The entire heating system of residential and industrial premises at least once every five years requires the application of a protective layer using dyes. This manipulation will prevent the destruction of heating communications due to the impact on them of external adverse factors, corrosion, and will also maintain a pleasant appearance. Pipe paint must meet certain requirements and fulfill a number of tasks assigned to it. The market of modern building materials offers the consumer a large selection of goods that differ in both price and performance.

Reasons for painting pipes

Before analyzing the types of paints and making a choice of one of them, we will consider the main reasons for painting work. So:

- Protection of new surfaces from external corrosion and other negative influences. Even plastic material needs to be processed and protected.

- The poor condition of the old highway requires coverage correction. When the coloring layer begins to peel off, fall off, and also succumb to rust, it must be replaced.

- The decorative appearance of heating communications does not correspond to the design of the room. If this element does not correspond to the general appearance of the interior, you need to repaint it.

- Prevention of damage to the heating system. It is necessary to carry out painting work in a timely manner in order to avoid the appearance of rust, traces of decay.

After replacement, the pipes need to be put in order

How to paint the heating system?

Example of paints for pipes and radiators.

Currently, the construction market provides a wide range of these products, each of which has such qualities as elasticity, protection against corrosion. For example, the above advantages of enamel for pipelines are characteristic of pentaphthalic variants, of which PF-115 is optimal. In addition, it is recommended to paint radiators with alkyd paints and heat-resistant organosilicon enamels (KO-168). Experts believe that painting the heating system should not be done with oil paints, as heat may darken their color.

To paint the pipelines of the heating system in the bathroom, you need to use lead-red lead primer number 81, and then paint with the following: enamels GF-0119, PF series 519, 233, 187, 167, 156, 115, alkyd-type polyurethane enamels and paints, containing VL-51 or bakelite, ethylene varnish. Heating pipes painting should be renewed every 2 years. Enamels for pipes of modern heating systems are designed very carefully: they do not have a peculiar unpleasant smell of alkyds, and their matte sheen will allow you to hide some imperfections in the surface of your pipes.

Further, issues related to the painting of pipes of the heating system, the selection of paint, painting with aerosol paint will be considered.

White enamel.

What should be the paint

Having found out the reasons, we will analyze the question of what performance characteristics the enamel should have and, accordingly, what paint to paint the heating pipes. List of characteristics:

- resistance to abrasion, adverse effects of the external environment. A durable coating should not peel off, darken;

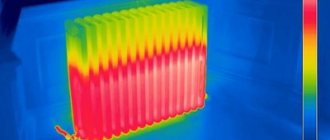

- heat resistance, the protective paint layer must withstand temperatures up to 100 degrees when the battery is heated;

- safety, from the moment of application, ending with the entire period of operation, the paint should not emit harmful substances;

- lack of a specific smell.Odorless paint for heating pipes does not adversely affect the respiratory system, vital functions of the body;

- color, dark shades are the best conductors of heat. A metallic shade will help to avoid darkening the room. Combined compositions and patterns are relevant.

Pay attention to: Painting laminated boards: the pros and cons of the method

The next important step when choosing how to paint a heating pipe will be the selection of one of the types of enamel:

- Alkyd enamels. Durable, heat-resistant, not afraid of abrasion, a large selection of colors. However, they have a specific odor throughout the entire period of use. Another disadvantage is that the treated surface loses its shine over time.

- Acrylic enamels. Less pronounced specific odor. Plus in good wear resistance, a variety of shades (matte and glossy options). The acrylic layer retains brightness for a long time, hides roughness, unevenness.

- Water-dispersive compositions. The safest option for painting heating pipes. Advantages: odorless, quick-drying composition, durability, heat resistance, beautiful appearance.

- Oil based paints. Painting pipes with oil compounds is no longer relevant.

Alkyd enamel

Acrylic enamel

Water dispersion enamel

Oil paint

Analysis of market offers

What are heat-resistant soils? Let's take a look at a few offers of the modern market as examples.

GF-031

Alkyd heat-resistant primer is produced according to TU-2312-030-00206919-2002 and is a suspension of pigments, antioxidants and surfactants in glyphthal varnish.

