Home »Classification of gas boilers» Principles of operation »Setting up gas boilers Proterm

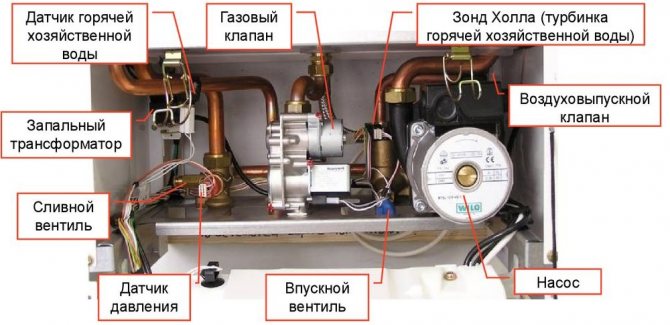

Gas boilers Proterm are popular with consumers due to their reliability, European quality and reasonable price. Among floor devices, the Bear series is known, and among wall devices, the Cheetah is considered the most versatile line. Models with letter designation MOV are equipped with an open combustion chamber, and MTV are equipped with a closed combustion chamber. Consider how to set up Proterm gas boilers.

…

- 1 Heating modes Proterm Cheetah

- 2 How does Proterm Cheetah work when connecting thermostats?

- 3 Setting up the gas boiler Proterm Medved

Heating modes Proterm Cheetah

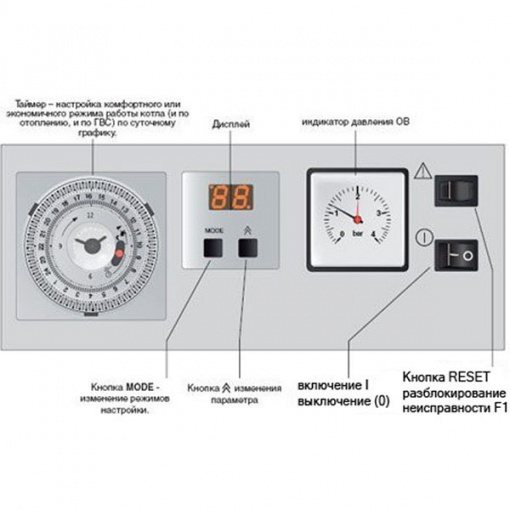

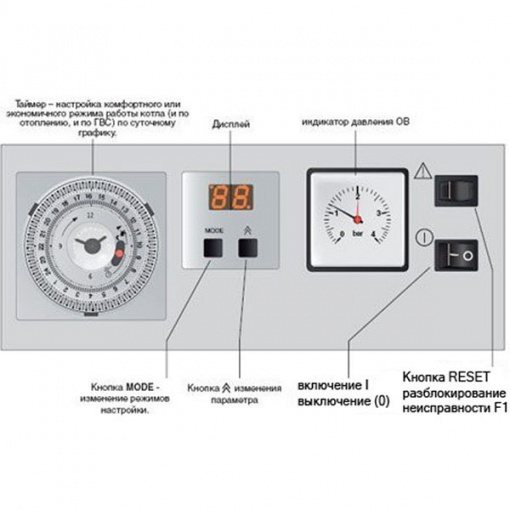

The gas boiler Proterm Gepard can operate in several modes:

- "Heating" - press the MODE button once, and the display will show the "radiator" symbol with the current pressure value in the heating system. While in this mode, the unit works only for the production of heating, while DHW is turned off.

- "Summer" - activated by pressing MODE twice. The display will show the pressure in the heating system together with the symbol "tap with a drop of water". In this mode, the boiler operates only for hot water supply.

- "Vacation" - press the MODE button three times, and the OFF symbol appears on the screen with the pressure reading. In this mode, heating and domestic hot water does not work, but all protective functions of the device are active.

The desired heating or hot water temperature can be adjusted using the "+" and "-" buttons. The setting is carried out as follows:

- The DHW temperature is regulated as follows: after pressing the "+" or "-" button, the symbol "tap with a drop of water" and "ºC" start blinking. The required temperature value is set in the range from 38ºC to 60ºC.

- The heating temperature is also set using the "+" and "-" keys. After pressing one of them, click on the MODE button, a blinking symbol "radiator" and "ºC" appears. Then, using the "+" and "-" keys, set the optimal value of the heat carrier in the range of 38-85ºC.

The operation of the gas boiler Proterm Cheetah without thermostats is not very economical. For maximum savings, it is recommended to purchase a room thermostat.

