Home | Construction | How to insulate walls from foam blocks from the outside?

Date: December 29, 2018

Comments: 0

Foam concrete today is considered one of the most common materials that are used in low-rise construction. Therefore, the insulation of walls from foam blocks from the outside is important for the owners of such houses.

The popularity of houses made of foam concrete is due to a set of characteristics that make it convenient and profitable for housing construction:

- low coefficient of thermal conductivity, as a result of which less costs for thermal insulation are required;

- small weight with impressive dimensions, which reduces the cost of transportation and installation of foam blocks;

- environmental friendliness;

- fire safety;

- frost resistance;

- affordable price.

Among connoisseurs, one can hear disputes about whether it is necessary to insulate walls for houses from a foam block. There is reason to be sure that it is still necessary - the cellular structure of the foam block helps it retain heat, however, in our climatic conditions, thermal insulation is still necessary. In addition, if the foam blocks are fastened not with an adhesive solution, but with concrete, then their thermal insulating properties significantly decrease - concrete seams remain excellent conductors for cold.

Before proceeding with a small overview of the most suitable materials for external insulation, it is useful to recall some of the features of foam blocks

Insulation of the foam block is possible both outside and inside the building. Each method has its own advantages and disadvantages. Thermal insulation of the foam block outside does not "steal" the space inside the house and does not create problems with fogging the walls.

Insulation of the walls inside is convenient in terms of implementation, it gives more options for choosing a heater, however, this reduces the space inside the house and there are problems with the "dew point", which have to be solved with the help of vapor barrier.

For thermal insulation of the foam block from the outside, choose one of two insulation options - expanded polystyrene or mineral wool. The methods of using each of them are different - below we will look at the features of each of them. Based on this information, it will be easier for you to decide how to insulate the walls from foam blocks from the outside, and you will know how to do this.

Foam block as a base

Foam block is a building material that consists of cement mortar, sand, water and special substances involved in the formation of a stable foam.

The material has high performance in heat and sound insulation, is resistant to moisture penetration, fire resistant and is not able to freeze.

It is not used as a material for the capital construction of a load-bearing wall, but an internal partition or non-load-bearing structures can be made of it.

Prices for foam blocks

The price of the foam block depends on the manufacturer and brand.

Average prices:

- A structural block of a standard size 600x300x200 will cost 3200-4500 rubles. / 1 m³.

- Structural and heat-insulating block (wall) - 120-140 rubles / piece; half-block - 60-75 rubles. /PC.; the average price of 1 m³ varies in the range of 3200-3800 rubles.

- A heat-insulating block of grades D100-D500 and a size of 400x200x600 mm will cost 2,700-3,000 rubles. / 1 m³, 1 block costs 117-120 rubles.

The sizes of aerated concrete blocks may vary from manufacturer to manufacturer. When buying, you should pay attention to the color and surface quality of the material.

High-quality foam concrete should have a uniform grayish color.According to the technology, the blocks cannot turn out to be bright white; violation of the process leads to fragility. On a smooth surface, there should be no chips or cracks, the cells do not interconnect.

Warming reasons

Insulation of external walls only with foam concrete is quite popular, since the blocks are lightweight, durable and have good durability. In addition, in some cases, additional insulation of the foam block itself can be performed.

There are a number of reasons for this:

- protection against moisture, which has a very bad effect on the durability of the wall;

- when freezing, there is a risk of complete destruction of the building material;

- prevention of condensation on the main wall and, as a result, the formation of fungus, mold.

Also, experts advise to insulate buildings from foam concrete exclusively from the outside.

Features of wall insulation from aerated concrete and expanded clay blocks

Of course, the walls of nine-storey panel concrete buildings and even old brick houses need to be insulated. Their thermal insulation does not stand up to criticism, and you just need to flee from the cold. But the insulation of expanded clay concrete blocks of walls from the outside or the hanging of foam panels on foam concrete should be carried out with the participation of specialists and carefully calculated. There are several reasons for this.

First of all, foam concrete and expanded clay concrete have good thermal insulation of their own. But most importantly, it is necessary to take into account the high vapor permeability of such walls. This means that water vapor flows out freely through them, and the walls "breathe". The vapor permeability of foam, especially dense foam, is much lower.

Therefore, from people who have insulated the house outside with foam, the reviews are the most controversial. For example, they say that the house has become, not only warm, but also damp, and it is necessary to arrange additional forced ventilation. In addition, it is necessary to take into account the mechanical strength of the walls and the depth of freezing.

