Features of the operation of pellet heating

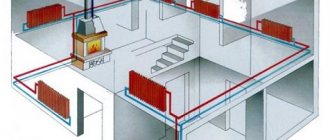

The principle of space heating is considered to be a boiler plant for burning wood pellets. Fuel is poured into tanks and fed to the boiler furnace using automatic auger equipment. The consumption of pellets is calculated based on the heating needs of the room. The higher the need for heat, the more pellets are needed for laying.

When the required temperature is reached, the supply of pellet fuel to the furnace stops, significantly reducing material consumption. The fuel hopper can have a different volume, determining the capacity of the pellets from a few days to a whole year. The requirements for the heating unit must correspond to the area of the room, the main season of use, and the financial capabilities of the customer. When using pellet equipment, as a rule, an additional boiler is installed.

Pellet quality

The characteristics of fuel pellets determine further heating, its feasibility and functionality. Pressed briquettes for this kind of boilers require compliance with storage and handling conditions. Compared to the requirements for liquid and gaseous fuels, the situation with pellets is much simpler. It is only important to control the permissible level of humidity in the room.

If it is not possible to check the granules in this way, then we offer you alternative methods:

- Visual inspection of granules. The surface of the pellets should be smooth and shiny, without obvious cracks and chips. These indicators confirm the observance of the technological process at the time of manufacture and pressing, and natural wood was used as a bundle.

- Test for brittleness. High-quality fuel material should not crumble on palpation, so it is best to use solid pellets. Pellets with a violation of the manufacturing process will begin to crumble already at the time of transfer by auger equipment to the furnace.

- Choose pellets packed in bags. Fuel under such storage and transportation conditions will not combine with dust, which negatively affects the operation of the entire heating system.

- You should buy fuel material according to parameters, sizes and typesspecified in the passport of the boiler plant itself.

- Examine the shade of the granules. Pellets of light colors indicate the use in the production of wood materials without bark and unnecessary impurities, they are considered the most efficient for heating. Dark granules indicate that the manufacturer used bark and wood waste as raw materials, so their effectiveness will be much lower.

Heating stoves with wood

Wood-fired heating stoves provide efficient heating of residential and non-residential premises. They are presented in many models, differing in their technical characteristics and device. They use ordinary firewood as fuel - they can be purchased with whole trucks. But this fuel cannot be called modern and efficient. And today it has been replaced by fuel briquettes for heating stoves.

In order to be clear, consider the main disadvantages of traditional woodfuel:

Ordinary firewood must first be chopped, and then also put in neat woodpiles. This is a very laborious and time-consuming process.

- It is inconvenient to put firewood in neat masonry - if they are of the same size and format, then this is not so bad. But if some logs are thin, while others are thick, and even knotty, then the masonry will be crooked and oblique (although much depends on the "curvature" of the arms);

- Firewood needs to be chopped - they are often supplied in the form of round blocks that require felling. Swinging an ax in cold weather is a dubious pleasure (albeit useful);

- Firewood is often damp - seeking for their own benefit, lumberjacks sell the wood in a raw state, without prior drying. Compared to almost dry fuel briquettes for heating stoves, it will not be easy to ignite them;

- Low calorific value - a cubic meter of firewood gives less heat than the same wood briquettes of the same volume;

- Firewood gives a large amount of ash - the same wood briquettes practically do not clog the stoves;

- The wood burns with clicks and crackles, burns unevenly, obviously losing in this to briquettes.

Pros and cons

The obvious advantages of this type of fuel are the following:

- no harm when stored properly;

- adequate, stable price in the commodity market;

- use of automated equipment.

Of the shortcomings, we note:

- the need for a large warehouse during storage in winter;

- with the onset of the warm season, it is necessary to control the humidity in the pellet warehouse;

- the price of such a fuel plant is much higher than when buying electric or gas boiler facilities.

