Can you imagine life without hot water? The comfort of our home directly depends on the installed equipment. If you decide not to depend on utilities, use resources sparingly and not overpay, then it is important to choose the right equipment.

Gas water heaters "Rossiyanka" are represented by a small number of models. But they are all assembled in Russia, which means they are completely adapted for local conditions. Curious to know what makes the speakers special? We will tell you the details in the publication.

Gas column Proton-1M

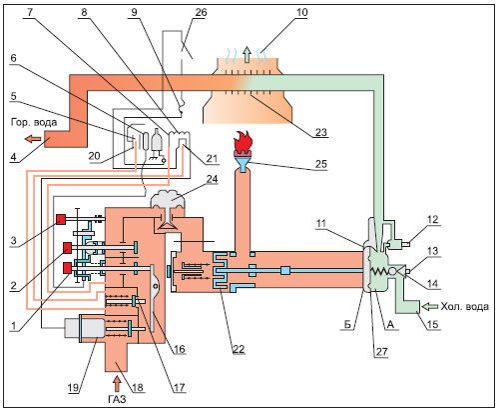

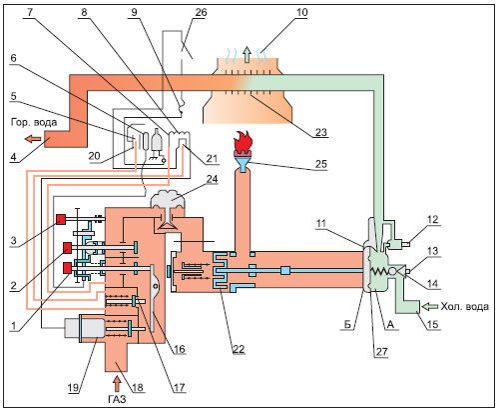

The factory name for these models is VPG - 1712 - V11 - UHL4.2. The appearance of the apparatus is shown in Fig. 1. Dimensions (height X width X depth) are 719X360X230 mm, weight - 13 kg, productivity - 5 liters of hot water per minute. The functional diagram of the gas column is shown in Fig. 2.

Let's take a closer look at the principle of operation of the device.

Cold water from a water pipe or a well under a pressure of 2.0 ... 2.5 kg / cm2 from inlet 15 enters the heat exchanger 23. Here the water is heated to a predetermined temperature and through outlet 4 goes into the hot water supply system of the premises. Natural gas from the main through the inlet 18 enters the valve 19. The purpose of the valve 19 is to interrupt the gas supply in the event of an emergency failure in the column or insufficient gas pressure in the inlet main. Having passed the valve, the gas enters the reducer, which reduces the excess pressure, and then through the valve 22 - to the central burner 25. The central burner is ignited by the flame of the pilot burners 7, 20, 21.

When you turn off the device with button 1 and hold it down for 3 seconds. Lever 16 opens valve 19 and valve 17. Gas enters the fast ignition burner 20. Button 1 contains a piezo ignition device connected to spark plug 5. At the moment of pressing button 1, a spark is formed between the central pin of the spark plug and the body, igniting the gas in burners 7, 20, 21. After a short time (2-3 seconds), an emf appears on the thermocouples 6, 8, which keeps the valve 19 open. When button 2 "Open" is pressed, gas flows through the reducer 24 and valve 22 to the main burner 25. In the initial state, the valve is closed and opens if there is a flow of hot water.

The stability of the water temperature at the outlet of the apparatus is ensured by a pressure reducing valve 24 and a valve 14, which maintain constant gas and water pressure, set by a regulator located on the front panel of the apparatus. In the "Proton-1M-1" model, a thermometer is additionally installed for visual control of the water temperature. The device is switched off by pressing button 3 "Extinguishing" mechanically connected with button 1 "Ignition" and button 2 "Opening". After the first click, the main burner turns off. The device switches to standby mode when only the pilot burner is on. Then, upon further pressing, after the second click, the ignition burner is also turned off. To transfer the gas water heater from standby to working mode, it is enough to open the tap in the hot water supply system. Consider the operation of the column automation system in various emergency situations.

