufacturers produce heating systems designed to work with any type of fuel. Such devices are equipped with a volumetric combustion chamber for loading firewood or coal and provide for the possibility of connecting one or more electric heating elements. In addition, an additional combustion chamber is provided for burning pellets, diesel fuel and natural gas.

Depending on the energy source used, a pellet, gas or diesel burner can be used in combined boilers. To convert the system, it is enough to install the corresponding burner. Since the parameters of pellets, gas and diesel fuel are similar, they are burned in a universal combustion chamber, and the modular design allows for quick burner changes.

Gas boiler, but what gas?

Gas boilers operate not only on main gas (methane), but also on liquefied gas in cylinders (propane-butane mixture)... After a specialist has replaced the nozzles and set the pressure settings on the gas valve, the unit can easily switch from liquid gas to normal gas or vice versa. But for the user himself, the situation changes dramatically.

In terms of operating costs and associated costs, liquefied gas is significantly inferior to the mainline gas and appears as if in a different echelon, where it competes with diesel and solid fuel. If the main gas pipeline delivers fuel directly to the boiler, then when using liquefied gas, the consumer will have to solve the problem of fuel delivery and storage himself. You will need to purchase and install a gas tank on the site, preferably with an extended neck of the tank to maintain productivity in winter, do not forget about the Russian frosts. To heat a house with an area of 200 m², a gas tank with a volume of 2700 liters is needed, for a house with an area of 400 m² a tank of 4800 liters is more suitable. The total cost of installing a gas tank (4800 liters), including earthworks and commissioning, starts from 200,000 rubles. The price of propane-butane in the Moscow region, taking into account delivery, is about 15 rubles / liter.

Installing a gas tank

Calorific value of various fuels:

| Type of fuel | Calorific value |

| Dry firewood | 3,900 kW / kg |

| Wet firewood | 3,060 kW / kg |

| Anthracite | 5,800 kW / kg |

| Brown coal | 2,900 kW / kg |

| Diesel fuel | 11,700 kW / kg |

| Natural gas | 10,000 kW / m³ |

| Liquefied gas | 20,800 kW / m³ |

| Eurodrova | 5,300 kW / kg |

| Pellets | 5,000 kW / kg |

Which combination boiler to choose for a private house

When choosing a combined heating device, special attention should be paid to the following:

- Is there a DHW circuit providing autonomous hot water supply;

- The main and reserve energy carrier should be chosen taking into account the availability of this or that type of fuel in the region;

- if the supply of electricity is intermittent, it is better to stop at a non-volatile model, the design of which does not provide for the use of automation to control the boiler;

- the capacity of the installation must be selected taking into account a reserve of 15–20% for unforeseen circumstances. In general, the required output for heating 100 m2 with a ceiling height of 2.8 m is 12-15 kW.In the presence of a DHW circuit - 20-25 kW.

Based on these parameters, you can choose a combi boiler that fully corresponds to a specific heating scheme. Before making the final choice, it will be useful to analyze the reviews of the owners of heating units.

Is liquefied gas a worthy alternative to mainline gas?

The price of liquefied gas (propane-butane mixture) is significantly higher than that of the main gas (methane), but if there is no choice; then today it is quite an interesting alternative to diesel fuel, electricity and solid fuel pellets. The only nuance associated with liquefied gas is its storage. The fact is that the installation of a gas holder is a rather expensive pleasure, and it makes sense to bury money in the ground only if the main gas is not foreseen even in the future. Working with cylinders and constantly changing them in a house with an area of more than 150 m² is very laborious, since in winter, in frosts, one cylinder of 50 liters will be enough for a maximum of one or two days.

In addition, it must be remembered that it is not recommended to remove more than 10 kW from each cylinder, otherwise freezing of the cylinder and the gas reducer may occur. For example, for a 24 kW boiler, it is better to put 3 cylinders in parallel. In general, the safety requirements for such systems are spelled out in the regulations. For example, cylinders cannot be placed in basements, since liquefied gas is heavier than air. At least once every six months, you need to check the tightness of gas reducers and gas pipelines, and even better, install a gas leak detector. Many models of gas boilers can operate on liquefied gas if you change the nozzles and reconfigure the equipment, but a specialist should perform the adjustment.

Advantages and disadvantages of combined boilers

As with any equipment, such installations have their strengths and weaknesses. The indisputable advantages include:

- combined heating boilers allow owners of private households to use the most affordable type of fuel;

- the use of multi-fuel installations guarantees the uninterrupted operation of the heating system, since, if necessary, you can switch to another type of fuel;

- the ability to switch from the main energy carrier to the reserve one without outside interference. If the fuel backfill has run out, the ACS can switch the device to power supply. After loading a new portion of fuel, the heating element is automatically turned off.

