ROOF ROOF TOP

5000 rubles / cubic meter m.

High density mineral wool. Density…

ATTENTION: The prices for the material are indicated for the wholesale volume (70-80 cubic meters), in multiples of a wagon. Free delivery to the object is possible in multiples of trucks. Wholesale and retail prices for the material can be obtained from the managers of the company.

Thermal insulation IZBA Is a modern insulation for a wide range of applications in construction, suitable for efficient energy saving of residential, public and industrial buildings. It is made from environmentally friendly mineral slabs, with the addition of a synthetic binder. The use of IZBA insulation at the stage of new construction or during special thermal insulation of objects can significantly reduce heat loss and reduce heating or air conditioning costs. In addition, savings occur already at the stage of construction, newly erected buildings, by reducing the cost of materials for the foundation, when insulating the walls, their thickness is significantly reduced, respectively, the weight of the structure is lower.

The main application of IZBA insulation is associated with various tasks in the field of construction and energy saving. The line of the manufacturer IZBA has a wide range, with different characteristics in terms of density, they allow you to select the optimal density for each building structure.

Insulation IZBA is recommended for thermal insulation:

- Walls and partitions,

- Plaster facades (plastering on the surface of the insulation),

- Pitched roofs and attics,

- Soft roof,

- Interfloor ceilings,

- Insulation of the floor along the logs,

- The loaded floor (laying the screed directly on the insulation).

High density, unique mineral filling and porosity of the structure of the material are an effective combination that allows you to achieve excellent results in heat and sound insulation when using insulation, even with minimal thickening with insulation systems.

IZBA thermal insulation is non-combustible, refractory, withstands temperatures above 1000 ° C. degrees. The material is hydrophobic and resistant to mechanical stress. Basalt thermal insulation of the IZBA brand in its technical properties fully complies with the current Russian standards and regulations.

Insulation IZBA - this is high-quality and environmentally friendly thermal insulation, an excellent combination of affordable cost and high product quality.

Insulation production process Izba

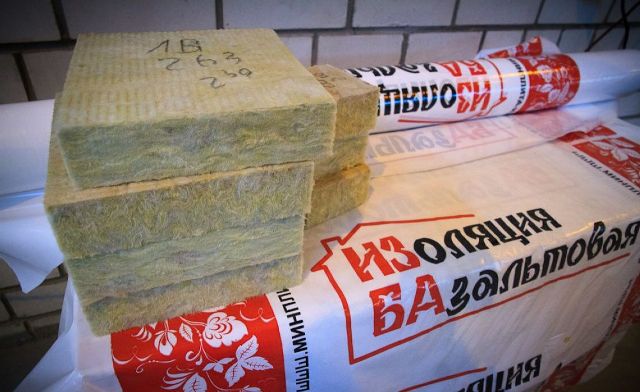

Insulation Izba is made of basalt.

What the Izba insulation is made of is encrypted in its name. The abbreviation stands for basalt insulation, respectively, it is made of basalt. Basalt is a rock of volcanic origin. In fact, it is a stone, therefore this insulation is also called stone wool.

The rock is mined in quarries and delivered to a processing plant. There, large stones are broken into small fractions, so that later the rock can be melted. Red-hot basalt is cooled with air under strong pressure. The viscous mass is simply inflated, as a result of which fibers similar to cotton wool are formed.

The size of the fibers is quite modest, only a few centimeters.

Intertwining with each other, they form a single structure, the degree of density of adhesion of the fibers is controlled at the stage of forming the plates. The higher the pressure is applied to the material, the denser the Izba thermal insulation is obtained.

Particular attention is paid to the environmental friendliness of the product, while it is impossible to completely eliminate harmful substances in the production process. It is a bonding agent due to which basalt fibers stick together.The composition of the binders, although in small quantities, still includes formaldehyde resins. It cannot be said that this is extremely dangerous for a person, at least if the insulation is not allowed to enter the body.

Modern stove heating of a private house is strikingly different from traditional approaches.

Here is information about air heating: advantages and disadvantages, cost, installation methods.

Properties and qualities of basalt insulation

The technical characteristics of basalt fiber (a stone variety of mineral wool) overlap with the properties of a mountain stone:

Has high strength Basalt slabs are non-combustible Have hydrophobic impregnations

- I would like to note the highest strength. Basalt insulation has a long service life. And even after decades, it is still the same in its original state: no defects, no seals, no changes in shape or size.

- High rate of heat resistance. Stone fiber insulation can withstand high temperatures, over +1000°

C. For example, Isover mineral wool begins to melt only at a temperature of + 1110C. Basalt insulation is often used to insulate pipes through which hot liquids are distilled, to decorate the chimney of a bath. - High hydrophobic characteristics. This indicator suggests that the influence of moisture and water on stone fiber insulation is minimal. It does not penetrate further than the upper layer. This makes it possible to use the material in a process such as warming wet rooms. For example, this is ideal for a bath.

- Wet air vapor penetrates the basalt insulation, but does not stay in it, passing through. This ability to "breathe" allows you to increase the service life of not only the insulated layer, but also the building structure as a whole.

Important... The vapor permeability of the basalt fiber heat insulator is one of the highest, hence the ability to maintain the necessary microclimate inside the baths, showers, pools and other wet rooms.