Consumption and calculations of fuel pellets per 100 m²

It is worth considering that the material made of wood pellets is a packaging product, packed in bags of a certain volume. Therefore, it is not difficult to calculate what the consumption of pellets will be per 1 kW, 1 m². There is no need to interpret weight in volume, because pellet manufacturers always carry out product registration in kg, and the unit for heat is kW. High-quality fuel material has an exceptional ability to generate heat, therefore, when burning 1 kg of wood pellets, about 5 kW of energy is generated.

Therefore, to obtain 1 kW of heat in a room, it will be necessary to burn about 200 g of pellets. It will not be difficult to identify the average data on the consumption of granular fuel per 1 m², given that for every 1 m², 100 kW of heat energy is needed, subject to the permissible conditions for a ceiling height of 3 m. 100 W of thermal energy is obtained by burning 20 grams of fuel.

The efficiency of heat generators is also indicated by higher rates, but will barely reach 85%. It turns out that when burning 1 kg of pellets in a fuel tank, no more than 4.25 kW will be released (5 × 0.85 = 4.25). You can also calculate the values in reverse. Another point will be that when heating 1 m², 100 W of heat will be required if the ambient temperature is sufficiently low and unchanged for 5 days. With average data, energy consumption for the entire heating season is almost 2 times less, which means a specific heat transfer per 1 m² of 50 W. The consumption of pellet fuel in the boiler plant for 1 hour is an incorrect calculation, and the final indicator is too small and inconvenient for calculations. It would be ideal to calculate the weight of fuel in 1 day.

What is the consumption of pellets per day? Per month? Considering Watt as a unit of measurement of power per hour, 50 W is needed for heating 1 m² per day (50 × 24 = 1200). In this case, you will need to consume 0.28 kg of pellets per day. With the data on the specific gravity of the fuel, it is possible to clearly determine the financial parameters regarding the use of the average weight of wood pellets over the whole season:

- 28 kg will be consumed per day (0.28 × 100 = 28);

- 840 kg (28 × 30) will go in a month.

According to the results of the calculations, it turns out that heating with pellets of 1 m² will have to spend 8.4 kg of fuel material. On the other hand, reviews and comments from users of this type of room heating on various Internet resources indicate the consumption of pellets in cold weather up to 550 kg. If these indicators are recalculated for the square of the area, then it turns out 5.5 kg / m². All this indicates that the figure of 840 kg per month is too high and does not correspond to reality.

Based on the parameters obtained, the following conclusions can be drawn about the consumption of pellets for heating a house, depending on the area:

- 100 m² - 840 kg of fuel will be required when heating a weakly insulated room, 550 kg - with good thermal insulation;

- 150 m² - 1260 kg and 825 kg, respectively, for the first item;

- 200m² - 1680 kg and 1100 kg.

When buying a plot, I understood that there would be no gas, and in general, gas is not always a panacea.

But what to heat with when there is no gas, how to understand what is profitable?

In previous articles, I described in detail how to calculate the heat loss at home and compared it with actual consumption, and we see that everything can be accurately estimated even before the start of construction.

Now let's take my house as an example and see how much it will cost to heat such a house with various types of fuel in the Moscow region. I will make a reservation right away that I am considering only common and easily accessible options. For those wishing to count for themselves - left the download link below.

Let me remind you. My house is 130m2 made of aerated concrete, the attic floor and floors are 200mm of insulation, the windows are an ordinary 70mm profile, the door is Finnish. Heat loss was calculated as 4.02 kW * h.

Previously calculated heat loss of my house, taking into account DHW and Ventilation.

To do this, even at that time, I made such a plate where you can enter the cost of energy carriers and the heat consumption of the house for the season (in the picture above, the second column, second line from the bottom), the download link at the end of the article.

Inputs. Energy cost.

We insert the consumption for the season and the cost of energy carriers in your city. I took the cost of electricity from my personal account, the rest from the Internet, incl. I do not pretend to be precise.

You can always fix it, you write me your prices, I will correct them for yours.

The tenth line - this specially calculated how much comes out when heating day-night on average, so to speak, the average daily rate.