Combined heating units are almost an ideal solution to the problem of heating a home, however, there are still some disadvantages:

- the price of a combined boiler is significantly higher than that of any other heat generator of the same power;

- the complexity of the design and the presence of a multifunctional ACS practically exclude the possibility of self-repair;

- A noticeable decrease in performance when using a backup energy carrier.

Despite the above disadvantages, combined heating boilers are most widely used among owners of private houses.

Solid fuel heating boilers

Residents of regions remote from the center, most likely, will prefer to heat their houses with solid fuel, since firewood, peat or coal are generally available, in Russia the reserves of these resources are huge. Heating a house with an area of 150-200 m² per season requires 22 m³ of firewood or 6 tons of coal. The process of laying firewood in the furnace does not lend itself to automation, therefore a solid fuel boiler may well do without modern computer automation, and therefore without electricity.

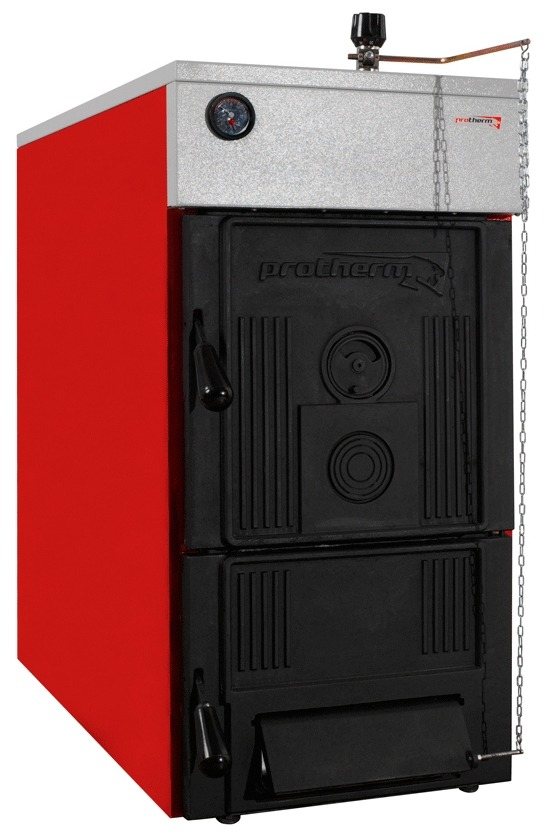

Solid fuel boilers:

Solid fuel boiler from the BOSCH company - Junkers Supraclass SW |

Solid fuel boiler from the BUDERUS company - Logano S111 |

Solid fuel boiler from the JASPI company |

Solid fuel boiler from Protherm |

Solid fuel boiler from VIADRUS - U 22 |

Solid fuel boiler from the WIRBEL company - Eko-EL |

The result is a completely autonomous system, ideal for those who rely only on themselves.But this also becomes the main disadvantage when the conditions are not so harsh and the desire for comfort is justified. After all, solid fuel burns quickly (coal in 6 hours, firewood is twice as fast), so you have to regularly visit the boiler room in order to throw firewood.

In addition to firewood, they use coal, peat, briquettes (wood, peat, coal) or more modern ones - pellets... All these fuels differ in characteristics (heat transfer, burning time, ash content, volatile matter release), cost, packaging, ease of storage and use.

Pellet boiler models:

Pellet-fired solid fuel boiler BIOMASTER CS |

Solid fuel boiler operating on pellets SIME Solida 8 PL |

| Junkers Supra Pellet solid fuel pellet boiler |

Solid fuel pellet boiler from BIOTECH |

The BIOTECH boiler can be operated using a screw and / or pneumatic pellet feeding system from the hopper to the burner.

For use in solid fuel boilers, it is increasingly recommended to use various fuel briquettes, in Europe they have been produced and used for heating houses for several decades, but for Russia it is still a curiosity. Although we already have a fairly new concept - eurowood, that is, fuel briquettes from pressed sawdust and shavings, are sold in packs of 10 kg. One ton of such briquettes takes 1.5 m³ and gives the same amount of heat as 5 m³ of birch firewood, forming ten times less ash during combustion. The cost of wood fuel briquettes is from 6,000 to 8,000 rubles per ton.

Eurodrova - fuel briquettes from pressed sawdust

Coal briquettes packed in bags of 15-20 kg and offered at a price of 8,000 to 9,000 rubles. per ton.

Coal briquettes

Peat briquettes in polypropylene bags of 25 kg each cost 5,000 rubles per ton.

Peat fuel briquettes

The manufacturers of solid fuel boilers are now quite different both among foreign companies and among our Russian ones: ATMOS, BUDERUS, DAKON, BOSCH, OPOR, VIESSMANN, WIRBEL, KONORD, KIROVSKIY ZAVOD.

To facilitate the stoker's task, boilers with an enlarged combustion chamber are produced. So, for example, the Wirbel EKO-14 model (power 14 kW, price 38,000 rubles) doubles the intervals between fuel loading compared to a conventional boiler.

