Characteristics of solid fuel devices

Steel and cast iron boilers for solid fuels differ in that:

- easy to install, they can be assembled by hand, since this usually does not require the use of welding equipment and complex pipe connections;

- have a long service life - a well-made unit is able to serve without breakdowns for at least ten years;

- for the installation of solid fuel boilers with a cast-iron heat exchanger, no permits are required, the only condition is a good chimney design;

- they have a long burning period, although not all devices have this characteristic, but many manufacturers strive for this;

- have economical fuel consumption - this quality is the main reason why solid fuel cast iron heating boilers have gained wide popularity;

- efficiently distribute heat - it does not go into the chimney, but enters the room through special valves;

- quickly heat up the premises, especially for heat generators;

- in units of long burning, the duration of work on one tab of firewood reaches 10 - 12 hours;

- they have autonomous functioning, since the devices, as a rule, are non-volatile.

In order for cast iron solid fuel heating boilers to function for a long time, when buying them, you need to pay attention to the terms of service offered by the manufacturing company, what guarantees it provides for its products.

The fact is that on the market for heating units, you can buy a fake - a device made by a handicraft method. Often, such steel and cast iron solid fuel boilers are of good quality, but they do not have service and warranty obligations. Buyers of such units in the event of a breakdown cannot make claims to anyone.

What will the market of solid fuel boilers offer us in Russia?

note

that some cast iron solid fuel boilers have a preference for fuel, this is stated in the characteristics of the manufacturer. Also, the manufacturers have foreseen that the gasification prospects are quite large, therefore they immediately create two-fuel ones.

Solid fuel boilers for wood raw materials.

- Buderus Logano G211 D (Germany) - installed on the floor, it is not recommended to exceed the fuel moisture content of more than twenty percent, the recommended tree size is up to 68 cm. Types of performance of cast iron solid fuel boilers of this model: 16 kW, 20, 25, 30, 34 kW.

- VIADRUS U22 D (Czech Republic) - installed on the floor as solid fuel, and use wood with a diameter of twenty two centimeters, coke and coal. Performance options of this model: 23 kW, 29, 34, 40, 46, 49, 58 kW.

Pay attention, poorly dried wood does not heat well, but creates a lot of smoke. As a result, little heat is obtained - a large consumption of raw materials. More importantly, you spoil your heating. In this case, the boiler performance is reduced to fifty percent.

Solid fuel boilers for coal combustion

- Buderus Logano G211 - installed on the floor, used for raw materials: coal, wood, pressed solid fuel. It is not advisable to use brown coal. Performance options of this type of coke / coal: 20/18 kW, 26/24, 32/30, 36/34, 42/40 kW.

- VIADRUS U22 C - installed on the floor, recommended raw materials: coke, coal, wood can. Performance options for this type: 12 kW, 17, 23, 29, 34, 40, 46, 49, 58 kW.

Gas generating solid fuel boilers

- Dakon DAMAT PYRO (Czech Republic) - installed on the floor, wood, wood pellets are used for solid fuel, moisture content is not more than twenty percent. Performance options of this type: 15-20 kW, 18-24, 22-28, 25-32, 28-36 kW.

Variety of types of boilers

In special shopping centers for heating equipment, in addition to steel and cast iron boilers for solid fuels, they sell units operating on waste oil, gasoline, diesel fuel, etc. A wide variety of these products allows you to choose exactly the device that can provide a comfortable stay in the house.

Solid fuel boilers are distinguished:

- coal-fired products;

- devices for which pellets are used;

- long burning ovens;

- heat generators.

Basic parameters of solid fuel boilers and stoves

Solid fuel heat supply is characterized by relatively low initial costs. There are affordable solid fuel home heating boilers on the market. However, the process of installing equipment and the entire system as a whole must be carried out according to certain rules.

