Types of gas heating convectors

There are three types of gas convectors:

- Permanent installation: With a closed combustion chamber (parapet).

- With an open combustion chamber (chimney).

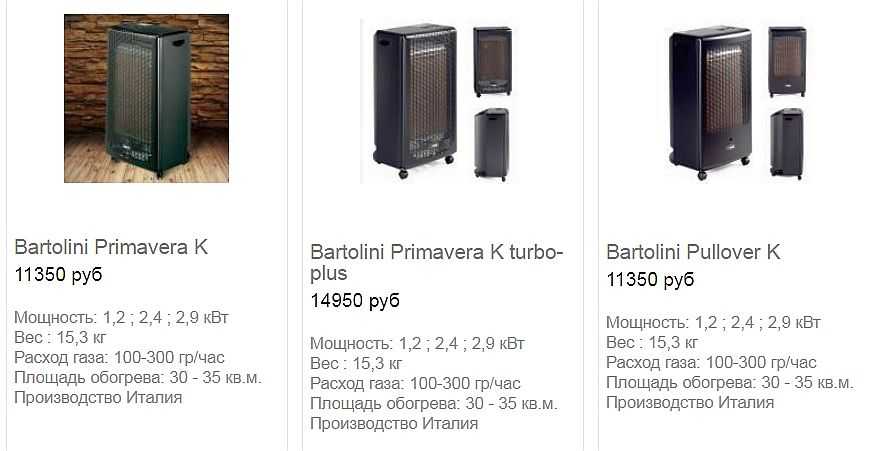

At first glance, mobile gas convectors seem to be the best solution. Maybe this is so, because a new principle of generating heat is used. They are a casing on wheels, in which a bottle with liquefied gas (optional, can be installed outside), a catalyst and the gas radiator itself are packed. There are not many such models. So far, there are only Italian Bartolini on our market (Primavera and Pullover models).

Mobile gas convector

This device is called "catalytic gas heater". It does not use conventional combustion, but catalytic decomposition (combustion on the surface of solids). Due to this, the usual exhaust and smell are absent, and the gas decomposes almost completely. Since such devices are used in Europe, there is no reason to doubt their reliability. But, so far, they are not very popular - the option with combustion without exhaust seems too incredible. In addition, even catalytic oxidation requires oxygen. And, therefore, it is taken from the air that is in the room. Well, then, when the catalyst runs out, will you have to buy it? Or completely change the device? In general, there is no real operating experience yet. But about the other two types of gas convectors - parapet and chimney - let's talk in more detail.

With an open combustion chamber

Gas convectors with an open combustion chamber use oxygen dissolved in the air for combustion. Therefore, the room must be equipped with full ventilation. A chimney is required to remove the combustion products. That is, the connection is like a traditional boiler of the same type or a gas water heater. Gas convectors with a closed combustion chamber have an efficiency of about 80%. This is 10-15% lower than most units with a closed combustion chamber.

If you decide to replace a boiler or a column, buy a gas convector with an open combustion chamber and connect it to the existing communications. But usually few people want to build everything anew. Indeed, for air heating with convectors, one device must be installed per room. It is costly and troublesome to remove so many pipes. The second option is to install a more powerful heater, with air duct routing in several rooms. But here a design solution is required, since it is necessary to accumulate heated air somewhere, and then distribute it to other rooms. Otherwise, it will be too hot in the room where the powerful convector is installed.

Chimney type gas convector with open combustion chamber

Gas convectors with an open combustion chamber also have advantages:

- work more stably (with a properly arranged chimney and sufficient draft);

- can have a large capacity (used for heating industrial, commercial and office buildings);

- there is no deterioration in thermal insulation and sound insulation (when installing parapet models, a hole must be made in the wall).

In general, a good option if you need to organize heating of a small country house, garage, workshop, greenhouse, etc.

Advantages and disadvantages

Such convectors have both their advantages and disadvantages, which the reviews clearly show.

Among the advantages are such as:

- Heating a summer cottage with a gas converter is suitable for virtually any type of premises, since there are no space restrictions for equipment.

- They are compact in size and excellent in design. Thanks to this, they will be able to fit into any type of interior.

- For the installation of such devices, it is not necessary to take into account the location of the pipes of the heating system. Also, you do not need to take into account their slope or the dependence of heating devices from each other. The installation of such convectors is not difficult.

- Heating a country house with gas convectors does not depend on adjacent premises.

- Gas convectors are highly frost-resistant.