Technological innovations also open up new perspectives - long-burning pyrolysis (gas generating) boilerscharacterized by high efficiency (up to 85%) and the ability to control the fuel combustion process. Their work is based on the principle of gasification of wood, the fuel in them does not burn, but smolders, so it is enough to heat such a unit twice a day. The disadvantage is dependence on electricity required for automation.

Viessmann Vitoligno 100-S - floor standing solid fuel pyrolysis boiler |

Bourgeois-K T - floor-standing solid fuel pyrolysis boiler |

A domestic-made Bourgeois-K T-30 boiler with a capacity of 30 kW costs about 65,000 rubles, an imported Viessmann Vitoligno 100-S of the same power - about 140,000 rubles.

Another invention that makes it possible to automate the process of loading and burning solid fuel is pellet boilers. Pellets Are wood pellets with a diameter of 6-8 mm and a length of up to 50 mm, produced from sawdust, shavings or husks. The calorific value of pellets is 1.5 times higher than that of dry wood. But the main thing is not even this, but the flowability of the granules, due to which the fuel loading can be automated. The pellets are stored in a waterproof hopper, from where they are conveyed by auger to the burner. The built-in photosensor stops feeding when the combustion chamber is full. The decisive disadvantage of such fuel pellet boilers is the still rather low availability of granular fuel - pellets. But the growth of pellet production is higher every year, and more and more such industries begin to develop in the regions.

Pellets - fuel pellets, compressed cylindrical sawdust

Today, hundreds of enterprises are already engaged in the production of pellets. However, before purchasing a pellet boiler, be sure to decide on reliable fuel supply channels from the manufacturer. The cost of granules is from 5000 rubles / ton.The fuel consumption of a 25 kW unit is approximately 3 kg / h. Pellet models are more expensive than standard solid fuel ones. The OPOR BioComfort boiler for 24 kW costs from 140,000 rubles, Astor (25 kW) - 120,000 rubles.

Solid fuel or liquid fuel? The costs are comparable, the choice is influenced by: the availability of fuel, the possibility of its storage, the level of desired comfort.

The principle of operation of a long-burning boiler

Any long-burning boiler works according to the following principle:

- The fuel in the combustion chamber gradually smolders. Slow burnout is ensured by the fact that oxygen is supplied in a limited amount. Due to the slowing down of the combustion process, the frequency of fuel loading increases - the boiler can operate on one batch for 80% of the time longer than the standard version. Of course, with such work, the boiler needs to be paid much less attention.

- When smoldering, a large volume of gas is released, containing a mass of potential thermal energy. The gas is directed to the afterburner and burns actively when mixed with oxygen. In the process of combustion, not only the gas itself burns out, but also the substances contained in it, which in ordinary boilers enter the chimney, polluting it and the environment. Long-burning boilers emit into the atmosphere the purest possible smoke, which does not have a negative effect on the atmosphere.

- The wood in the firebox starts burning from the top. The fire moves down at a slow pace, due to which the rate of fuel burning is reduced, but heat transfer, on the contrary, increases. In different models, the combustion rate of one batch of firewood can vary within a fairly wide range. Most boiler models can work for about 1-2 days on one tab, but there are also more serious modifications that work autonomously for more than 3 days.

Diesel version of heating boilers

Liquid fuels also have their competitive advantages. Although diesel fuel is already not cheap, the installation of boilers with diesel burners in "standby mode" is popular, when the main gas is planned to be brought to the house in the near future, but no one knows exactly when it will come. As soon as the gas is supplied to the house, the burner is changed to a gas one, and the diesel one remains in reserve, which provides the heating system with higher reliability. Liquid fuel boilers are produced by many companies: ACV, BAXI, BIASI, BUDERUS, SNAPRE, STS, DAKON, DE DIETRICH, FERROLI, FONDITAL, KITURAMI, LAMBORGHINI, MORA, PROTHERM, ROCA, SIME, VAFILLANT, VOL. KIROVSKIY FACTORY.