Further, in another plate, we supply the heat of combustion and the efficiency of the boiler (I took everything from the Internet).

For electricity, efficiency = 100%, because everything that the boiler takes from the outlet will be spent on heating both the heating system and heating the wires, in a word - all the heat will remain inside the house.

The cost of heating with different types of fuel.

I will immediately explain the abbreviations:

NT - night tariff, that is, heating with an electric boiler only at night, I told you in more detail earlier, link below;

ТН - heat pump;

ТН on НТ - heat pump at night rate.

Now it can be seen that the cheapest heating is various variations of heating with a heat pump and main gas.

Next come firewood and coal, heating with a night tariff and pellets is slightly more expensive.

And the most expensive is liquefied gas and diesel fuel.

Including before you are offered to bury the barrel under gas or diesel fuel - think about whether it is worth it.

Also, I hope, now it has become clear to many that gas from a gas tank or cylinders differs from the main one, and the cost of heating is much higher.

Draw your own conclusions, and in the following articles I will reveal even more the topic of heating a private house without gas.

And what do you drown with and how much do you get? - write in the comments.

Choosing a wood briquette boiler

The choice of a long-burning boiler on pressed wood briquettes can be difficult due to the large range of products offered. The domestic market offers models made in Russia, European countries and neighboring countries.

To facilitate the selection of equipment, all proposed boilers for burning briquettes can be divided among themselves into several categories, according to the territorial principle - the country of manufacture:

- Germany - Bosch Solid.

- Czech Republic - ATMOS, Dakon (owned by Bosch), Wattek.

- Russia - Nibe Viking, Zharstal Dobrynya, Dragon.

- Turkey - Radijator.

- Poland - Heiztechnik.

- Italy - Ferroli.

The proposed list contains boilers for burning briquettes using the principle of pyrolysis combustion. All models enjoy constant popularity, which is clearly shown by the sales statistics.

The better to heat the boiler - with wood or briquettes

A solid fuel boiler on wood briquettes, despite its good thermal performance, remains a rarity in most regions of Russia. But the trends are gradually changing.

To decide on what to heat a solid fuel boiler, with wood or briquettes, it is worth considering what characteristics distinguish pressed fuel:

- Relative humidity - the indicator does not exceed 8-10%. Firewood, even after two years of drying, has a moisture content of at least 20%.

- Calorific value - varies at the level of 4.5-5 kW / kg. Pellets and coal have the same characteristics.

- Profitability - the efficiency of a solid fuel pyrolysis boiler on wooden briquettes exceeds by 5.3% the identical indicators when using coal.

The calorific value table of wood briquettes shows that pressed fuel is superior in performance to conventional wood. The constant use of stoves is economically profitable, it increases the autonomous operation of solid fuel boilers.

In all respects, the use of briquettes is more profitable. There are a few more parameters to consider:

- Technological results - combustion is characterized by stability and uniformity. Under normal traction characteristics, the flame is bright yellow. During combustion, no soot is emitted. The chimney heats up quickly, there are no temperature drops. As a result of these features, a decrease in condensation is observed.

- Environmental characteristics - the emitted smoke is transparent. There is a sour smell. The combustion products do not contain harmful substances and soot that negatively affect human health.

- Production characteristics - briquettes facilitate the work of service personnel. Even when using plates in classic units, the operating time from one tab increases to 8 hours. In equipment for pyrolysis or long-term combustion, the time is increased to 20 hours.

Considering all the characteristics, it is better to heat the boiler not with wood, but with briquettes.

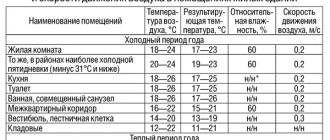

Initial data for calculation

The calculation of solid fuel consumption for a boiler in a season depends on many parameters: the area of the house and the height of the ceilings, the average temperature in the cold season, the duration of winter, the quality of wall insulation, the heat transfer of the fuel and the efficiency of the equipment.