- In terms of efficiency, some gas convectors surpass even the latest generation gas boilers.

However, gas convectors also have some disadvantages, among which the following can be distinguished:

- Only one room can be heated with a gas convector.

- Heating with gas convectors cannot be used to heat water.

- They have a rather limited thermal conductivity. Most gas convectors have a capacity of 2 to 7 kW.

- Gas convectors are not as compact as water convectors, so it is rather difficult to disguise them.

- In residential premises, hot water has always been needed. Double-circuit gas boilers will be able to fully meet such a need for residents, but gas convection heating will not.

- Gas convectors have a rather beautiful design, however, thanks to gas boilers, you can use compact radiators or a floor heating system, which is completely hidden from view.

- The efficiency of gas convectors is approximately at the same level as that of gas boilers.

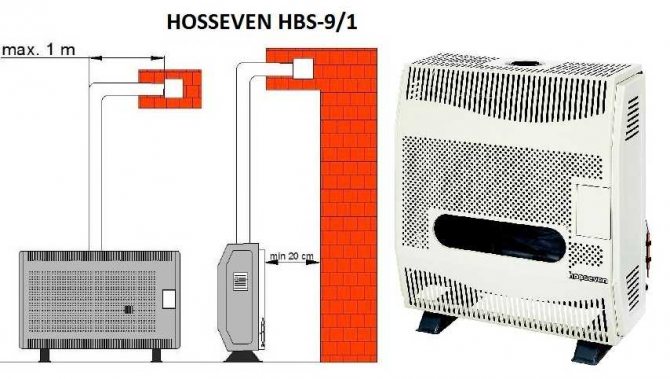

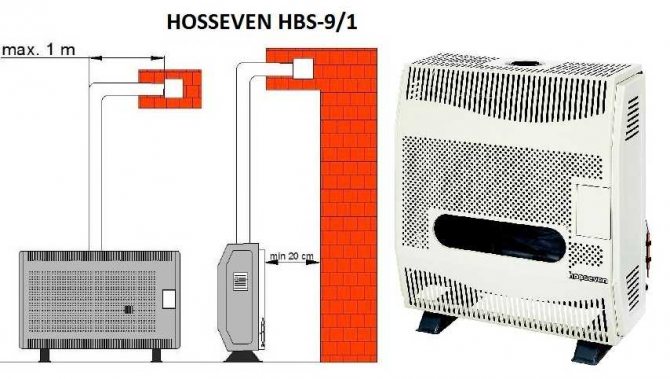

Parapet gas convector

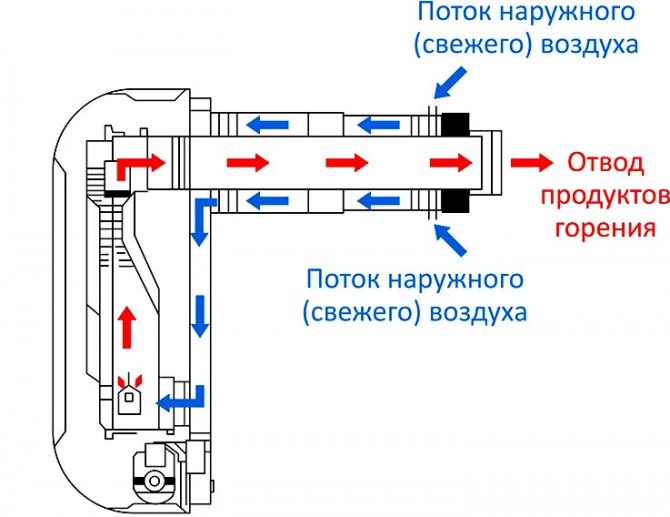

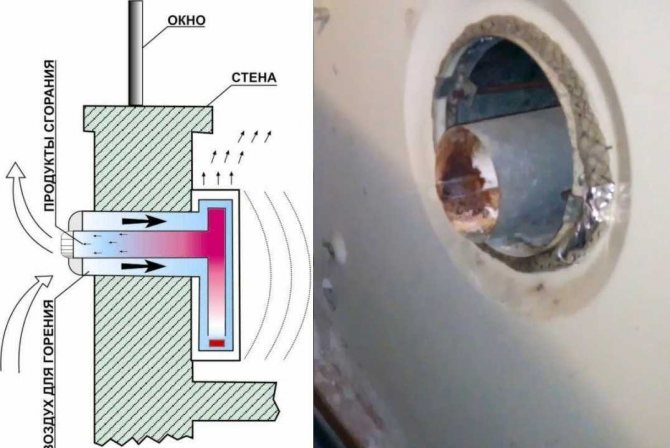

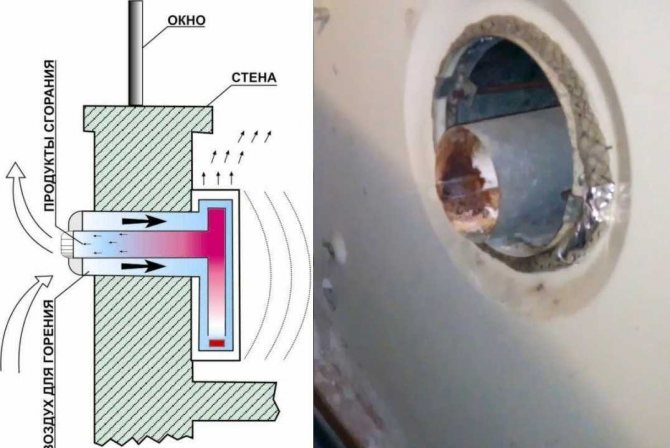

