Properties of water as fuel

Almost everyone knows the formula of water - H2O. It contains two hydrogen atoms (H2) and one oxygen (O2). They are interconnected by a covalent bond. Here it is worth recalling the essence of any fuel. These are substances capable of oxidation under the action of an oxidizing agent, which is oxygen.

An oxygen molecule (O2) can perform the function of an oxide in water. In this case, hydrogen (H2) becomes a kind of fuel. When it burns, it releases 3 times more energy than when using ordinary natural gas, and 2 times more than when burning gasoline. It was these properties that formed the basis for the idea of using water instead of fuel.

DIY making

So, having decided to make a stove that runs on water, the first thing to do is determine the basic design of the future heater.

Using this method, any oven can be converted into an economy option.

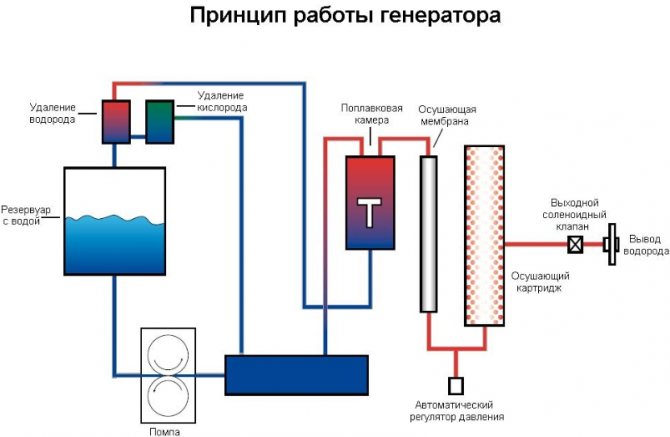

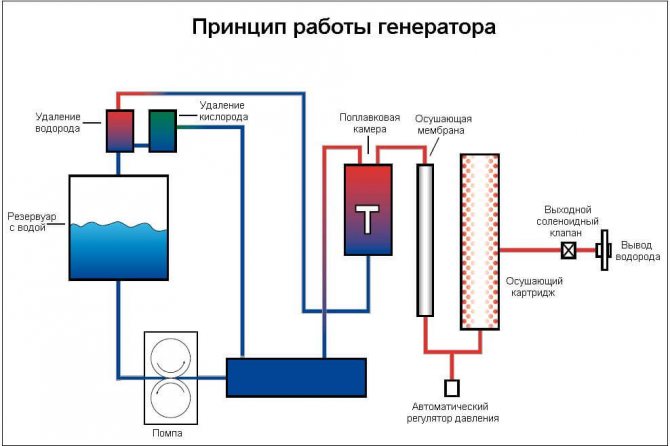

Most often, such a heater is already available and it just needs to be modified. Here is a flow chart:

- Find a container for water and fix it.

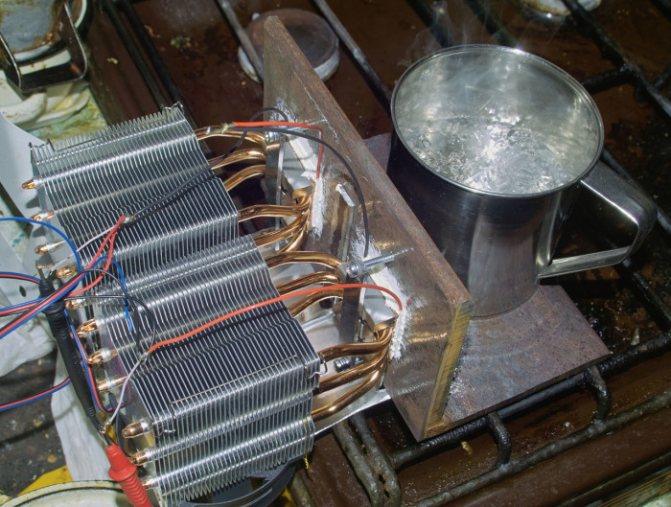

- A steam generator is made.

- They think over its fastening and heating method in order to get steam.

- Make a superheater. Usually it is a thin-walled stainless steel tube with uniformly cut holes. It is wrapped with a stainless steel mesh - this device will serve as a noise damper.

- Think over the connection and fastening scheme of all parts. The superheater must be located on the grate of the furnace in order to have good oxygen access to it. Many people come up with additional devices so that it does not become clogged with ash and the oxygen supply is constant.

