Purpose of the device

Oil radiators are used as additional heating, as they consume a lot of electricity

Oil-fired electric radiators are designed for main and additional heating.

As the main source of heat, devices are used in small buildings: cabins, security carriages, outbuildings. Heating private houses around the clock in this way is economically unprofitable.

Oil convectors turn on during cold summer nights, in autumn and late spring.

The devices help the main heating on particularly frosty winter days. Radiators are installed in children's rooms, offices of administrative buildings, and other premises.

Design features

Heating element in oil cooler

All types of heaters are built according to a single functional diagram.

The composition includes:

- sealed metal container;

- tubular electric heater (hereinafter - TEN);

- control panel with toggle switches and knobs for adjusting operating modes;

- overheating emergency shutdown sensor;

- butter;

- electrical connection wires;

- fittings for installation on the floor or hanging on the wall.

When the supply voltage is applied, the heating element begins to warm up, which gives off heat to the intermediate heat carrier. Most often, transformer oil is used, which:

- protects internal parts from corrosion;

- does not boil, giving off oxygen like water;

- does not conduct electric current to the case when the heating element is destroyed.

For ease of use, oil heaters are equipped with wheels for moving on the floor and devices for winding excess wire.

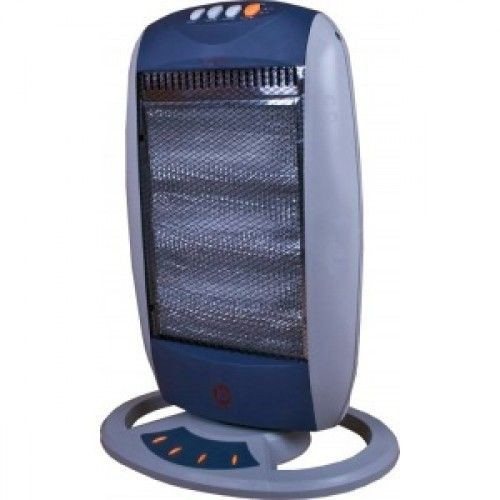

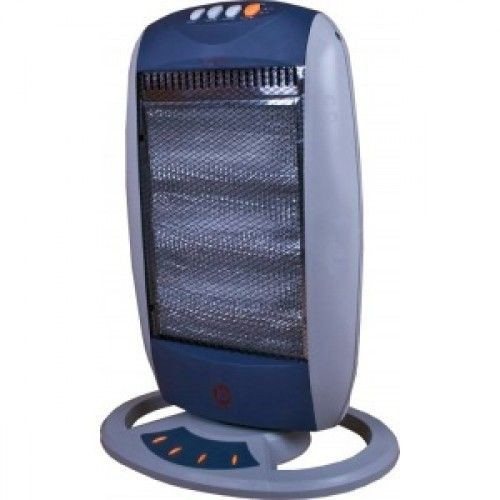

Heating elements on carbon lamps

A carbon lamp is a vacuum tube made of quartz glass, inside of which there is a radiating element made of carbon (carbon) fiber, more precisely from several fibers twisted into a bundle. This emitting element is sometimes referred to as a carbon spiral, although this is not entirely correct.

Carbon fiber has appeared relatively recently, but has gained great popularity in various technologies. Not only carbon emitters are made from it. Using special technologies, carbon fibers are made from carbon fibers.

The range of application of carbon plastics is very wide, about twenty areas: from aircraft construction and rocketry to strings for musical instruments. CFRPs are widely used in the automotive industry, mainly in sports cars. Those who are fond of recreational and sport fishing have appreciated all the delights of carbon rods.

Carbon fiber has a fibrous structure, which greatly increases the radiation area. This area is tens and hundreds of times larger than the area of a spiral made of nichrome, tungsten, ceramics, flamentine or other materials. Such a developed area leads to the fact that the heat transfer of carbon fiber is 30 ... 40% higher than that of conventional heating elements.

Carbon heater operation

When voltage is applied, the carbon fiber heats up instantly, the generation of radiant heat immediately begins, and, moreover, without harmful radiation in the ultraviolet part of the spectrum. The increased heat dissipation of carbon fiber leads to more economical energy consumption than conventional nichrome coil heaters.

Carbon heaters generate more heat for the same power consumption.At the same time, the heat does not go to the ceiling, as in the case of heating, for example, with an oil radiator or a central heating battery.

