How to start a gas boiler: preparation

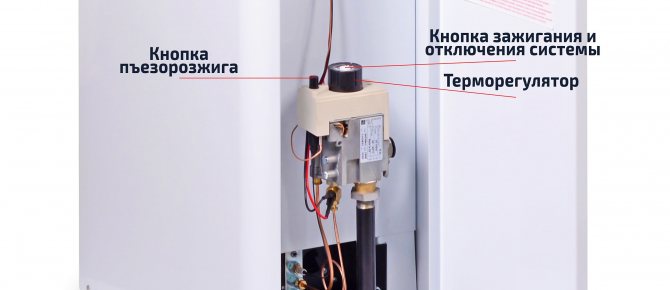

There is a simple instruction explaining how to start the gas boiler shown in the photo. The starting start is performed when the installation and piping of all elements of the heating equipment is completed, and the correctness of the work has been checked by the relevant authorities.

The location of the heating unit must be selected in accordance with safety standards and rules that prevent the occurrence of fires. The boiler must be located at a certain distance from the wall, which depends on the manufacturer's recommendations. By the way, for some models of gas appliances, this requirement is not relevant. Also, make sure that there are no flammable materials or objects nearby.

In addition, it is forbidden to place boilers near windows, since their work is disrupted. Equal positioning of the device case is of no small importance - even slight distortions are unacceptable.

After the installation is completed, they begin to connect the equipment to the source of cold water: the plugs are removed from the nozzles, and a filter with a ball valve is placed at the inlet. Such a device protects the heating structure from all kinds of contaminants that cause breakdown. Ball valves must be installed on all branch pipes used for piping.

When solving the problem of how to start a gas boiler, special attention should be paid to the piping from the gas main. They do not carry out these installation work on their own, but invite specialists from the relevant services who are engaged in connecting, sealing and, if necessary, installing a gas meter.

Until the moment you turn on the gas boiler, a separate power line should be laid specifically for the heating unit. The equipment must be supplied with an electric cable with a plug, and an outlet must be installed next to the device, separating it from the others.

After that, the boiler is connected to the chimney, in which the draft and its performance are checked. She must go outside. The installation work for the installation of the chimney depends on the type of heating device.

Completing the preparation for start-up, the boiler is disconnected from the power supply to fill it and the heating system with cold water. Then they check for leaks, turn on the thermostat to the maximum value so that the operating mode switch lights up in automatic mode.

Master's recommendations

View gallery

If you also decided to follow the experience of the majority and choose a gas boiler for heating a suburban building, then it is certainly recommended to read the operating recommendations, from which, among other things, you can learn how a gas boiler works, how to turn on this equipment, and also how to avoid it premature breakage. For example, in order to exclude the ingress of foreign bodies into the system, a hard filter should be installed at the inlets of running water, gas, as well as the heating circuit. It is also important to ensure that a voltage stabilizer is present in the system, which is located at the entrance to the wall-mounted boiler. This will protect the control board from power surges.

Rules for filling the system with water before turning on the gas boiler

Before igniting the gas boiler and turning on the heating system, first it is filled with cold coolant, which, after heating, will circulate through pipes and radiators.During the first launch, everything is carefully checked so that the work in the future is uninterrupted, and the equipment does not require repair.

There is a special valve in the body of the unit, located near the branch pipe, for supplying the coolant to the system. During the filling process, the pressure in the system is monitored, thanks to the presence of sensors and pressure gauges. They are already installed in modern boilers, and you do not need to purchase them additionally. When the appliance is filled with water, a mark rises on the sensor. When it reaches the 1.5-2 atmosphere mark, the water supply is shut off and thus the filling is completed.

These pressure parameters can be changed, since they depend on the manufacturer's requirements for the operating pressure in the heating system. But the filling with cold water does not finally end there, since recharge will be required after the structure has been freed from air jams.