…

Installation Guide, Introduction

Page 19

- Picture

- Text

17

The installation must be carried out, on the basis of the project, by a qualified technician of a licensed specialized company, who is responsible for proper installation and compliance with existing rules, regulations and regulations.

When installing the boiler on a base made of combustible materials (eg wood, PVC, etc.), the boiler must be mounted on a base made of non-combustible materials.

A warning:

During operation, the boiler temperature in the upper part (especially on the sides and top panel) can exceed the ambient temperature by up to 50 ° C. The minimum working space that must be left free near the boiler must be such that it is possible to freely and safely carry out repairs and service (it is recommended to leave at least 300 mm on each side and at least 600 mm in front of the boiler).

The way of removing the combustion products for this boiler is into the chimney with a constant draft of 2 Pa. The size of the outlet for connecting the chimney varies depending on the boiler output:

- for boilers PROTHERM 20, 30 KLZ - Ø 130

mm,

- for boilers PROTHERM 40 KLZ - Ø 150

mm,

- for boilers PROTHERM 50 KLZ - Ø 180

mm.

A warning:

It is forbidden to place objects in the chimney that impede the passage of combustion products (for example, different types of heat exchangers for using residual heat). The flue is not included in the scope of delivery of the boiler.

The chimney design must comply with all standards and requirements established by laws and

The Protherm KLZ boiler is used as heat generators in autonomous hot water heating systems.

A warning:

Commissioning of the PROTHERM KLZ boiler may only be carried out by a specialist authorized by Protherm and a specialized organization.

A network of authorized service centers is used for boiler installation, commissioning, warranty and post-warranty repairs.

The gas heating boiler is intended for installation inside buildings in residential or business premises, subject to mandatory compliance with the local rules and regulations for the placement of gas appliances, as well as the requirements for the premises for their installation.

Water with a carbonate hardness of up to 3.0 mol / m3 should be used as a heat carrier in the heating system. (6.0 mEq / L, 16.8 dH), colorless, pure, without precipitation. In case of harder water, the water hardness must be reduced to avoid the formation of limescale.

When installing boilers, one should be guided by the SNiP in force in the area, the Safety Rules in the Gas Industry, PUE, PTE \ PTB of electrical installations of consumers, other norms and rules in force in the area, as well as local regulations of gas and power supply organizations.

Malfunctions resulting from the formation of scale or dirt deposits in the boiler or heating system are not covered by the warranty.

Coordination of the choice of the installation site, as well as the organization of supply and exhaust ventilation is carried out in accordance with the procedure established for a given area in accordance with the regulatory documents in force for a given area.

Installation guide

Installation guide

Introduction

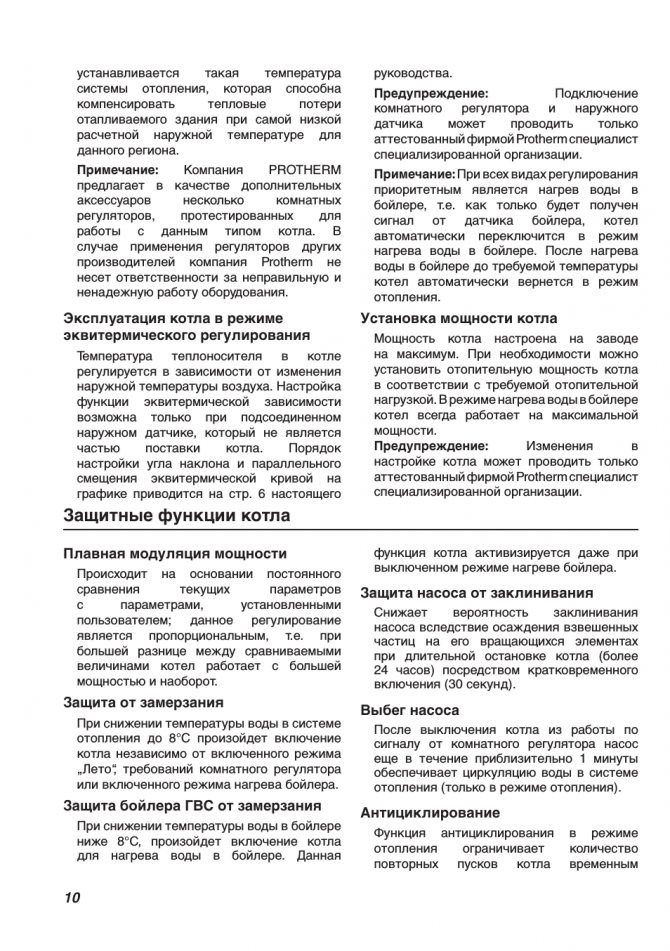

How does Proterm Cheetah work when connecting thermostats?