A parapet is a gas convector with a closed chamber and a coaxial chimney. It is usually installed under the window - to block the zone of the most active intake of cold air. The chimney is led out through the wall. The hole is made at a certain point, which depends on the design of the model, but most often it is hidden behind the body of the heater. From the side of the room, the hole is covered with a metal plate, which is part of the mounting kit.

Gas radiators of this type are the most popular because they are easy to install and assemble. When they talk about gas convectors, they usually mean this type of equipment. And all because they can work both from natural and from bottled gas, oxygen for combustion is taken from the street, the exhaust is discharged there. The gas combustion chamber in parapet models, in relation to the room, is sealed, that is, the exhaust does not enter the room under any conditions. The peculiarity of this heating equipment is that it uses a coaxial chimney. It is also called "pipe in pipe".

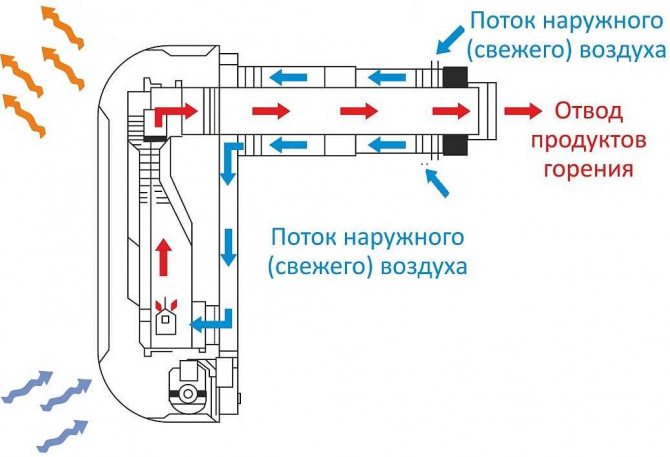

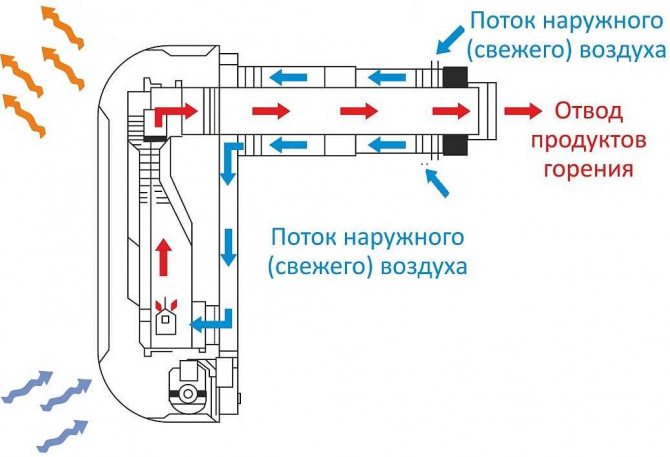

The principle of operation of the parapet gas convector

The gas burner is located at the bottom of the heat exchanger. Air from the street enters the combustion zone through the outer pipe, exhaust air with combustion products is discharged through the inner pipe. Since the air flows are separated only by a layer of metal, the air coming from the street, as it moves, heats up. Therefore, units with a closed combustion chamber have a higher efficiency: less heat escapes into the pipe.