The optical radiation of carbon fiber lamps is very low. A slightly visible red glow does not affect vision at all, does not dazzle, but the glow is still noticeable. The picture above shows a working carbon fiber heater.

In the upper part of the heater there are switches that set the operating modes. In the base of the heater there is an electric drive that makes the heater turns in different directions, similar to how the fans do it. With these turns, an increase in the heating area is achieved.

Varieties of devices

Depending on the type of housing, convectors can be panel or sectional.

Due to the larger surface area, sectional heaters give off heat to the air better, but at the same time, they are more difficult to manufacture and more expensive. The flat case is better suited for wall mounting.

Depending on the method and place of installation, there are floor, wall and baseboard types.

For quick heating, some of the oil heaters are equipped with fans that blow heated air from the body into the room.

Mechanical or electronic thermostats are responsible for maintaining the selected temperature. In the first case, electrical contacts are installed on the bimetallic plates, through which the heating element is connected. When heated, the plates change their configuration and the contacts "diverge", turning off the power. After cooling, the petals take the initial (working) form - the contacts are closed, heating resumes. The operating mode of the mechanical thermostat can only be changed manually.

Wall

Plinth

Floor

Electronic controllers can work as timers, they are programmed for a day or a week. An external sensor located anywhere in the room can be connected to the device. The device will turn on (turn off) when the air temperature changes at the specified location.

Regardless of the type of heaters, all models are equipped with an emergency shutdown sensor in case of overheating, which happens when the thermostat contacts "stick".

When buying, preference is given to oil coolers with a rollover sensor - the high temperature of the metal case will not spoil the floor covering.

Selection table for immersion heaters based on oil volume

Oil volume, l

| OPERATING PARAMETERS OF THE THERMOSTAT | IN | kw | Connection type | |||

| On 16 ° C / Off 27 ° C | On 27 ° C / Off 38 ° C | On 38 ° C / Off 49 ° C | ||||

| SINGLE PHASE - ELEMENT LENGTH 305 mm | ||||||

| 114 — 171 | E01021W-156V-00 | E01021W-158V-00 | E01021W-151V-00 | 220 | 1 | V-Retainer |

| E01021W-156A-00 | E01021W-158A-00 | E01021W-151A-00 | 220 | 1 | Thread | |

| 171 — 228 | E01521W-156V-00 | E01521W-158V-00 | E01521W-151V-00 | 220 | 01 May | V-Retainer |

| E01521W-156A-00 | E01521W-158A-00 | E01521W-151A-00 | 220 | 01 May | Thread | |

| THREE-PHASE - ELEMENT LENGTH 305 mm | ||||||

| 114 — 171 | E01033W-106A-00 | E01033W-108A-00 | E01033W-101A-00 | 380 | 1 | Thread |

| E01033W-106V-00 | E01033W-108V-00 | E01033W-101V-00 | 380 | 1 | V-Retainer | |

| 171 — 228 | E01533W-106V-00 | E01533W-158A-00 | E01533W-151A-00 | 380 | 01 May | Thread |

| E01533W-156V-00 | E01533W-158V-00 | E01533W-151V-00 | 380 | 01 May | V-Retainer | |

| SINGLE PHASE - ELEMENT LENGTH 458 mm | ||||||

| 228 — 342 | E02031W-156A-00 | E02031W-158A-00 | E02031W-151A-00 | 220 | 2 | Thread |

| E02031W-156V-00 | E02031W-158V-00 | E02031W-151V-00 | 220 | 2 | V-Retainer | |

| THREE-PHASE - ELEMENT LENGTH 458 mm | ||||||

| 228 — 342 | E02033W-156A-00 | E02033W-158A-00 | E02033W-151A-00 | 380 | 2 | Thread |

| E02033W-156V-00 | E02033W-158V-00 | E02033W-151V-00 | 380 | 2 | V-Retainer | |

Explosion-proof models of Class I, Group D heaters with thermostat for hazardous locations are also available to order. To order an explosion-proof model, replace the letter "W" in the heater number with the letter "E"

KIM HOTSTART ADVANTAGES

- Precision manufacturing guarantees a long service life - Kim Hotstart manufactures an anti-vibration pad that, along with high quality manufacturing, virtually eliminates element failure due to excessive vibration.