When the gas boiler Protrem Cheetah is working without room thermostat, the heating of the premises depends on the setting of the heating medium temperature.

When connected to a gas boiler Proterm thermostat it becomes possible to set the desired heating temperature. It must be such that the unit can support it, regardless of the outside temperature. The regulator will only control heating within the selected range.

Note! In the room where the room regulator is located, the radiators cannot be equipped with thermostatic valves.

Unit Proterm with on-off regulator able to maintain the set heating temperature. The boiler will receive a signal to switch on or off depending on the temperature in the room in which the regulator is located.

When connected to a gas appliance continuous regulator the power will change smoothly to maintain the set room temperature.

The room regulator will control the room temperature and send a signal to the unit to turn off if the heat level reaches the set one or turn on if the temperature decreases.

…

The most modern and accurate is equithermal regulation... It is performed by a thermostat with an outside temperature sensor. When such a device is connected to a gas boiler, the latter will regulate the temperature of the coolant, depending on the conditions outside.

If the operation of the unit is controlled by an equithermal regulator, it is not recommended to set the maximum temperature of the coolant - this will significantly reduce the efficiency of the system.

Find out here how to make a gas boiler more economical?

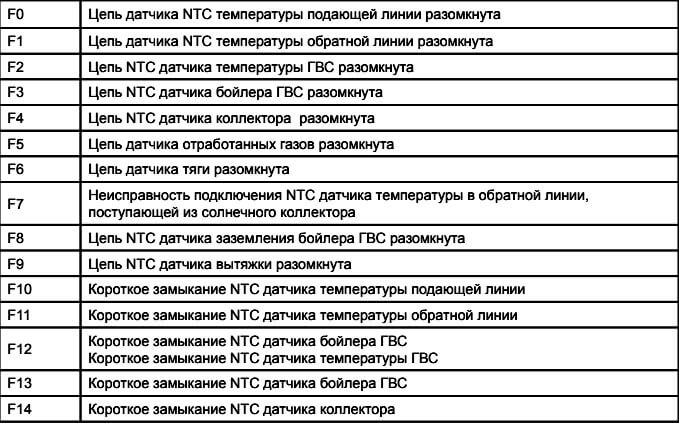

Malfunctions of gas boilers Proterm and their elimination

Features of ignition of different models of gas boilers

documents that are relevant to this issue. Issue ...

Page 20

- Picture

- Text

18

documents that are relevant to this issue. By fulfilling the requirements listed in the standards, you can avoid such undesirable phenomena as excessive cooling of combustion products, penetration of moisture into the masonry, fluctuations in the chimney draft, and, thereby, their negative impact on the operation of the boiler.

The combustion air enters the boiler from the room in which it is installed. Ensure that a sufficient amount of combustion air flows into the room - about 11 m

3

air for 1 m

3

natural gas.

The boiler is installed in a frost-protected room near the chimney. The permissible ambient temperature for the operation of the boiler is from + 3C to + 45C.

The combustion air supplied to the apparatus must be technically free of chemicals that may contain, for example, fluorine, chlorine or sulfur. Sprays, paints, solvents, cleaning agents and adhesives contain substances of this kind that can cause corrosion during operation of the appliance under unfavorable conditions, including in the chimney system. The combustion air must not contain mechanical impurities, for example: construction dust, sand, etc.

For the removal of combustion products of boilers PROTHERM 20, 30, 40, 50 KLZ, you can use the additional device "PROTHERM PT 20 (30, 40, 50) SEMITURBO" extension, which provides forced removal of combustion products.

The device makes it possible to operate cast iron boilers in cases where it is not possible to use the normal removal of combustion products into the chimney. The extension is connected to the boiler outlet to connect the chimney. The outlet of the combustion products of the extension allows the use of elements of separate chimneys from the Protherm chimney catalog for wall-mounted boilers.

The maximum chimney length is 10 equivalent meters (1 equivalent meter = 1 meter straight section or one 90 ° elbow).

A warning:

When using the PROTHERM PT 20 (30, 40, 50) fan extension, the terminals of the flue gas thermostat must be bridged before the boiler is started up. In this mode of operation, the air manostat, which is included in the delivery set of the PT 20 (30-50) chimney extension, acts as a safety element. Only a specialist from a specialized organization certified by Protherm may install and operate the boiler extension.

When performing service work while the extension is connected to the power supply (even with the mains switch turned off), the safety instructions must be observed!