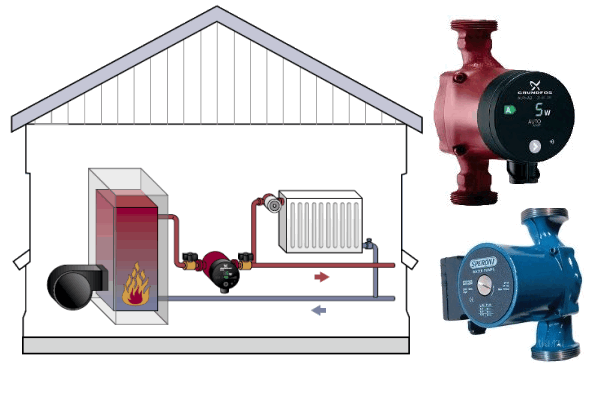

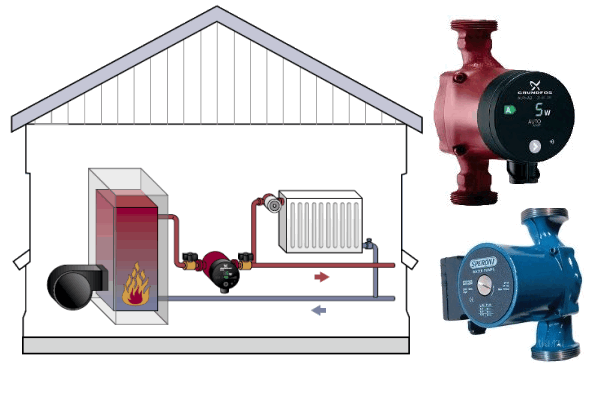

Solid fuel boiler in the heating system

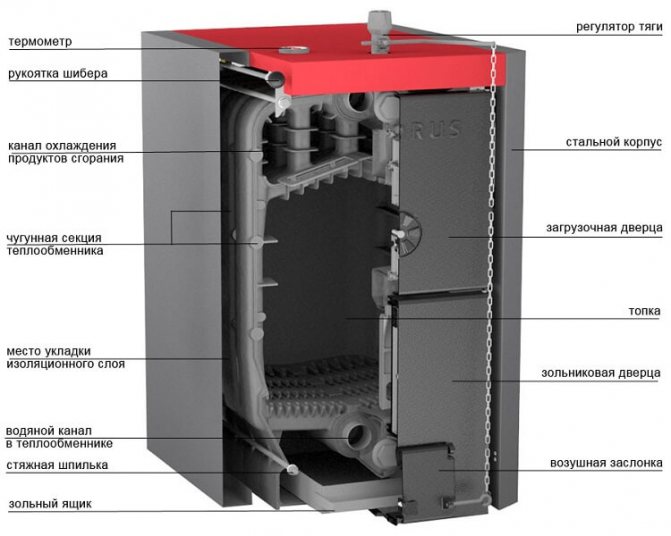

Almost all solid fuel stoves and boilers for hot water heating have the same characteristics. Their knowledge and ability to use information correctly will help you choose the right equipment for heating your home. When choosing, you should pay attention not only to technical aspects, but also to workmanship. Home heating boilers for solid fuels must be made of special grades of steel. The case is at least 2 mm thick. For the combustion chamber, heat-resistant steel with a thickness of 3 mm or more is used.

The advantage will be a guarantee from the manufacturer and seller of heating equipment. You also need to pay attention to the presence of a network of service centers for maintenance and repair. In order for reviews of solid fuel heating boilers to be only positive, when choosing equipment, you should study the following parameters:

- Rated power. It is determined by preliminary calculations of heat supply. To form a small stock, heating a private house with solid fuel must have a capacity of 15-20% more than the calculated one;

- Heat exchanger material... The most reliable are cast iron solid fuel heating boilers. Their disadvantage is a large indicator of inertness and possible destruction under strong mechanical stress. The alternative are lighter and cheaper models with a steel heat exchanger;

- Boiler type. In addition to classic direct combustion equipment, you can choose pyrolysis or long-burning boilers.

Do-it-yourself solid fuel heating boilers are often made. But to do this work, you need to choose the right manufacturing scheme and materials. The advantage of such designs is the ability to adapt according to the above parameters to a specific heating system.

All solid fuel air heating stoves are designed to use coal, wood, fuel briquettes or peat. Exceptions are pellet boilers, which differ in design and are intended only for pellets.

Coal fired boilers

The peculiarity of the production of these devices lies in the fact that for their manufacture they use super-strong metal, for the welding of the elements of which a special technology is used. This design allows you to burn fuel in the combustion chamber without breaking its tightness.

Boilers of this type can operate not only on coal, they can also use pellets, sawdust, etc. Their disadvantage is that a cast iron solid fuel boiler of this model is expensive.