Weak heating

Weak heating of water, as the gasmen explained to me, is due to the low pressure of the gas, and its poor quality. I got out of the situation simply - I drilled out the nozzles. Only here it is important not to overdo it. It is better to drill the holes on the plate one at a time, slightly increasing the diameter. Conduct an experiment after each step.Even a slight increase in diameter (we are talking about tenths of a millimeter) gives a significant increase in flame. If the flame is too large, then in addition to overheating when turned off, another nuisance may occur - a significant decrease in the flame on the wick when the column is turned on.

Proton gas column malfunctions

# 1. Ignition burner has gone out

Possible reasons: short-term interruption of gas supply, blowing out of the flame with a gust of air, thermocouple malfunction. As a result, thermocouple 6 stops heating up, the voltage at its outputs decreases to zero. The solenoid valve 19 is turned off by a spring and interrupts the gas supply to the apparatus. The column turns off.

# 2. Lack of draft in the chimney

Possible reasons: chimney clogging, mechanical damage. In this case, the outflow of hot gas through the chimney is sharply reduced. The temperature of the thermostat 26 rises above 900C and the thermostat turns off. As a result, the voltage supply circuit to the valve 19 is broken and the device is turned off.

Number 3. Lack of water in the heat exchanger

A possible cause is a violation of the tightness of the heat exchanger. The temperature of the heat exchanger 23 rises sharply. At temperatures above 1300C fuse 9, located on the thermostat, melts. The voltage supply circuit to valve 19 is broken and the column is turned off.

No. 4. Short-term interruption of gas supply from the main

Possible reasons - repair work on the gas main. As a result, the ignition burner 7 goes out, the thermocouple 6 stops generating emf, and the solenoid valve 19 interrupts the gas supply. When the supply is resumed, the gas will not be able to enter the device, since the valve 19 is closed. To resume work, you must turn on the column again. This is done in the usual way.

No. 5. Interruption of water supply or pressure drop below 25kPa (0.25 kg / cm2)

A decrease in pressure in the city water supply system occurs mainly among consumers living on the upper floors of high-rise buildings during the hours of maximum water intake. For a country house, there are possible reasons: a decrease in the debit (productivity) of a well, a malfunction of a water supply station. To prevent an accident, the device has a device called a "water unit". The device works as follows. When the water is turned off, the pressure in cavities A and B are equalized. Membrane 27 moves to the right and valve 22 cuts off the gas supply to the main burner. The column switches to standby mode.

In order to ensure the reliability of the gas water heater, the elements of the automation circuit are completed with parts produced by well-known foreign companies, for example, the thermostat is manufactured by the English company Elmwood Sensor, and the solenoid valve and thermocouple are manufactured by the Czech company Mora Moravia. To protect against the ingress of foreign objects, filters are installed at the gas and water inlets. The fact that Proton - 1M is the winner of the competition "100 best goods of Russia" also speaks about the reliability and quality of the device.

How to adjust the temperature of the liquid?

The liquid flow control toggle switch is on the right, you can adjust the gas supply using the left gas control knob. Between these two handles is a thermometer showing the heating temperature.

If you have hard water, it is highly recommended to heat the water to such a temperature that it does not mix with cold water for use. This way you minimize the formation of limescale on the heat exchanger. For gentle use of the device, it is not recommended to increase the limit of 55-60 degrees.

Lower part of the geyser Atlan 1 10 LT

If a low liquid flow rate is set, that is, the liquid flow control knob is set to minimum, and the gas flow rate is at maximum, overheating will occur. The burner will be shut off automatically by the control system.

Gas column "Proton - 3 / 3-1"

The factory name of these models is "VPG-17 12-V11-UHL 4.2". They have a power of 17 kW, overall dimensions 809 X 360 X 250 mm, weight - 15 kg and productivity - 5 liters of hot water per minute. The functional diagram of the apparatus is shown in the figure.

Let's consider the principle of operation of the Proton - 3 / 3-1 apparatus.