The relevance of insulation of houses from a foam block outside

Foam concrete was created for those buildings that are erected in one layer. It has good thermal insulation properties. However, in a continental temperate climate, winters are very cold and windy, so experts still recommend additional thermal insulation of foam concrete.

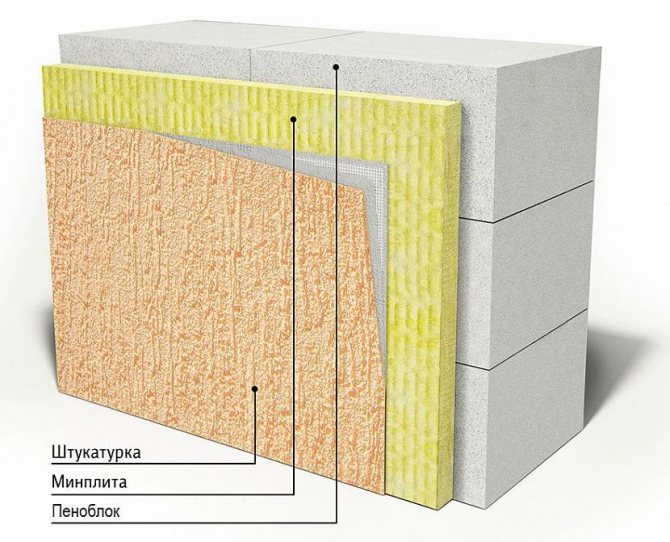

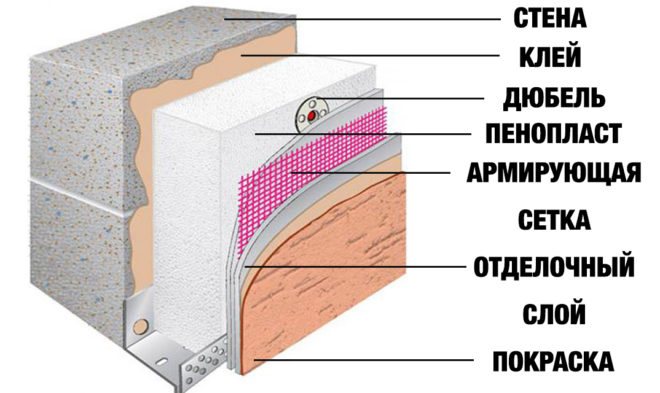

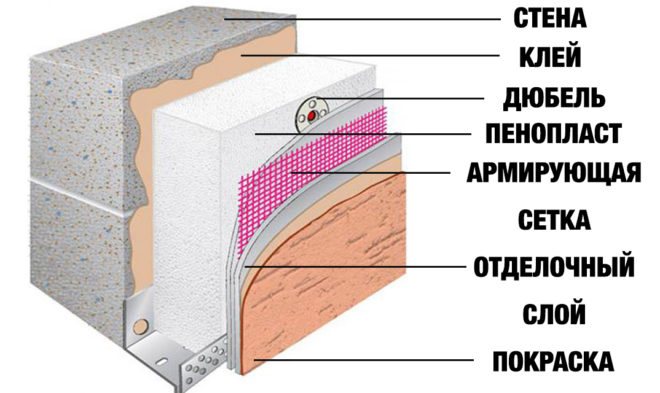

Scheme

Another important factor is that foam concrete can freeze during prolonged cold and even absorb moisture. To prevent this from happening, insulation is carried out exclusively from the outside of houses from a foam block, which has a number of advantages over the inside:

- saving space indoors;

- condensation does not accumulate inside, and also does not settle on the main wall;

- thermal insulation protects foam concrete from freezing and moisture penetration.

What is the best time to work

Before insulating the house from the outside, a certain time must pass. After all, at the plant, foam blocks are immediately after production sent into sealed packaging and delivered to the construction site. Provided that the building is erected quickly, the blocks will still retain their original moisture level upon completion of construction. And if insulated immediately, the blocks will absorb all the water and steam into themselves.

Because of this, vapor permeability decreases and in frost when heating devices are turned on inside the building, moisture inside the walls moves to where the partial pressure is lower (in the direction of the house, that is). When moisture reaches the interior finish, it collects on the surface and the wall becomes damp. Foam blocks freeze, the insulator actively rots and the performance of the entire building deteriorates significantly.