- Check the device for efficiency and fire safety. The absence of smoke from the chimney when the stove is on fire indicates correct operation. All rubber, wood and plastic parts of the device must be kept at a fireproof distance from fire and hot parts of the structure.

More details about the stove on water in this video:

Installing such a design can save a lot of money. In addition, as a fuel, water in the stove reduces air pollution from combustion waste. Even the simplest way to modify the stove can lead to remarkable results.

For example, some summer residents use a water blower. That is, a metal container with water is inserted under the firebox. As a result of evaporation and heating, such a simple method turns an ordinary stove into a water one and improves its performance many times over.

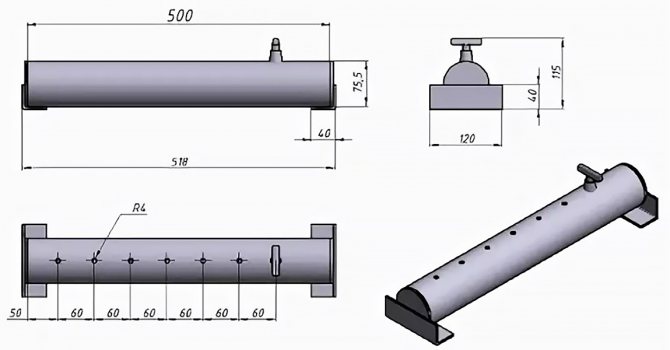

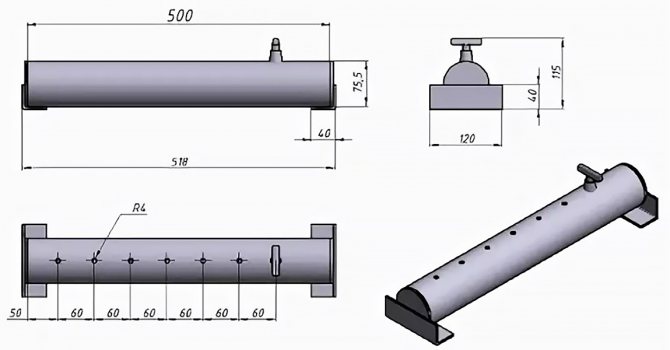

Is there an eternal log

In reality, this is not a log, but an ordinary metal tank (pipe), welded on both sides. Above, along the entire length, holes are made in it for steam to escape. The pipe itself also has a hole that can be closed with a valve after the entire volume is filled with water.

You can use a cold one, but with a hot one it will heat up faster. How the device works:

- The tank is placed on the very bottom of the stove. To the left, to the right and from above, they cover it with ordinary logs. The stove is melted.

- When heated to a high temperature, water vapor begins to escape from the pipe.

- It goes to burning coals, mixing with air. The specific heat capacity of such a mixture is 2 times higher than that of ordinary air. Water vapor has a heat capacity of 2.14 kJ / kg K, and air has a heat capacity of 1 kJ / kg K.

The results of such an experiment, according to the statements of those who conducted it:

- Black soot leaves the smoke. This is due to the reaction of carbon particles with oxygen.

- The flame becomes more intense, with long tongues.

- Firewood burns longer: 1 hour 40 minutes.in comparison with 1 hour 10 minutes. when burning without an eternal log. Time increases by 40%.