Varieties

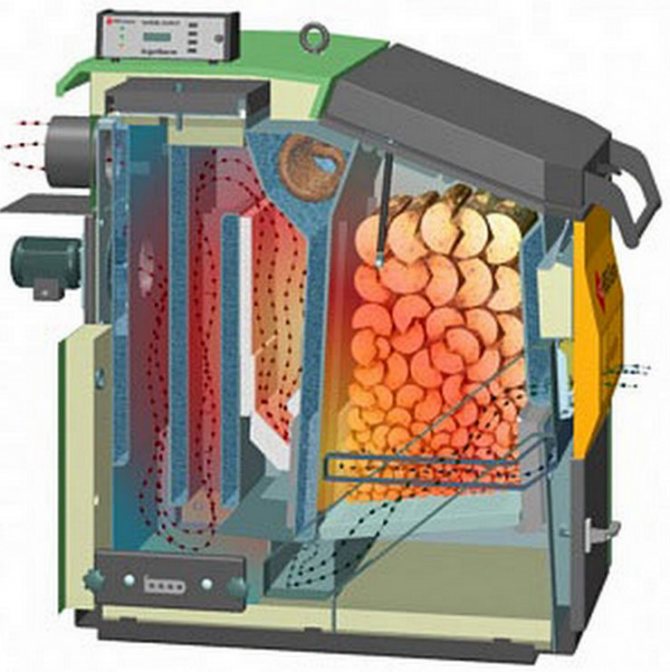

All solid fuel boilers are divided into two categories: conventional and pyrolysis or long burning.

The principle of operation of conventional heaters is based on the combustion of fuel in the furnace. The released heat heats the heating medium of the heating system. Carbon monoxide gases and part of the heat energy are removed through the chimney to the outside. The second type of equipment should be discussed in more detail.

Pyrolysis units

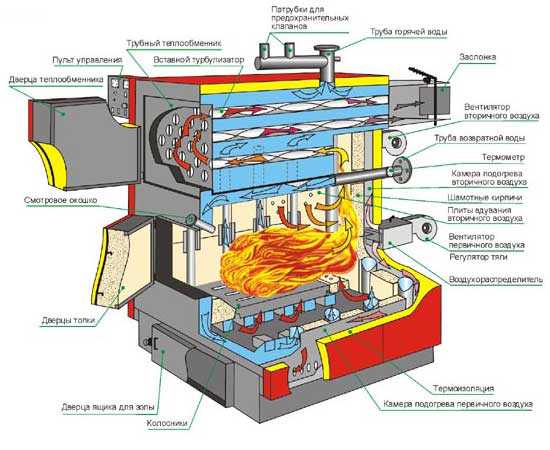

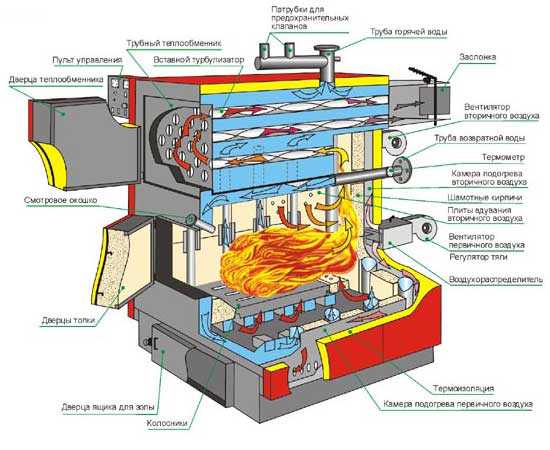

How do they differ from the usual construction of a solid fuel boiler? To answer this question, it is necessary to understand what the pyrolysis process itself is. This is an unusual combustion of solid fuels, which takes place with a minimum of oxygen. At the same time, a sufficient amount of heat is released plus pyrolysis gas, as one of the combustion products of the same firewood, coal, sawdust, and so on.

The principle of operation of such devices lies in the fact that the gas released during fuel combustion is used as an additional type of fuel. Therefore, in the design of pyrolysis-type heating units, two combustion chambers are installed: in the first one burns fuel, in the second pyrolysis gas.