To turn on the gas column, press the button 3 of the solenoid valve all the way. While holding down the button 3, the button 1 of the piezoelectric ignition is pressed. Gas from the line passes through valve 5, filter 23 and enters the ignition burner 18. The spark on the spark plug 17 ignites the gas. After that, the button 1 is released. Keep button 3 pressed (for about 30 seconds). During this time, the thermocouple 16 heats up. At its output, an emf appears, which keeps the solenoid valve 6 open. Now button 3 can be omitted. Radiator. Gas will begin to flow to the main burner 19 only after the hot water tap in the system is opened. This will open valves 9, 10 and the burner will light up. The device has a water reducer 13, which allows you to maintain a constant inlet water temperature when the pressure in the water supply changes. The device has a thermometer to control the temperature of hot water. On the front panel of the column there are knobs for adjusting the gas supply to the main burner and the water flow rate. The operation of the automation system in the event of emergency situations (similar to that discussed earlier in the Proton-1 M apparatus).

Disadvantages of the gas column "Proton - 3/3 - 1" in comparison with "Proton - 1M":

- due to the absence of an additional thermocouple, the column turn-on time increased from 3 to 30 sec;

- due to the absence of a gas reducer, the change in gas pressure in the inlet line is not monitored, which leads to an increase in the instability of the hot water temperature;

- insufficient mechanical strength of the solenoid valve activation button.

The advantages of "Proton - 3 / 3-1" include a lower price with a high degree of reliability of the automation circuit.

Model overview

After examining user reviews, we came to the conclusion that not everyone can understand the instructions for connecting the unit. In this case, contact your gas service. Remember that it is forbidden to crash into the main line on your own and connect equipment to gas. An on-site specialist will carry out the installation and acquaint you with the features of operating the column.

If you decide to opt for a domestic manufacturer of heaters, then it will be interesting to know the characteristics of the models. It is not easy to find them in stores today. Therefore, we do not indicate a pricing policy. You can contact directly the supplier of Rossiyanka-M equipment or make a request in the online store.

"Rossiyanka" VPG-5 mini

The only model in the series that does not require a chimney connection. Its low performance ensures stable operation with normal ventilation in the room.

VPG-5 mini is suitable for household needs. Therefore, it is better to install it in the country or use it as an additional source of hot water. The design includes a thermal sensor against overheating and a safety valve.

| Productivity (l / min) | 5 |

| Thermal power (kW) | 8,70 |

| Inlet pressure (atm) | From 0.18 |

| Ignition type | Piezo ignition |

| Installation method | Wall. Through the bottom vertical liner |

| LPG connection | Yes |

| Weight, kg) | 6,3 |

| Dimensions (WxHxD), mm | 255x485x205 |

"Rossiyanka" VPG-E

Belongs to the category of speakers with an increased level of comfort. Electronic ignition is convenient for daily use. There is no need to hold the ignition button every time, just open the mixer and wait for hot water. An open combustion chamber requires a chimney connection.

A thermostat and a modulating burner are provided to maintain the set temperature. Enough performance for showering and washing dishes at a comfortable temperature.Gas control protection protects equipment from fuel leakage. When the temperature is exceeded, the overheating protection is triggered.

| Productivity (l / min) | 14 |

| Thermal power (kW) | 24,40 |

| Inlet pressure (atm) | From 0.25 |

| Ignition type | Electronic |

| Installation method | Wall. Through the bottom vertical liner |

| LPG connection | Yes |

| Weight, kg) | 16 |

| Dimensions (WxHxD), mm | 460x865x300 |

"Rossiyanka" VPG-24

One of the most powerful water heaters in the series. Great for multiple pick-up points and a family of 3-4 people. The burner is ignited using a piezoelectric element. The water flow regulator allows you to save on consumption.

The security system provides for:

- Overpressure fluid relief valve.

- Temperature sensor as protection against overheating.

- Gas control.

| Productivity (l / min) | 14 |

| Thermal power (kW) | 24,40 |

| Inlet pressure (atm) | From 0.25 |

| Ignition type | Piezo ignition |

| Installation method | Wall. Through the bottom vertical liner |

| LPG connection | Yes |

| Weight, kg) | 15,3 |

| Dimensions (WxHxD), mm | 460x865x300 |

Gas columns "Proton-2 / 2-1"

The factory name for these models is "VPG 17 12-V11UHL 4.2". They have a power of 17 kW, overall dimensions 809 X 360 X 250 mm, weight - 15 kg, productivity - 5 liters of hot water per minute.