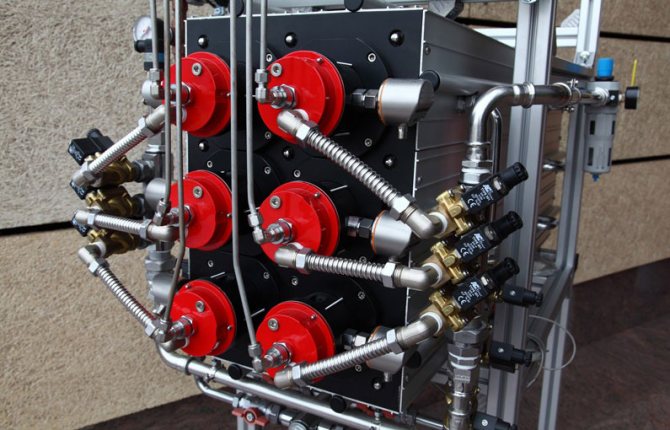

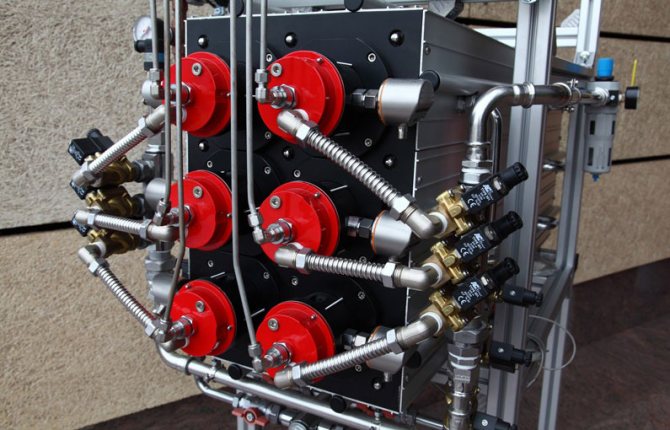

Factory and homemade installations

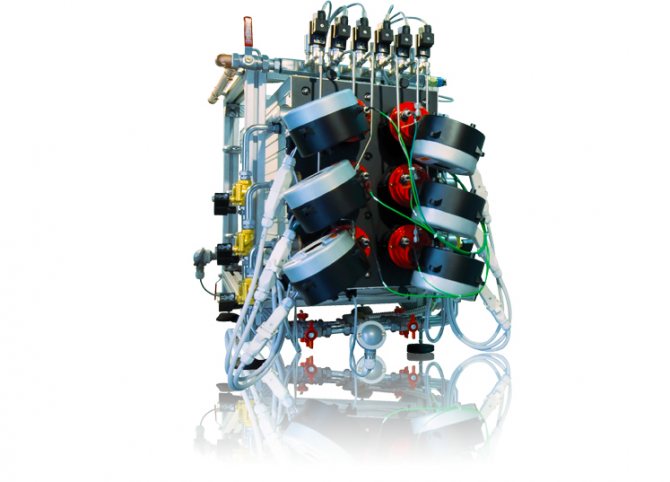

In terms of the meaning, hydrogen heating generators, created by their own hands, differ little from their counterparts that were produced at the plant. Their principle of operation is identical, the only difference is the selection of material, as well as other components. Many users and supporters of hydrogen heating agree that creating a system with your own hands is:

- profitable - the selection of materials is made at your choice;

- convenient - you can save on minor elements;

- simple - no need to resort to the help of specialists;

- reliable - you yourself are responsible for the quality, which gives you the right to choose such materials that would satisfy all your needs.

Some users complain that Chinese units, which are more affordable in price, break down after the heating season. Moreover, their repair in most cases requires large investments. At the same time, a self-made installation guarantees that its productivity will be at the highest level, and any breakdowns will be eliminated as easily and quickly as the system itself was assembled.

Hydrogen factory heating system manufacturers

Among the most popular models of factory installations of hydrogen generators are the following:

- MegaTank100 - an electric hydrogen generator powered by the network. It has several levels of protection systems against short circuit and overheating, which makes its work more productive and less dangerous. Its cost is 55,000 rubles, depending on the configuration.

- STAR-2000 - is capable of heating an area of about 250-300 square meters, has an economical energy consumption, but has a high price - 230,000 rubles.

- Kingkar - has high performance, operates from the network, but its cost exceeds 100,000 rubles.

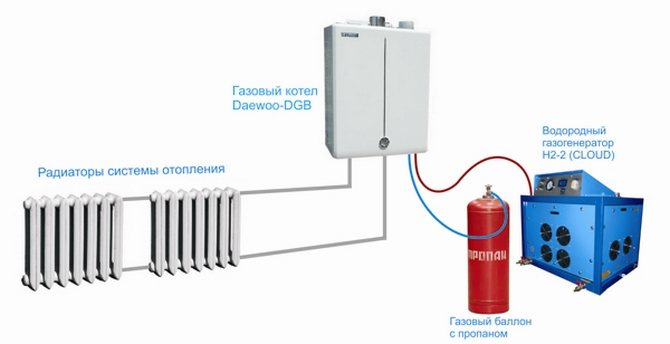

- H2-2 Is an Italian manufacturer providing a good hydrogen generator capable of heating from 300 square meters of floor space, while minimizing energy consumption. Its price is about 250,000 rubles.

- Free Energy - has a multilevel pressure and voltage regulation sensor, but most of the processes are fully automated. Costs from 15,000 rubles to 35,000, depending on the expected heated area and capacity.