What is the principle of long burning based on? The thing is that fuel combustion occurs with a minimum supply of fresh air (oxygen). Therefore, the process itself can hardly be called combustion. Firewood, pellets and sawdust slowly smolder inside the first furnace, releasing heat and gas. The latter, under the influence of high temperature (according to physical laws), independently moves into the second chamber, where it burns, releasing a large amount of thermal energy.

Depending on the design of the boiler, fuel can burn inside it from eight hours to two days. That is, there is no need for frequent periodic filling and cleaning of the ash pan, which means that the constant presence of a person is reduced to a minimum.

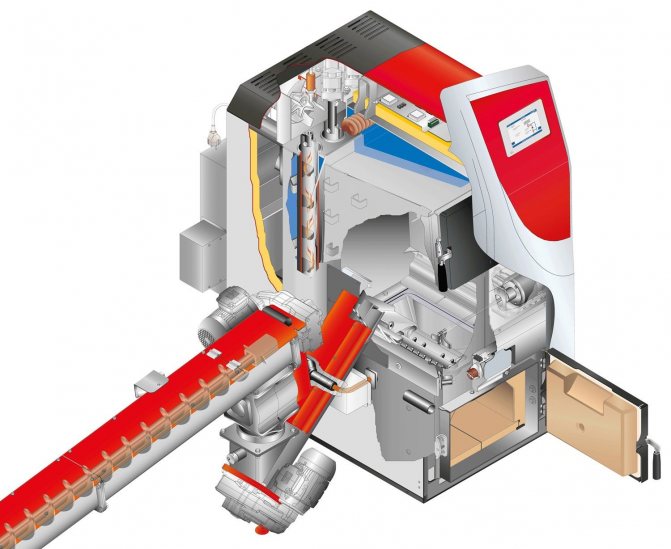

Pellet boilers

They have an interesting design solution and are able to effectively heat the premises. The device of such a unit is simple: a special funnel for fuel granules is attached to its frame. At a certain time, small quantities of pellets are fed into the combustion chamber.

When purchasing such equipment, one should take into account the degree of its volatility. When it is connected with the operation of the funnel, that is, with the supply of pellets, then this is acceptable, since when the power supply is turned off, the fuel can be filled up manually. But if the operation of the boiler requires the functioning of electronic automation, then you need to think about the feasibility of purchasing it.

Solid fuel boiler for long burning

One of the alternatives to a pyrolysis heating boiler are long-burning models. This is a relatively new heating structure, which is characterized by low fuel consumption and a long combustion period.

Long burning boiler

The classic scheme for installing a solid fuel heat supply boiler provides for significant heating of water in a heat exchanger. Currently, low-temperature systems are gaining great popularity. It is for such schemes that a long-burning boiler will be optimal. It differs from classical models in the absence of an ash pan and in the way of air supply to maintain the fuel combustion process. Reviews of long-burning boilers for solid fuel heating indicate their high efficiency and reliability of operation.

Structurally, it consists of a large combustion chamber that occupies about 90% of the total boiler volume. The air is supplied through the top pipe, which is lowered by gravity as the fuel burns. In fact, a smoldering process takes place, due to which the temperature of the coolant does not exceed + 70 ° C.

It will be useful for the consumer to know the following properties of a long burning boiler:

- The presence of an automatic draft regulator... This is a mechanical device that has a thermocouple in its design. When it heats up, the air flow decreases. The reverse process provokes a decrease in the temperature of exposure to the thermoelement;

- No need to connect to the mains;

- Ash removal is carried out once every 3-4 days of work... However, with a large amount of combustion products, a sharp deterioration in the operation of the boiler occurs;

- Burning occurs only at the top... This results in a significant reduction in fuel consumption.

One of the disadvantages of long-burning boilers is their high cost. However, with the correct design of the heating system, compensation for primary costs will occur after 4-5 heating seasons. It is also necessary to protect the structure from moisture.

It is necessary to control the circulation rate of the coolant. Its intense cooling can provoke moisture loss on the surface of the heat exchanger..

Long burning ovens

Basically, such devices are standard stand-alone steel or cast iron solid fuel heating boilers. They are able to work using various wood materials (firewood, sawdust, brushwood), as well as fruit seeds, etc.

As a rule, they do not operate on coal or pellets due to the fact that the technology of manufacturing the combustion chamber does not allow burning this type of fuel. Experts recommend that you carefully study the features of the selected model before buying a long-burning cast-iron solid fuel boiler.

