Home | Construction | How to insulate the foundation with a house for the winter?

Date: 14 November 2017

Comments: 0

All types of foundations used for the construction of residential buildings require thermal insulation. To extend the service life of buildings and ensure a comfortable microclimate in the room, it is desirable, along with the foundation, to insulate the floor and external walls as well. Professional builders believe that it is advisable to insulate the foundation with the house for the winter at the same time, insulating all problem areas. This allows you to significantly reduce heat loss. It is important to follow the rules of the insulation device and use effective insulation.

Is it possible to insulate the facade in winter?

Wise customers think about the thermal insulation of their building in advance, i.e. in spring and summer. During this period, it is possible to quickly carry out work and prevent heat loss. Unfortunately, not everyone remembers this and realizes his condition with the first cold weather. It is during this period that the excitement begins and most of the customers wait for their turn until winter.

Yes, insulation of the facade is possible in winter, but the weather: low temperatures, wind, snow, dampness significantly complicate and delay the work. Added to this are the nuances associated with the characteristics of the materials and tools used (weather tolerance). The choice of thermal insulation must be carried out carefully: give preference to moisture-resistant and non-responsive specimens. \

Additional work features

In the process of warming, certain difficulties may arise. In many situations, thermal insulation in winter is made using extruded polystyrene foam, which is absolutely justified. The fact is that the presented material is resistant to the effects of a wide variety of materials and substances that are often used in construction. We are talking about acids, alkalis, dyes, alcohols, etc.

Experts say that even the insulation of a wet facade is real. True, the corresponding procedure becomes more complicated and costly from a financial point of view. Many companies that offer their customers a "wet" method of insulation prefer to work exclusively in the warm season. This is how they differ from experienced professionals who will cope with this task even in winter. True, they cannot do without the use of antifreeze additives. It is also difficult to create a warm outline around the entire construction site.

Wet facade technology

One of the most common technologies for insulating and cladding buildings. The device of the insulated facade by the "wet" method involves the use of liquid materials. To begin with, the thermal insulation slab is attached to the wall with glue or dowels, and reinforced with mesh on top, plastered. Among the advantages of this method:

- Suitable for any building;

- Does not carry a significant load;

- Choosing an adhesive type of fastening, you can even mount it on a hollow base.

- The result is a smooth, seamless finish that is easy to repair even on your own.

- Unfortunately, the method has its downsides:

- Not used at temperatures below + 5 ° C;

- Not applicable for timber structures;

- Installation is quite laborious.

The modern construction market is replete with claims that there are frost-resistant additives that facilitate the hardening of the plaster layer, allow outdoor work even at -15 ºС. Yes, it is possible to carry out the installation of insulation and plastering of the building in winter, but this is far from the best option.

Is it possible to insulate the house in winter outside the basement of the building

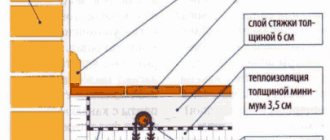

Proven technology allows you to thermally insulate the lower part of the building, observing the following sequence of operations:

- Prepare a pit around the perimeter of the building.

- Place moisture barrier in the trench.

- Pour expanded clay.

- Waterproof insulation.

- Add sand and concrete.

Self-performance of work is not difficult.

Is it possible to insulate the walls outside in winter with penoplex

It is allowed to perform thermal insulation of the walls and the base of the building with penoplex. For thermal insulation of the walls, glue the penoplex and plaster the surface.

The algorithm for warming the foundation is as follows:

- Dig a trench around the foundation.

- Apply bitumen to the surface of the base.

- Stick on penoplex.

- Waterproof insulation.

- Fill in the pit and make a blind area.

Penoplex provides a high level of thermal insulation.

If it is necessary to insulate the outside of a wooden building in winter, remember about the change in the properties of materials under the influence of natural conditions

Wet facade in winter - technology

At temperatures up to minus 5 degrees Celsius, you can make a wet facade in winter. Technological sequence of works:

- Clean the surface.

- Fasten the heat insulator.

- Reinforce the surface with mesh.

- Apply plaster.

- Paint the walls.

Use a special primer to protect the façade.