Recommendations for the operation of the Baxi boiler

View gallery

If you have purchased a gas heating boiler, you can find out how to turn it on by reading the information in the instructions. However, this is not only important for the correct operation of the equipment. Each consumer should know what are the rules for operating the device. For example, you can connect the Baxi boiler to heat exchangers and radiators with two-pipe or one-pipe wiring. The cross-sections are determined according to the usual formulas, while taking into account the characteristics of the head flow used in the pump system.

The first start-up is carried out exclusively by a specialist of the service center. If an additional pump is to be used in the heating system, a low loss header of the required size must be installed downstream of the boiler. This will ensure correct operation of the hydraulic pressure switch.

When a flow-through double-circuit boiler is connected to a system with solar panels, the hot water temperature at the inlet should not exceed 60 ° C. A gas boiler, the operating instructions of which must be studied by every consumer, is sometimes set in a low temperature mode, as regards the presence of underfloor heating in the system. For this, the maximum heating water temperature should not exceed 45 ° C. If the above requirements are not met by the consumer, then the manufacturer's warranty will lose its validity.

Removing air pockets before igniting the gas boiler

Before igniting the gas boiler, you need to fill the heating structure with cold liquid heat carrier. But filling with water alone is not enough. It will either not work, or the degree of heating of the room will be insufficient. A full-fledged first start is impossible without bleeding the air accumulated in the system. Often, modern gas boilers have a special system that automatically releases air when filled. But often its effectiveness is insufficient: you will still need to manually reset air jams. Only then can the launch be carried out.

It is necessary to remove air plugs before turning on the gas boiler not only from the heating unit, circulation pump, but also from all heating radiators. The process should start with batteries - for this, as mentioned above, they are equipped with Mayevsky cranes. They are opened by substituting a container from below. There will be a slight whistle at first, indicating that air is gradually escaping from the system. After removing the plugs, water begins to flow. Then the taps are closed. A similar procedure should be done with each of the radiators.

On the features of the first start

View gallery

If you decide to purchase a gas boiler, you can find out how to turn on this device by reading the information in the article. When equipping the heating system, many homeowners today prefer double-circuit boilers.This is due to their efficiency, reliability and the ability to provide in the house not only hot water supply, but also heating.

In order for the device to work for a long time and does not require repair, it is necessary to organize its first launch. For this, the system is filled with water, and air is removed from the pump and radiators. In order to facilitate this process, Mayevsky taps can be used for radiators. They are unscrewed until water flows. If we are talking about a pump, then first you need to remove the front panel and make adjustments. As soon as it is possible to get rid of the air congestion, the equipment can start working.

Useful Tips

To start the boiler, it is necessary to supply power and set the heating regulator to the required operating position. The presence of a faint hum indicates that the circulation pump is working. Using a screwdriver, slightly unscrew the cover in the detected part. But this must be done before the water starts flowing. If liquid begins to seep out, screw the cap back into place. Such actions are performed several times and after that the air locks will be completely removed from the system. The bubbling sounds will also disappear and the pump will run quietly.

Major malfunctions and ways to eliminate them

Burner

The entire process from installation to setting up the baxi installation must be carried out in strict accordance with the instructions and the slightest deviation from the recommendation can cause a breakdown of the gas valve or bridge.

Switching off the baxi boiler

With a decrease in the pressure level, a breakdown occurs, the elimination of which can be carried out by, then, replacing the automation microcircuit.

Temperature sensor failures

In most cases, the problem lies in the pressure sensors themselves, which, as a rule, either burned out or their service life has expired.

Heating circuit failure

In this case, the solution to the problem will be to replace the secondary heat exchanger. To do this, you need a device for cleaning pipes, gaps of other hard-to-reach spare parts for the baxi boiler.

Malfunctions in the ignition system

In case of malfunctions in the ignition system, the automation issues an error code e01. In some cases, you can independently repair the baxi gas wall-mounted boiler by re-igniting or checking the health of the gas pipeline.