What can you tell about its properties and features?

- The primer is intended for steel, magnesium and aluminum surfaces. In particular, GF-031 is used in civil aviation - for coating aircraft bodies.

- The maximum operating temperature is + 200C.

It is curious: the reservation about civil aircraft construction is not accidental. The outer skin of the interceptor fighter at a speed of about 2.5M (2.5 times faster than the speed of sound), due to friction against the air, heats up to 300-500 degrees.

- Solvent - solvent; it also dilutes the soil when thickening.

- Application method - by spraying or using a hand-held painting tool.

- The thickness of a single layer coating after drying should be 15-20 microns. Primer consumption per layer - 60-80 g / m2.

- TU specifies the color of the applied pigments. Produced in accordance with technical specifications GF-031 - yellow.

Phosphogrunt

The name is a trademark of the Moscow company KrasKo. As you might guess, we have before us the so-called phosphating soil.

It reacts with the substrate and forms a thin layer of insoluble phosphates, which improves adhesion and prevents corrosion.

The chemical composition of the phosphating agent.

- A mixture of acrylic, formaldehyde and epoxy resins is used as a binder. It is logical to assume that the primer is intended exclusively for open air or industrial conditions: formaldehyde in a living room will obviously be superfluous.

- The working temperature range is up to +300 degrees.

- Due to its composition, the primer can be used with all types of heat-resistant and conventional paints. It can be used not only for metal: the manufacturer allows its use to improve the adhesion of the final coating on fiberglass or ceramics.

- The primer can be applied not only to the previously cleaned, but also to the rusty surface.

However: when applying a primer with your own hands, it is still worthwhile to first remove the layer and loose rust. The phosphating composition can change its chemical properties, but it will not change the spatial structure of the fragile oxide.

- Phospho-primer is diluted with acetone or toluene.

- Thanks to organic solvents, the composition can be applied at negative temperatures down to -10C. Drying time for a single layer coating at +20 - no more than 30 minutes.

- The average consumption of the primer is 70-90 grams per square meter.

In the photo - Phosphogrunt packing.

This heat-resistant primer for stoves and fireplaces impresses with its heat resistance. An operating temperature of 1200 degrees is declared for it, which, you see, is very impressive against the background of the solutions described earlier. The composition of the water-dispersed soil is not disclosed by dealers; however, the colossal thermal stability suggests that the main binder in G-77 is heat-resistant silicone.

Primer application serves two purposes:

- Improving the adhesion of putties and plasters.

Useful: at high operating temperatures, you can forget about the usual gypsum and cement mixtures. A mixture of clay and sand is used to decorate stoves and fireplaces; often ... skim milk is added as a binder: the casein contained in it (milk protein, also known as fat-free cottage cheese) retains excellent binding properties even when denatured at temperature.

Plastering the oven with clay mortar.

- Strengthening the foundation... The resins contained in the soil penetrate into its pores and bind the surface layer of the material into a single whole.

Pipe painting instructions

Any average person can disassemble all the subtleties of how to paint heating pipes in an apartment. To do this, it is not necessary to be a professional builder, it is enough to clearly follow the step-by-step instructions.

Preparatory stage

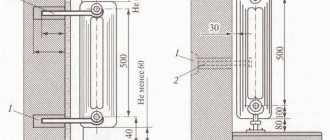

Before proceeding with the main manipulations, it is important to first prepare the surface for subsequent painting. It is important to take into account the initial state of batteries, radiators, devices:

- A new battery, radiator, another heating element, without any coatings, requires cleaning from dust, dirt, degreasing and priming. High-quality processing, primer promotes good adhesion of enamel to the surface of communications.

- If the heating elements are already painted, then the coating must be removed or sanded.

- A damaged surface, the presence of cracks requires a special approach. You will need to remove it with a spatula and a hair dryer. To do this, apply a special gel-like solvent remover with a brush, after a while remove the layer with a spatula or metal brush. Be careful to avoid excessive force to avoid damaging delicate joints.

- Rusty communications are the most difficult option. You will need to remove the entire damaged layer. To do this, you can use chemicals, a spatula, sandpaper. Then degrease with white spirit, prime.