- Models for various objects - No matter where you plan to use the heaters for heating water or heating diesel in explosive areas, Kim Hotstart has the heater you are looking for.

- Nickel Plated Switches for Better Reliability - Instead of copper phase switches and contactors, the heaters use nickel-plated switches for a more reliable connection to the mains.

- Various types of thermostats are available - Each heater is equipped with different types of thermostats with preset and adjustable temperature values.

- Manufacturing and construction quality - the heating elements and the heater body are sealed, assembled and hydraulically pressed into a single structure.

Currently, almost every driver in winter conditions, faced with the problem of difficult starting the internal combustion engine of a car in severe frosts. One of the reasons for this is the increased viscosity of the engine oil in the crankcase, which impedes the rotation of the crankshaft and prevents the internal combustion engine from starting. In addition, in such conditions, the lubrication of the internal combustion engine, in the first minutes after its start, is ineffective, which leads to increased wear of the piston group, as well as the crank mechanism. This problem can be partially solved by preheating the crankcase in order to eliminate the excessive viscosity of the engine oil. Many drivers are mistaken, believing that the main problem with a cold start of the internal combustion engine is the insufficient power of the battery, due to its low charge in the cold. A much more important and significant drawback is the inefficiency of the lubrication system. Engine oil, viscous in the cold, does not flow to the units and assemblies in the required quantities, and the friction force increases during their dry operation. And, as a result, the wear of the internal combustion engine itself increases significantly and its resource decreases [1].

To facilitate the operation of the internal combustion engine in winter conditions and reduce its wear, an oil heating system in the crankcase is required. Today, there are various ways to achieve this effect, but they can all be roughly divided into two groups:

1. Mechanical methods [1]: Mechanical (or external) methods of heating the oil in the crankcase include a cycle of work that is not related to intervention in the structure of the vehicle by installing additional equipment. The most common type of such work, which provides heating of the crankcase, is the use of open fire. A bonfire built under the car at the location of the crankcase, a blowtorch and other devices will effectively warm up the oil and achieve the start of the internal combustion engine. However, this method also has significant drawbacks: infrastructural difficulties during preliminary and direct work (overalls, inconvenient location of the crankcase, etc.); the need for additional equipment and materials (heat sources); unsafe work performed (probability of fire). The second mechanical method is the use of special removable electrical equipment, which contributes to heating the entire internal combustion engine (a special tape equipped with electric heating elements operating from a standard electrical network), but this heating is not without its drawbacks, consisting in the need for such equipment and the complexity of the procedure for placing it around ICE (with mandatory subsequent dismantling).

Specifications

Recommended power of the oil cooler depending on the area of the room

To perform the tasks assigned to the heater, the following are considered important:

- Power. The characteristic for household appliances is in the range of 900-2500 watts. On average, a 1 kW device is needed to heat 10 m2 of area (20 m3 of volume). The value depends on the quality of the building insulation, the number of doors and windows. Supply voltage - 220 V.

- The number of sections or the area of the body of the panel version. The more sections, the more intense the convection.Among home models, there are heaters with a number of elements from 4 to 11.

- The number of operating modes - the more there are, the easier it is to set the desired temperature range. For mechanical thermostats, 1-3 switch positions are considered the norm, electronic ones allow you to adjust the temperature with an accuracy of 1 ° C.

- Built-in fan. It does not increase the power of the appliance, but it accelerates air circulation and heat exchange in the room.

- Mass. The parameter is important for ease of movement.

- Additional functions - air humidifier, ionizer, built-in timer.

Taking into account all the parameters is important when choosing a specific model.

Benefits and Limitations

Among the advantages of an oil cooler with a fan are:

- electrical safety - the heating element is located inside a reliable case, access to open electrical parts is limited, if the heating element is destroyed, the dielectric properties of the oil will not allow the voltage to reach the parts accessible to touch;

- fire safety - a thermostat and an emergency shutdown sensor minimize the possibility of heating external elements above 60–80C;

- service life of 10 years and more - oil inside the housing prevents corrosion;

- maintainability - spare parts are unified and are always on sale, self-replacement of failed parts is available to most people;

- low temperature of the device, which does not lead to the appearance of a burning smell, since the dust does not burn;

- preservation of oxygen, which does not burn out, because the heating element is built into the body and does not come into contact with air, like most infrared heaters;

- the power of the device, which is higher than that of classic monolithic convectors;

- energy savings due to the presence of a thermostat.