When buying a baxi boiler, it is important to think over all the nuances, so it is important to initially purchase an exhaust hood for conducting a chimney that will draw out the combustion products outside. It is from the installation of the baxi boiler and the output of waste materials that the chimney depends on the state of the entire heating system

So, natural gas, as a fuel, during combustion, emits certain substances that must be removed from the room - this is what the chimney is designed for.

The process of installing the heating system as a whole and the durability of the baxi gas boiler depend on the quality of the chimney. If there is a model with a two-circuit system as a baxi gas wall-mounted boiler, then it is necessary to purchase a voltage stabilizer that minimizes damage from sudden changes in direct current. The Teplocom model ST-450 can be used as a stabilizer.

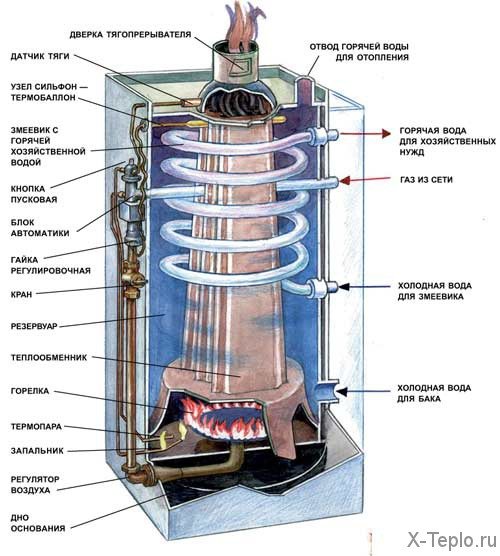

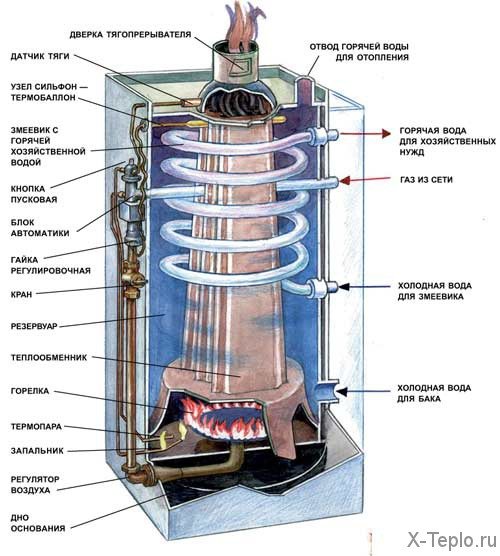

Device and principle of operation

Comparison of AGV with a samovar, which is found in some descriptions, although somewhat exaggerated, is not without grounds. The device is a large steel cylinder filled with water, into which a pipe is mounted. Gas burns in this pipe, heating the water. The boiler is equipped with automatic control systems.

The main advantage of AGV is that it does not require power supply.

Upgraded options

Hollow vertical sections (usually no more than three) are installed in modernized gas boilers, which are connected at the outlet into one chimney. A chimney with a diameter of at least 135 mm is mounted to it, which brings smoke out into the street.An example of such a hot water device is AOGV-23.2-1.

Two in one

Completely new models are also capable of heating running water for household needs. For example, AKGV — 23.2-1. At the end of the heating season, the system is disconnected from the boiler using shut-off valves, and it only works to heat water. The latest models of such devices have two independent combustion chambers.

As a result, AGVs are used both for home heating and for hot water supply, like the latest double-circuit boilers. This variety will allow the user to choose the most suitable model.

Chimney of the AGV boiler.

How to handle AGV

So that the boiler itself does not create unnecessary problems during operation, it is necessary to take into account some points related to the installation and maintenance of this unit:

- First, AGV is installed in a separate room.

- Secondly, the chimney diameter should not be less than 135 millimeters. The pipe itself must be brought out into the street above the level of the roofing material. The outer part of the chimney and the one in the attic must be insulated and insulated. Increasingly, they are trying to install a kind of pocket in the chimney itself for collecting debris that has fallen into the chimney.