It is convenient to monitor the deviation from the initial water pressure in the heating system using the pressure gauge on the boiler control panel, using the red arrow of the pressure gauge. If the pressure in the heating system drops, locate and eliminate leaks or bleed air from the heating system or check the expansion vessel.

The expansion tank of the boiler must be adjusted depending on the parameters of the heating system - in this way, the heating system and all its elements during operation are protected from unwanted load during sudden changes in pressure.

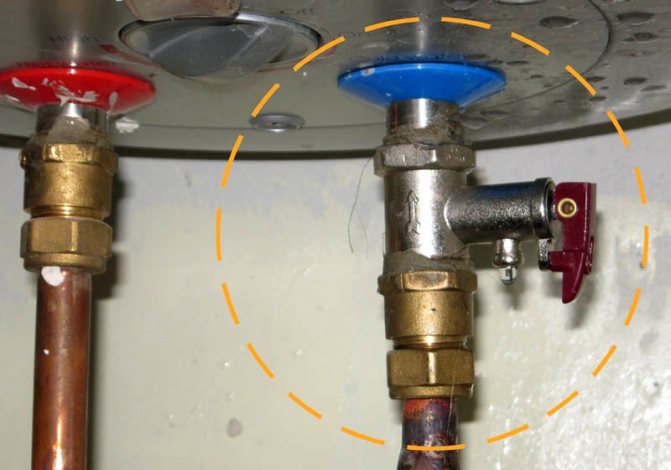

When filling the built-in DHW boiler, it is necessary to open the cold water supply line to the boiler and the DHW outlet line from the boiler. As soon as water starts to come out of the DHW line, this will mean that the boiler is completely filled with water.

Note:

In front of the boiler (i.e. on

heating return) it is recommended to install a slag sump from the heating system. The sump can be combined with a sump, it must have service shut-off valves.

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

I'm not stupid, I strictly follow the instructions.

Manualza! Manualza.ru

Still not with us?

Setting up a gas boiler Proterm Medved

The floor-standing gas boiler Proterm Medved has a simple design. There are models on sale that can only provide heating, and there are those that produce hot water. Depending on the characteristics, the Proterm Medved gas boiler is configured as follows:

- DHW temperature - press the MODE button, the lamp in the upper left corner will start blinking, and another diode will be on in the lower right. Using the button with the image of two arrows pointing upwards, set the required temperature in the boiler in the range of 40-70ºC. Confirm the selected temperature by pressing the MODE button.

- Heat carrier temperature - in the heating temperature setting mode, the lamp blinks in the upper left corner. Using the button with two arrows pointing up, set the required temperature of the heat carrier in the range of 45-85ºC. Press the MODE button to activate the selected value.

The temperature list contains the parameter -. When it is selected, the gas boiler switches to summer mode, when the heating is turned off and the hot water supply mode is working.

When an equithermal temperature regulator is connected to the boiler, additional settings are made.