Before painting, the pipes must be cleaned

Painting process

Highways are painted at room temperature, the heating in the house must be turned off. Professionals advise to apply the dye from all sides (front, back, side). Unpainted places will soon begin to rust. Step by step:

- Step 1. We put a protective film (paper, polyethylene) on the floor under the entire highway.

- Step 2. We select a tool for applying the coloring layer: a brush, a roller, a can, a spray gun or a spray gun. The most popular use is a brush with non-stiff bristles. It is better to purchase 2 brushes: a classic straight one and a curved one with a long handle for problem areas.

- Step 3. Apply the enamel carefully in two layers. The first thin layer should lie evenly over the entire surface, we begin to paint from top to bottom. After drying, we fix the result by reapplying over the entire surface, paying special attention to pronounced gaps.

- Step 4. After completing all the work, we leave the heating communications alone until completely dry.If you turn on the heating system, ignoring this point, then the enamel will bubble, irregularities will appear, and will begin to slip.

Heating pipe painting process

Radiator painting process Pay attention to: Paint for flowers: varieties and methods of painting

General information

Bumper finish with alkyd primer

Alkyd primer is the most versatile surface treatment. It can be used both on a metal base and on wood or concrete and even under a laminate. Forming a strong film at the application site that dries within 24 hours, it creates excellent adhesion conditions for the base and finishing material. Having the property of strengthening surfaces, the alkyd primer does not allow putties or paints to flake off. But an alkyd-based polymer primer can be used for external and internal work. It is applied before gluing wallpaper, before puttingty or applying paintwork. On such a primer, you can apply not only alkyd compounds, but also various nitro paints and enamels. Latex or acrylic paint also works well on a substrate treated with such a composition.

If the alkyd mixture is applied in outdoor work to various metal structures, then it is also called an anti-corrosion primer, as it protects against these negative manifestations.

Important! Do not use an alkyd compound on putty or plaster. In general, it is not used for all crumbling substrates, the only exception is concrete.

Alkyd primer has the following varieties:

| View | Intelligence |

| Glyphthalic | Moisture-resistant mixture that can be used for indoor and outdoor use. Suitable for concrete surfaces, wood, glass and metal. The material contains a coloring pigment and a filler |

| Perchlorovinyl | For outdoor use only. Dries within 1 hour and is applied to concrete, metal and plastered surfaces |

| Polyvinyl acetate | Dries in 30 minutes and can only be used with alkyd paint |

| Polystyrene | Can be used for wood and outdoor use only. Toxic, but can be used under laminate flooring |

| Alkyd-urethane primer enamel | Moisture-resistant mixture that is used for metal surfaces |

Primers for MDF and OSB boards

OSB primer

Primers for wood are also furniture compositions that are used before painting products from MDF, OSB boards and plywood. I want to say right away that, unlike conventional primers, the primer for plywood, MDF and OSB is colorless, it is necessary to preserve the texture of the painted material.

Plywood, like other materials, is covered with a layer of primer to acquire the properties of protection against deformation and destruction. In addition, the soil protects against cracking, and the antiseptic component protects against mold and material decay. MDF panels are widely used for the manufacture of furniture products, since the material is inexpensive, and thanks to painting, it acquires the properties necessary for it. Priming and painting MDF has the following advantages:

- MFD becomes resistant to temperature changes - if the panels are used in the kitchen, then it is allowed to put hot dishes on them

- Dyeing creates a flawless and unique look. Due to various additives, the panels can have a pearlescent sheen or metallic

- After painting, MDF products remain an environmentally friendly material

If you do not know which soil to choose, then remember that polyurethane mixtures or enamels are used for such purposes, they are also used under linoleum. For OSB slabs, choose soils that are suitable for wood, have antiseptic properties and protect against moisture. Since OSB boards have properties to swell when wet, the soil must be water-repellent.For OSB, you can choose a glyphtal primer or a varnish-based one.

Since I have repeatedly carried out repair work with OSB, I would like to advise you to prime the ends of the slab even before installation. This is due to the fact that such places are the most vulnerable to moisture.