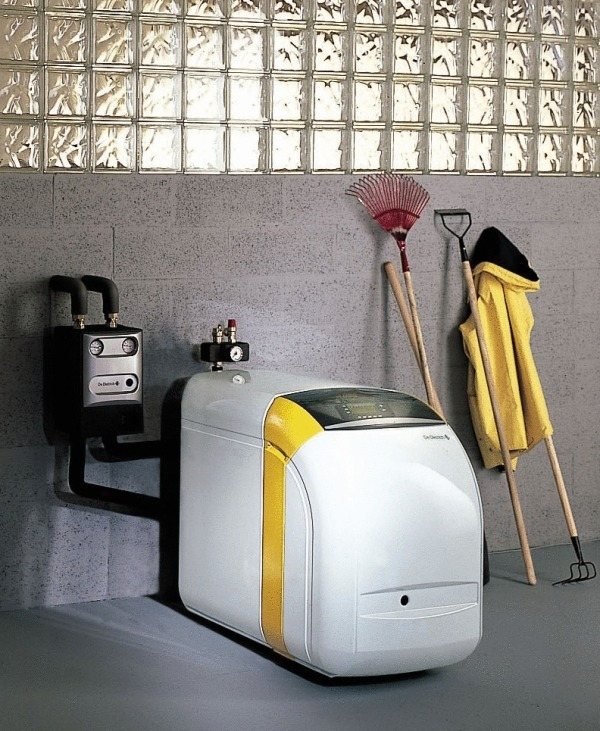

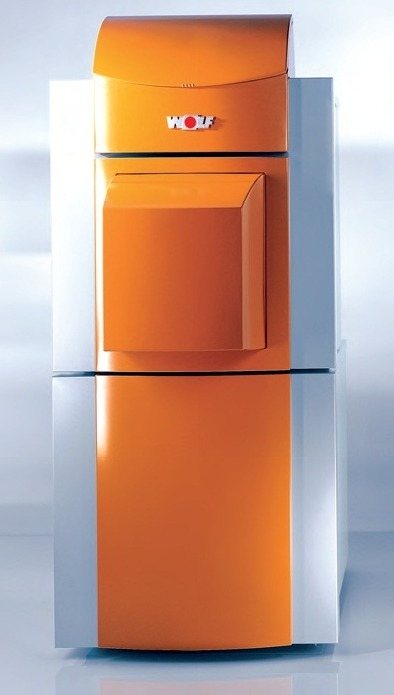

Oil fuel models of heating boilers:

Buderus Logano G125SE - floor standing oil boiler |

DE DIETRICH GT 120 - floor standing oil (gas) boiler |

VIESSMANN Vitorond 200 - oil (gas) boiler with gas or oil burner |

Wolf CNK - oil (gas) boiler with forced draft gas or oil burner |

The cost of the Viessmann Vitola 200 VB2A model (power 33 kW) is from 75,000 rubles, and the domestic diesel boiler KChM-5-K-38 (38 kW) is about 55,000 rubles. For storage of liquid fuel, containers are installed (usually plastic, block type). In the boiler room itself, it is permissible to put a tank with a volume of no more than 750 liters. Such a container can be purchased for 10,000 rubles. In the Moscow region, diesel fuel is supplied for 23,000 rubles. per ton. But diesel prices are constantly changing depending on oil prices and the season.

One more important factor should be noted, albeit not financial: diesel fuel has a persistent smell, which will be constantly present in the boiler room and you need to be prepared for this.

The closest to gas boilers in terms of technical and functional characteristics are liquid fuel boilers, which is explained by the following factors:

1) High efficiency. This indicator for a diesel and gas boiler is almost the same and reaches 91-92%.

2) Possibility of autonomous operation of the boiler house on diesel fuel. The choice of control panels - from the simplest mechanical to programmable weather-dependent.

3) Possibility of quick transfer of the boiler from liquid fuel to gas if it is connected.

4) The environmental indicators of liquid fuel boilers, of course, are slightly lower than that of gas boilers, but they are not critical. The disadvantages of this equipment include rather high costs for the organization and operation of the boiler room.

Coaxial boiler manufacturers

The leading positions in the coaxial gas installations market are shared by several companies:

Baxi

The first enterprise was founded in England in 1866. At present, the holding includes 16 manufacturing enterprises located in 7 countries of Western Europe. The main production is concentrated in Italy. The production capacity of the concern allows for the production of more than half a million high-quality gas heat generators, including coaxial units. The products of the enterprise are distinguished by a high level of automation and great functionality.

Navien

This South Korean corporation is one of the largest manufacturers of heating equipment. The company's products are in demand in more than 30 countries around the world, and in 2008 they were presented on the Russian market. The products are distinguished by high reliability of automation capable of withstanding significant voltage drops and a long service life. Coaxial installations produced by the concern, as a rule, are equipped with an original chimney.

Vaillant

The company was officially registered in 1873. Today, this German company has a production capacity to produce more than 2.5 million heating devices per year. Due to the quality and reliability of products, Vaillant heat generators are successfully sold in more than 70 countries around the world, including the Russian Federation and the CIS countries. A special place in the model range is given to coaxial installations. These products are easy to operate and maintain, as well as the ability to connect a large number of additional modules.

Among the domestic manufacturers of coaxial boilers, one can note such companies as Lemax, Rostovgazapparat, ZhMZ and Konrod. The products manufactured by these companies are fully adapted to Russian realities and are highly reliable and affordable.

Choosing a coaxial gas installation, it will not be superfluous to read the reviews of the owners of such equipment.

Electric heating boilers

Against use electric boilers High operating costs are unambiguous evidence. In addition, there is a serious infrastructural limitation: the power allocated to the consumer often does not exceed 10 kW, and this may not be enough to heat a large house. It should be remembered that boilers with a capacity of 7 kW or more require a three-phase power supply. Despite this, electric boilers are in steady demand and are manufactured by many companies STS, DAKON, KOSPEL, PROTHERM, ROCA, WESPE HEIZUNG, EVAN, RusNIT.

