Copper pipes are one of the most suitable solutions for air conditioning systems. The products are durable, resistant to corrosion, resistant to various external influences and are highly durable. The copper pipe is lightweight, and also withstands high pressure and different temperature conditions well. The wide range of air conditioner elements allows you to choose the most suitable diameter.

Safety and environmental friendliness of copper pipes determine their use in air conditioning systems

Applications

There are several situations when it is better to choose this material:

- The current option for installing a copper pipe heating system is connecting to a solid fuel boiler. This is due to the fact that such systems are exposed to prolonged exposure to high temperatures (over 100 degrees Celsius).

- Compared to other materials, copper is better if it has a complex shape.

- Installation will be 100% justified if the owner of the house has enough funds, he wants to get the highest indicator of durability.

When considering other options, you need to pay attention to plastic or stainless steel.

Types

In specialized stores, you can find a large number of copper elements intended for the manufacture of heating systems. They are divided according to different factors:

- The material from which the pipeline elements are made. It can be pure copper, tin alloy, zinc alloy.

- Seamless or welded.

- Pressed or drawn.

- Non-insulated, plastic coated.

Plastic-coated copper pipes are protected from physical impact, damage. In addition to this, the rate of heat loss is reduced, and the efficiency of the system increases.

Labeling and cost

Pipes for heating are manufactured and marked according to GOSTs For example, products with a wall thickness of 0.8–10 mm are manufactured in accordance with GOST 617-90 standards. Another designation refers to the purity of copper, regulated by GOST 859-2001. In this case, the marks M1, M1p, M2, M2p, M3, M3 are allowed.

According to the marking that is indicated on the manufactured products, you can find out the following information:

- Cross-sectional shape. Designated by the letters KR.

- Length - this indicator has different markings. BT - bay, MD - dimensional, CD - multiple dimension.

- A method of manufacturing a product. If the element is welded, the letter C is indicated on it. On drawn products, the letter D.

- Special operational features. For example, increased technical characteristics are indicated by the letter P. High plasticity - PP, increased cut accuracy - PU, accuracy - PS, strength - PT.

- Manufacturing precision. The standard indicator is indicated by the letter H, the increased one is P.

To visually understand how to read the marking, you need to deal with a simple example - ДКРНМ50х3.0х3100. Decoding:

- It is made of pure copper, designated by the M1 brand.

- The product is stretched.

- The shape is round.

- Soft.

- The outer diameter is 50 mm.

- Wall thickness - 3 mm.

- Product length - 3100 mm.

European manufacturers use a special marking system DIN 1412. They put the designation EN-1057 on the elements of water supply and heating systems. It includes the number of the standard by which the pipes are manufactured, an additional element included in the composition - phosphorus. It is needed to increase resistance to rust.

Copper pipes in the factory

Installation of copper elements

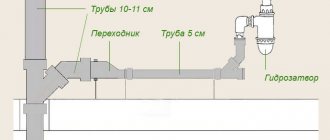

For the purpose of installation, two main methods are used - connection by means of fittings with special ferrules and union nuts, like metal with plastic, and traditional brazing of copper parts. In the case of connection by means of a fitting, the pipes must be flexible in order to be able to squeeze the inside of the fitting (union). When soldering pipes, before the actual connection process, the workpieces must be flared. Next, insert one end of the pipe into the socket of the other, then fix it with solder. It is recommended to use a soft tube when bending.

Materials (edit)

Manufacturing methods:

- From blister copper, by means of special processing of the ore, blowing with oxygen in order to remove unnecessary components from it;

- Further, the manufactured copper slabs, 99% free of impurities, are converted into pipes.

As a result of mechanical finishing - rolling, stamping, the plastic component of the copper billet disappears. Such unannealed copper pipes have a tensile strength of 340-350 MPa. In this case, the elongation in case of rupture is up to 6%.

Specifications

Annealing process

For the manufacture of pipes with the required quality characteristics, it is imperative to perform annealing - heating the product to 600-7000C. Further, it is necessary to gradually cool the workpiece - vacation. The result is a material of appropriate quality. A copper pipe after this tempering annealing process has a low tensile strength, within 220 MPa, but at the same time acquires sufficient plastic qualities and is easily stretched. Such annealed copper pipe (GOST 617-90) can stretch 1.5 times and not break.

Permissible operating pressure depending on the operating temperature and soldering method when using fittings according to DIN EN 1254-1

Advantages and disadvantages of copper pipes

The copper elements that are used for the manufacture of heating systems have strengths and weaknesses. Benefits:

- The service life is up to 50 years.

- Withstand pressure over 30 atmospheres.

- The material does not react to ultraviolet light, it is resistant to corrosion in natural conditions.

- No air leaks through the walls.

- Copper does not emit harmful substances. Possesses antibacterial properties.

- Light weight.

- It is possible to defrost the system 3 times.

- The material withstands prolonged exposure to active chemicals, does not emit any additional elements.