We insulate a building made of wood from the inside of the building

Thermal insulation of a building from the inside cannot be compared in efficiency with external thermal insulation, which protects the base and walls from freezing. Consider the features of the use of various heat insulators.

Using expanded clay for internal thermal insulation of the base

The use of expanded clay for interior work allows:

- insulate the base of the building;

- insulate the floor of the room.

Sequencing:

- Form a moisture-wicking layer.

- Pour expanded clay.

The gap between the floor and the expanded clay layer promotes moisture removal and ventilation.

The use of mineral wool for insulating the inside of the basement

Insulate with mineral wool as follows:

- Make grooves at the bottom of the walls to collect moisture.

- Waterproof the surface.

- Slice and secure the mineral wool.

- Moisture up the mineral wool.

Due to the increased hygroscopicity, mineral wool needs reliable protection.

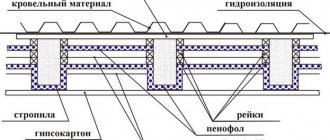

"Dry" facade

Thermal insulation of the facade with the "dry" method is universal. This method works for any weather and any foundation. The main distinguishing point is the absence of liquid components.

A prime example is the fastening of extrusion or rock wool insulation to a prepared wood or metal frame. From above, the insulation is covered with a windproof membrane.

Among the disadvantages of the design:

- significant weight, which requires carrying out calculations of the bearing capacity;

- many types of structures that cannot be assembled on their own.

Let's give an example of two special cases of dry thermal insulation of a building.

Insulation review: which one to choose for external and external work

Mineral wool.

Suitable for both types of insulation. But you will need external sheeting. Installation work can be done independently. For internal work, you need to install a metal profile structure and lay the holes with cotton wool. Sew up with facing material. Usually they take drywall, sometimes plastic panels. If you insulate the facade from the outside, think about siding or professional sheet for cladding. You need sheet materials that can handle the stress.

Example: Isoroc is a mineral wool based insulation with a porous surface that has a low thermal conductivity. Non-flammable, fireproof. Width - 50 cm, thickness - 10 cm, length - 1 m.Density - 50 kg / m3. The package contains 4 mats.

Price - from 380 rubles.

Styrofoam or expanded polystyrene

- most often used for external thermal insulation, less often for internal. For installation, use a special glue. The main task is to hermetically glue the panels. If the walls are crooked, they must be leveled first.

Polyfoam is the cheapest option for insulation from the outside. You don't need to invest in expensive wall decoration. Styrofoam sheets need to be reinforced and plastered with special glue. Next, decorate. Usually, paint and decorative plaster are used for this. It is important to choose the right thickness of the foam sheet: take 5-10 cm.

Example: PSB-S-25 foam with a density of 15-20 kg / cubic meter, thickness - 5 cm.This is one of the cheapest options for insulation, but its thermal conductivity is comparable to a brick wall 75 cm thick.It can be cut with an ordinary stationery knife, it is light in installation.

Price - from 140 rubles.

Thermal insulation of wooden structures

Special attention is paid to the insulation of a frame or wooden house. Wood is a natural material and is easily exposed to atmospheric influences: it dries out, absorbs moisture, and eventually becomes unusable. It is important to insulate the house made of wood and provide it with additional protection in the form of cladding. You already know that the insulation of a wooden and frame house with subsequent plastering is not carried out. Therefore, the insulation is fixed with a wooden frame.

Preparation for insulation is, first of all, preparation of walls (cleaning from dirt, dust) and anti-mold treatment. After the walls are completely dry, a waterproofing film is mounted, which will not let steam from the premises into the insulation. The insulation itself is selected based on the customer's requirements. Considered: ecowool, mineral wool and expanded polystyrene. To fix the slab, you need to build a wooden frame or crate. It is mounted vertically to the bar wall. Between these bars, a heater is laid with an overlap and secured with front dowels. To protect the insulation from the outside, a windproof film is attached to the crate. Siding is perfect as a finishing layer.

Multi-storey building: when to insulate

Sometimes multi-storey buildings are insulated with “pieces”. Pieces of insulation are laid by residents of individual apartments to feel dry and comfortable. But such insulation can do more harm than good. Of course, for residents of cold corner apartments, blown by all the winds, this is just a necessity. As well as for "damp" apartments on the ground floor, where mold can easily grow.