Repair and adjustment of boilers Proterm

The gas boiler Proterm klz 30 is in operation. I turn on the heating of hot water. Heats up, turns off and gives a F1 error. I reset the error and the device starts working again. Is the semi-turbo extension installed? If so, then the rear traction sensor must be unscrewed, and let it weigh on the wire below. If it is aspirated, it means poor draft or the gas modulation on the ignition unit is incorrectly adjusted. In the instructions for the floor boiler Medved 40 KLZ, practically nothing is written on how to adjust the day / night mode. It is clear that there is no need to heat water for hot water supply at night, and the unit turns on at night and inefficiently consumes gas. A KLZ 30 boiler was installed and connected, a hydraulic arrow for 3 supply circuits, each with a pump. Do I need a pump from a hydraulic arrow to the boiler return? The circulation pump is desirable for the minimum flow in the boiler circuit. We installed and connected the boiler Proterm Medved 50 klz. DHW is set to 60, and heats up to 80. It drops to 72 and the heating turns on again and drives up to 80. The timer is ignored. What is the malfunction? This is the norm for these boilers. The minimum is set for water, and maximum for heating. When you set the temperature to 40, it heats it up to a maximum of 80, until it heats up, and switches to heating. And when the temperature in the boiler drops to the 40 you set, it will turn on again and will heat up to the maximum. The Proterm TLO 40 boiler is in operation. It worked well. 3 weeks ago, the heating power dropped, it does not respond to the temperature setting, it heats up to 40 degrees and turns off. What is the fault? Look for gas, chimney and heating temperature sensor. Floor standing boiler Protherm 50 KLZ is in operation. When the heating is turned off, the heating still periodically works. How to repair? When DHW is heated, the boiler operates at full capacity, regardless of what temperature the water in the boiler is set to. When the boiler heats up to the set temperature, the device automatically returns to heating the CO at the set temperature. The house is about 180 sq. m, heating system - aluminum radiators and underfloor heating. The heating system is made to work by gravity. After various inquiries, I found out that I needed a floor-standing boiler and an indirect gas boiler. Recommended Protherm as sufficient for my needs. Which device to choose from the 40 KLOM, TLO or PLO modifications? Non-volatile boiler - TLO. You can take the Wolf cheaper, or you can choose domestic ones with a stainless heat exchanger. 1. If you need CO by gravity, you can take the TLO. Warm floors do not work by gravity. Then put 2 pumps: one on CO, the second on a warm floor. In this case, the meaning of non-volatility disappears, since underfloor heating will not work. If it suits you, go ahead. 2.If it is critical for you that there are TP, then take a volatile boiler. 3. A gas boiler is a container heated by a burner to comfortably obtain hot water supply. Don't forget that it needs a chimney. Although options with BKN will be more effective and no chimney is needed. You need a floor stand with a power of strictly up to 20 kW (boiler replacement) with a comfortable connection to the BKN. Electricity in general is not annoying, but planned outages (repair) and force majeure are present, and, as you know, once a year and a stick shoots. These are wishes for the boiler in terms of energy independence and the threat to the failure of automation. The choice is between 17 kW - Protherm Bear 20 PLO, KLOM and 20 TLO. But there is also a Wolf 16 KSO (16 kW). Bear TLO and Wolf KSO are non-volatile. This is, of course, a plus. I learned that KLOM is the most optimal in terms of connecting a boiler, but the automation is confusing. Its protection can also result in a tidy sum, which you unwittingly add to the cost of the boiler. The boiler will not be located in an insulated boiler room, but in a room next to the gas stove. What they write in those. I studied and compared the characteristics of each boiler. I did not see an obvious leader in terms of user friendliness. I would like to provide a problem-free, in terms of boiler maintenance, period of 10-15 years. In this regard, saving 10 thousand at this stage does not seem so important. Tell me, you can connect a sensor from Vaillant 306257 to the KLOM 40 gas boiler instead of the 0010006491 boiler sensor. The house is 140 sq. meters in two floors. Warm floors on the first floor and a bathroom on the second. All together 80 m2, then radiators 13pcs, BCS for 200 liters. The unit only has a coaxial chimney. I initially considered the Panther 25 CTO, but they advise a floor-standing one with a cast-iron heat exchanger and more powerful, for example, KLOM 30 or PLO 30 with a turbo attachment. What is the difference between KLOM and PLO? The capacities of the boiler and the BKN are the same, but there will still be radiators and warm floors. Is it necessary to take a boiler unit with a power reserve so that it does not work at full capacity, to conserve its resource - can it last longer? And about reliability: in the wall-mounted copper heat exchanger, and in the floor-mounted cast iron. The service life is probably different for them? Cast iron will last longer, right? The difference is in the ignition, the number of functions. KLOM has electric ignition, PLO has wick ignition. PLO is the same TLO only volatile and with the ability to connect semi-turbo. the boiler has a magic function. The priority is called. Heats alternately either the boiler or the house. The service life of the boiler does not depend on the material of the heat exchanger. Can I install PLO burner control on TLO? The reason for the question is the choice of a boiler to replace the leaking one. Candidates - 40 TLO or 40 PLO with partial loss of non-volatility, but the ability to at least stepwise power control. No you can not. What is the difference