Hydrogen boilers have one distinctive feature - the type of power supply. Among the most popular electric ones, there are also gas ones. The device of the boiler itself, as well as its cost, differs from the type of power supply. Boilers adapted for the electrolysis process using electricity are the most economical, but they have an increased level of danger.

Why are they still not drowned with water?

Intermolecular bonds of water arise and break much more easily than intramolecular ones. Therefore, they decided to use them in heat transfer processes. Chemists have experimentally found that the energy of intermolecular bonds of water is in the range from 0.26 to 0.5 eV (electron volt).

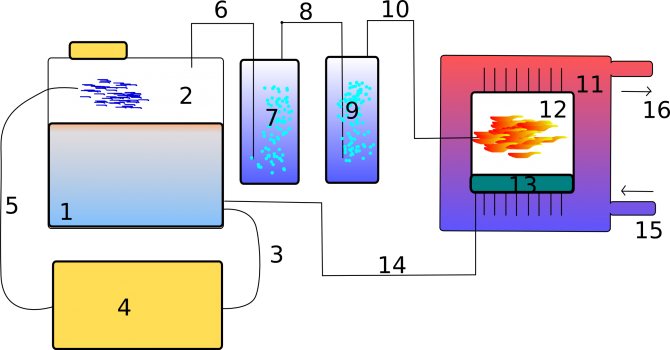

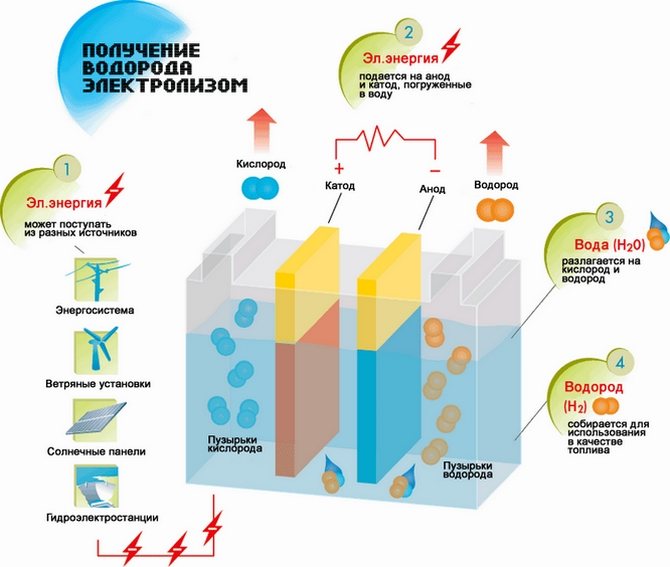

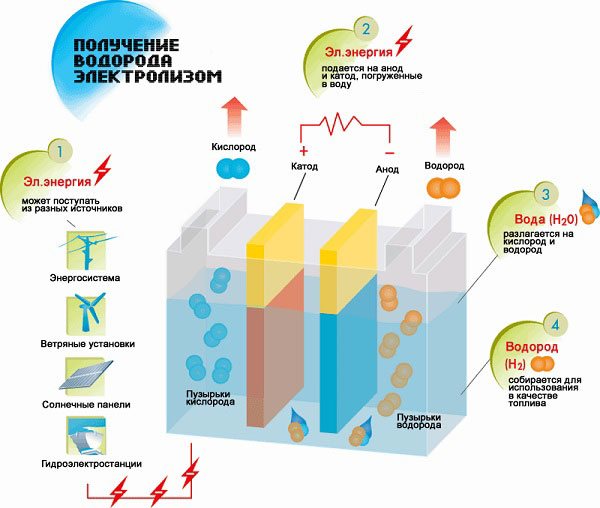

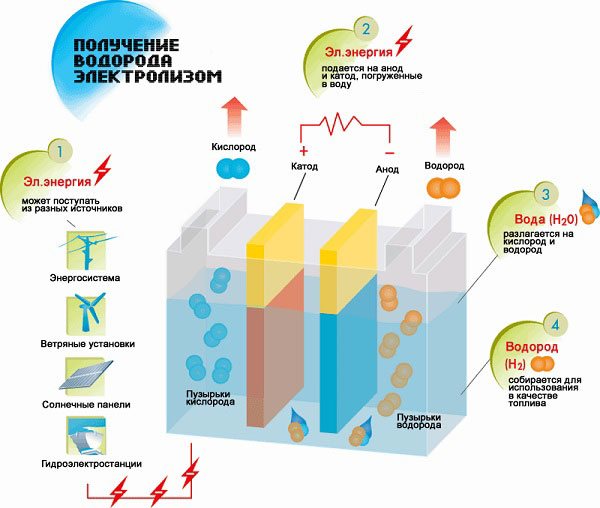

The problem is that in order to obtain fuel from water, it must be decomposed into its constituents. In simple words, it needs to be decomposed into oxygen and hydrogen, then hydrogen is burned and water is obtained again. The splitting is achieved by passing an electric current through the liquid.

When boiling, water does not break into separate molecules, but only evaporates. Heating from normal combustion does not cause any other reaction in the liquid. Moreover, this process requires a lot of energy that could be used with benefit. For instance:

- burning 1 kg of dry wood with a moisture content of no more than 20% gives about 3.9 kW;

- if the moisture level of the wood rises to 50%, then only 2.2 kW is released from 1 kg.

The decomposition of water to obtain real combustion requires a significant expenditure of energy.It needs much more than it will be released when using the recovered elements again as fuel. An approximate ratio can be given:

- 100% of energy - for splitting;

- 75% of the energy comes from the combustion of the recovered components.

It is precisely the fact that less energy is released during the reverse reaction of the released hydrogen and oxygen, and is the reason why water as a fuel for cars and not only is still not used. Economically, this method turned out to be unprofitable. It is more realistic to make fuel from garbage. It can be liquid, gaseous and solid.

Is there a "water" vehicle

In 2008, in Japan, the "water" car was presented by Genepax at an exhibition in Osaka. A glass of tap or river water, or even regular soda, could be used as fuel.

The device split the liquid into hydrogen and oxygen molecules, which began to burn and give the car energy to drive. As of today, it is known that the Genepax company went bankrupt and closed a year later.

Is it possible to independently create a hydrogen generator

