What is better foil foam or basalt insulation

The building materials market is full of types of insulation. They have their own characteristics, positive, negative sides.

General parameters of thermal insulation:

- Weight. The insulation should not weigh much, because, when mounting it on the structure, there should be no weighting.

- Thickness. The thinner the material, the more space is left in the room.

- Low thermal conductivity.

- Moisture permeability. The material should absorb moisture as little as possible.

- Noise isolation. Does not pass sounds from the street.

- Environmentally friendly material. Should not emit harmful substances.

- Easy to install.

Comparing basalt insulation and foil-clad penofol, you need to compare their characteristics.

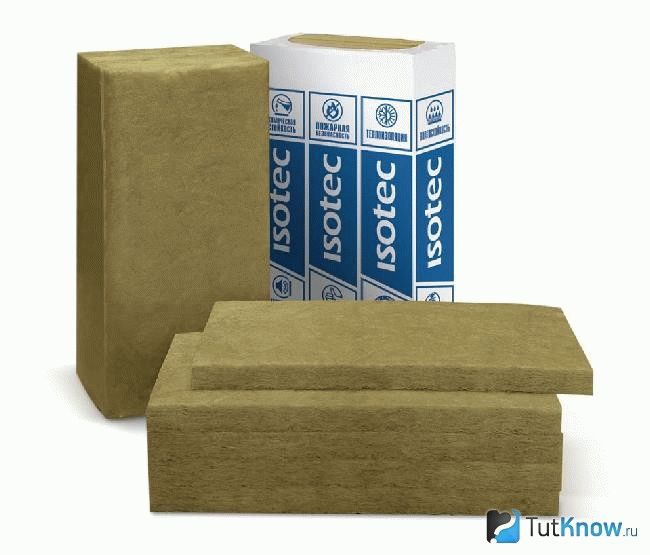

Basalt wool

Produced from rocks of volcanic origin. It does not burn, has good sound insulation performance, and does not lose its qualities over time. It is completely safe for health.

Penofol - application

Produced from polyethylene foam with a porous structure. A layer of foil is glued on top as a heat reflector. This heat-insulating material is several times thinner than basalt wool. In addition, it reflects heat and practically does not absorb it.

What kind of insulation to choose depends on the budget for insulation, as well as personal preferences.

Secret. How to glue foil insulation to the wall.

Kind. Somehow I ran into a problem to glue the foil insulation to the wall. There is a lot of information on this in the Internet. But how and with what glue I did not try - in the end, nothing happened. Everything fell off. And the secret is simple. The insulation is covered with a thin plastic film, to which the glue does not stick (to a smooth surface, it has nothing to catch on) The manufacturer did not take this into account, or did not want to. It is enough to make the places for applying glue, rough, that is, sanding with sandpaper. You can use any glue, as well as polyurethane foam. And you won't need a stapler, nails, dowels, military strategic poisonous fluids - as mentioned in many construction forums. Good luck to everyone, go for it.

Small observation. But many do not see the little things. Hence the big problems.

It is enough to make the places where the glue is applied, rough, that is, sand it with sandpaper.

And most importantly - why spend money on this and other materials and glue something that will not bring any effect.

jekasus wrote: And most importantly - why spend money on this and other materials and glue something that will not bring any effect.

Apparently the vehicle just has material for free and time must be killed.

jekasus wrote: And most importantly - why spend money on this and other materials and glue something that will not bring any effect.

Yes, I agree with you. But this effect is not in the preservation of heat, it is enough, water heating comes from the house. If you take a closer look at the last photo - this is an extension of the future greenhouse from the north side, of course there will not be enough light for the plants. Reflective paint is out of stock. So the foil serves to reflect it. Even with artificial lighting, when entering the room at night it is not possible to look, the eyes are cut by a bright, dazzling, iridescent light. (Checked, a few light bulbs are enough) That's a plus for energy saving. In general, the issue was not considered on the construction of greenhouses and where, why should the foil insulation be glued. The meaning of how to glue!