The oil in the radiator heats up for a long time, so the device is effective as an additional source of heat

The disadvantages include thermal inertia - the device goes into operation for a long time (1-1.5 hours), compared to infrared types of "stoves", which begin to heat the surrounding objects immediately after switching on.

The oil heater cools down longer during emergency power outages, which can be especially important for small rooms - gatehouses, trailers, etc.

Large mass is both an advantage and a disadvantage. It can be difficult to deliver the device to the place of installation, and later the movement takes place on wheels. On the other hand, a massive appliance keeps heat longer.

The device is dangerous for small children - sharp edges can cause injury if dropped.

Operating rules

We figured out how to turn on the heater correctly. Now let's look at a few rules that should accompany its operation. They must be observed in order to preserve both the operability of the device and the safety of all people living in the house or apartment. The rules are as follows:

- the parameters of the electrical network must correspond to the parameters of the heater. As a rule, the equipment is designed for 220 V, but just in case, you should clarify this point by reading the instructions;

- Like any other appliance, the oil cooler needs to be cleaned periodically. Naturally, only the outer part of the device, that is, its body, is cleaned. Before cleaning, be sure to unplug the equipment to avoid electric shock;

- if it is planned that the radiator will not be used for a long time, then it must also be disconnected from the mains. However, this should be done with any electrical appliances;

- during operation of the radiator, the power cord must not come into contact with the case (of course, the place of direct connection does not count). Do not forget that the surface of the equipment heats up very much, so the sheath of the cord may melt or burn out after prolonged contact with it;

- during operation, regularly inspect the device.If you notice any damage to its case or power cord, then you should immediately contact a repair shop or purchase a new radiator. It is strictly not recommended to use a device with visible damage, as this can lead to fire, injury, and other serious situations. The same applies to the performance of sensors, especially temperature sensors. If it is broken, then you cannot use the device until the replacement of the failed element, since you will not be able to notice overheating on your own, and this will lead to equipment breakdown;

- another prohibition concerns the placement of various items on the oil heater. For example, you cannot dry clothes, bedding and other textiles on it. Also, there is no need to cover the radiator with decorative panels and mask it with other methods. All this can lead to overheating and, as a result, to equipment breakdown. If drying clothes on a heater is absolutely necessary, then choose the model with an attached dryer. It is categorically impossible to throw fabric on the radiator itself;

- if your heater belongs to a mobile version - that is, it can be moved from place to place thanks to the wheels on the bottom panel - in no case move it by the power cord, as this can lead to a break in the cord and, as a result, to a short circuit ;

- when placing the device, pay attention to its distance from the walls. If the distance from them is less than half a meter, then the radiator will constantly overheat and turn off, so it needs a little more space.

Security measures

When using the appliance in a bathroom, take into account the room humidity and the IP rating.

When buying, it is important to make sure of the quality of the device by demanding certificates of conformity from the seller. Their absence directly indicates the poor quality of the product.

During operation it is prohibited:

- allow contact between the heated case and the power cord;

- use when repairing wires and plugs that are not designed for the consumed load;

- use extension cords with cables of insufficient cross-section - extra plug-socket contacts increase resistance, there are often cases of short circuits;

- connect the device to the network with the protective cover removed;

- leave the device unattended, especially in rooms where children and animals can be - the device may overturn, cut off (bite) the power cord;

- place oil heaters in rooms with high humidity, install devices on an earthen floor without a dielectric mat;

- turn on a heater in a horizontal or inclined position;

- place the device closer than 50 cm from walls and pieces of furniture;

- store products in the open air, as well as in the open air.

The plug from the socket is disconnected only after the thermostat has been moved to the "off" position. Manipulations are prohibited under load.

Frequently asked questions from users

Can the device explode

In the overwhelming majority of cases, heaters use transformer oil, the flash point of which is about 130 degrees. The flash occurs only in the presence of air, it is in the body in the amount of 10-15% of the volume.

Oil reaches critical temperatures when two protection devices fail simultaneously:

- Thermostat contacts "stuck";

- the emergency shutdown sensor is out of order.

Do not leave any heaters turned on unattended.

