It is quite easy to insulate a frame house with mineral wool from the outside, from the inside and inside the frame. During the work, no special tools and special knowledge are required. You need to adhere to the manufacturer's recommendations, as well as follow the recommendations of professionals, which can be found on the Internet or in this article.

The article describes the methods of insulating a country house using mineral wool, the main points that need to be taken into account when insulating the floor, walls and ceiling, and also tells you which of the heaters is better to use, relying not only on its thermal insulation properties.

The thickness of the material for insulating a frame house

To insulate frame structures, regardless of the type of mineral wool used, the thickness of the layer of heat-insulating material must be calculated according to special formulas, but not less than 15 cm.

At the same time, different types of heaters have different thermal conductivity and other indicators from each other, as can be seen in the table below.

| Parameters | Glass wool | Stone wool | Slag |

| Thermal conductivity coefficient, W / (m * deg. C) | 0,037-0,041 | 0,032-0,048 | 0,046-0,048 |

| Vapor permeability coefficient, mg / (m * hour * Pa) | 0,6 | 0,3 | 0,6 |

| Density, kg / m³ | 11-130 | 30-100 | 75-200 |

| Moisture absorption,% | 0,5-1 | 2 | Up to 2 |

| Sound absorption | High | High | Good |

The parameter of the thickness of the insulation for frame houses depends on the climatic conditions in the region where the building is located. You can focus on the following numbers:

- 150 - 200 mm of mineral insulation if your house is located in central Russia, for example, in the Moscow region, and with gas heating;

- 200 - 250 mm - the same, but in the case of heating with electricity;

- 200 - 250 mm in the wall, if you live in the north or in Siberia and you have gas;

- 250 - 300 mm, if you drown yourself with electricity while living in Siberia.

Thermal insulation work options

There are a lot of materials for thermal insulation of houses made using Finnish technology. Each has its own drawbacks and positive aspects, therefore, in order to understand how to choose a heater for a frame house and apply the best option for thermal insulation, it is worth taking a closer look at the most popular thermal insulators on the construction market.

Mineral wool for thermal insulation of the frame structure

How to properly insulate a frame house with mineral wool? This material is often used not only by construction companies, but also by private developers.

This is understandable - the insulation has excellent sound absorption and perfectly retains heat. Minvata is an environmentally friendly, fire-resistant material. An insulator layer of 5 cm is able to retain heat just like half a meter thick brickwork.