Since in some circumstances, namely a boiler that runs on electricity turns out to be the best, but temporary solution.

Firstly, the initial investment is relatively small. For example, the domestic model EVAN Standard-Economy of the EPO-24 series (power 24 kW) costs only 15,000 rubles, and the Protherm SKAT 9K (9 kW) version will cost 24,000 rubles. But in the house itself, for heating with electricity, you will need to conduct a powerful electrical wiring. By entrusting the boiler with hot water supply, it is possible to organize a non-liquid heating system on electric radiators (the total cost of equipment and installation of such a solution starts from 60,000 rubles).

Secondly, with a two-tariff electricity payment scheme using an electric boiler only at night turns out to be a relatively inexpensive pleasure (2-3 times cheaper than during the day). So, in practice, the use of an electric boiler is quite economically profitable if it works to heat a small house as a backup device, at a night rate, or, as they say, for the first time, until the main gas is connected.

Electricity choices if a workaround is required and discounted night electricity rates are in effect.

In addition to traditional models on heating elements (boilers), they produce electrode boilersthat consume 20% less electricity due to direct heating of the coolant. For example, a domestic-made Galan Geyser-9 electrode boiler with a capacity of 9 kW costs only 6,000 rubles.

Heat exchangers and their types

The most widely used are cast-iron heat exchangers. Since cast iron does not corrode and, in more rare cases, burns out. The only drawback is its very large weight, which makes it somewhat difficult to install and increases the likelihood of accidental damage during transportation and installation. Despite the fact that cast iron is durable and strong, it is still a rather brittle metal.

Cast iron heat exchanger

Steel heat exchangers are not so durable (average service life is about 15 years) and are more susceptible to corrosive effects. But they are less afraid of various mechanical damage.

Steel heat exchanger

Regardless of the type of boiler chosen, the following recommendations should be remembered and followed:

- it is necessary to inspect heating systems for water leaks, if such are detected, immediately eliminate them;

- the salt content in the heating medium should not exceed the permissible limits, since the scale formed in this case can damage the heat exchanger body and contribute to the appearance of cracks in it;

- avoid impacts and excessive mechanical pressure on the cast iron housing of the system.

In the process of deciding which boiler is better for heating, wall or floor, it is necessary to take into account the presence of natural draft and chimney. In the absence of a chimney in the house, and as a result - natural ventilation, it will be necessary to additionally equip the boiler with a fan to remove exhaust gases. With artificial ventilation, a wall-mounted type of heating boiler is more suitable.

When choosing equipment for heating a house, you need to know the difference between different types and models of boilers. Currently, gas wall-hung boilers are in increasing demand. The price for them is lower than for floor models. Self-installation does not cause great difficulties and may well be done in absolutely any room. But on the other hand, floor-standing boilers have an order of magnitude higher power, which allows them to provide heat to large areas of living space.

Heating boilers for all occasions. Replaceable burners and three types of fuel

It was already mentioned above about the advantages of replaceable burners, they provide the consumer with independence in the choice of fuel. The most in demand are inexpensive solid fuel boilers with gas burners of domestic production: Don (KONORD plant), Ochag (GAZSTROY), Yaik (Novosergievsky mechanical plant). The cast iron solid fuel boiler KChM-5 (Kirovsky plant) is very popular in the central region. A three-section model with a power of 21 kW costs 27,000 rubles, a gas burner worth 3,000 rubles is used with it.

Boilers designed for three types of fuel (solid, gas and diesel), produced by foreign companies SNARREE, DAKON, VIADRUS, DEMIR DOKUM, ROCA, JAMA. Record holders among combined boilers have a built-in heating element and are also capable of operating on electricity. Such boiler models are manufactured at STS and JAMA factories. For example, for a STS 2200 Trio with a capacity of 45 kW, all types of fuel are suitable (price - 240,000 rubles).

Service of heating boilers

The warmth in the house is one of the most important components of a comfortable stay, but no heating system is guaranteed against failure. The cause of a breakdown can be both a manufacturing defect in the equipment and improper installation, as well as natural wear and tear of various components. Of course, aging of parts cannot be completely avoided, but proper maintenance can significantly slow this process down.

The costs of preventive maintenance will be significantly - ten times - lower than the possible costs of repairing equipment, in most cases requiring complete dismantling and removal of the faulty boiler to a service center.

Choosing a wood-fired boiler for heating

There are several factors to consider when deciding which wood-burning boiler to choose. The first step is to calculate the power required to heat the building so that the boiler provides full heating of all rooms. In addition, in the calculations, it is necessary to take into account the efficiency of a particular model and take a small power reserve taking into account this indicator.