But such patches in general do not have the best effect on the walls. At the boundaries between the insulation and the wall, water often collects and freezes. Ice destroys the wall over time - it can even damage concrete. In addition, a temperature difference is created. The part of the wall, which is hidden from the sun or cold, differs in temperature from the rest of the facade. This also leads to the destruction of the material.

Ventilated facade

The device of a ventilation facade in the cold season is the best option for thermal insulation. The structure is a rigid frame fixed to a load-bearing wall, insulation and cladding. The subsystem is designed in such a way that there is a gap between the cladding material and the thermal insulation, where air circulates. These streams remove all excess moisture from the insulation and ensure its long service life.

Installation of the ventilation facade is carried out in any weather. Today on the market there are many different options for the design of a ventilation facade for different cladding materials. The main stages look like this:

- Installation of brackets to the load-bearing wall;

- Thermal insulating layer device;

- Installation of a windproof membrane;

- Installation of guides;

- Installation of cladding.

The cladding is selected by the customer prior to choosing the ventilation façade subsystem.

What to do if cold weather comes, and you suddenly find that you have forgotten about the thermal insulation of your house? Is it possible to insulate it in winter, and if so, how best to do it? Yes, it is possible to insulate the facade of the house, including in the winter.

However, you will have to follow some rules if you want the venture to succeed.

Winter, as you know, dictates its own terms in many things, and thermal insulation is no exception. Take, for example, the fact that you have to spend time choosing a really high-quality material for home insulation. The main criteria in this choice will be several parameters, which also include resistance to temperature extremes in different seasons and conditions of high humidity.

What rules must be followed during winter thermal insulation?

Watch the weather closely. The ideal temperature outside for insulating your home is + 5 ° C. If the season does not indulge in warmth, then rely on the possible minimum in the form of -5 ° C. If the thermometer drops below, you will have to wait with the thermal insulation.

Also watch out for humidity. Its indicators should not fall below 65%. It is best to do insulation during calm or, at least, minimal wind. Rapid impulses affect not so much the quality of the result as your safety in the process. But a constant strong wind can greatly spoil the result itself, because because of it, the plaster composition dries much faster than is necessary for proper work with insulation.

Of course, you can ignore these rules and do everything according to your intuition. In this case, do not be surprised if the thermal insulation lasts for a maximum of one season.

Winter insulation methods

Depending on what kind of insulation and material for finishing you have chosen, thermal insulation can be made in two ways: dry and wet.

Let's start with the dry method. Most of those who are engaged in house insulation in winter prefer this method. Its advantage is that the process involves a minimum amount of water and the materials it contains. This means that low temperatures and cold wind will bother you much less. But how, then, to fix the insulation on the walls? For this, special fasteners are used. They can be made of both metal and plastic (they are also called fungi). Working in a "dry" way, people prefer several heaters.

- First of all, it is polystyrene. It provides a great level of thermal insulation and also boasts that it practically does not absorb moisture. This material is characterized by a huge amount of debris that remains after the installation of the insulation - after all, the foam is very easy to crumble. Also, such a heater is extremely susceptible to fire and ultraviolet light, which makes it, albeit the most affordable, but not the best choice.

- But polyurethane foam does not suffer from such misses, and even outperforms foam in speed and ease of installation. It is applied by spraying, which means that you do not need additional fasteners. True, you will have to pay for such advantages with an extremely low level of thermal conductivity.

- If you want better insulation, look at two other materials: mineral wool and basalt insulation. Cotton wool is resistant to fire and also does not deform during temperature surges. And basalt insulation is rightfully considered the best material due to the fact that it combines all the positive properties of previous materials, does not rot and perfectly retains heat in the house.

The second method is “wet”. When you contact a construction company, you will find that almost everyone uses this method in the thermal insulation process.It differs from the dry method in that the insulation is held in place with bolts and dowels, as well as additional layers of glue and plaster. This method is famous for its light weight, which eliminates the need to calculate the load on the foundation of the house. Also, the "wet" method can be used with almost any walls, except for wooden ones. Frame-type houses also fall under the ban. Despite all the advantages listed above, in winter this method is significantly inferior to the "dry" one in several points. First of all, the laboriousness of the process due to low temperatures. Secondly, because these very temperatures have to be carefully monitored. The walls for this method will have to be prepared in advance, cleared of dirt and everything that sticks out. And, of course, in winter it will be much more difficult for you to level the surface for insulation and work with a primer composition.