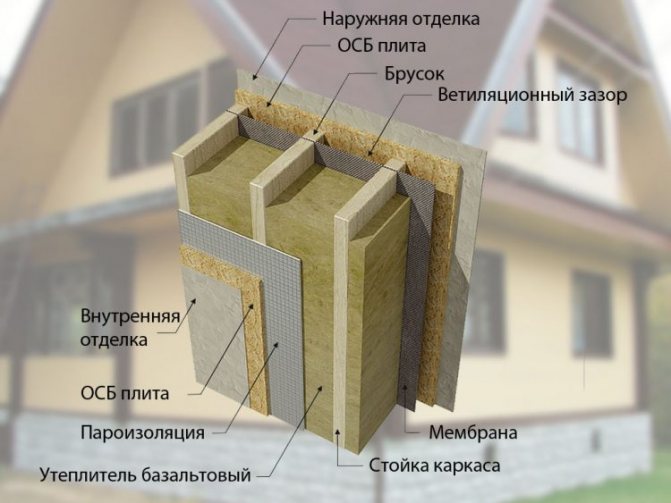

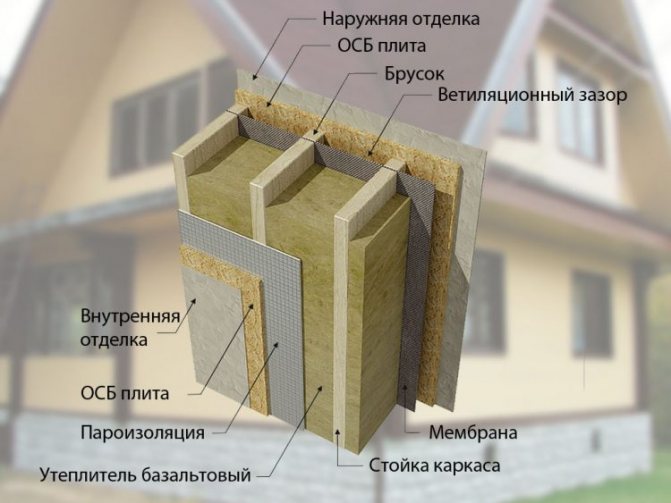

The main nuance during the installation of basalt insulation is the arrangement of a vapor barrier to protect the material from moisture. The fact is that when mineral wool gets wet it loses its thermal insulation properties.

If it is decided to use this insulation for insulation, then do not spare funds for the purchase of vapor barrier material and special membranes.

How to insulate with mineral wool

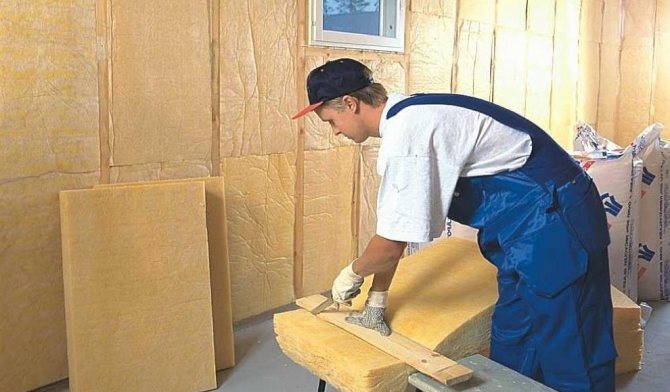

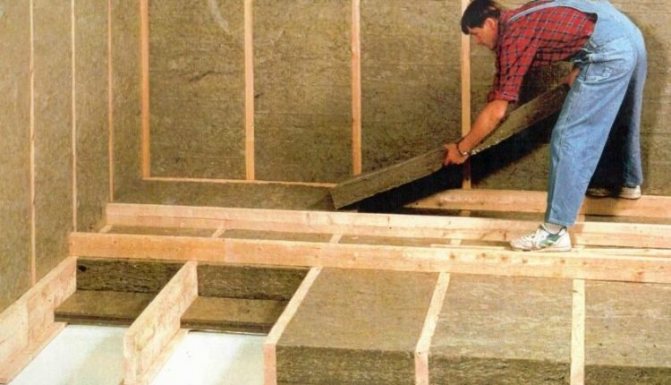

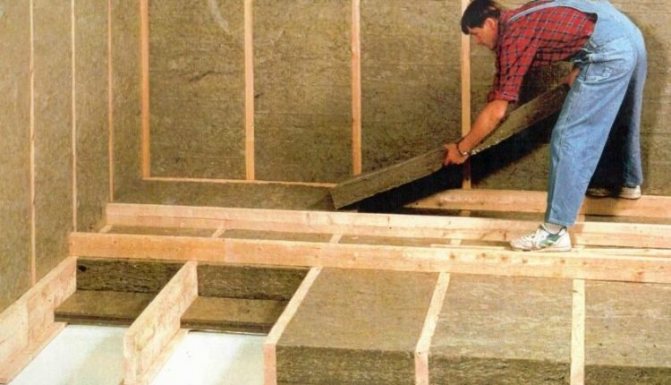

The walls of a frame house are insulated using a crate, the cells of which should be in increments of 60 cm - this is essential, since stone wool is produced in a roll of this size. The insulator must be cut so that the cotton wool enters between the bars with effort and does not sag.

The thickness of the material is chosen based on the weather conditions in the region. If the climate is harsh, then it is better to use layers 20 cm thick; in mild climates, 5-10 cm is enough.

With multilayer insulation, cold bridges may appear, in order to exclude them, plates of 5 cm are laid in two layers, in cells.It should be understood that the guide bars should be with a section of 10x10. The second two layers of material are laid on top of the frame bars.