Is it possible to dry things on the heater

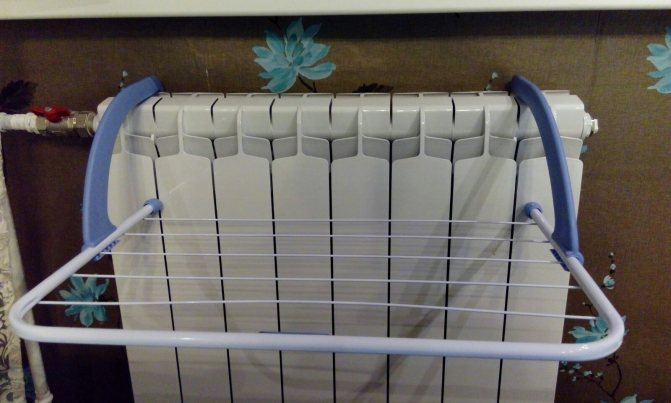

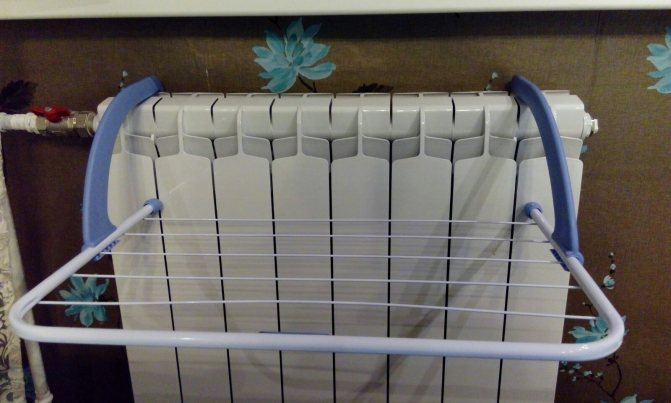

Device for drying clothes on an oil cooler

The temperature of the case when fully heated can reach 60-80 degrees.

Clothes, towels can be damaged or lose their attractive appearance.Often left fabric items burn to the surface, the heater coating deteriorates, and the remaining traces are difficult to remove.

The shelter of things hinders the movement of convection currents, which leads to increased heating of the case. The device will start to turn off faster and turn on less often. This mode will lead to a decrease in the room temperature.

Why does it burst when working

If you hear clicks and a crackling sound during operation, this indicates various malfunctions or may be normal operation. When a malfunction is detected, pay attention to the duration of extraneous sounds.

If, during assembly at the factory, water gets into the case along with oil, crackling will be heard until the heater comes into operation, having heated up to 60–70 degrees. The water in the container will evaporate, turning into a gaseous state, the crackling will stop. A similar phenomenon can be observed when water enters the oil in a preheated pan. The fault does not require intervention if the sound stops 5-15 minutes after switching on.

A defective thermostat can make sounds during operation

If the radiator is moved or dropped, the oil may mix with air. After plugging into the network, the air is released and the noise will stop by itself.

A crackling sound from the controls is a sign of a malfunctioning thermostat. Bimetal plates often change configuration, there is a constant opening-closing of contacts, which emit clicks. Repair of the oil heater in this case consists in replacing the faulty thermostat with a new one.

If the crackling does not stop after entering the operating mode, it is necessary to repair the oil heater in a specialized workshop.

How much electricity consumes

The maximum power of any model of an oil heater is indicated in the instructions or the product passport.

Most of the heaters consume from 900 to 2500 W / h. Multiplying the resulting figure by the number of hours of work, they will approximately find out the maximum amount of electricity spent.

It should be borne in mind that due to the operation of the thermostat, the heating element is turned on from 8 to 12 hours a day. For example, a two-kilowatt heater works about 12 hours a day and consumes about 24 kW of electricity during this time.

The exact indicators depend on the mode in which the thermostat is set, what is the air temperature in the room, the quality of the insulation of the walls.