The next item is the boiler material. The most common choice is between steel and cast iron. The material from which the wood-burning boiler is made directly affects the quality of the structure, its weight and heating efficiency. At this stage, it is also worth considering the future location of the boiler and choosing its dimensions so that it can fit in the prepared place.

Understanding which coal boiler is better, it is recommended to study the products of several well-known manufacturers in order to have an idea of the cost of heating equipment and its characteristics. Directly upon purchase, it is worth checking the boiler well so that there are no defects and flaws in it.

What is serviceable?

Obviously, distribution manifolds, pipelines and heating radiators do not provide any special measures to keep them in working order. A visual inspection of the accessible parts of the system for the detection of corrosion and leaks, as a rule, is carried out without the involvement of specialists, or even not at all. Circulation pumps, thermostats, valves and gate valves must also be replaced only upon failure: this procedure can be quite time consuming and expensive, since the coolant will have to be drained from the corresponding circuit or even from the entire heating network.

By the way, many boiler manufacturers strictly limit or even prohibit the use of special antifreeze, disclaiming all warranty obligations in case of violation of this condition. The most convenient and reliable coolant is ordinary water with special additives, chemically purified and deaerated.

Thus, the boiler itself needs periodic inspection and maintenance, regardless of the type of fuel used, as well as the fuel supply line and chimney. Particular attention is paid to checking and adjusting the operating parameters of boiler equipment, control and safety automation, cleaning of burner elements.

Practice shows that serious breakdowns in boilers do not occur so often that the record time of arrival of specialists is of great importance when drawing up a service contract.

What is a combi boiler

First of all, it is necessary to clearly formulate what a combined heating unit is.

A combined boiler is a device that allows, by simple adjustment or replacement of some structural elements, to change the type of energy carrier and continue to work without losing performance and replacing elements of the heating circuit.

Most often, the changeover of the unit is carried out by changing the burners or turning on the electric heating element. In addition, there are models that have separate combustion chambers for different types of fuel. With this design, replacement of parts is not required, however, this design inevitably leads to an increase in the overall dimensions of the product.

Various combinations of the energy carriers used allow you to choose the best variant of the combi boiler.

Who is the best to entrust the boiler repair and maintenance work?

There are a number of organizations that service boiler equipment: as a rule, any seller of such equipment will be happy to give the buyer detailed information on this matter. As in any industry, large firms with branches in various areas of the suburbs and smaller companies without a developed network of service centers are represented here. Some are trying to interest customers with affordable prices, others - with a wide range of works, sometimes not too necessary for the consumer, while others declare a large number of mobile teams and the shortest time for the arrival of specialists to quickly eliminate the breakdown.

Without trying to single out any of the listed advantages as the only one important when choosing a service organization, let's say that here you need to look for a middle ground. Very low prices look suspicious: the market for such services is saturated enough for someone to offer real dumping prices. A mobile team consisting of one certified specialist and a bunch of random people who can only work with a wrench can do more harm than help. Most likely, there is no point in overpaying for a set of additional services: the list of necessary measures is contained in the documentation with which boiler manufacturers supply their products. The importance of performing work not included in this list is often far-fetched.

In addition, the myriad of repair teams ready to arrive on call within almost a couple of minutes are also not a reason to overpay.Even in a severe frost, if there is good thermal insulation in the house, complete cooling takes place in 3-5 days, besides the tenants can use local heaters - for example, electric or infrared. So, if the organization guarantees the arrival of repairmen within 24 hours (in most cases, this is the period indicated) - this is quite enough.

As for the documentary confirmation of the right to carry out both installation and commissioning works, as well as measures for the maintenance of boilers, this type of activity is currently not subject to licensing. However, a prerequisite is the presence in the company's staff of employees trained to work with gas equipment (with the issuance of an appropriate certificate) and admitted to work on electrical equipment with a voltage of up to 1000 V (3rd and higher electrical safety group). Passing certification for the maintenance of specific brands of boilers is advisory and may not be documented in any way. At the same time, a large number of all kinds of diplomas and certificates on the walls in the office of the company does not in itself mean anything: they may not have anything to do with the employees of the field teams. But there is nothing wrong with that: the company in any case bears full responsibility for the actions of its personnel, and modern boiler equipment of various brands does not have significant design differences.