Ideally, when the house is built in the spring, and the insulation is carried out at the end of summer.Then the foam blocks have time to dry completely and the efficiency of further work increases.

Insulation types

If you still decided to insulate the walls of foam concrete, then the question certainly arose before you: "What kind of insulation to choose?" Considering the fact that today the market is overflowing with various types of insulators for insulating petroconcrete, they all differ in their characteristics and properties. The final choice can be made by examining all the main parameters of the proposed raw materials.

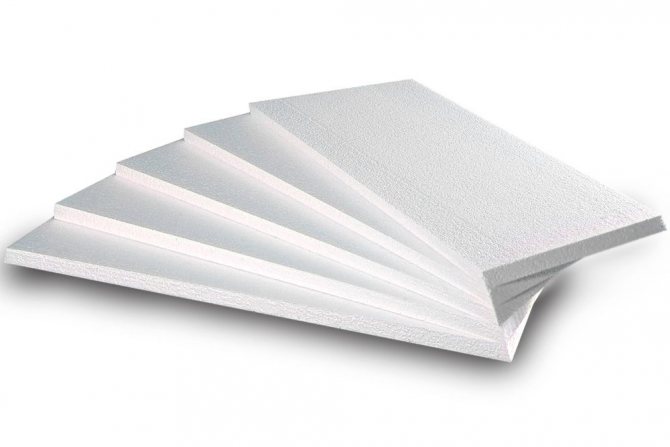

Foam application

Styrofoam

Polyfoam, also known as polyurethane foam, is a lightweight plate for thermal insulation of any walls. The advantages include not only low cost, but also resistance to moisture and sudden changes in temperature.

The peculiarities of foam concrete insulation with foam include the mandatory performance of facing work, since the slabs are unstable to UV radiation.

Use of mineral wool

Minvata

Minvata is also quite popular for foam concrete insulation.

It has a number of advantages:

- long service life if all work was done correctly;

- fire resistance;

- excellent heat preservation performance;

- additional sound insulation;

- does not absorb moisture.

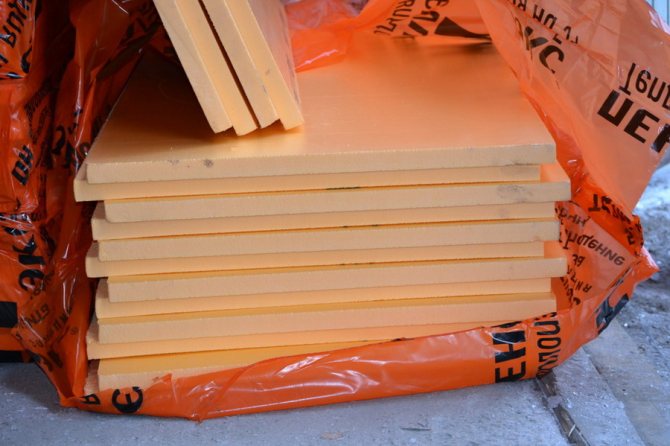

Penoplex analogue to polystyrene

Penoplex

This insulation looks very much like foam, but the materials are produced in a completely different way. Another name for penoplex is extruded polystyrene foam. These are slabs that do not deform, are resistant to moisture and mold.

However, the vapor permeability coefficient of the material is slightly worse than that of ordinary foam, which increases the ventilation requirements for a house made of foam concrete insulated with extruded polystyrene foam.

Thermal panels

Thermal panels

Thermal panel is a material consisting of a heat insulator layer (for example, expanded polystyrene, polyurethane foam, extruded polystyrene foam), a decorative outer layer (clinker, artificial stone, ceramics) and an adhesive base, which serves for gluing the decorative layer and the thermal insulation base.

The main advantage of such slabs is that there is no need for cladding work, since they already contain a decorative layer. In addition, there are other advantages of using thermal panels, and they are quite significant:

- installation at any time of the year;

- resistance to decay, the formation of all types of fungi and mold, as well as other microorganisms;

- special mounts that simplify installation work;

- the obligatory use of the lathing excludes the violation of the geometry of the facade;

- a variety of colors and textures allows you to embody the most daring design solutions into reality;

- high coefficients of heat and sound insulation;

- durability of the structure and resistance to ultraviolet radiation.

The only drawback is the high cost of thermal panels.

Is it possible to insulate aerated concrete with foam

How to insulate a house from aerated concrete, which insulation material to choose? These questions concern many who decided to build a house from cellular materials. Since the distinctive property of aerated concrete is vapor permeability, this property must be preserved.