It is better not to take risks, since such a process is associated not only with the need to know the intricacies of technology and chemistry, but also requires proper adherence to safety rules. But do-it-yourself installation of equipment is possible. To do this, it is enough to follow the instructions and prevent amateur performances.

Heating of any house should ensure not only a comfortable living for a person, but also an ecological cleanliness of the environment. This is achieved due to the fact that no harmful compounds are formed after the combustion of hydrogen.

In Western countries, heating with hydrogen generators has gained widespread acceptance and economic justification. If this method takes root in Russia, it will significantly increase the heating efficiency with minimal resource costs.

Adding water to regular fuel

Water as fuel for your car can be used in conventional diesel fuel. This is another hypothesis that was put forward by "home" inventors. It turned out that when a small amount of diesel fuel was added to a bottle of water, the resulting mixture burns. Moreover, less soot is released, and the combustion process becomes more violent.

Also, in the process of burning a piece of paper that is dipped into the resulting mixture, a crack appears, but it only indicates the evaporation of the liquid. In addition, shaking does not dissolve diesel fuel in water. A homogeneous mixture will not work here. Over time, diesel fuel, like oil or gasoline, collects on the surface.

A similar experiment was carried out with a tractor, which was filled with diesel fuel and water, mixed in certain proportions. The unit started up and began to rumble, standing still. But only for this is the energy of such a fuel sufficient. And there is a high risk that the engine will fail.

The myth that a hydrogen boiler is the most economical way to heat your home

You can often hear that a hydrogen boiler is the most economical heating method for a private house. Usually, to substantiate this thesis, references are used to the high heat of combustion of hydrogen - more than 3 times higher than that of natural gas. A simple conclusion is drawn from this - it is more profitable to heat a house with hydrogen than with gas.

Sometimes, as an argument for the efficiency of a hydrogen boiler, the so-called "Brown's gas" or a mixture of hydrogen and oxygen atoms (HHO), which releases even more heat during combustion, and on which "advanced boilers" operate. After this, the justifications for efficiency simply end, leaving the imagination of the layman to draw beautiful pictures under the general title "heating for almost nothing." Just think - hydrogen burns "warmer" and is obtained from practically free water, a sheer benefit!

The imagination is also fueled by the news about the ever-growing fleet of cars running on hydrogen fuel, as an alternative to traditional ones. Say, if cars run on hydrogen, then a hydrogen boiler is really a worthwhile thing.