Usually, such units are purchased for the following purposes:

- for heat supply of suburban households and summer cottages;

- for heating utility rooms;

- for installation and operation in greenhouses and hotbeds;

- for heating industrial buildings;

- for farm buildings.

If you have to heat large buildings with several rooms, then it is better to purchase a modified version of a long-burning unit, namely a heat generator. Of course, it costs much more, but this price fully justifies itself.

Advantages and disadvantages

Cast iron perfectly resists corrosive processes, so our compatriots increasingly choose a solid fuel cast iron boiler for heating a private house. Most manufacturers claim a service life of 25 years. The inner surface of the cast-iron heat exchanger is not covered with limescale, which has a positive effect on the efficiency of the device. In addition, the TT of cast-iron heating equipment also has a lot of advantages that make them in demand, namely:

- More resistant to chemical and electrochemical attack.

- Suitable for repair and modernization by replacing and building up sections.

- Not demanding on the quality of the coolant.

- Variable in the fuel used.

- Low requirements for the frequency of maintenance and operation.

For example, a classic floor standing cast iron solid fuel boiler can operate with little or no maintenance. The only thing is filling the fuel and cleaning the ash pan. The fuel for cast-iron boiler plants can be: firewood, coal, coke, pellets and woodworking waste.

For complete objectivity, mention should be made of the shortcomings, the most significant of which is the fragility of cast iron. That is why special attention should be paid to the correct installation of the device.

Important! To prevent the formation of cracks in the heat exchanger, it is necessary to monitor the absence of temperature drops in the coolant. It is highly desirable not to allow large temperature differences in the room where the TT cast iron boiler is installed.

- Cast iron has a high inertia (it heats up for a long time and gives off heat for a long time). That is why, when the boiler heats up, part of the heat energy inevitably "flies out into the pipe".

- High price.

Heat generators

These are convection-type ovens to which an electric fan called a "snail" is connected. There are special openings on the surface of this equipment for connecting flexible pipes.

Heat generators function in a certain way: fuel is loaded into the combustion chamber, ignited and then a fan is turned on, which injects air into it. Thanks to this, the firewood burns better, and the heated air, moving along the sleeves, is faster at the target. Flexible pipes come in different lengths, and their ends can be bred into rooms.

Benefits of heat generators:

- duration of continuous burning on one filling is about 8 hours;

- economical fuel consumption;

- devices can be used to heat any premises;

- units are capable of heating very large areas;

- it is possible to increase the power if necessary, for which a section is added to the boiler structure.

The disadvantages of heat generators are as follows:

- the need to install flexible pipes to move warm air;

- in the absence of electricity, the fan, the air blower cannot work, which affects the distribution of heated air in separate "hoses".

Fuels for solid fuel boilers

The list of fuels suitable for use in a solid fuel boiler is quite wide; it can include almost everything that is not gas or liquid and can burn. In most cases, heat sources are:

- coal;

- peat;

- wood briquettes;

- pellets;

- waste in the form of wood shavings and sawdust;

- husk and husk of oilseeds and grain crops;

- straw.

Solid fuel for boilers

Each type of fuel has its own requirements for the material and design of the furnace, the air supply system and some other components of the boiler. Of course, the fuel will burn even if all these parameters do not match, but the boiler efficiency in this case will be much lower than the maximum possible. therefore before choosing a suitable model of a solid fuel boiler, you should decide exactly what type of fuel you will use in it.

The disadvantage of household solid fuel boilers is that this equipment is not capable of operating without user intervention. Even in models with automatic fuel supply, it has to be constantly poured into the storage hopper, and the owner also needs to periodically remove the ash.

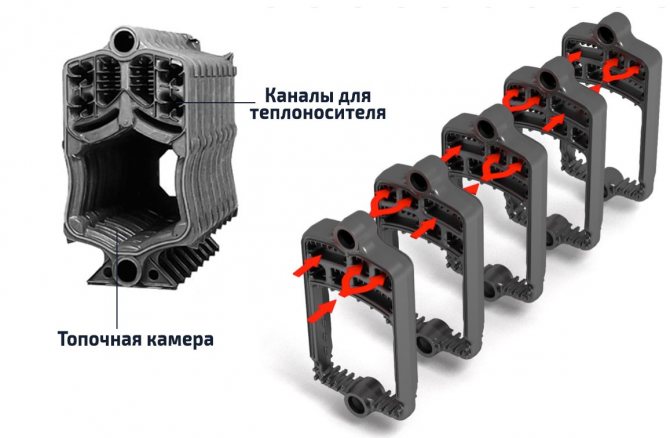

Features of cast iron boilers

It should be noted that almost every cast iron solid fuel boiler can operate on wood and coke. It costs more than a steel product, but its characteristics justify the price. The fact is that their production takes much longer than assembling a device from steel.