- Deposits do not accumulate on the inner surface of the products.

- Low rate of thermal expansion, no expansion joints required.

Disadvantages:

- High price when compared to other materials.

- The connections are one-piece, because of this, difficulties may arise during installation.

- Electrochemical corrosion can occur if you try to combine copper with other metals.

- If the room is with a high level of humidity, corrosion may appear on the surface of the products.

- A high rate of electrical conductivity contributes to the deterioration of the condition of the walls of products.

- To reduce heat loss in the walls, it is necessary to use additional insulation.

Benefits of using copper pipes

Choosing a cheap material, many consumers do not take into account its characteristics. But, withstanding the maximum pressure, copper pipes serve for many years. Therefore, smart owners do not skimp on the purchase of quality materials.

Benefits of using copper pipes:

- high thermal conductivity;

- exceptional resistance to corrosion;

- resistance to defrosting, temperature fluctuations;

- outstanding working temperature range - + 110‒250 degrees;

- no deposits form on the inner walls, even with prolonged use;

- the duration of the operational period reaches half a century or more;

- minimum costs for pipeline maintenance throughout the entire period of operation.

There are also disadvantages, or rather, features: high cost and the need for special equipment for installation. The price will pay off with interest in the duration of operation. And the calculation of the copper pipe for strength and installation can always be entrusted to workers with the proper qualifications.

Methods for connecting copper pipes

Copper pipelines are reliable, durable, resistant to physical stress and corrosion. However, they can boast of such properties only with proper assembly. To combine individual elements into one system, there are several methods:

- Compression fittings. These are special elements used to connect copper pipelines: push-in fittings, crosses, bends, couplings. They are made of bronze, brass, copper.

- One-piece connection method. This is a pressing technology that is carried out using press fittings, crimp sleeves. The strength of the finished joint is comparable to the soldering method.

- Compression connection. It is detachable, with high strength. For work, you need hand tools, special collet clamps. However, this type of connection weakens over time from pressure surges, temperature drops. It is important to monitor it, periodically change consumables.

- Soldering using copper fittings. A special element is used, which is called capillary. Solder is needed to create a secure connection.

It is important that after soldering the products cool under natural conditions.

Compression fittings for connecting pipes

Advantages of copper products

Due to its performance properties, copper pipes are widely used to transport various liquids. Among the advantages of such products are:

- Plasticity and strength. Copper products have high strength and ductility. At low temperatures, these properties increase significantly. This makes it possible to use a copper pipeline for transporting non-freezing liquids.

- Resistant to sudden changes in temperature. Copper pipes do not lose their performance at extreme temperatures. This also applies to high pressure. Such pipes are capable of withstanding a load of 400 atmospheres.

- Slight thermal expansion.

- The versatility of the material. For the construction of one or another engineering communication, pipes with a small wall thickness can be used. So, for example, if we take steel or plastic analogs, then to solve a similar problem, products were needed, the wall thickness of which was several times higher.

- Resistant to chlorine and other chemicals that may be contained in the transport fluid. On contact with copper, oxide forms, which prolongs the life of the product.

- Copper pipes are not afraid of ultraviolet rays, chemically aggressive substances and corrosion. Due to these properties, the service life of the pipeline can reach 100 years or more.

- Copper inhibits the growth of bacteria, which makes the pipeline safe.

- The inner walls of copper products have a flat surface. Due to this, pipes with a small diameter can be used for the construction of the pipeline. At the same time, the throughput is at a high level.

- The dismantled copper pipes can be reused for the construction of new piping for the heating or water supply system.

- Copper pipes are attractive in appearance. This makes it possible to refuse the device of decorative boxes. The products themselves can be used as a decorative element.

Due to the presence of such advantages, copper pipes are especially popular among professionals and are used in various fields.

Installation of copper heating pipes

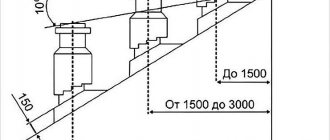

The most reliable, popular way of installing copper heating pipes is brazing.Step-by-step instructions for performing work:

- Cut off part of the product to the desired length.

- Chamfer the inner diameter.

- Clean the outside of the pipe, the inside of the connecting piece (fitting). To do this, you need to use a synthetic brush.

- To create a reliable connection, it is required to cover the treated surfaces with a layer of flux.

- Ignite the gas burner, slowly heat up the parts to be connected.

- Heat surfaces until the flux melts.

- When the flux is liquid, take the soft solder that is sold in bars and place it where you want the seam to form.

- Gradually, the wire will melt, begin to spread along the joint, filling the free space.

Wait until the seam is formed along the entire joint without voids, wait for the finished joint to cool.

Calculation of pressure in a copper pipe

The design of heating or plumbing systems is an important process during which it is determined how much pressure a copper pipe holds. It is created by modern pumps, the range of which is quite extensive. Knowing the design pressure, it is easier to choose a unit with the required characteristics.

