The most valuable building materials in modern construction are those that allow you to comprehensively solve several problems at once. Insulation Basvul has excellent characteristics, it is fireproof and perfectly vapor permeable. Thanks to such versatile protection, any surface acquires the required sound and thermal insulation properties; moreover, the use of this heat insulator ensures safety and a longer service life.

Description and main characteristics

Mineral wool Baswool is produced by Agidel LLC, one of the leaders in the production of thermal insulation materials. The insulation described in the article can be used for insulation:

The material is equally effectively used both in private construction and in the construction of industrial facilities. It is made from molten rock - basalt - at a temperature of a thousand degrees. It is thanks to this production technology that the insulation received its exceptional characteristics. Let's consider them.

- The weight of this heat insulator can vary between 25 and 225 kilograms per cubic meter.

- The moisture absorption indicator does not exceed 1 percent of the total weight, as well as 2 percent of its volume.

- Thermal conductivity, as a rule, does not exceed 0.038 W / m * K.

- Baswul has a high vapor permeability - at least 0.3 milligram / (h * m * Pa).

- The standard dimensions of the insulation boards are as follows (WxDxH) - 600x1200x30-200 millimeters.

- Finally, in terms of its flammability, it belongs to the A1 class.

Now let's take a look at what are the advantages of Baswool heat insulator and how exactly it differs from competing heaters.

Strengths of Basvul heat insulator

As we noted above, the basalt wool described in the article has numerous advantages, thanks to which it has gained immense popularity. Let's consider the advantages of insulation in more detail.

- It has excellent sound and thermal insulation properties.

- It weighs a little, which means that there are no special difficulties with styling.

- The vapor permeability of the insulation is quite high, and therefore the most comfortable microclimate is maintained in the insulated room.

- The material is easy to install.

- It is environmentally friendly, and despite the fact that its operational life is practically unlimited.

- During the entire service life in buildings, neither the dimensions nor the properties of the material change.

- Insulation shrinkage is minimal.

- Finally, it is hygroscopic.

In addition, Basvul insulation is a representative of the class of non-combustible materials, it fully complies with all fire safety standards and can even be used as fire protection in appropriate fences.

Note! The manufacturing company produces and sells a fairly wide range of mineral wool slabs for insulation, from the lightest (about 25 kilograms per cubic meter) to heavyweight (up to 225 kilograms).

Video - Basalt wool Basvul

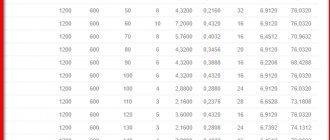

Due to the characteristics listed above, Baswul compares favorably with other thermal insulation materials. The table below shows the comparative characteristics of the described insulation and its closest "competitors", that is, EPS and foam.

Table. Comparison of insulation materials

Parameter name

Thermal insulator

Baswul

Styrofoam

Extruded polystyrene foam

Among the many thermal insulation materials, mineral wool products have an advantage in terms of fire safety issues. One of them is Baswul.It is used when performing a wide variety of types of thermal insulation work. There are different types of this building material: Basvul Light, Standard, Flor P, ECOROCK, Basvul Vent Facade, as well as others, the technical characteristics of which indicate the high quality of products.

Floor insulation (floors)

All work begins with the dismantling of the floor covering. If the flooring is to be reused, it must be removed very carefully. In this case, it is advisable to mark with chalk where a particular fragment lay.

Base leveling

The floor surface must be leveled. This will greatly facilitate the subsequent steps and increase the comfort of being in the room. Most often, the screed is poured. However, with slight fluctuations of the surface, you can resort to other methods of leveling the base, depending on the type of overlap, as well as financial capabilities.

If the base has not been properly prepared, cracks and crevices may form in it during subsequent use. As a result, the floor will be cold.

Laying of vapor barrier and installation of logs

After leveling the base, a layer of vapor barrier is laid. The material should be selected taking into account the peculiarities of the operation of a particular room. Laying must be done with an overlap on the walls. The overlap should correspond to the size of the lag.