Principle and features of work

How is the indoor air heated? The air heated by the burner rises up along the walls of the heat exchanger, warming them up, then exits through the inner pipe of the coaxial chimney. The heated walls of the heat exchanger heat the air that is nearby. For its active movement in the casing, which covers the heat exchanger, holes are made in the lower and upper parts. Cool air enters through the lower ones, rises up, heats up from the heat exchanger body, and exits through the upper holes.

A gas convector for heating a garage is an almost ideal solution

Some models have built-in fans for more active heating. But the fan can be attached by yourself. But the blowing mode creates a very active air movement, so it may even feel cooler. Especially if you are in a zone of passage of air currents.

Advantages and disadvantages

The advantages of the parapet gas convector are simple installation. There is no need to build a chimney. You just need to lead the pipe through the hole in the wall. But this - the hole in the wall - is also a disadvantage. First, the hole degrades the thermal insulation. Second, sound insulation decreases. If you stand at the opening, you can clearly hear what is being said in the room.

For installation, you need to make a hole in the wall

The problem with thermal insulation can be solved - fill the gap with heat-resistant insulation (mineral wool with an operating temperature of + 500 ° C). They will slightly worsen the permeability of sounds, but it will not work to achieve the same level of sound insulation.

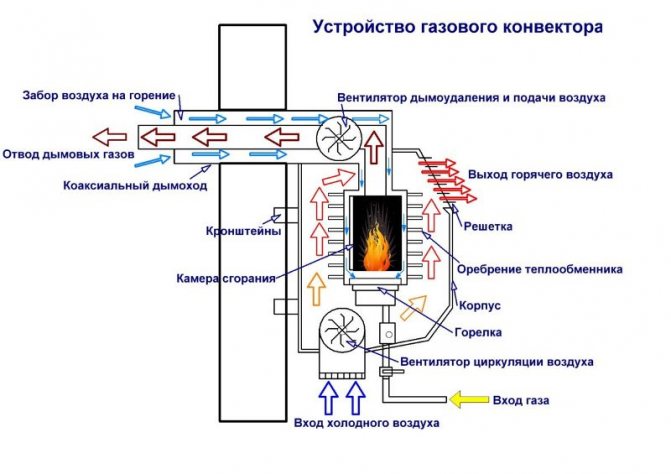

Device and principle of operation

The convector heats the room by circulating air through an internal heat exchanger, either by natural or forced convection.

In general, the operation of the heating device is as follows:

- The liquefied fuel comes from the gas cylinder unit to the burner device, where it burns, forming hot flue gases.

- Flue gases, under the influence of natural or forced circulation, wash the outer surface of the heat exchanger, thereby heating it to high temperatures.

- Cold air entering it from below is heated through a developed heating surface and enters the room naturally or forcibly with a fan.

- The exhaust gas manifold retains the combustion products in the heat exchanger for maximum cooling and then removes them through the chimney or coaxial pipe to the atmosphere. When using such a pipe, hot air enters through the inner ring for complete combustion of gas in the convector; it is taken from the atmosphere.

To ensure the combustion process and transfer of thermal energy to the heated room, the convector is made of the following structural elements:

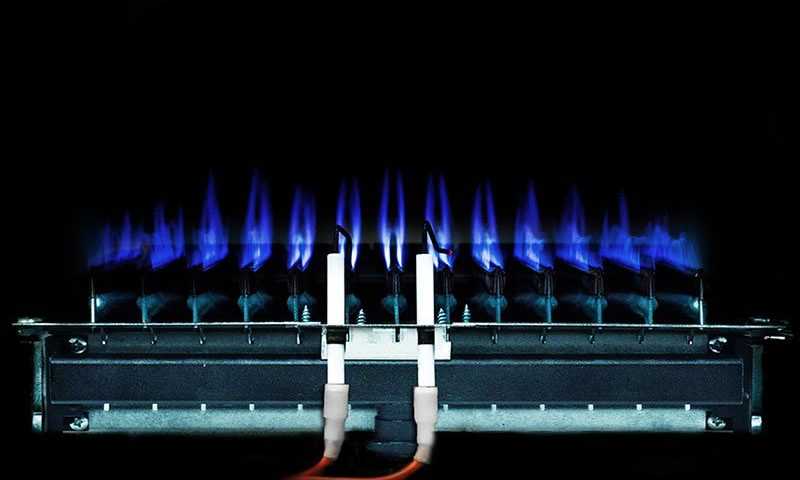

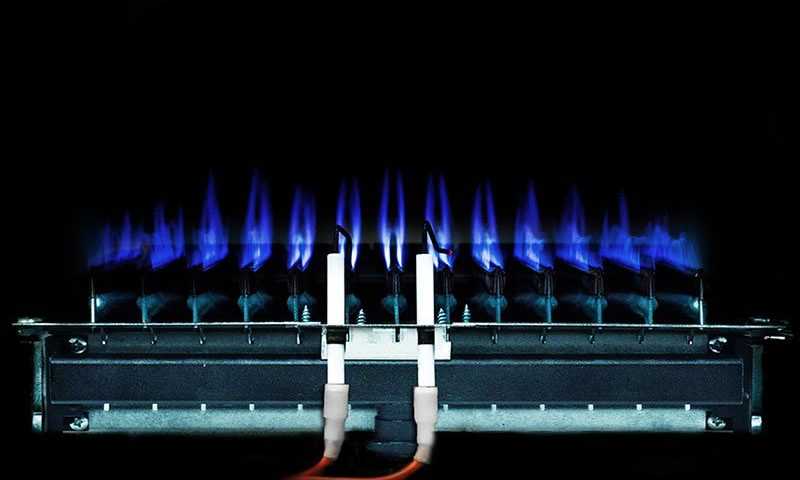

- The gas burner organizes the process of complete combustion of gases and the transfer of heat energy to the heat exchanger.

- The heat exchanger organizes heat transfer from the flue gases to the air masses inside the room.

- The control module performs temperature control and regulation of the gas supply volume.

- The chimney or coaxial pipe removes the combustion products into the external environment.

- The fan carries out forced air circulation.

- The gas cylinder unit serves for storage and transportation of liquefied gas to the burner device.

Cylinder gas convectors

How to choose the power

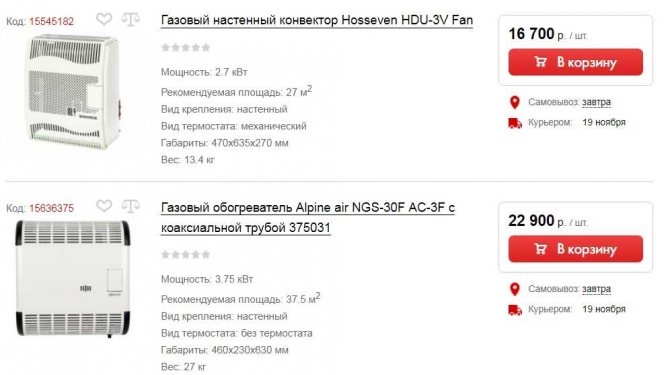

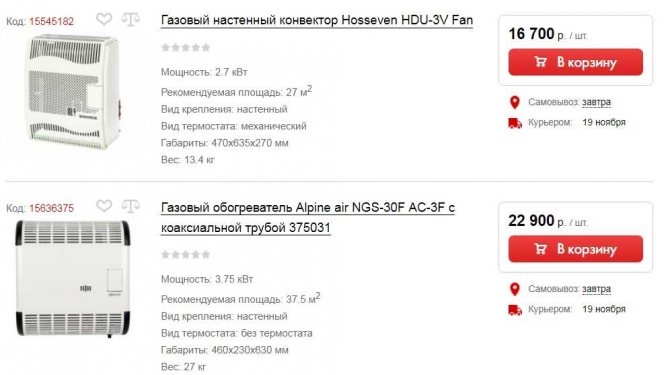

Each heating device, and a gas convector too, in the description has such a line as the recommended heated area. The data are given for "average" insulation and standard ceiling heights (up to 2.7 m). If your room goes beyond these parameters, you need to adjust the power up or down.

Power is one of the first selection criteria

If it is necessary to estimate the power of a gas convector in advance, the calculation is carried out by area: 1 kW of power is taken for 10 square meters. But this is if the insulation is "average" and the ceilings are 2.5-2.7 m. In case of differences, again we correct in one direction or another. And one more thing: it is better to take power with a margin of 20-25%. The benefit is twofold:

- in case of extreme cold weather, you will not freeze;

- the unit will almost never operate at the power limit, which will extend its service life.

If you need a more accurate calculation, taking into account the materials of the walls, the region, the location of the room, etc., you can find information here.