Only representatives of the regional gas industry have the right to connect the AGV to the gas pipeline, who will register the device. It is imperative to insulate the pipeline through which the coolant will rise to the radiators. The return circuit does not need to be insulated.

When installed and used correctly, safety is guaranteed

If the house uses a scheme with natural circulation of the coolant, then the device must be installed below the location of the radiators. Usually it is placed in a basement or a separate room with a recessed floor is built.

The diameter of the pipes must be accurately selected according to the canons of plumbing requirements. In addition, it is necessary to correctly set the angle of inclination of the horizontal sections of the pipe routing. It should be 1 centimeter per meter of pipeline length. This is a prerequisite that improves water circulation, reduces the likelihood of airlock formation and helps drain water from the system during its conservation or for repair work.

Please note that when the temperature reaches +50 C, condensation begins to form on the walls of the pipes and the boiler. It shortens the life of metal parts and system components. In addition, at a given temperature, the coolant itself ceases to circulate.

Build a house

The most economical way of heating residential premises today is gas heating. And this is understandable, because gas is generally available and belongs to the cheapest energy resources. Today, most homeowners prefer to use traditional automatic gas water heaters (AGV) for heating low-rise and single-story buildings. They allow not only to heat the living space, but also to organize hot water supply.

So, a modern AGV can be:

- Single-circuit;

- Double-circuit.

Today there are two modifications of it:

- AKGV (complex gas water heating apparatus), which allows the selection of hot water;

- AOGV (gas water heating device), which is used exclusively for heating.

When replacing an old unit, it is always necessary to modernize the heating system as a whole. The only device that does not require changing the system is AOGV, manufactured by the Italian company Beretta for the CIS countries.

Principles of AGV operation

The main component of any AGV is a water tank made of galvanized sheet steel, the thickness of which is 3 mm. Gas water heaters in the first approximation can be compared with an ordinary samovar.The tank is placed in a special casing, and a flame tube is installed inside it, which is heated by natural gas combusted in the fuel chamber. The flame tube functions as a heat exchanger, that is, it heats the water in the tank, which subsequently goes to the heating system. The combustion products are removed through the chimney.

All modern boilers are equipped with automatic thermostats, with the help of which the required water temperature in the water tank is maintained.

When operating heating systems based on AGV, two principles can be used:

- The principle of natural (thermosiphon) circulation. According to the laws of physics, lighter warm water rises through pipelines to heating devices, where it cools down, giving off heat to the surrounding air. The cooled water is then returned to the water tank for heating.

- Forced circulation principle. In this case, to accelerate the movement of water in order to enhance heat exchange processes, injection circulating electric pumps are used.

Gas boilers are absolutely safe devices. They use automatic devices that turn off the gas supply in the event of a drop in water pressure in the line or damping of the burner. Also, AGV is turned off when there is not enough draft in the chimney.

Advantages and disadvantages of AGV heating

The efficiency of the AGV heating system is its main advantage. This is due to the low cost of the boiler and the low energy consumption of the circulating pumps used. For example, a 48 kW device consumes no more than 35 kW per month. In addition, it is possible to additionally save energy consumption by installing special automatics on the boiler, which will turn off the pump at a time when the water is not heated.

Another advantage is the simplicity of the design, which guarantees fast and high-quality service, as well as low repair costs.

The disadvantage of AGV is its massiveness. The device is developed exclusively in a floor-standing version and takes up a lot of space. The heating system itself provides for the use of large-diameter pipes, so living quarters do not warm up very quickly and cool down for a rather long time.

Installation of AGV in city apartments

Today, many townspeople are striving to abandon centralized heating. At the same time, many choose AGV for this. But it should be remembered that their installation is not always possible. This is due to strict requirements for the presence and size of chimneys, as well as for the diameter of the underwater pipe. It is always easier to obtain permission to install AGV heating in old low-rise buildings, in which stove heating was previously used, and chimneys have been preserved. When installing AGV heating in apartments of multi-storey buildings, the chimney is led out through the wall of the building.