The functional diagram is shown in the figure.

These are budget models. Compared to the previous devices, they have a simpler design and a gas-water unit of domestic production. Due to the absence of water and gas reducers in the circuit, the temperature of the heated water changes depending on the pressure of water and gas in the supply lines. A hot water thermometer is not provided. On the front panel of the device, there is a piezo ignition button 1 and a gas supply adjustment knob for the main burner. To turn on the gas column, the gas supply adjustment knob is moved from the extreme left position to the ignition sector. The hot water tap in the system must be closed. Press button 1 all the way. Piezo ignition of the pilot burner takes place. The burner flame is clearly visible through the cutout on the front panel. After a short time (about 20 seconds) required for the thermocouple to warm up, the button is released.

I turn on the hot water tap. The central burner then lights up. Set the desired water thermocouple with the gas supply knob. "Proton 2 / 2-1" refers to devices capable of operating at reduced water pressure (from 4 kPa). This is especially important if there is no centralized water supply. The value of the minimum pressure is set using the adjusting screw, which is located on the housing of the water reducer. It should be noted that due to the simplified design of the apparatus and the absence of additional locking devices in the automation circuit, it is necessary to strictly follow the rules for operating the gas column.

It is strictly forbidden to turn on the column in the sector of the main burner with the hot water tap open! In this case, a large amount of gas from the mainline can accumulate in the device and an explosion is possible when the piezo ignition is turned on.

If you smell gas in the room, turn off the column and close the gas valve installed on the gas pipeline in front of the device. Do not perform actions that could lead to the formation of a spark: do not light a fire, do not turn on electrical appliances and lighting, do not smoke. It is necessary to ventilate the room. This precaution is necessary! A mixture of gas with air forms an explosive mixture that can explode from the slightest spark. The location of the gas leak is determined using a soap solution.

Checking with a lit match is prohibited! The most common cause of malfunctions of the gas columns listed above is a leak in the plug valve at the inlet of the column. Over time, the lubricant inside the tap dries out and the tightness is broken. To eliminate the malfunction, shut off the gas supply from the main line and disassemble the valve.Old grease is removed with kerosene or another solvent.

If there are deep scratches during the repair of the gas water heater, grind the tap cone with fine sandpaper. Then the cone is abundantly lubricated with a thick grease, inserted into the valve body and tightened the nut. For lapping, turn the tap round and round several times. In ball valves, the defect is much less common. Leakage at the pipe joint is eliminated by additional tightening of couplings and nuts.