How to fix isolon to the wall

Kind. Somehow I ran into a problem ** to glue ** foil insulation to the wall.In the ** Internet ** there is a lot of information about this. But how and with what glue I have not tried - in ... - photo- Forum Mastergrad

How to attach insulation to the ceiling

- Choosing a heater for your home

- We fix the insulation to the ceiling

A country house always requires additional insulation, because there is much less heat here than in an apartment. That is why you need to prepare properly for the onset of cold weather.

For those who live in private houses, you should take care of the insulation of the ceiling.

In this case, it is necessary to insulate not only the floor and walls, but also the ceiling.

You need to know the process of installing thermal insulation to the ceiling, as well as have an idea of what material to choose for this. So, what to fix to the ceiling and how to do it yourself?

Choosing a heater for your home

Before you start insulating the ceiling, you need to decide on the material.

First you need to choose the insulation material, with the help of which the thermal insulation process will be carried out. It is proposed to consider several of them, since each of them has a number of both positive and negative sides. This is quite natural. The main selection criterion is the individual characteristics of the house, as well as climatic indicators.

Mineral wool is the most popular material for thermal insulation. Minvata is able to withstand temperatures not lower than - 35 ° C. For most regions, this indicator will be sufficient, but there are also areas where the thermometer drops significantly below this figure. In this case, you will need to look for something other than mineral wool. For example, expanded clay concrete tolerates severe frost.

Those who choose mineral wool for insulation and are going to fix it to the ceiling should know a little about this material. It is made on a mineral basis from artificial fiber. The composition of mineral wool includes dolomite, limestone and basalt. Mineral wool is a fairly strong and durable material.

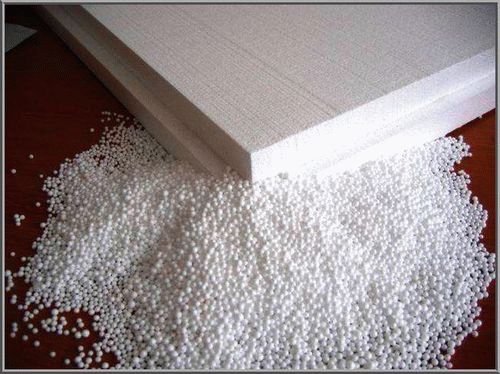

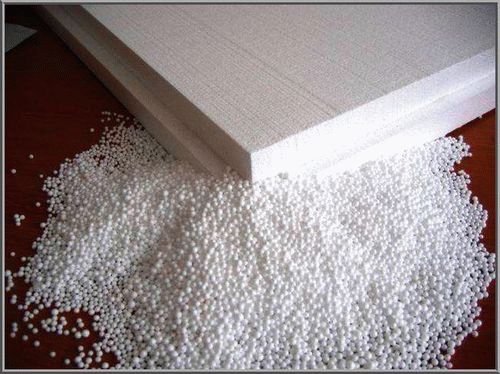

Polyfoam is another contender for the role of insulation for the ceiling. This insulation is made of foam, made, in turn, of plastic. It attaches well to almost any surface and is easy to handle. In addition to heat-insulating properties, it also has good sound insulation.

The next material is foam, which is a liquid foam. It is inexpensive, but problematic in installation. Here you cannot do without the help of a master. It is usually used to insulate large surfaces.

The most environmentally friendly material is ecowool made from cellulose.

Recently, some people prefer to use ecowool, which, as the name implies, is very environmentally friendly. It is based on cellulose, and ecowool itself is thin wood fibers. Ecowool is obtained in the course of waste paper processing. This insulation is installed with the help of a wizard. It is very difficult to do this on your own. It is assumed that soon ecowool will overtake mineral wool in popularity.

Slag wool has recently been considered not a very good material. And this harmful insulation has a lot of competition.

Which of the following to choose and what to fix is everyone's business.