For thermal insulation materials, this coefficient should be slightly lower than that of the material from which the walls are erected. If this parameter is higher, there is a possibility of moisture accumulation.

Can polystyrene, a material that is very popular, be used for insulation? How to properly insulate gas silicate walls at home?

What material is most preferable: possible harm to health

Fire hazard

When choosing an insulator for foam concrete insulation, the question of safety arises. It's not only about the release of harmful substances during operation, but also about fire safety.

All of the above-described thermal insulation materials will not harm human health if the installation work is performed correctly. All of them are produced using anti-flammable mixtures that prevent not only ignition, but also contribute to self-extinguishing in the event of ignition.

Given the fact that synthetic resins from the phenolic group can be used in the production of mineral wool, it will not emit harmful substances due to its external location.

Advantages of insulated houses

The most noticeable advantage of using heaters in the case of a foam block is effective heat conservation inside the house, as well as significant savings on heating costs in the winter. For such houses, this option is the most acceptable and profitable. In addition, the building material receives additional protection from temperature extremes, precipitation and wind. Another advantage lies in the removal of the dew point beyond the boundaries of the enclosing structure, which prevents blocks from freezing and their premature wear.

Do not forget that all procedures for insulating a building from the inside can lead to the loss of a considerable part of the usable area. Such events inside the house can be carried out only with a significant reduction in financial and time costs. Another case of using this option is that an expensive finish has already been made or people live in the house.

Features of insulation technology with various materials

After you have decided on the material for the insulation of foam concrete, you can proceed to the preparatory activities. First of all, the amount of material required is determined, and the necessary tools are selected.

It is important to remember that due to the size of any sheets for wall insulation, you will need an assistant to facilitate the entire installation process.

How to insulate a house from foam blocks outside with foam

Before starting work on the insulation of foam concrete walls, they must be prepared. They must be free of old paint, debris, plaster. It is also recommended to patch up all cracks and holes.

The process of foam insulation itself is as follows:

- a deep-penetrating primer is applied to the wall to ensure maximum adhesion of the adhesive to the foam concrete;

- an initial plank is installed at the bottom of the building to support the starting foam strip;

- an adhesive solution is prepared according to the manufacturer's instructions;

- the surface of the foam is processed to create a roughness;

- a layer of glue is applied with a spatula to the plate;

- the insulation is fixed on the foam concrete, the rows should go from bottom to top;

- the foam is additionally reinforced with dowels with a wide head.

After the installation of the insulation is completed, decorative and facing activities are carried out.

Thermal insulation of foam concrete with mineral wool: stages of work

When insulating foam concrete with mineral wool, it is also necessary to pre-clean the walls. In this case, the surface should be as flat as possible.

Step by step, the whole process looks like this:

- a solution of antiseptic agents is applied to the foam concrete;

- steam and waterproofing membranes are attached;

- brackets for lathing are installed;

- vertical and horizontal guides are mounted;

- insulation is inserted and fastened with dowels.

When using mineral wool, plaster and further painting are most often used as cladding.

Installation of thermal panels

The most optimal option for installing thermal panels on foam concrete is a ventilated facade system. As soon as the structure is mounted, they begin to install the panels. As a rule, they all contain special grooves for fastening, so work is done quickly and easily. All work should be started from the corner of the building, after installing the starting elements.

In this case, it is recommended to strengthen the film to protect it from moisture on the main wall.

Warming with foam

Work on the insulation of foam concrete with penoplex is completely identical to work on the insulation of walls with foam. In this case, preparatory work is also carried out, an adhesive solution is prepared, the plates are attached to the facade in a similar way, the fiberglass mesh is mounted, and decorative and facing work is performed.

Penoplex thermal insulation

When using foam for foam concrete, there is no need to use additional vapor barrier membranes, since the raw material already has high performance in this parameter. Also, due to the light weight of the plates, the work can be done independently, without the help of a partner.

How to choose the thickness of the heat insulator

It is also necessary to take into account the thickness of the insulation panels. Since the granular foam used for insulation practically does not allow moisture to pass through, it accumulates between the thermal insulation and the wall. And it can turn into ice by tearing or swelling foam sheets. If the freezing point moves inside the wall (with insufficient thickness of the heat insulator), this can lead to the destruction of blocks or joints between them.