- Basalt thermal insulation is the highest thermal insulation and technical characteristics combined with high noise absorption.

Basalt wool structure

I would like to make an addition on the strength of the basalt fiber material. The structure of the heat insulator is a chaotic arrangement of stone fibers. This is what allows the insulation to withstand quite serious loads.

Basalt thermal insulation is used in various sectors of the national economy. This is not only construction, although it is here that it is most used for insulating walls, floors, roofs, basements, various kinds of pipes and air ducts.

Advice. For a chimney, this is the optimal solution due to the fact that this stone fiber insulation has a high fire resistance.

Let us again recall the baths, facades insulated from the outside. For a frame house, this is the ideal filling of the space between the wall finishes. It is also used for thermal insulation of pipes for various purposes in production.

Advantages and disadvantages

The melting temperature of stone wool is over 800 degrees - the material does not burn

The advantages of Izba mineral wool include:

- minimum level of thermal conductivity - dense material keeps heat well even during severe cold snaps;

- vapor permeability of the coating - walls with insulation "breathe", therefore they do not collapse;

- environmental safety - during installation and during operation, no toxic substances are emitted;

- fire resistance - stone wool is classified as non-combustible material;

- low hygroscopicity - moisture-resistant boards can be installed outside the house and in damp rooms;

- no crumbs and waste when cutting;

- density that provides sound insulation even for a thin wall;

- ease of laying and processing by cutting;

- resistance to chemicals, damage by rodents and insects, the formation of mold and mildew.

The disadvantages of the heat insulator include fragility, which leads to damage as a result of transportation and installation. Basalt slab weighs more in comparison with other mineral insulation materials.

Insulation types

We list all products of this type on the construction market:

- Super Light;

- Light;

- Standard;

- Venti;

- Facade;

- Roof.

Super Light

Since the density of this type is low, only 30 kg / m³, such an insulating material is used in non-stressed structures. It can be pitched roofs, wooden floors on logs, walls, partitions, an attic room.

Its thermal conductivity is 0.036 W / m K. Water absorption by volume is only 0.3%, but by weight up to 20%.

Light

This insulation is used in the same designs as the previous type. But it has a density of 40 kg / m³ and the same thermal conductivity. Therefore, when choosing a particular material, they usually look at the price. Light has it higher.

Standard

The same as with the two previous species, but with a higher density - 50 kg / m³. Thermal conductivity 0.035 W / m K.

Experts recommend using the Standard under the screed to level the floor bases, since the density allows it.

The only thing is that you will have to close the basalt insulation with a waterproofing membrane. Unfortunately, this type has a high percentage of moisture absorption: up to 1.5% by volume, up to 10% by weight.

Venti

This type is used for external insulation of buildings under ventilated facade structures. Most importantly, there is no need for it to install a windproof film.

Density 80-90 kg / m³, thermal conductivity 0.035 W / m K. It has increased characteristics of sound insulation and fire resistance.

Facade

This type of heat insulators Izba is used only for insulating facades. Its density, equal to 135 kg / m³ and high moisture resistant qualities, make it possible to apply plaster solutions to the installed insulation on a reinforcing synthetic mesh. Thermal conductivity 0.036 W / m K.

Roof

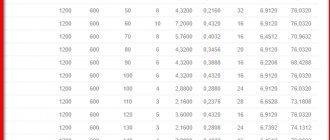

To begin with, there are two types in this group: Roof Bottom and Roof Top. They have different densities: the first has 110 kg / m³, the second has 190 kg / m³. Hence their purpose. Roofing Top is most often used for thermal insulation of flat roofs with double overlapping roofing material. Roof Bottom if the roof covering is single.

Practice shows that most often builders choose basalt insulation from the Top group for all types of flat roofs. And although it costs 40% more, its technical and operational characteristics cover all costs a hundredfold. Plus a longer service life.

IZBA Super Light, Light

This category includes slabs of low density (from 30 to 40 kilograms per cubic meter). The area of application of such non-loadable insulation is roofs pitched type, attics, attic floors, ceilings, internal partitions, as well as floors (for installation between logs as thermal insulation).

| Characteristic | IZBA SUPER LIGHT - 30 | IZBA LIGHT - 35 | IZBA LIGHT - 40 |

| Density, kg / m3 | 30 (± 10%) | 35 (± 10%) | 40 (± 10%) |

| Thermal conductivity at 283 K (10 ° C) W / (m ° C), no more | 0,036 | 0,036 | 0,036 |

| Water absorption at full immersion,% by volume, no more | 3,0 | 2,5 | 1,5 |

| Water absorption at partial immersion,% by weight, no more | 20 | — | — |

| Organic matter content,% by weight, no more | 3,5 | 3,5 | 3,5 |

| Moisture,% by mass | 0,5 | 0,5 | 0,5 |

Advantages and disadvantages of minvata izba

Basalt insulation has its advantages:

- environmentally friendly;

- has a high degree of resistance to mechanical and chemical stress;

- belongs to the group of non-combustible materials;

- has a percentage of hygroscopicity close to zero.

The last parameter is extremely important, since a damp insulation loses all its thermal insulation properties.For this reason, many private developers refused to use mineral wool. It absorbs moisture well from the air and needs high-quality waterproofing and vapor barrier, which leads to an increase in the cost of construction.