Other selection options

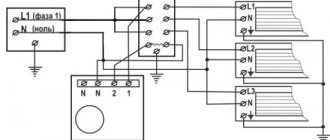

Gas convectors of low power (up to 10 kW), can be wall-mounted, and can be installed on the floor. The more powerful ones are always floor-standing. This is due to weight - a heavy unit may not be able to stay on the wall. Wall-mounted models are supplied complete with brackets, floor-standing ones are equipped with legs.

Floor standing models look good too

Heat exchanger

The efficiency of the unit depends on the shape and material of the heat exchanger. As a rule, heat exchangers are made of cast iron or steel. Cast iron are more reliable, but they are heavier and more expensive. If the wall has a bearing capacity constraint, weight can be critical. In other cases, it is better to purchase products with cast iron heat exchangers. But during operation, it is necessary to exclude the ingress of water on the hot surface of the cast iron - even a few drops of cast iron can crack.

Although the heat exchanger is covered with a casing, water can enter through the holes

The advantages of gas convectors with cast iron heat exchangers include a longer service life, no noise during operation. In a steel heat exchanger, clicks occur due to thermal expansion. This happens when the metal heats up and cools down. In living rooms, the periodic appearance of extraneous sounds is very unpleasant.

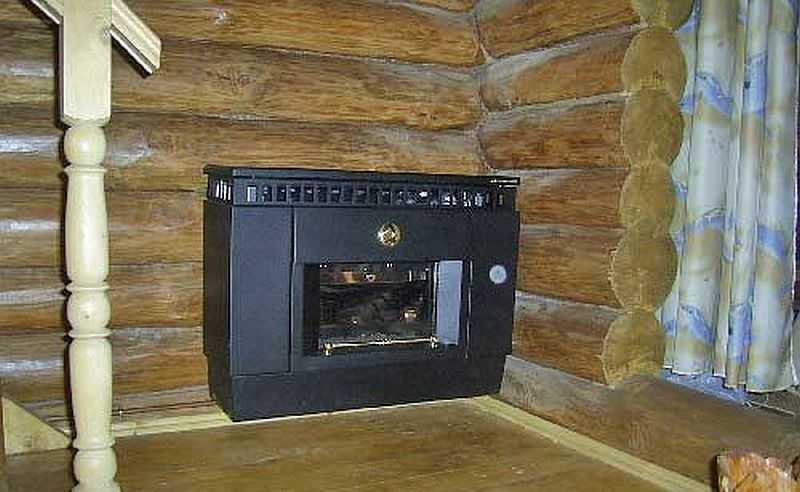

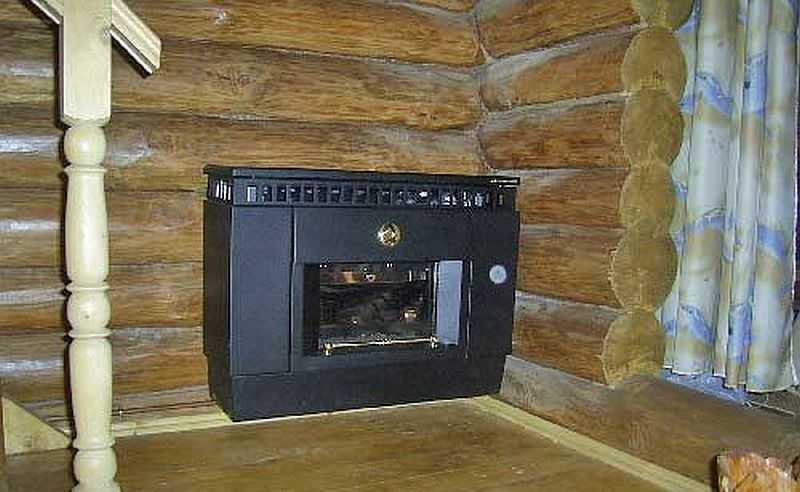

But steel heat exchangers are made with glass inserts. The flame can be observed through this window. This, of course, is not such a pleasure as watching a flame in a fireplace, but it is still more pleasant than an ordinary piece of iron.

You can look at the flame while meditating

Burner type

A burner in a closed or open combustion chamber can be modulating or not. The modeled ones differ in that they smoothly adapt to the requirements of the current moment. But they are more expensive and should be controlled by more sophisticated automation. For this reason, a gas convector with a simulated burner will cost more than a similar unit with a burner that can only operate in two modes: 50% and 100%.