A cast iron solid fuel heating boiler is more durable than a steel one, it is able to withstand higher temperatures. Cast iron cools down much more slowly, which saves fuel.

In addition, for cast iron appliances:

- there is a significant advantage - this is durability, since their service life reaches 25 years;

- they take up less space than steel units;

- cast iron is more resistant to corrosion processes than steel.

This heating equipment has disadvantages:

- A solid fuel boiler with a cast iron heat exchanger is sensitive to mechanical stress in the form of shocks. The cast iron body can crack under a certain load. For this reason, it should be handled with care.

- In the event of a sharp temperature drop, the cast iron can crack, therefore, experts do not recommend cooling such boilers with cold water or loading cold fuel into a heated combustion chamber.

- It takes a long time to heat up a case made of this material.

To even better understand what is the difference between a cast iron heating boiler and a steel one, you should familiarize yourself in more detail with the properties of solid fuel steel units:

- the impact resistance of devices is especially important during transportation, even if they fall or overturn, then with a probability of 99% it can be argued that the body will remain intact, and the tightness of the combustion chamber will not suffer;

- even large temperature drops are not dangerous for steel boilers;

- products are relatively lightweight;

- if one of the elements breaks off in the heating equipment, it can be welded without problems.

Among the negative points, it should be noted the susceptibility to corrosive processes, as well as the inability to increase power.

Comparison of steel and cast iron boilers

Comparison of the two types of boilers must be carried out according to real operating conditions and heat load.

Kentatsu boiler

For comparison, the following indicators are used:

- Dimensions, they are limited by the conditions of placement at a specific object, here the best performance is for cast-iron modifications, which are much more compact.

- Weight - the best indicators for steel boilers, especially gas, in connection with which they can be wall-mounted.

- Cost is an advantage over steel options.

- The service life is an advantage for cast iron units of 50 years versus 20 for steel boilers.

- Corrosion resistance is an advantage for cast-iron devices; in fact, this parameter affects the duration of the operation of the units.

- Resistance to temperature extremes and water hammer is an advantage for steel boilers.

Double-circuit cast iron boilers

Sectional devices are subdivided into single- and double-circuit. The first of them work only for heat supply. Heating equipment such as a solid fuel double-circuit cast-iron boiler is capable of providing both housing heating and hot water supply. The long-burning double-circuit solid fuel boiler has a built-in broiler, which can be located under the outer casing.

Such a structural device of a solid fuel cast iron boiler involves the installation of a pump to ensure water circulation. Double-circuit devices differ from other models in large sizes.

What models of cast iron boilers are available

According to their design features, cast iron boilers are divided into two generally accepted types:

- single-circuit;

- double-circuit.

The first option is a limited functionality type of heating unit. Single-circuit boilers provide only autonomous heating.

Important! Hot water supply is not possible in this case. A way out of this situation will be to connect a water heating tank to the boiler or install an additional heat exchanger with a large and constant water flow. For normal operation, the installed DHW elements must be tied to the automation of the heating boiler.

The second option is the most common. Many residents of private houses are interested not only in heating, but also in hot water for domestic needs. In this case, cast iron solid fuel boilers are connected to an additional circuit through which hot water is supplied. The additional circuit can be replaced by installing an indirect heating boiler.

On a note: for household purposes, a boiler with a capacity of 80-100 liters is selected. The limited amount of hot water and the massiveness of the structure itself is a significant drawback of such an engineering solution.

If your water consumption is constant and in small volumes, a double-circuit cast iron solid fuel boiler is quite suitable.

Cast iron heating boilers are structurally divided into units with natural draft and forced ventilation. In the first case, the air inside the residential building is supplied to the working area of the boiler in a natural way.Combustion products, soot and soot come out through the chimney in the same natural way. The system is designed for small boilers and is suitable for installation in small buildings.