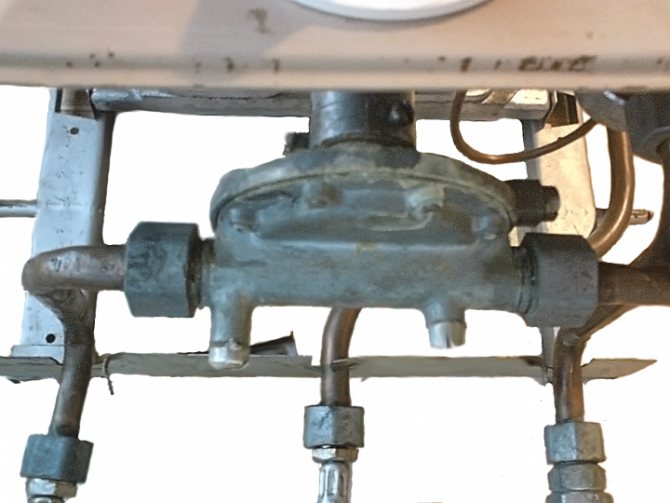

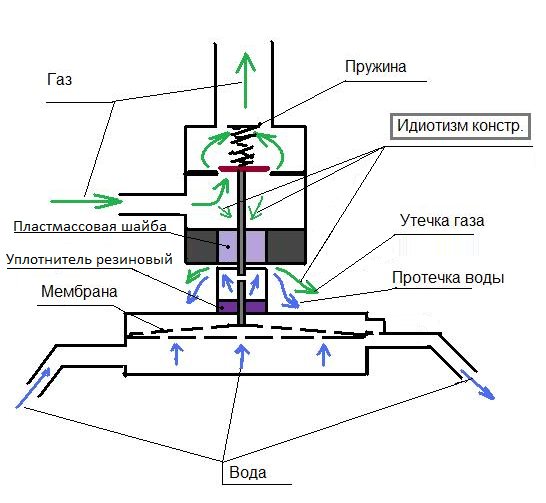

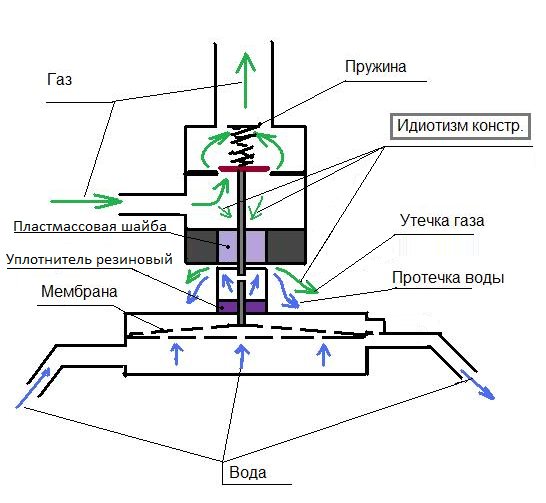

Water unit and central valve

A malfunction of the water unit can cause:

- Unexpected speaker disconnection

during work (the second most important reason, after problems with the wick) - Pops when turning on the column

and even micro-explosions - Weak pressure of hot water

- The column does not turn on

, - at the same time the gas flows and the wick burns (the most dangerous case)

The main reason is jamming of the valve tappet rod and deformation of the diaphragm.

The problem can be eliminated only by replacing the stem, diaphragm, etc. - everything that is included in the standard repair kit (tel. Below). In addition, there are still problems that I managed to overcome only by improving the design.

In general, everything is most interesting here.

As a result, when the seals are worn out or under-tightened, a gas leak begins to occur, even when the column is not working (but only the wick is on). At the same time, in the worst case, the gas can (and it is) accumulate in the lower part of the column and flash before the main burner, when the column is turned on, igniting the nozzles of the main guides. The column is buzzing wildly, overheating in the area of the main nozzles (those same plates), and the main burner "receives less" gas (which, however, is not the worst thing in this).

Worst of all, ignition can occur at the leak! The greatest probability of this is when the column is turned off (when the water is shut off). And this is already quite bad, tk. there are rubber and plastic parts in this place.

If you overdo it and squeeze the seals, then the rods will wedge, as a result of which the response will be delayed (turning on and off), which again can lead to pops, boiling water in the radiator and wear of the rod (a narrowing forms on it in the central part, due to which the seals in extreme positions they are pinched, and on average - undersqueezed).