between Proterm 30 plo bear and tlo? Possibility of connecting a semi-turbo extension for exhaust gases without installing a chimney. What could be the malfunction? Hot water flows in the kitchen sink, and intermittently in the bathroom. It's all about the speed of the water flow, first put on more watering can. At the minimum flame, the boiler begins to exceed the preset water temperature, turns off, when it goes down, it turns on again, this is called cycling. If it does not help, you need to readjust the gas valve. We installed the Protherm Medved 30 KLZ boiler, house area 170 sq. m. The boiler is connected to liquefied gas (cylinders), gas consumption is one cylinder per day. This is normal? How can gas consumption be reduced? What did you imagine when choosing a boiler for liquefied gas. KLZ is one of the best units in terms of price and quality, and efficiency is at a level higher only for condensing models. It may be better to buy a pellet one. Yes, it is more expensive, but the cost of heating is roughly the same as natural gas. In operation, a new floor-standing boiler 40 klom, when the boiler is turned on, the boiler starts up, it heats up, but the pumps do not work, I change the polarity in the outlet, the pumps turn on, but the unit starts to issue an F1 error.How to carry out repairs? In operation, the Proterm bear 40 KLZ (35 kW) boiler operates for 2-3 minutes, heats up, rests the same amount. I suppose that this boiler operation is not correct. Heated area 220 sq.m. radiators and the same warm floor. I don't use water yet. What is the way out in this situation? When the boiler is heated, the boiler operates at a maximum temperature of 85 degrees. When the set water temperature is reached, it will automatically switch to the heating circuit. DHW has priority, this is its operation algorithm. The igniter of the boiler Protherm 20 goes out. When the main burner is started, the flame on the pilot starts to twitch and come off. The boiler shuts down. I added an igniter - anyway, a separation occurs when the main burner is started. Before that, he worked and gave out the required temperatures. Installed and connected boiler 30 KLZ, house area 200 sq.m. It works well in winter, keeps the temperature at 75. With the onset of spring, the temperature was lowered to 65, and the device began to turn off periodically, with an F1 error. This happens approximately every three days. What is this malfunction? Error F1 - loss of flame. Check the burner and find out why the flame is lost. The Protherm klz 50 boiler is in operation, it has been working for 4 months. Now he heats the water in the boiler to 85 degrees, and the pump does not work, does not accelerate the water through the heating system. Tell me what kind of breakdown? Why did the pump stop working? Most likely, the relay is faulty on the control board. Gas boiler 50 KLZ is mounted, grounded, periodically gives error F1. We switch phase 0. Can anyone have a similar malfunction? In work 6th month. This is apparently their defect. See the minimum gas setting. At a high flow rate in the gas line, the unit will give a large subsidence and the electrode will not see the flame. Boiler Proterm Medved 30 klz ignites noisily. What to do? Maybe turn down the gas supply where necessary? There is a starting power setting in the menu. Make adjustments. I decided to repair the Protherm 40 TLO, namely, to clean the pilot burner. He took off the tube, unscrewed the bar, on which the thermocouple, thermogenerator, burner and igniter. The burner consists of two plates, one on top and one on the bottom. On the sides and in front there are 3 round channels, 3 flame tongues, a thermogenerator heats up on the left, ignites the main burner in front, and a thermocouple on the right. I looked, the tip of the thermocouple is farther than the right channel, unscrewed the thermocouple and put it exactly against the channel. I wanted to clean the burner, but did not understand how and what to clean there. Only the jet was cleaned with a thin needle. I collected everything, turned it on, began to measure the voltage, under a load of 22 mV! Directly on the valve 13.5 mV, more than a fourfold margin (clicks off at 2.5 - 3 mV, time after turning off the gas 30 sec). But most importantly, the voltage does not float, as before, but practically stands still (somewhere, the run-up is only 0.2-0.3 mV with any switching on of the main burner). With the old thermocouple, the gap is also very strong, it turns out that the thermocouple was incorrectly installed at the factory, and on the new boiler, the shutdown time was about 10 seconds. Well, now let's see how long it will work with this thermocouple. From time to time, I will measure the voltage of the thermocouple. The boiler TLO 20 is connected to the system. The device is completely new and is already running. The temperature delta is two degrees. Heats up for a minute, cools down for three, and so on for days. Is it possible to adjust for a large temperature difference so that there is no clock? The Medved 30 TLO boiler is installed in the system. Worked well. In the summer, only heated towel rails were heated through it. The heating has now been turned on. The temperature was set to 50 degrees. It catches up with heat, then turns off and the batteries cool down. And it does not turn on anymore. If immediately, as it turned off, increase the temperature, it starts. It also works if you click the piezo ignition. What is the fault? We launched a new boiler 40 TLO (floor standing, non-volatile). The system is gravitational, but there is a pump. And immediately - that is, from the first launch - questions arose: 1.After starting, the boiler worked for several minutes, warmed up to a certain temperature and turned off. I decided to call specialists for insurance. They came and said that this boiler would not work without a pump! It's strange, because the device is non-volatile. The boiler started up with the pump and is now working well. Will