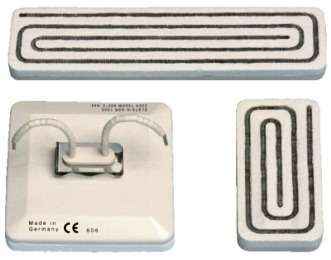

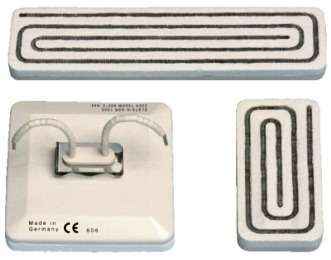

Ceramic infrared heaters (emitters)

They represent an ordinary heating element, "sharpened" in a ceramic shell - a case. The heat from the heating element heats up the ceramics, and already from it the heat rays are emitted into the external environment. The ceramic shell has an area several times larger than the area of the heating element, so heat is given off more actively.

The appearance of the ceramic heater is shown in the figure. Such heating elements are often referred to as infrared panel heaters. The shape of the heating panels is very diverse. The heater can be flat, concave, or, conversely, convex.

Appearance of the ceramic heater

On the front surface, you can see the configuration of the heating element, on the back surface there are wire leads insulated with ceramic beads. The working temperature of the ceramic heaters is 700 ... 750 degrees, the specific surface power is up to 64 kW / m2. The power of ceramic heaters can range from several tens of watts to several kilowatts. As they say, for all occasions.

Some types of ceramic heaters have an open, visible coil, such as the HSR type. The working temperature of the heater is 900 ° C, the heater is designed for quick warm-up. The appearance of the HSR heater is shown in the figure.

Heater type HSR

Ceramic IR heaters are of three types: volumetric (solid), hollow, and heaters with a built-in thermocouple. Volumetric elements are quite inertial, they warm up for a long time and cool down slowly. Hollow heaters are used in cases where periodic switching on / off of the heater is required.

They are less inertial, which allows them to be used in various technological processes where it is required to maintain the exact temperature of the working environment by periodically turning on / off the emitter. Due to the reduced weight, the heating rate of hollow radiators is 40% higher than that of bulk ones.

Unlike volumetric emitters, most of the radiation from hollow emitters is directed forward. The backward radiation is prevented by a hollow thermal barrier on the rear side, which provides a gentle temperature regime for the elements of housing structures, and also increases the efficiency of the emitter. Compared to volumetric emitters of the same power, the reduction in electricity consumption reaches 15%.

When using a volumetric radiator, this heat distribution can only be obtained using a reflector. Some types of IR panel heaters have a built-in K or J type thermocouple to allow precise temperature control and regulation. It is very convenient for use in technological processes.

There are a lot of technological processes where IR emitters are used. Here are just a few of them:

- Drying paint (two-component paints, epoxy varnishes),

- Plastics processing (PVC vulcanization, thermoforming of ABS plastics, polyethylene, polystyrene, auto body parts, powder painting)

- Drying of adhesives,

- Food processing (keeping warm, grilling, sterilization and pasteurization),

- Textile products (silk-screen printing, decals on T-shirts, carpet latexing),

- Health and beauty (infrared thermal cabins, saunas)

Self-repair

All malfunctions, except for the destruction and depressurization of the case, can be easily eliminated on your own - no special skills and equipment are required for repairs.

Common malfunctions and methods of their elimination are collected in the table.

| Malfunction | External sign | Possible reason | What to do |

| The appliance does not heat up | There is no light indication | Lack of voltage in the network and the integrity of the power cord is damaged | Eliminate or wait for power supply |

| Light indication is | Check the integrity of the toggle switch | Replace with a serviceable one | |

| Thermostat does not work | Replace | ||

| Broken wires in the electrical circuit | Eliminate | ||

| Defective heating element | Replace |

You can fill the radiator with car oil.

In order to be able to carry out troubleshooting manipulations, remove the cover that protects the controls. On different models, the protective screens are fastened with screws or plastic clips. To remove, inspect the fastening mechanism, unscrew the fasteners or push the latch petals with a screwdriver.

Before disconnecting the wires from the thermostat or heating element, it is recommended to photograph or draw a diagram in color - this will help with assembly after the malfunction has been eliminated.

You can unscrew the heating element with a plumbing wrench. When reassembling, the threaded joint is sealed with linen winding and sealant, if the design does not provide for rubber or silicone gaskets. If such are installed, newly purchased ones are used when installing the heater.

Oil is poured into the container by 75-80% of the volume, since it will expand by 5-7% when heated to 90 ° C. In the absence of an empty space, the heater body will break at the places where the welded seams pass.

Reliable manufacturers

Oil heaters are in the assortment of most brands that produce heat engineering products.