All variables cannot be taken into account, but we can calculate the average value for different types of fuel in order to be able to compare and choose the option that suits you.

- The duration of the cold season is 111 days, from November 27 to March 13.

- The area of the premises is 100 square meters.

- The amount of heat for heating 1 square meter is 100 W per hour.

- Accordingly, there are 24 hours in a day and an average of 30 days in a month.

If necessary, you can substitute the actual area of the house for you in the formula, the duration of the cold season, depending on the region of residence.

Boiler wood briquettes

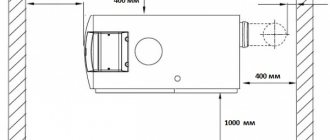

At the moment, the production technology has been changed. The consumer began to offer fuel of a cylindrical shape, up to several centimeters long, which made it possible to use wood fuel briquettes in automatic boilers.

How and from what wood briquettes are made

Heating wood briquettes for boilers are made in three different ways, each of which has its own characteristics and marking:

- Rectangular RUF briquettes - received the marking due to the fact that the first pressed fuel was created on equipment manufactured by the German manufacturer RUF. In its shape, the finished product resembles a small brick. The principle of production is based on pressing sawdust and waste by means of hydraulic presses at a pressure of 300-400 bar.

Cylindrical briquette - pressing of briquettes for solid fuel boilers, of this type, is carried out on hydraulic or shock mechanical equipment. When pressed, the pressure rises to 600 bar. The disadvantage of the cylindrical type of fuel is the fear of moisture and susceptibility to mechanical damage.

Pini & Kay - pressing wood briquettes for heating boilers, carried out on mechanical auger equipment. The difference in production is the simultaneous use of high pressure (up to 1100 bar) and thermal firing. The resulting "logs" have edges and a characteristic dark brown color.

- Washers - similar in structure to Pini & Kay, have four or six faces and a radial hole in the center. The briquette is only a few centimeters long.

- Coniferous briquettes - quickly flare up and create a high temperature in the firebox, but quickly burn out, due to the large amount of resin emitted. Heating with coniferous briquettes is not profitable due to the high fuel consumption, but it is advisable to use them for kindling the boiler.

- Pressed hardwood slabs - have a high calorific value, are hard to ignite and slowly burn out. Average consumption is 10 kg for 6-7 hours.

The technology used for the production of briquettes is reflected in the quality and cost of fuel. Pini & Kay have the highest calorific value, they are resistant to moisture and mechanical stress, and also burn longer when fired.

Consumption of briquettes in the boiler

Solid fuel for boilers in briquettes, made from various types of wood. The burning time and fuel consumption depend on the type and type of wood:

Another type of briquette that has not found widespread use is slabs made exclusively from bark. This type of fuel burns out hard, but during combustion, it has practically no flame and smolders slowly. At the same time, the temperature is maintained until the plates are burned. The average burning time is 12 hours.

The cost of wood briquettes

It is economically profitable to use fuel briquettes due to the high calorific value and low content of incombustible residue.

Methodology for calculating the amount of fuel for the season

Let's figure out how to calculate the consumption of any type of fuel for a room. First, we will calculate how much heat is needed to heat the entire house per hour. Multiplying by 24, we get the daily value, then multiplying by 30 and 111 days, what is the consumption per month and for the entire heating period.

After that, we calculate the heat transfer of the adopted unit of measurement for each type of solid fuel. Dividing the amount of required heat per month and season by heat transfer, we will see how much is needed per month and for the whole year of this type of combustible materials. This will show us how much fuel we need to store for the winter and will allow us to compare the efficiency of different devices.

Approximate calculation of solid fuel for a house with an area of 100 square meters

Firewood

To heat a house of 100 square meters, we need 100 square meters. m. * 100 W = 10 kilowatts of thermal energy per hour. Accordingly, per day it will be 10 kW / h * 24 h = 240 kW. In a month we will need 240 kW / day * 30 days = 7200 kW, for the entire heating period 240 kW / day * 111 days = 26 640 kW.