such a unit work without a pump or not? If not, why not? 2. Now I am purchasing a new device. Since the boiler is under warranty, I draw up a contract with a service organization. Is it the responsibility of the service organization to repair the boiler? The fact is that after installation, it turned out that the thermometer was knocked down to 0 - i.e. need to replace the thermometer. At whose expense should this be done? 3. Again, the specialists who connected the boiler expressed doubt that the pipe leaving the apparatus should be as hot as it is. The chimney in the wall of the house, brick, height 12 m. I checked the chimney - clean (well, not counting the soot left over from the previous one). There is supply ventilation, and the window is also constantly open. Boiler room in the basement. The unit is connected to the chimney through a stainless steel pipe D150 mm - i.e. a pipe with a height of about 40 cm goes up from the boiler, then a turn of 90 g and another 30 cm of the pipe to the chimney in the wall. Did I do everything right? Its heat exchanger is made of cast iron sections, similar to the familiar cast iron batteries. The burner heats up the heat exchanger and the water in it expands, i.e. its density becomes less. At the top of the heat exchanger there is an outlet (supply). "Light" water begins to rise upwards and cold "heavy" water flows from the pipe below (return) to its place. Thus, there is a circular movement of water in the heating system, which is called circulation. The higher the column of "light" water, the greater the force driving it through the system. For this reason, after leaving the boiler, a high vertical section is organized, which will create this draft. Until this area warms up, the traction will be poor. During initial starts, it happens that air locks remain in the system, which impede the movement of water. All sorts of constrictions impede the movement. Have you done all this? If the heating system is done correctly, then the TLO will work without a pump. But the circulation is provided by the heating system, not the boiler. The warranty implies free elimination of defects that arose through the fault of the manufacturer. If the thermometer has been faulty since the moment of purchase, then the question may arise why this was not recorded at the time of purchase. Malfunction of the gas boiler Protherm 40 TLO. After one heating season, the igniter began to go out. At first, occasionally, then more and more often, then almost after every heating. The draft thermostat closed first, then the emergency thermostat. It did not help, it stopped extinguishing when I closed the wires of the circuit of these thermostats near the solenoid valve (I soldered the jumper). The resistance of these wires (not measured) is of the order of 0.01 Ohm. At a current of 1A, the drop is about 10 mV. The thermocouple should output about 30 mV. These 10 mV are not enough to hold the valve. I think we need to change the thermocouple (the voltage has become less output). Who faced such problems? Can the thermocouple deteriorate at the junction with the solenoid valve? I have never dealt with thermocouples. There is a tube, apparently a conductor inside, on the tube there is a nut at the valve. How to check a contact? Unscrew the nut, clean the contacts, or can they only be wiped with something? Is it permissible to tighten the nut tighter for better contact, because hundredths of an ohm already play a role? I adjusted the size of the igniter flame (on the automatics the Pilot adjusting bolt), made it minimum and maximum, and this did not affect the operation of the boiler in any way. As the igniter goes out, it goes out. The only thing I can 100% say is that it wasn’t blown away. (since it goes out simultaneously with the click of the valve, if you blow out the igniter - click after 3 - 5 seconds, until the thermocouple cools down).Disassemble and clean the boss on the valve where the wires come in. The click should be in 30-40 seconds. Well 15. But no less no less. The more the thermocouple is heated, the longer it cools. Screw the thermocouple directly into the valve. With such a connection, it holds for at least a minute until it clicks. Boiler repair results. Finally I took my multimeter with me. Measured no-load voltage: 17mV. I went to the store, bought a thermocouple, though not my own, but the thread came up to my SIT NOVA. No-load voltage: 38 mV. I connected everything as it was, under a load of 24 mV. It would seem that everything is fine, but I monitored when the boiler was running, when the main burner was turned on, the voltage first increased for 10 seconds, then it began to drop smoothly. At the end of a long heating cycle (about 15 minutes), the voltage across the valve is 8 mV, after the main burner was turned off, it still dropped to 6.5 mV! Then it began to rise and minutes after 1.5 12 mV at the valve and again 24 at the output of the thermocouple. On the wires of the protective circuit, 12 mV falls, i.e. 50%! Thus, at the most critical moment, only 1 mV remained before the valve was turned off. The voltage at which the valve is turned off is about 5.5 mV (turned off the gas and measured it until it clicks: 5.5 mV, time 15 s). The wires of this circuit are made with a wire of only 1.5 sq. mm, replaced the wires by 4 sq. mm, won 4 mV. While these 3 days have never been turned off, I left them turned on for a week, let's see how it goes. What is the reason for this effect? Maybe there is not enough oxygen, and I need to think about supply ventilation to the boiler room? Or is it a consequence of a "poorly executed" burner? I haven’t dared to drill the burner yet, I think we must first buy a spare new one and experiment on it. By the way, where can you find the 40 TLO spare parts catalog? There is a suspicion that the thermocouple is pushed too deep. Its tip should be warming up. It is possible that the dynamic gas pressure is low. And 17mV is very small. It should be at least 20-25.