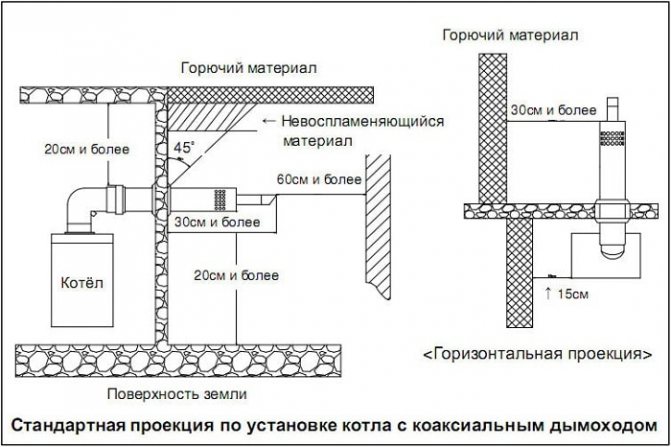

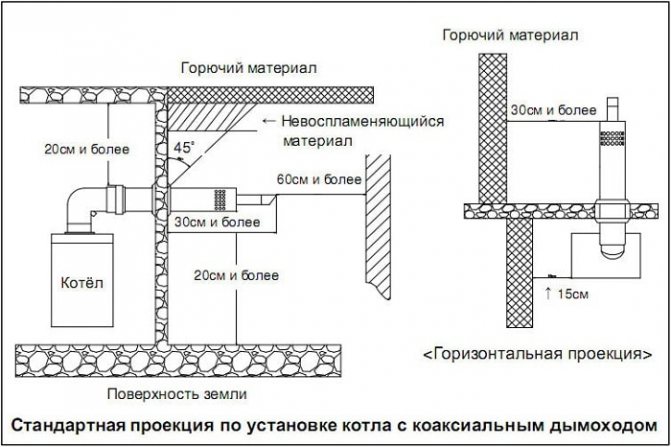

Coaxial boiler installation requirements

The use of coaxial systems makes it possible to use a gas heat generator with a closed combustion chamber not only in private households, but also in multi-storey buildings. Regardless of where the unit is installed, the following rules must be observed:

- Since the vertical section of the chimney is not a necessary condition for installations with forced removal of combustion products, it is advisable to conduct the outlet outside horizontally, through the wall closest to the unit;

- The maximum permissible length of the coaxial exhaust system should not exceed 3-4 m;

- The hole for the pipe outlet must be located at least 2 meters from the ground;

- The chimney must be located at a distance of one and a half meters from windows and doors, the proximity of the intake window of the hood is unacceptable;

- To ensure the removal of condensate, the coaxial system is installed at an angle of 3 - 50 to the horizon.

How much does the boiler maintenance cost?

As already mentioned, the cost of boiler maintenance may vary slightly depending on the specific service organization, as well as on the list of work performed. Below is an approximate range of prices for this type of service: approximately this amount will have to be parted when concluding a contract for a period of one year. The final price will be determined by the type of boiler, the complexity of work at the facility and its remoteness from the office of the company or its branch. The list of measures has been compiled in accordance with the requirements and recommendations of most equipment manufacturers, without additional services, the need for which may be controversial.