The appearance can be different

Which burner is the best? Simulated. What's better? There are several benefits. The first is gas savings, since the consumption is only in the amount that is needed. The second is precise temperature control. With a sudden change in temperature, this is convenient: do not wake up sweaty or frozen.

Ignition type

Gas burners are available with electronic ignition (volatile) and piezo ignition (non-volatile). Piezo ignition is an option with a pilot burner, i.e. a small light should always be on. When the machine is at rest, only the pilot burner is lit. When the main burner should turn on, it is ignited by the pilot.

Better and more economical simulated burner

A gas convector with a pilot burner has two pluses and two minuses. First, the pros: such a gas convector is cheaper and works regardless of the availability of electricity. The cons are as follows:

- It consumes about 25% more gas (the pilot burner must always be on).

- Less stable work. If the pilot burner is off, the unit will not start. And it can go out due to clogging, accumulated carbon deposits, lack of traction and a dozen other reasons. It can also be blown out by the wind, etc.

Please note that when choosing a location for installing a gas convector with a coaxial chimney, the prevailing wind direction must be taken into account. It is advisable to choose a place where the wind blows infrequently and / or lightly during the cold season. On the side of the prevailing winds, a plate can be placed to prevent blowing out. But all this should be borne in mind before buying a heating device.

This is what the chimney will look like outside.

Gas convection heaters with electronic ignition are good in that a spark is issued by a control command. That is, it is also extracted using a piezo or electric lighter, but only at the moment when it is necessary to ignite the gas. This means less gas consumption, more stable operation. But the minus is the need for electricity. If power outages are rare for you, this should not scare you. If the lack of power supply is not so uncommon, it is better to pair an uninterruptible power supply unit with a rechargeable battery. The power consumption is very low, so you don't need to charge the battery often. By the way, in such models, after the power supply is restored (the duration does not matter), all user settings (that you have set) are saved. This means that after the appearance of electricity, the electronically controlled gas convector will analyze the situation by itself and start the convector or not.

Exhaust gas temperature

The temperature of the exhaust gases is an indirect indicator of the efficiency of the heating equipment. If the heat exchanger is designed well, if the casing is designed correctly, a significant part of the heat goes to heating the air in the room. If mistakes are made, you have to “drown the street”. So we also pay attention to this point.

Data are indicated for the most favorable conditions

The flue gas temperature is indicated in the model data. If this parameter is not specified in the characteristic, there is reason to assume that the efficiency of the device is too low.

Natural (main) or liquefied (bottled) gas

Almost all models of gas domestic convectors can work with both bottled and main gas. To switch from one type of fuel to another, it is necessary to replace the nozzle (differ in the size of the nozzle holes). Some also require readjustment. The process is described in the operating instructions, but if you are unsure of your own abilities, you can order a unit for a specific type of gas. Then it will come to you with the factory setting for the required type of gas.

When installed on a combustible wall, you must protect it with a non-combustible backing

Another point: when searching for models and comparing prices, pay attention to the package bundle. For some, the injector for the second type of fuel is included in the basic kit (models with two injectors are usually slightly more expensive), for others it must be purchased separately. If you may need both kits, it’s better to buy them together. If only one type of fuel is used, there is no point in overpaying for an unnecessary part.

Legal and technical details

Of course, when using main gas, heating costs are lower. It is still the cheapest fuel in our country. But it must be borne in mind that for the installation of a gas convector, just like for the installation of any other gas equipment, a certified project is required. And this is money, time. And the money, I must say, is sometimes considerable.

To install a gas convector on main gas, a project is required

And further. If you are going to heat several rooms in this way, then each one needs its own convector. And pipes will pull to it along the walls. Moreover, the gasket is only open, that is, they cannot be hidden under the casing. Only on top. The installation of a gas convector, powered by a gas cylinder, does not require a project (if gas is not supplied to the house at all. If there is a gas supply, the project is still necessary).

Features of the operation of gas cylinders

So, although it is more expensive to use bottled gas, it is easier. But there are some peculiarities here. A mixture of two gases, propane and butane, is pumped into the cylinder. Fractional matching is approximately 50/50.One gas evaporates well even at deep minus, the other at -40 ° C turns into a liquid state and practically does not evaporate. We don't have such severe frosts very often, but -20 ° C can last for weeks. In such a frost, the gas evaporates, but very slowly. And only one cylinder is allowed to be stored indoors. So that might not be very convenient either.

We advise you to additionally read the article "Heating with gas cylinders in a private house".