Why does combustion products accumulate?

The raw material for a heating boiler can be wood, coal, peat or pellets. Burning, any fuel leaves behind various deposits that negatively affect the operation of the device. Resin in a solid fuel boiler accumulates much faster in the following cases:

- use of low quality or wet fuel;

- too much fuel material in the combustion chamber;

- the use of a heating device for the disposal of household waste;

- insufficiently high operating temperature, due to which the fuel smolders, and does not burn;

- the use of firewood, in large quantities emitting volatile resinous substances, which, when the temperature drops, settle on the walls of the boiler.

Read more about boiler temperature problems on our Zen channel.

Oxygen deficiency and mistakes made during the assembly of the heating device, in particular, insufficiently high chimney height, can also increase the amount of unwanted deposits.

The heat exchanger of the gas boiler is clogged with scale, what should I do?

The most vulnerable part of any boiler, if it is not a water boiler, is the heat exchanger. This is where the water is heated. And if it is of poor quality, or does not soften, then sooner or later such a problem as flushing the boiler or its clogging will come. What problems can low-quality water create for the heat exchanger and, as a result, for the boiler?

| Equipment type | Effects |

| A gas boiler | The heating period is increased Heating quality drops Heat exchanger may burn out Scale causes the heat exchanger plates to stick together Scale from the heat exchanger enters the boiler Scale build-up begins to be deposited wherever the water comes into contact |

Scale cannot be avoided if the correct softener is not installed on the farm. But what if you can't afford a softener yet? How to clean the boiler from scale with your own hands? And will it give at least some effect, at least temporary?

When the heat exchanger becomes clogged with hard scale deposits, the problem can be solved in two ways:

- Flushing the device with caustic cleaning agents;

- Having disassembled the device and soaked the especially affected parts in caustic solutions;

- Having bought a softener, no longer remember this problem.

There is no need to bring the heat exchanger to such a state until it clogs! Therefore, each consumer, when installing a boiler room, must begin by assessing the condition of the water. But, if this factor has already been missed? The consumer learns that the heat exchanger is clogged by several factors. The walls of the heat exchanger began to become very hot, the water heating takes longer, and scale particles from the exchanger began to enter the water.

The girl independently rinses the boiler with her own hands

And this is the reason to sound the alarm! It's time for a flush. It can be major, or it can be preventive. In any case, without a softener, you will have to use both types of flushing.

It is possible to wash the inner surfaces of the heat exchanger with special aggressive agents (like antiscale, for example, or sulfuric acid), but for this you need to know exactly in what proportions to dissolve it all, how long to keep it, and how to remove adhering particles later. The rinses do not end with rinsing only. If the case is running, then you will have to disassemble the heat exchanger and work mechanically - that is, scrape off the softened parts of the scale. But this is precisely the disadvantage of flushing. They are very damaging to surfaces, which significantly shortens the service life of any equipment.

How to flush the heat exchanger of a gas boiler? There are several simple remedies that are good for prevention and there are aggressive liquids that need to be used according to the instructions and not often. Any housewife has vinegar and there is always citric acid in the house. Especially for those housewives who love to bake. So they can be used for the simplest flushing. It will be enough to dilute two tablespoons of flushing liquid per liter of water and hold the heat exchanger in this solution. Better yet, of course, drive such a solution through the device, At high temperatures. Vinegar works by analogy. Only for washing it is better to use essence, it is stronger than ordinary vinegar.

As for the purchased funds, there are a lot of them. It's easy to find them online and learn how to use them. Efficiency, of course, will have to be judged by trial and error. The water is different for everyone and somewhere Antinakipin works better, and somewhere only a solution of hydrochloric acid can help. The situation is complicated by the ingress of dirt and dust into the heat exchanger. That, in combination with scale, forms a poorly soluble plaque.

Limescale

This is a consequence of working with water with a high calcification threshold. Whitish sediment on the surface of the equipment is the most reliable sign of such water. But the consumer will only know about the fact that the water is not soft in about a month, when all the walls are covered with bloom. But this is only if you do not test the water. Therefore, to avoid the formation of plaque, you need to start by checking the composition of the water. And it is best to put a softener if the analysis indicated that the hardness threshold was exceeded. You also need to understand that the design of the boiler will make its own adjustments to the flushing process. It is much more difficult to flush the heat exchanger of the wall-mounted Baxi boiler than a conventional floor-standing boiler. Dismantling, assembly also takes a lot of time.