The calculations will require data on the physical characteristics of the material, which are described above. This refers to the coefficient of thermal expansion, weight, melting point. By plugging the data into an online calculator, it is easy to calculate the required value.

Consider four types of pressure in a copper pipe:

- working - measured under standard operating conditions of the system;

- trial - determined during the testing of the system during installation;

- conditional - measured at a medium temperature of 20 degrees;

- calculated - is determined in the process of designing engineering communications.

A meter of water is a practical unit of measurement for water pressure. What does this indicator mean? One atmosphere - this pressure is noted in the lower part of a pipe with water 10 meters high.

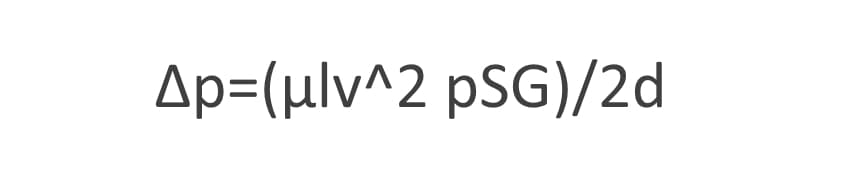

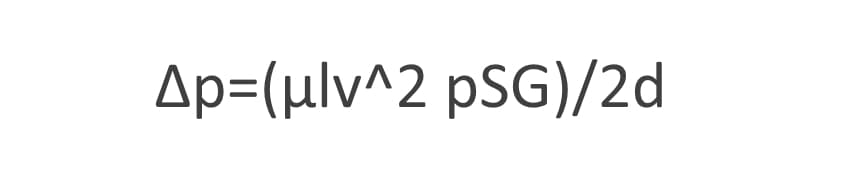

Working pressure is calculated by the formula:

Pressure losses are taken into account in the pipeline design process. They are calculated by the formula:

Thus, the design pressure in the pipeline is determined as follows:

Here μ is the friction coefficient, l is the line length, d is the inner diameter of the pipe, SG is the density of the liquid, and p is the pressure loss. The required indicators can be determined from the tables.

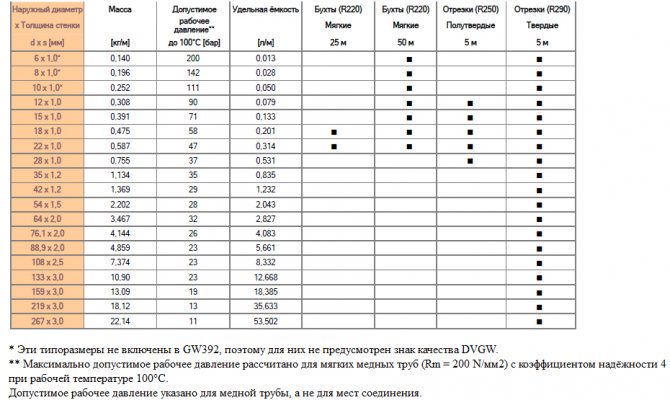

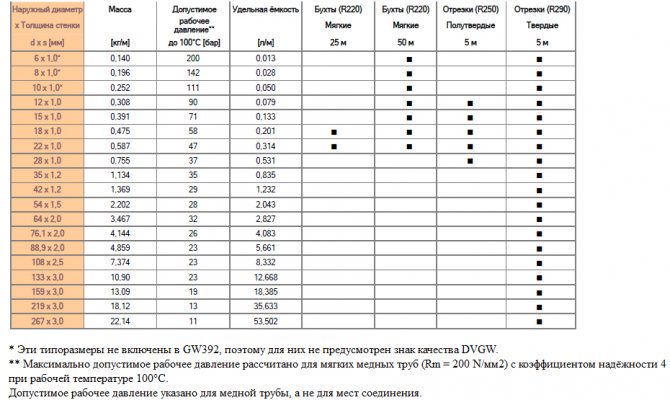

Let's say 15x1 is an indicator of the diameter and thickness of the product. We have a pipe weighing 0.391 kg / m and a capacity of 0.133 liter / meter. Working pressure for it is 5.7 MPa.

It is enough to find an online calculator and enter the relevant data. The calculation will be done automatically.

How to paint copper heating pipes?

To paint a copper product, you can use several types of paint:

- Alkyd enamel. Resistant to high temperatures, physical influences.

- Acrylic paint. Manufactured on the basis of organic solvents.

- Coloring composition on a water-dispersion basis. Dries quickly, but stays on the surface for a short period of time.

It is easy to paint on metal substrates. Its service life directly depends on the chosen coloring composition, the average durability is about 5 years. To increase adhesion, the metal must be cleaned with fine sandpaper.

Copper pipes are rarely used to make pipelines. This is due to their high price. If there are enough funds, this is the best option for durability and reliability. It is important to correctly choose the type of connection of individual elements so that the system will serve as long as possible.