Insulation of a frame house with mineral wool presupposes mandatory vapor barrier, but since the outer wall of the building is already equipped with this material, it may not be used before installing the insulation.

After laying the insulator, you need to take care of protecting the mineral wool from condensation vapors. The vapor barrier material is sold in rolls, and it will not work to lay it with one sheet, so we purchase construction tape for gluing the joints.

Floor insulation in a frame house is made with the same basalt wool. Only in this case, the insulator layer should be at least 20 cm. The work is carried out as when insulating frame walls.

Thermal insulation with ecowool

An environmentally friendly and affordable insulation for frame houses, in the production of which waste from the production of cellulose products is used: paper, cardboard. Ecowool is 80% fiber and 10% antiseptic, which protects against the development of fungal formations and microorganisms. In order for the insulation to be less flammable, 10% of special additives are introduced into its composition.

Ecowool - disadvantages

Private developers very rarely use this material to insulate their buildings. Ecowool has a number of features that some builders consider to be disadvantages:

- The thermal insulation qualities of the material deteriorate over time. This is caused by natural processes - the material cakes over time and loses a fifth of its mass, while decreasing in volume. Therefore, most craftsmen advise to lay ecowool with an excess of 25%, in this case the material will retain its insulating properties for the entire period of use.

- Hygroscopicity is another reason why this material has not become generally used. Like any cellulose product, ecowool absorbs up to 15% moisture, while the thermal insulation characteristics are reduced. In order to preserve the quality of the material, it must be well ventilated, and at the same time it is necessary to install moisture drainage.

- To insulate the frame house from the outside with this material, you will have to use special equipment, with the help of which the injection of the insulation will take place evenly over the entire area of the house. For high-quality insulation, you will have to invite a team of craftsmen who will accurately calculate the injection level.

- Ecowool can be applied dry simply by pouring it into voids, but much more material will go away, and many microscopic dust particles are formed that can cause allergic reactions. The technology of insulating a frame house with a "wet" method is much preferable, but it also has its drawbacks. Insulation is applied to the walls gradually, as there is a possibility of material slipping. The drying time for one layer is several days, so if the time is short, then you will have to use a different method of thermal insulation.

- Horizontal surfaces are insulated with ecowool on a specially mounted frame, which entails additional costs.

- Special components have been added to the material that increase the fire resistance, but, despite this, the material remains combustible. Therefore, you should not use it near fireplaces and heating systems. You can install a kind of barrier against smoldering - lay asbestos-cement slabs between the heat source and the insulation.

Strictly observe the norms for filling surfaces with insulation, which the manufacturer recommends, otherwise, during the shrinkage process, areas without insulation may form.

Positive characteristics of ecowool

Many may think that such a process as insulating a frame house for winter living using ecowool is inappropriate, there are a lot of disadvantages of this material.

But with strict adherence to the technological processes of application, the positive characteristics of the material are significantly enhanced:

- Low material consumption makes it cost effective.

- Ecowool has good sound-absorbing properties.

- The best insulation is made from natural raw materials, which determines its environmental friendliness and safety for people living in the house.

- The composition gets its combustion resistance thanks to additives, and it is worth studying the composition of the product before purchasing. If such components as boric acid and ammonium sulfate are included in the composition, then it is better to abandon its use. These components give the ecowool an unpleasant and persistent smell, while the fire resistance of the material practically does not decrease. You should buy only the product that contains borax.

- The material is laid without seams, which is a huge plus, since there are no cold bridges, and the insulation of a wooden house is of high quality and reliable.

But the decisive factor that speaks of the importance of using cross-warming of a frame house from the inside with this material is the inexpensive cost in a duet with positive characteristics.

Thermal insulation of a frame house with ecowool - a technological process

As you already know, you can insulate a frame house in two ways - "wet" and "dry". You can spray the material on the walls simply by diluting it with water or glue, then you get an excellent result. But most private developers follow a simpler path, and use a "dry" method of insulation, which we will consider.