The installation of the lag should be carried out taking into account the uniformity of the applied load. The optimal distance is considered to be about 90 cm. When choosing the size of the lag, one should focus on the total area of the room and the size of the thermal insulation material used. The lags must be securely fastened in the selected places.

Installation of insulation

Mineral wool should be cut taking into account the size of the grooves formed between the lags and placed in the space available. The thermal insulation material should fit very tightly to the joists. Gaps are unacceptable. To do this, each piece of insulation should be taken a centimeter wider than the groove width.

If possible, mineral wool is placed in two layers. In this case, the joint of the pieces of the first layer must be located in the middle of the second layer.

Waterproofing, finished floor

Waterproofing is laid on the insulation layer. Its characteristics must be fully consistent with the characteristics of the room for which it is purchased.

Installation of the finished floor begins with attaching a durable material to the logs that can take over and evenly distribute the load. For this purpose, you can purchase ordinary boards, as well as special drywall, plywood, chipboard or fiberboard. The selected coating is laid on top of it.

What is Baswul?

Stone wool is made from basalt rocks. To obtain this fiber, raw materials are processed at temperatures above 1000 ° C. The individual parts are held together with organic resins. Basvul is produced at a modern plant in Blagoveshchensk near Ufa. The first batches of insulation were released in the summer of 2011.

This basalt wool is used in the processing of private buildings, outbuildings, as well as industrial institutions. The price is affordable, therefore, even those who are not allowed to use expensive building materials can carry out thermal insulation work using this insulation.

Thermal insulation of walls

You can insulate walls with Basvul insulation in one of the following ways:

- on a metal or wooden frame;

- using mounting brackets;

- with a basement cornice.

The work can be done outside and inside the house.

Wireframe method

Wall insulation begins with the installation of a metal frame. The insulation is placed inside the frame and fixed with special glue or dowels.

Then a vapor barrier is mounted, for example, foil film, and the wall is sheathed with plasterboard.After that, the necessary finishing work is carried out.

Material specifications

Given the location of the application area of the mineral wool, the description of its technical characteristics will vary. Below are the main parameters:

- Density - from 25 to 225 kg / m 3.

- The thermal conductivity index is from 0.035 to 0.042 W / (m * K).

- Flammability class - A1. This level is assigned to those subspecies that are not subject to fire, that is, they stop the spread of fire.

- Water vapor permeability is about 0.3 mg / (m * h * Pa).

- Moisture absorption - no more than 1% of the weight, no more than 2% of the total volume.

Advantages disadvantages

This building material can be used for facades, interior works.

Baswool insulation in slabs is produced in a standard rectangular shape - 120 * 60 cm.The thickness of the slabs is produced in the range from 5 to 20 cm.

Different sizes of insulation allow you to choose products of exactly the thickness that is necessary for the purpose of high-quality insulation.

Application in different areas of insulation

- Non-flammability - it is completely fireproof.

- High level of sound insulation.

- Good vapor permeability.

- Environmental friendliness. Such material during operation will not harm those living in the house, which is insulated by it.

- The material does not rot, and is also not susceptible to beetles and microbes.

- It has a long operational period of 40 years.

Subject to the installation rules, mineral wool does not deform over time. Its properties do not change.

- Ease of installation.

- Has a low water absorption. Since moisture has a detrimental effect on insulation, this factor is important.

- As for any mineral wool, contact with water is undesirable. Although this model is hygroscopic, it should still be protected from rainfall as well as high humidity. This means that when performing facade work, it is necessary to start plastering the surface as early as possible (for wet facades). For ventilated facades, cotton wool should be covered if rain is expected.

- When performing installation work, you must provide yourself with all the necessary personal protective equipment. You need to work with gloves, glasses, and a respirator. Clothes should be long sleeves.