Sometimes, the calculations are based on the fact that the flame is actively burning only 10 hours a day, which is enough to maintain the set temperature. Then the required amount of heat is 10 kW / h * 10 h = 100 kW. Often, starting from this parameter, they write the flow rate in the operating instructions.

On average, when burning 1 kg of oak wood, 3.4 kW is released. 240 / 3.4 = 70.6 kg of firewood will burn per day, 7200 / 3.4 = 2117.64 kg per month, 26 640 / 3.4 = 7835.29 kg during winter. That is, in one winter, a solid fuel apparatus burns almost 8 tons of wood.

It is also important to take into account that the quality of firewood, in particular its moisture content, what kind of wood they are from, and the conditions of their storage, also strongly affects the calculation of consumption. To heat such a house with firewood, a Zota 15a apparatus is suitable.

Coal

One kilogram of coal burns out 7.75 kilowatts. Coal-fired equipment consumes 240 / 7.75 = 31 kg of fuel per day. A month will require 7200 / 7.75 = 929 kg of coal, during the entire heating season 26 640 / 7.75 = 3437.5 kg.

How much you have to stock up and load coal with each laying is greatly influenced by its type, ash content and the amount of impurities. For heating this room with coal, the model of the solid fuel boiler Teplodar Kupper OVK 10 is suitable.

For industrial premises with an area of 5000 sq. m., a Bratsk cast-iron hot water boiler operating on coal with a lump size of up to 100 mm, or Universal 5 and Universal 6 equipment are suitable.

Briquettes

A kilogram of briquettes, when burned, emits an average of 6.2 kilowatts. For one day, 240 / 6.2 = 38.7 kg will be consumed, 7200 / 6.2 = 1161 kg per month, 4297 kg of briquettes during the winter season. You can heat a similar house with briquettes using the Peresvet T 10 device.

Recommendations for the selection of fuel briquettes

To select the best home fuel briquettes that burn well and efficiently, follow these guidelines:

- Give preference - wood briquettes from sawdust... In terms of combustion quality, they are as close as possible to wood, burn well, have low ash content and high heat transfer. Briquettes from husk seeds also give a lot of heat, but due to oil they more intensively pollute the chimney and the heater with soot.

- Calorific value of fuel briquettes from hard and coniferous species of wood is the same, because they are based on the same woody substance. But softwood briquettes contain resin, which more pollutes the chimney with soot.

- Do not just verbally believe in the calorific value, moisture content and ash content of briquettes. Ask the seller for the test reports, which indicate the main characteristics of the briquettes. But be prepared for the fact that they may not be there.

- Choose briquettes with the highest density. The higher the density, the more evenly and longer the briquettes burn, and they also do not crumble and leave a lot of hot, long-burning coals. Pini Kei briquettes have the highest density, nonstro briquettes are medium, and ruf briquettes are the lowest.

- Before purchasing large quantities of briquettes, take 10-20kg samples at different locations. Check them for strength: if the briquette easily breaks and crumbles, then it is poorly compressed or contains a lot of moisture. Burn each sample in a heater. Pay attention to the heat, how long and at what draft do the briquettes burn? The lower the thrust at which the briquettes are capable of burning, the better. See what kind of coals they leave behind. Do they hold their shape or disintegrate into small coals? This is the only sure way to choose quality briquettes for heating.

Here you will find out:

Despite the widespread laying of gas pipelines, there are still many settlements and places in Russia where there is simply no gas. People have to use alternative heat sources such as solid fuel boilers. These units run on wood, but recently more modern types of fuel have begun to be produced for them - these are fuel briquettes for heating stoves. Let's take a closer look at them and find out their advantages and disadvantages.

In this review, we'll look at:

- Disadvantages of classic firewood;

- Fuel composition;

- The main types of briquetted fuel;

- Pros and cons of oven briquettes.

After reading the review, you can make a choice in favor of traditional firewood or in favor of a more modern briquette fuel.