Forced ventilation is a more advanced and reliable design. With the help of a fan, atmospheric air enters the furnace, ensuring the combustion of the loaded fuel. The hood works on the same principle. The fan additionally creates a low pressure zone, due to which combustion products are sucked into the chimney.

Solid fuel boiler and analogues. What are the differences?

An apparatus that runs on wood or other solid fuel is structurally different from gas equipment. In it, the firebox plays the role of a heat exchanger. Inside it, there is a process of burning wood or coal. Outside, it is surrounded by a coolant that heats up from the hot walls and, having reached a certain temperature, enters the system.

This is just one of the differences between solid fuel and gas heating devices. Another and no less important is its complete autonomy, which makes it possible to use such devices in open-type systems, moreover, in areas that are practically cut off from civilization.

Solid fuel boiler for home with dual combustion function

These innovative devices use the principle of pyrolysis - secondary afterburning of combustible substances formed during the combustion of the main fuel. The device with dual combustion technology can work on almost all types of solid fuels: wood - logs, briquettes and pellets, brown coal and peat. Combustion of volatile hydrocarbon compounds also occurs during normal combustion, but with a lower intensity, and in fact, a considerable amount of gaseous fuel is released into the atmosphere. In order to increase the efficiency of heating devices, an ingenious principle of their operation was invented, the essence of which is that the combustion of fuel and combustible fraction of flue gases is carried out in different volumes of the same furnace or even in different chambers. At the same time, long-burning solid fuel boilers are closed absolutely tightly during operation. This is necessary in order to ensure the supply of air in the required volume by separate streams to the fuel and to the place of combustion of combustible gases. The so-called secondary air supplied to the place of accumulation of flue gases contributes to their ignition and combustion at very high temperatures - up to 800 ° C. At the same time, a large amount of thermal energy is released, and the pollution of smoke with solid particles and carbon monoxide is significantly reduced.

An additional convenience of this method is that the air in the house remains fresh, since the air flow into the firebox goes through the air ducts from the street or from the basement. Thus, a long-burning solid fuel boiler turns out to be an environmentally friendly device, which, moreover, in comparison with a conventional one, has a higher efficiency. It reaches 90% for a number of models.

Such devices also use the principle of long-term combustion in their work, but a different technology is used for its implementation here than for devices with an upper or lower combustion zone. Its essence is in the regulation of the air supply, which can be adjusted both so as to obtain a high and hot flame, and so that the fuel does not burn, but slowly smolders. Of course, it only makes sense to reduce the air supply after the whole house has warmed up well. But then the slow smoldering of the fuel will free you from the need for its frequent backfilling, because such a boiler for heating a house on solid fuel needs it only two or three times a day. Compared to conventional units, in which one tab of fuel burns out in two to three hours, this device is much more convenient - it allows its owners to go away on business, without fear of returning to a cold house, and sleep peacefully all night, waking up in the warmth in the morning.

Of course, modern long-burning solid fuel boilers will have a higher price than traditional devices that are not equipped with a dual combustion function and controlled air supply. However, the primary costs are offset here by the fuel economy and higher efficiency.It is also important that the pollution of the atmosphere is reduced - the emissions from such a device consist mainly of carbon dioxide and water vapor with a small amount of other impurities. In Russia and Europe, it is these units that are certified for full compliance with environmental safety requirements.

Automated appliances for home heating

These include, first of all, solid fuel boilers operating on pellets - pellets from wood waste, peat, and agricultural waste - sunflower husks, corn waste, straw and even from nutshells. Pellets are available in light and dark colors. For household use, light granules are often used. Pellets have a standard size - the diameter of each of them is 6-8 mm, and the length is 30 mm. This is a homogeneous fuel that is automatically fed into the furnace.

Such models are controlled by an electronic device that controls the supply of pellets, controls a fan and a circulation pump. After burning pellets, very little ash remains - only 1-3%, so frequent cleaning of the ash pan is not required, and in some models ash removal is also automated. The only thing that limits the distribution of these very convenient devices is that the price for a solid fuel pellet heating boiler is, frankly, high. There is no doubt that in the future, when these devices are no longer new, their price will decrease, but for now it has to be paid for the opportunity not to be interested in what is happening in the boiler room until the moment when the device signals that the fuel has run out.

Cast iron or steel - which one to choose?