What are the varieties

Each insulation has a wide selection of models used in different areas of insulation. The same can be said about Baswul.

Baswool Light 45

The parameters and features of Basvul Light 45 make it possible to use it when insulating frame walls, interior plasterboard partitions, roofs, interfloor floors, and attic. You can also insulate floors with it by laying it between the logs.

It is produced in slabs with a density of 30-50 kg / m 3. There are different models of insulation Light 30, 35, 45. The number indicates the density of the material.

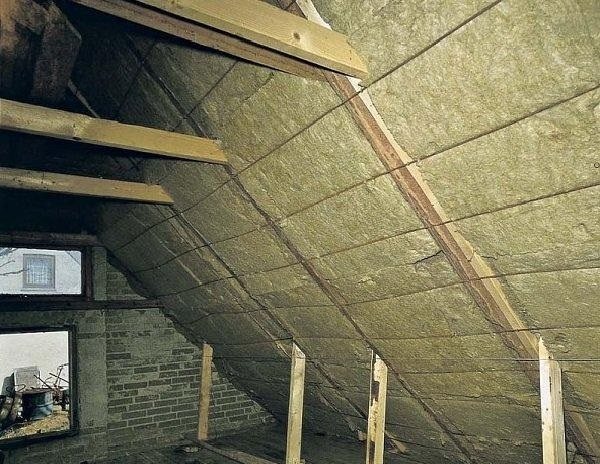

Roof insulation

Baswool Facade

It is produced in slabs with a density of 110-160kg / m 3. This building material is used to insulate the facade, followed by plastering and decorative finishing. Speaking about the properties of Basvul Facade, one can note the thermal conductivity of 0.036-0.040 W / (m * K), the peel strength 15-21 kPa (the indicator depends on the density, the higher it is, the greater the peel strength).

Baswool Vent Facade

It is produced in slabs with a density of 80, 90 kg / m 3.

The name contains a number indicating the density of the mineral wool.

The compressive strength of these two models is 17, 20 kPa, respectively. Peel strength of layers - 6, 8 kPa. Water absorption by volume is 1.5%. According to the entire lineup.

Basvul Vent Facade is considered non-combustible, prevents the spread of fire.

Thermal insulation of the facade

Baswool Standard

This model is produced in slabs of different density - 50, 60, 70 kg / m 3. It is used as a layer in a wall made of small pieces. It is used for frame insulation indoors, outside the building. Facade insulation Baswool The standard does not imply plastering of slabs. This option is intended before siding.

Basvul Standard absorbs no more than 1.5% moisture (volume percent). The thickness of the slabs ranges from 3 to 20 cm.

Frame insulation

Baswool Flor

It is made for floor insulation. It can be laid under the screed of a floating structure. It is also used for heated floors. Baswul Floor has soundproofing qualities. Density - 100-120 kg / m 3.

Types of mineral wool Baswool

According to the existing classification of materials used in construction, Baswool mineral wool (also called basalt insulation) refers to products made of stone, glass and slag. Accordingly, these materials are used in its production, and types of mineral wool are called stone wool, glass wool and slag wool. Each species has its own characteristics:

- Stone wool is particularly durable, can withstand any temperature - from low to high, has increased resistance to vibration. It is produced in wide plates - this adds convenience during its installation;

- Glass wool is an elastic material, with a low density, does not interact well with high temperatures. It is used in construction when insulating partitions in apartments and houses, it insulates well, but does not tolerate physical activity - therefore it is not used for insulating the facades of houses;

- Slag wool - has almost the same characteristics as stone wool, and is used in the same cases.

The density of Baswool mineral wool can be from 30 to 180 kg per cubic meter. The density is selected based on the purpose of the insulation. For facade insulation, mineral wool with a density of 135 kg / m3 is used. For the first layer in the roofing cake - from 100 kg / m3, for the top layer - from 175 kg / m3. When using single-layer thermal insulation, the permissible density is from 140 kg / m3.