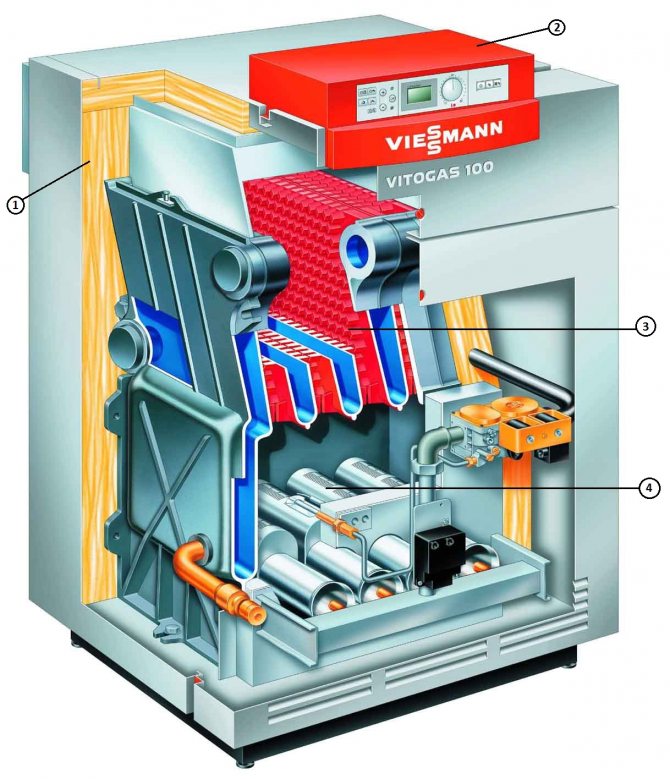

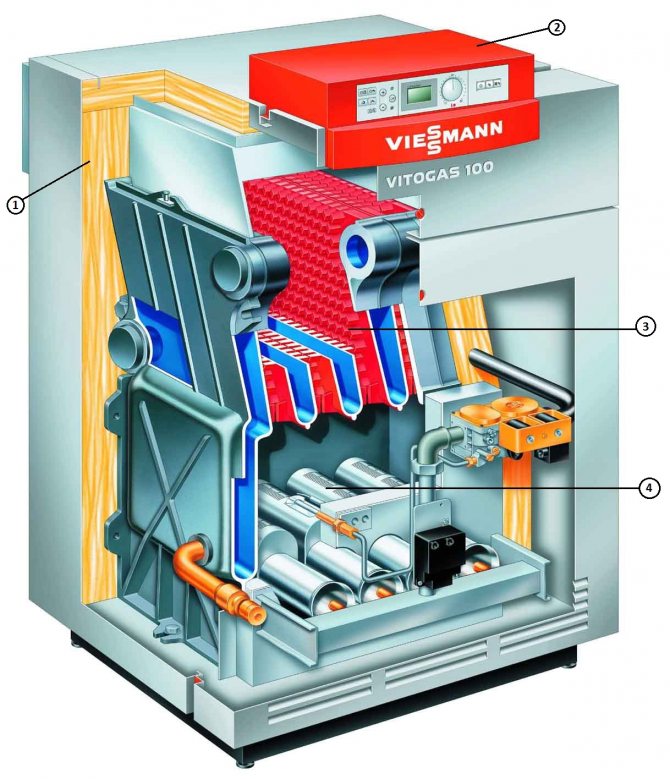

The construction of a floor-standing gas boiler using the example of Viessmann Vitogas 100-F. 1 - highly efficient thermal insulation, 2 - heat exchange surfaces made of special gray cast iron, 3 - stainless steel rod burner with partial premixing, 4 - digital boiler controller

So, concluding a contract for boiler maintenance twice a year (a requirement for a number of diesel models) will cost the customer 12,000 - 22,000 rubles: this cost includes an unlimited number of visits by repair teams to eliminate breakdowns. A similar agreement providing for a one-time performance of service work (sufficient for units of any type of low and medium capacity) is estimated somewhat cheaper: from 6,000 to 18,000 rubles. If the customer is confident in the reliability of the equipment used, then he can save a little more and pay from 4,000 to 10,000 rubles: this amount includes only boiler maintenance, and all team visits for troubleshooting are paid separately, and their cost depends on the specific breakdown.

The measures for preventive maintenance of the heating system (boiler) include:

- external inspection of the burner and boiler, diagnostics;

cleaning and maintenance of burners:

- cleaning the fire tube;

- cleaning the retaining washer;

- cleaning the arson electrodes;

- replacement of the nozzle;

- fan cleaning;

- flushing or replacing the fuel pump filter;

- flushing the photo sensor;

- cleaning the retaining washer;

- air sensor purging;

- dismantling and subsequent installation of the gas section;

- cleaning the boiler gas ducts to the smoke channel (subject to access to it and the possibility of dismantling);

- control of electrical parameters;

- burner and boiler adjustment;

- control of the composition of waste gases;

- boiler check;

- checking mixers;

safety automation check:

- checking the gas equipment of the boiler;

- external inspection of the gas pipeline;

- check for tightness of flange, threaded connections and welded joints on the gas pipeline;

- checking the actuation of the shut-off valve.

These articles may also be of interest to you:

- Replacing the siphon and sink drain

- Installation and repair of electric water heaters

- Removing clogging with a plunger with a pump

- The original design of a small kitchen

What else to read?

Tags: gas burners, gas condensing boilers, gas boiler, gas generating boilers, euro wood, pressurized boilers, wall-mounted gas boilers, heating boiler, heating, pellet boilers, pellets, pyrolysis boilers, home heating system, electric heating boilers, electrode boilers, electric boilers

How to protect a coaxial chimney from icing and wind

The main problem associated with the operation of coaxial systems is the possibility of freezing of the pipe during severe frosts. Icing of the air supply channel leads to a decrease in the flow area and, as a consequence, a lack of oxygen in the combustion chamber. This leads to a sharp increase in gas consumption and a significant drop in the efficiency of the heat generator.

The appearance of icicles at the end of the chimney clearly indicates violations committed during the design and installation of the coaxial flue system. With the correct calculation of the chimney parameters and quality installation, the likelihood of icing is minimized.

In order to prevent and eliminate the resulting icing, it is recommended to use the following methods:

- Installation of a special tip that allows you to eliminate icing even if the coaxial device is incorrectly installed;

- Installation of a chimney with a slope towards the boiler. This allows the condensate not to stagnate in the pipe, but to drain into a special collector located inside the unit. If there is a condensate drain, the pipe head should be extended 55 - 65 cm from the outer wall;

- Thermal insulation of the outer pipe with mineral wool or other heat insulator also helps to reduce the intensity of condensation and freezing.

Another problem that can arise during the operation of a coaxial chimney is the possibility of back draft. In order to avoid this phenomenon, it is necessary to take measures to ensure protection from wind and draft. The installation of a special diaphragm will help prevent the burner from damping and the ingress of carbon monoxide into the living space.

In addition, when installing the chimney, SNiP should be strictly observed, which specifies the distance from the outlet pipe to window and door openings. The minimum distance allowed is 1 - 1.2 m. For efficient and safe operation of the coaxial installation, first of all follow the instructions of the equipment manufacturer.