Experience shows that the thickness of the foam must be selected depending on the climatic zone. And it should not be less than 50 mm. And in order to guarantee not to encounter the effect of freezing of water between the insulation and the wall, it is best to use sheets with a thickness of 100 mm for the middle strip.

Of course, this makes the work more expensive compared to thinner sheets. However, among the owners who carried out such insulation of the house outside with foam, the reviews were the most favorable.

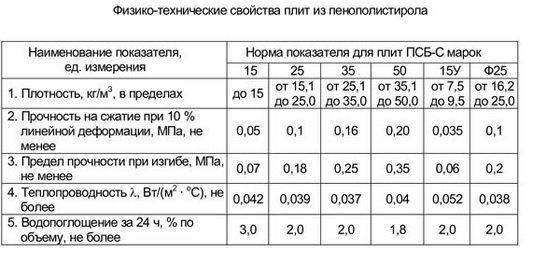

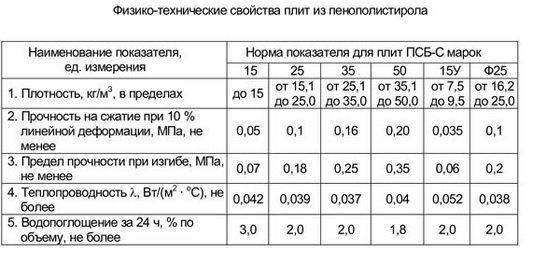

It is also necessary to pay attention to the density of the installed foam. They try to install the least dense one, which is also characterized by the highest rate of thermal insulation. However, it should be borne in mind that in construction it is forbidden to use foam with a density of less than 25 kg / cubic meter. meter. In ten years, such material will simply turn into dust and will have to be changed.

Granular polystyrene grade PSBS-25 is optimal for insulation. Less dense (PSBS-15) does not withstand mechanical stress, and PSBS-35 is much more expensive and has worse thermal insulation characteristics.

Protecting the thermal insulator

Any insulation needs protection. And it's not just that materials behave differently when exposed to moisture or sunlight.

An open thermal insulator does not look attractive outwardly, and in any case, decorative cladding is required.

Masonry

One of the most expensive, but at the same time durable, cladding methods. During the work, simultaneously with the laying of the insulation, the foundation is expanded. Its thickness is equal to the thickness of the insulation and plastering.

Masonry

Some construction organizations advise to carry out work on the insulation of foam concrete and brick laying at the same time in order to reduce the cost of gluing the insulator.

Wet facade

This method is often used for basalt wool and expanded polystyrene.

Wet facade

Its principle is as follows:

- walls are cleaned, their plane is leveled;

- a deep-penetrating primer is applied;

- insulation elements are attached with glue;

- additionally, the plates are fixed with dowels;

- a layer of adhesive solution is applied on top;

- the reinforcing mesh is recessed;

- a thin layer of plaster is applied;

- paint is applied to the dried surface of the facade.

Ventilated facade

This method is ideal for insulating foam concrete walls. The bottom line is to install a special metal structure - a ventilated facade system.The peculiarity of such a hinged system is that there is a ventilation gap between the main wall and the insulation layer, in which air circulates freely, thereby preventing the appearance of condensation and contributing to better heat retention.

Curtain wall system

It should be remembered that when insulating foam concrete with mineral insulators, an additional installation of a windproof film is necessary, but for expanded polystyrene this is not a prerequisite.

Summing up, we can say the following: foam concrete is a building material, which still needs to be additionally insulated, despite good heat resistance indicators. In addition, it is better to carry out insulation from the outside of the building so as not to reduce the space from the inside of the room and not to expose the insulation to interaction with moisture and precipitation.

Choosing the best insulator is a matter of personal preference. As for the method of installation, in this case, the most suitable system will be a ventilated facade, which provides free air circulation inside the structure, which will avoid the deposition of condensate on the surface of the main wall.

Construction features

- Foam concrete structures need reinforcement, which is carried out on every 4-5 row of blocks and next to openings, even for one-story buildings. This will allow for a reliable installation of floors and rafter systems.

- Blocks for facade finishing must have a frost resistance coefficient of 50 (the coefficient of D500 running blocks ranges from 25-35), otherwise deformations are inevitable.

- For wall decoration, special plasters and paints are used; regular finishes are deformed and guaranteed to crack. During work, the structure should be protected from waterlogging.

- In the conditions of the middle strip, the minimum thickness of the masonry should be 640 mm (the standard block has a thickness of 500 mm), a monolithic strip foundation is preferable.