Having decided to buy a solid fuel heating boiler, you should familiarize yourself with the consumer properties of the materials from which it is made. The industry produces steel and cast iron heating devices. For the manufacture of the first, some brands of heat-resistant stainless steel or special boiler steel are used. Steel appliances are made not only in the floor, but also in the hinged version - due to their relatively low weight compared to cast iron. They are inexpensive, and their service life can be from 10 to 20 years - an example is the Bulgarian-made Sunsystem unit presented in our catalog.

The durability of the device depends not only on the strength of the steel, but also on the characteristics of the system in which it operates. During natural circulation, active oxygen constantly enters the water, which gradually destroys the walls of the heat exchanger. If forced circulation is selected, then in such a system the device will last a little longer. Acid-containing condensate falling on the walls of the combustion chamber also has a destructive effect.

Cast iron boilers for solid fuels have become widespread - the price for them, however, is higher than for steel ones, however, their strength and durability do not cause complaints from buyers, since with proper installation and proper use, they can last up to 50 years. Cast iron appliances heat up more slowly than steel ones, however, cast iron also has a higher heat transfer than steel. In addition, cast iron is more resistant to corrosion from which steel appliances suffer.

A cast iron boiler is often made of several sections, which is very convenient for transportation and increases the possibility of its repair, since, if necessary, replacing one of the sections is cheaper and easier than buying whole new equipment. The weight of cast iron units is more than steel ones - for example, Jaspi double-circuit devices, produced in France and Finland, weigh from 290 to 450 kilograms, so they must be installed on a foundation prepared for them. The cast iron unit can run on anthracite, since, unlike steel, cast iron withstands the high combustion temperature of this type of coal.

A feature of cast iron is its fragility, therefore, the temperature difference between heated water and cooled water coming back should not exceed 20 ° C, so that microcracks do not appear in the heat exchanger.

As already mentioned, modern devices with the functions of long-term combustion and secondary afterburning of flue gases are volatile - for the operation of pumps, a control unit, a device for electric ignition, a fan for supplying air to the furnace and a metering unit in boilers with automatic fuel supply, electricity will be required. Therefore, in the event of a power outage, unfortunately, a temporary shutdown of the heating system is inevitable.

Installation and use rules

Regardless of whether you decide to buy a solid fuel boiler for long burning or prefer the traditional version of this unit, when installing it in a house and then operating it, you must comply with the standards set forth in the factory instructions for the device, as well as in the fire safety rules and SNiP.

- the first thing to do is to choose the right place for installing the heater. Some of them can be placed in the kitchen or rooms, however, from the point of view of aesthetics, this is not always acceptable. For other models, the rules require a separate room. In any case, the distance from the device to combustible objects cannot be less than 1 m;

- you need to make sure that the floor in your house is able to withstand the weight of the unit, otherwise you will need to build a solid foundation under it;

- on the floor in the place where the unit will stand, a coating is made of non-combustible material, for example, from stainless steel sheets;

- after the device is installed in place, you can connect it to the chimney using the corresponding outlet pipe;

- the height of the chimney should correspond to the power of the device, and its diameter should correspond to the diameter of the outlet chimney. As a rule, the manufacturer gives precise recommendations on this matter;

- after the completion of these works, the device can be connected to the heating system;

- before starting a test kindling, solid fuel boilers with a water circuit, like all equipment included with them in one system, must be checked for defects.

Mastering this household appliance does not require long training, since the rules for handling it are simple:

- a small supply of fuel, which is usually kept near the heater, should be no closer than 0.5 m from it;

- fire safety standards prohibit kindling boilers with any flammable liquids;

- do not burn laminate, hardboard or chipboard trims in the firebox of the device, since toxic chemicals are released during their combustion;

- ash and slag formed during the combustion of wood and coal must be removed in a timely manner, otherwise the traction will be disturbed and the fuel will not burn completely.

Compliance with these simple rules will ensure a long life for the unit, and for its owner, there will be no problems and unnecessary repair costs.

By phone, in writing or in person when visiting the salon, you can ask questions to our technical consultants who will help you in the selection of equipment. You can be sure that whichever device you choose in our catalog - whether it is a traditional device or a modern long-burning solid fuel boiler - their prices fully correspond to their set of functions and quality. also provides the services of experienced specialists for the delivery and installation of the purchased units.

.