What you need to pay attention to when insulating a house in winter

- If you decide to make thermal insulation using the wet method, you will have to attend to the construction of a thermal curtain.

- Having chosen polystyrene as a material for insulating a house, you must treat it with special compounds that will protect it from damage and too rapid destruction.

- It is possible to insulate a wooden house only after it has shrunk. This process takes the first three years after the construction of the house.

- Among the heaters suitable for winter, mineral wool, polyurethane foam, ecowool and expanded polystyrene are distinguished.

Separately, it is worth talking about the insulation of a wooden house.

This process is carried out in several stages. First, you need to prepare the walls for insulation: remove all protruding parts and treat the wood with a protective compound. After that, the waterproofing sheet is laid with an overlap. A 5x5 cm timber is used to create the lathing. After that, you need to pave the voids with the selected material for insulation, securing it with dowels for reliability. If you want to give your home additional protection from mice and other rodents, we recommend adding a metal mesh. And finally, after all the steps taken, the frame is assembled for subsequent cladding with siding or other material.

Thanks for attention. As always, you can send your questions to us in the form of fraternal communication. Angelina was with you, I love you! : - *

The choice of winter insulation

Polyfoam, expanded clay, glass wool - similar heaters are used somewhere else. But in our article, you can forget about them. Construction technologies have long stepped over these materials and issued new ones. Each of the materials has its own pronounced advantages and disadvantages that determine their popularity. We will give an example of two types of materials that we actively work with.

1. Mineral wool. Leader of materials for thermal insulation of all types of buildings and structures. Its structure, vapor permeability, fire safety won her this title. The mineral wool façade breathes and prevents condensation and mold growth. Minvata is suitable for all types of buildings and for all types of technologies.

2. Expanded polystyrene. A competitor to mineral wool in all industries. The slabs of the material are light, with a low coefficient of thermal conductivity, but they have significant disadvantages. Among them are fire hazard, poor tolerance to UV radiation, vapor permeability.

Internal insulation: what is the danger?

When it is not possible to insulate the house from the outside, but it is very necessary to make the house warmer, a layer of insulation is laid inside the room. It is possible to retain heat quite effectively, but the main disadvantage of this method is condensation.

So mold comes into your house, the spores of which quickly grow on “healthy” walls, leading to their destruction. You need to competently approach the issue and think over the ventilation of the room so that the condensate evaporates and does not accumulate in your apartment.Otherwise, after a while, you will have to tear off all the insulation from the walls and do it over again. And most importantly: from the outside, the walls are still cold, they depend on the vagaries of the weather.

Benefits:

- You can do the work yourself without involving outside specialists.

- A good option for floor or ceiling insulation, attic.

- Easier to fix flaws.

Minuses:

- Will eat your square meters: the room, sheathed with insulation, is reduced by 1-2 square meters.

- Not suitable for small kitchens, making them very tiny.

- Can cause trouble: lead to condensation and black mold.

- The walls are not protected from precipitation, frost and sun.

- You will have to put up with the inconvenience during the renovation work, move things away from the walls.

But everything is not as sad as it seems. You just need to carefully approach the calculations and not save much on insulation. There are many nuances to consider. Among them are the thickness of the insulation, hydro and vapor barrier. Because if the so-called "dew point" shifts and moisture starts to form, you will have to redo everything. How can you avoid this?

- Choose insulation with high vapor permeability. This is the ability of the material to accumulate and release moisture. If he actively "drinks" water, then eventually, condensation will begin to form. Mold will appear in the house. Beware of using a vapor barrier material such as styrofoam indoors.

- Don't skimp on materials. You need a high-quality vapor barrier that prevents condensation from forming.

- Do not leave gaps between the insulation and the wall. Apply adhesive with a comb and smooth thoroughly.

- Good ventilation is a must. Otherwise, all steam and moisture will turn into condensation, which will destroy the thermal insulation.

- Treat the walls with an antiseptic to prevent mold growth.