Timberk, Pollaris, Dellongi, Electrolux stand out from the quality products presented on the Russian market.

When choosing a specific model, they pay attention to the power, design, additional capabilities of the heater. Be sure to take into account the opinions of buyers, which can always be found on special consumer forums, reviews and on the websites of large retail chains.

With the right choice, competent operation and strict observance of safety measures, universal oil heaters serve for a long time and without failure.

The main criteria for choosing infrared heaters

How Do I Pick a Good IR Heater for Home? When choosing the model that is optimal for you, always pay attention to the type and material of the emitter, power, functionality, as well as the manufacturer's warranty. Let's consider the selection criteria in more detail.

Heating element type

All types of electric infrared heaters differ in the shell, in which the radiating element is placed, emitting waves of a certain length. This shell can be made of quartz, ceramic or metal.

The most popular heating elements are infrared heaters, which are divided into types:

Halogen

Such a heating element is a vacuum tube filled with an inert gas. When heated, the lamp emits waves in the infrared range. The visible spectrum is light with a golden hue, which puts strain on the eyes. The main disadvantage of halogen heaters is radiation in the short-wave range, which negatively affects a person.

Halogen infrared heater

Carbon

The carbon heater is a sealed quartz tube filled with carbon fiber. Heaters equipped with such a heating element are more economical and are often used for medicinal purposes.

Advantages: fast heating and high efficiency.

Disadvantages: high energy consumption, short service life (about 2 years), dangerous for allergy sufferers and asthmatics.

Quartz infrared heater

With ceramic sheath

In ceramic infrared heaters, a special cable with a ceramic sheath is used as a heater, which emits infrared waves under voltage. Most of the models are produced in the form of a ceramic panel with an external thermostat.

Advantages: long service life (more than 3 years), cost-effectiveness.

Disadvantages: slow heating and rather high cost.

With ceramic sheath

Tubular (micathermic) metal elements

This type of heating element is a construction of a hollow aluminum tube and a steel spiral installed exactly in its center. The space between these elements is filled with insulating material with a high coefficient of thermal conductivity.

Advantages: reliability, high heat transfer.

Disadvantages: high cost and possible crackles during heating.

TEN infrared heater

Heating element material

The material from which the heater is made also matters when choosing a device. The main materials for their production are:

- Black metal. This material is susceptible to corrosion, therefore, devices with such elements cannot be used to heat rooms with high levels of humidity.

- Stainless steel. Corrosion resistant material. It can be used in any conditions.

Foil thickness on emitter

When deciding which infrared heater you need to choose to heat your home, experts recommend paying attention to the thickness of the reflective layer of the emitter of the model you are interested in.

Minimum acceptable thickness 120 microns... Anything thinner is bad, the reflector will work ineffectively. How can I check this? If the thickness of the reflective foil is more than 120 microns, any pressure will not damage the material and will not leave any traces of impact on it.

Electronic control

Power

When calculating the power of an IR heater designed to heat an apartment, use the standard algorithm: 10 m2 of living space requires (on average) 1 kW of thermal energy. In addition, to cover heat losses through the material of the enclosing structures, 15 to 30% should be added to the design power.

Advice! A device with a power of 300 to 500 W is sufficient to heat a standard garage. When choosing an IR heater for heating a summer cottage during the off-season, you should adhere to the following calculation scheme: 1 m2 requires 60 to 80 W of device power.

Warranty period

The manufacturer's warranty is what you should also pay attention to. Typically, the warranty period for an infrared heater varies from 1 year to 3 years. If during this period of time any breakdowns of the device occur due to the fault of the manufacturer, then the device is repaired free of charge.

Important! In order for the consumer to benefit from the warranty, it is necessary that the device is operated in accordance with the conditions specified in the instructions.

For clarity, all the optimal values of the IR heater are collected in a single table.

| Parameters | Characteristics | Recommendations |

| Power | 100 W to 9 kW | 10 m2 requires 1 kW of power |

| Execution | Stationary Mobile | Used to heat one room Used when it is necessary to move the heater |

| Heating element type | Halogen Quartz Ceramic Heating element | Radiates infrared waves in a short range. Not recommended for residential use. Recommended for short-term use. Short service life. Ideal for mobile devices. The best option for long-term heating of living quarters. |