But in reality, things are a little more complicated. If pure hydrogen were an element readily available in nature, everything would be so, or almost so, it would be. But the fact is that pure hydrogen is not found on Earth - only in a bound form, for example, in the form of water. Therefore, in practice, hydrogen must first be obtained from somewhere, moreover, with the help of energy-consuming chemical reactions.

Boiler operation tips

To improve the functionality of the unit, it is important to adhere to the attached instructions. It is possible to improve the operation of the device by adding additional details (in this case, you should strictly follow the safety rules).

A flame sensor installed on the burner increases the safety of the system. When the fire is extinguished, the device automatically shuts off the flow of combustible gas into the burner, thereby preventing it from entering the room

It is possible to mount special sensors in the inner part of the heat exchanger to monitor the increase in water heating indicators, as well as to supplement the burner design with shut-off valves.

It is enough to connect it directly to the temperature sensor so that the boiler turns off automatically as soon as the heating reaches the set value.

It is also useful to install a standardized boiler cooling device.

Hydrogen devices can be used not only as the only heating equipment in the house, but also be combined with other heating systems. In this case, the main heating plants can operate in a low-temperature mode.

If the operating standards are observed, the hydrogen-powered unit will serve for more than a dozen years. Although the warranty period for such devices is 15 years, in practice they can work efficiently for 20-30 years.

Repairing such devices will not be difficult for an experienced craftsman, since the schematic diagram of a hydrogen boiler is not too different from analogues working on other types of fuel.

Where does pure hydrogen come from?

Note to the owner

"To draw attention to their products, some hydrogen boiler manufacturers make references to a" secret catalyst "or to the use of" Brown's gas "in their devices."

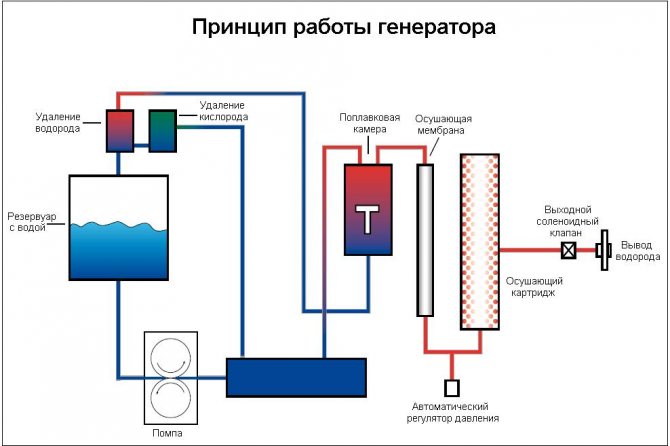

For example, you can extract hydrogen from methane gas, where there are already 4 atoms of hydrogen! But why? Methane itself is a combustible gas, why waste additional energy to generate pure hydrogen? Where is energy efficiency here? Therefore, most often hydrogen is extracted from water, which, as everyone knows, cannot burn, using the electrolysis method. In its most general form, this method can be described as the splitting of water molecules into hydrogen and oxygen under the action of electricity.

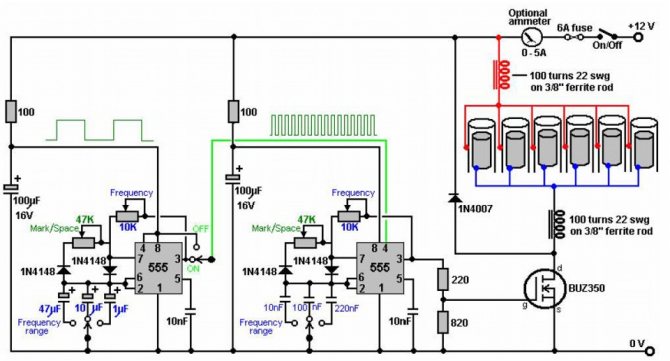

Electrolysis has long been known and widely used to produce pure hydrogen. In practice, not a single industrial hydrogen boiler, in any case, can do without an electrolysis plant or electrolyzer. All is good, but this installation requires electricity. So, a hydrogen boiler must necessarily consume energy. The question is, what are these energy costs?

All talk about the "heat of combustion" of hydrogen takes us a little away from this issue, but meanwhile, it is the most important. So, a hydrogen boiler can be beneficial in the only case - the heat energy produced by it must be higher than that consumed for the operation of the boiler.