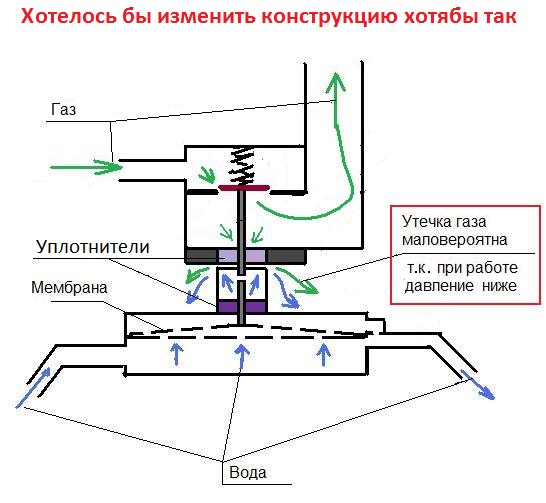

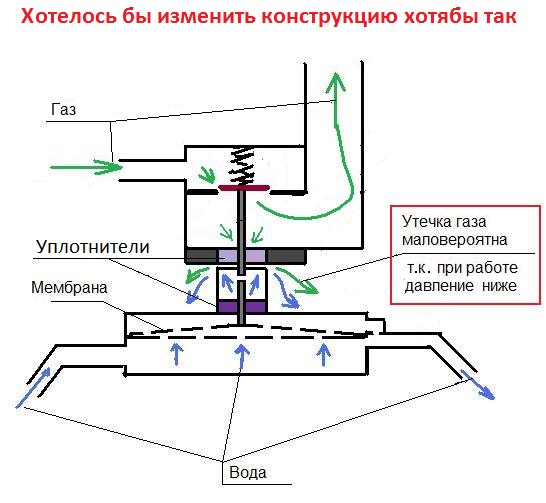

Of course, the smartest thing would be to do so that when the main valve is closed, the possibility of gas leakage would in principle be excluded.

I even dreamed a little and imagined how this part could be done (see the picture above). But, unfortunately, these are only dreams - such revision is hardly possible at home. And most importantly, it is meaningless. It's easier to buy a new modern speaker.

In general, after much suffering, I slightly modified the design (see the picture above).

The lower stem (diaphragm) is lubricated with a thin layer graphite grease

(on the advice of a gasman). A thin layer is when it is almost invisible on the stock. The springs are very soft. The lower one is quite small. The springs from the fountain pens fit well. The seals (red in the picture) should slide easily so that the springs can move them. But, at the same time, so that the gas does not pass (i.e. the effort should still be, albeit small). I bought a plumbing kit and selected the matching rings from it.

Scale on the heat exchanger - how to fix

The need to clean the heat exchanger is usually caused by the following reasons.

- The water heats up for a long time.

- Poor water pressure.

- The overheating sensor is triggered and the column turns off.

If the above happens to the column, this means that it is necessary to clean the heat exchanger, since a large amount of scale has formed in it.

Step-by-step instruction

Cleaning the heat exchanger consists of the following steps.

- It is necessary to shut off the water supply to the heater with a valve, and dismantle the heat exchanger by disconnecting it from the water pipes. If cleaning is carried out infrequently, it is recommended to use a lubricating spray for dismantling, which makes it easier to unscrew the oxidized nuts. After processing the nuts with a spray, it is necessary to wait 15-20 minutes and start unscrewing them.

- After dismantling the heat exchanger, you can start cleaning it. For descaling, you can use a solution prepared at the rate of 100 grams. citric acid in half a liter of hot water. With the help of a watering can, the solution is poured into the heat exchanger, and it remains there for 12 hours.

- Then it is necessary to drain the solution and thoroughly rinse the part with clean water. It is necessary to thoroughly clean the heat exchanger from the remains of scale, as it can clog the pipes, blocking the flow of water. This can be done with pressurized water or compressed air.

- The final stage, at which it is necessary to install the heat exchanger in place in the heater, having previously changed the sealing washers.

Replacing gaskets

One of the reasons for a column leak may be gasket wear. Also, one of the reasons for gas leakage from the heater is the wear of the gasket.

Step-by-step instruction

Replacing the gaskets consists of the following steps.

- Shut off the gas and water supply to the heater.

- Burn off the remaining gas and drain the water.

- Unscrew the heat exchanger from the water supply pipes and remove the old gaskets. Then install new gaskets and screw on the radiator in reverse order.

- After that, it is necessary to unscrew the column on the gas line, dismantle the old gaskets, install new ones and screw the heater back.

It is not recommended to use home-made gaskets made from improvised means, since this is something with bad consequences. It is better to purchase gaskets from specialized stores and of good quality.

When starting to repair a gas water heater, it should be remembered that this is a device of increased danger and requires unconditional adherence to safety rules. Also, when repairing heaters, you should adhere to the following recommendations.

- For any repairs, turn off the gas and water supply to the device itself.

- Use high-quality components and parts purchased from specialized stores.

- After dismantling the heater or its components, carefully check the tightness of the connections during re-installation.

- You should not repair the column if you have no idea how it works and what is the cause of the breakdown.

It should also be remembered that in the event of an unsuccessful repair, the column may fail and not be repairable, so this process should be scrupulously approached.