There may still be a shortage of gas at low temperatures and high flow rates. This is what usually happens. After all, the colder it is, the more heat is required, the higher the fuel consumption. To solve this problem, several cylinders are combined into a single system. In this case, the gaseous fraction is always sufficient.

Combine several cylinders into one system

Additional features and options

Additional features and options are not always superfluous. Some "bells and whistles" make the use of a gas convector more convenient, reliable and safe. Others allow you to tailor the work to your own needs or increase safety.

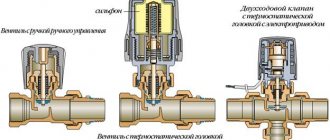

- A thermostat, in one form or another, is in any gas convector. It turns off the device when the temperature near it reaches certain values. That is, the gas convector does not work around the clock, but only when the room temperature drops below the set one. Most units allow you to set the desired temperature in the range from + 13 ° C to + 38 ° C. Models with a lower "starting" temperature, you will have to look well.

- Programmable automation (electronically controlled). Allows you to adjust the operating mode by the hour (cooler at night, warmer by the time you get up, etc.). More "advanced" models can generally be customized by days of the week. The disadvantage is the higher price.

- Flame control. There is in any model, but it is better not to forget to check.

- Gas contamination control. Until recently, gas convectors were not allowed to be used in residential areas. In technical, please. In the bedrooms, no. Not so long ago, changes were adopted in which operation is allowed, subject to the presence of gas control. In order not to bother with the installation of the system, it is easier to buy a model with a control function. And safety is a sacred thing, even in technical rooms.

With the development of technology and technology, the list will increase. Surely there are already some new items, but they are not very popular yet - because of their price.

The gas convector is good for heating a garage, greenhouses on an ongoing basis, as an additional or main

Pros and cons

LPG is a flexible and versatile fuel source, ideal for those living in non-gasified areas. In terms of its characteristics, ease of control and instant heating, it is no different from natural gas.

Advantages of cylinder gas convectors:

- "Clean" fuel. Comparing LPG directly to other fossil fuels, oil and coal, is a much cleaner use case. Burning produces less sulfur, nitrogen oxides, carbon dioxide and soot. Even if the fuel is "spilled", it will not pollute the land or water.

- Convenience. Conventional gas tanks can be used.

- The heat transfer process is easily controllable, like main gas.

- The heat generation process is quiet and gas-free. Compared to the combustion of liquid fuels, the devices have smaller dimensions, low cost of heat production and do not require special maintenance.

- Excellent efficiency. One of the key reasons for the popularity of using liquefied gas is this indicator. Modern gas convectors are very efficient.This is achieved through a more complete use of hot flue gases in a heat exchanger with a developed heating surface and the use of control and protection systems.

There are no ideal heat supply systems in the world, the use of liquefied gas for heating in convectors also has drawbacks that must be taken into account when organizing this type of heating:

- Delivery. Stable operation of the heating system will require reliable and inexpensive sources of supply of liquefied gas.

- The storage tank should provide a 10 day supply of gas.

- The need for annual maintenance of the gas cylinder installation by gas service specialists.

- The high price of liquefied gas, which in some areas is approaching the cost of electricity.

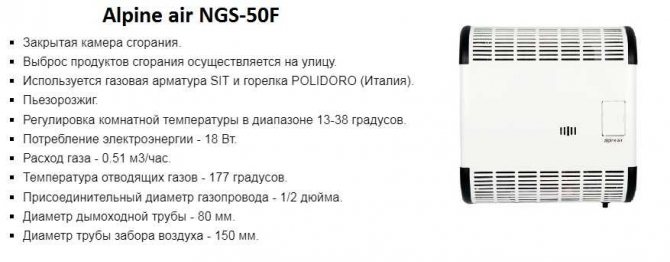

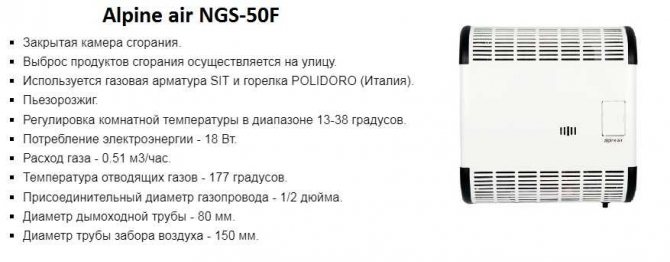

Gas convector Alpine Air NGS-20F