It might be interesting

Thermal insulation

Distinctive features and variety of ceiling tiles ...

Thermal insulation

How to insulate the ceiling in a wooden house?

Thermal insulation

What is a heating cable?

Thermal insulation

Warm "pie" for a metal chimney

So, we insulate the frame house with our own hands, ecowool according to the following algorithm:

- First of all, we will undertake to insulate the floor in the house, for this a pressed briquette of material weighing 15 kg must be loosened well, for this you can use an ordinary drill with a special nozzle. After these actions, the volume of the material will be three times larger;

- thermal insulation of the floor of a frame house is quite simple - the material is poured onto the rough covering between the beams with a slight excess, which will be taken by the weight of the board for the final covering;

- proceeding to the walls. Before the start of insulation, a frame is constructed from bars of the desired section. A vapor barrier is fixed to the racks, an indispensable element for insulation with ecowool. The frame is covered with OSB sheets in such a way that there is a gap on top for filling the insulation. The material will thicken under its own weight as it falls asleep, and from above it should be well tamped.

Work on the thermal insulation of a frame house with ecowool is worth stocking up with protective equipment: gloves, glasses and a respirator. You can significantly optimize the process by renting equipment that loosens the material and blows it off ready-made.

Linen based insulation

Flax has excellent heat-retaining parameters, this is achieved due to the optimal combination of density and porosity of the material.

Linen insulation is produced in several configurations:

- slabs can be used to insulate a frame house from the inside;

- linen strips of a structure made of glued beams;

- heap will hammer the walls of the log.

Due to its high density, this insulator is used for insulating roofs, floors, partitions and attic floors, in which recreation areas are equipped.

A flax fiber heat insulator can be considered the most preferable for insulating a house from the inside - it is environmentally friendly, serves for more than 70 years, does not rot, and mold does not form on it.Unlike ecowool, it is not subject to shrinkage.

Expanded polystyrene or polystyrene - which is more practical

The choice of insulation for a frame house is not an easy task, you need to take into account many nuances. As for such heat insulators as expanded polystyrene and polystyrene, both materials are successfully used to insulate a house from the inside and outside.

Polyfoam, of course, is inferior to its counterpart in some positive properties, but it is so cheap that many private developers prefer to use this material for home insulation.

Among the minuses it is noted:

- low level of noise insulation;

- when burning, toxins are released;

- the material is susceptible to rodent attacks.

Thermal insulation of the facade with foam

- Insulation of a frame house from the outside begins with the preparation of the surface, which needs to be leveled, repair cracks, primed with deep penetration impregnation.

- After the facade has dried, it is necessary to mount direct suspensions on it, which will not allow the slabs to move off the surface, they will be securely fixed.

- Five points of glue are applied to the foam, the edges are coated around the perimeter.

- The slab with glue is pressed tightly to the surface, acting from corner to corner.

- The second row of foam boards is staggered.

The composition of the glue is prepared in such a way that it can be worked out in an hour.

The material inconsistency is adjusted with a heated knife; when gaps are formed, they are sealed with the following compounds:

- crushed foam is added to the glue;

- pour penoizol;

- apply polyurethane foam.

For the strength of the structure, the heat insulator should be attached to the surface with plastic dowels, 5 pcs. on the stove. After that, you can apply any facing material.

Thermal insulation of the frame structure from the inside

The scheme of insulating a frame house from the side of the room is similar to the previous version. The only difference is in the soil used - you need a composition for internal work with antiseptic properties.

When using a heat-insulating insulator from the inside, a simple tile adhesive, coupled with dowels, is used as an adhesive.

Installed foam plates are tightened with an overlapping reinforcing mesh if it is supposed to putty the surface, but drywall is often used for wall cladding. This method of thermal insulation is much easier than insulating a frame house using ecowool.

Penoplex

Not sure what is the best way to insulate a frame house? Buy penoplex - an analogue of polystyrene, only with a denser structure, therefore it costs a little more. It is also worth noting that this material is much more demanding during installation - you need to protect it from moisture and sunlight.