You should pay special attention to mineral wool, since it is the most popular material for insulation, besides, its cost is quite low, and all work and fastening can be done easily and without problems on your own.

We fix the insulation to the ceiling

In order to do this type of work, you will need the following tools and materials:

- knife;

- hacksaw;

- a hammer;

- screws, screws, nails;

- Bulgarian;

- electric drill;

- screwdriver;

- mineral wool;

- construction stapler;

- wood planks (or drywall) and beams;

- polyurethane foam.

A frame from a bar should be built on the ceiling, then begin to insulate.

First of all, it is necessary to carry out all the necessary measurements of the existing surface. Further, the so-called formwork is made around the entire perimeter of the ceiling. This is a kind of ceiling frame. By the way, it should be borne in mind that after warming, the ceiling will lose a little in its height.

The frame must be made of wooden beams and fastened with screws and a drill. It turns out a kind of niche, into which mineral wool is then laid. It is better to choose rolls of mineral wool. For reliability, in the necessary places, the canvas is fastened using a construction stapler. All seams are carefully sealed with polyurethane foam.

If possible, it would be nice to install another layer of thermal insulation. Everything is done according to the already described algorithm. The process of warming is completed by processing the seams with polyurethane foam.

Now the formwork and the mineral wool in it are closed using the selected material. Let it be drywall, although there is no fundamental difference when choosing. Drywall is attached to the frame with self-tapping screws or screws. The thermal insulation for the ceiling is ready.

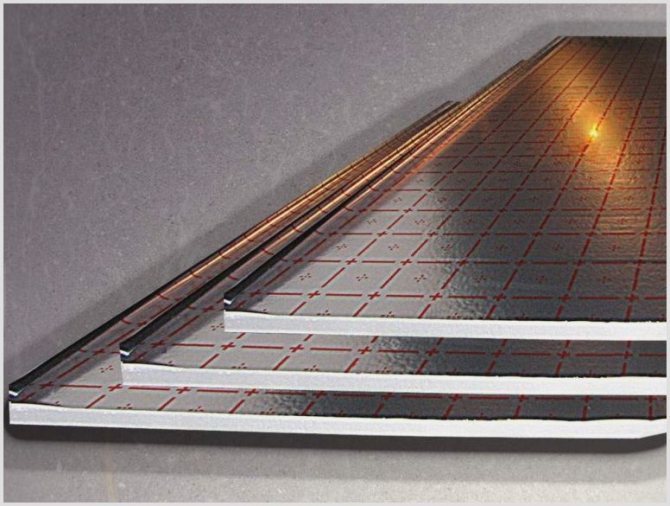

Types of foil-clad penofol

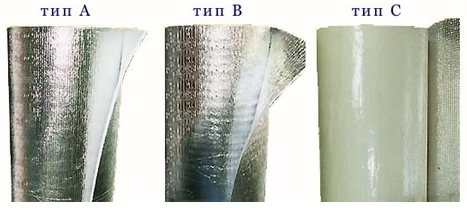

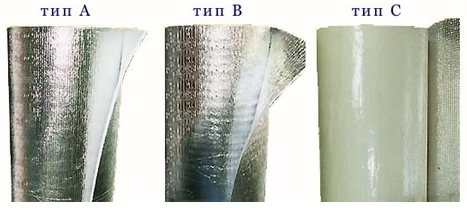

There are 3 types of foam foil on sale. Each is labeled with Latin letters, they indicate the packaging.

Folgoizolon for outdoor and indoor use

TYPE A - heat insulator with polymer, foil layer on one side. Produced in different thicknesses. Applicable for integrated insulation of buildings inside. Together with this insulation, glass wool is used. They also produce perforated foil insulation. It is mounted in log houses in order for the tree to "breathe".

TYPE B - the foil is located on both sides. This is the maximum protection against heat loss. Penofol type "B" is used for thermal insulation of the attic, supporting structure, basement, floor. As well as insulation of the pipeline, heating system.

TYPE C - on one side there is foil, on the other - a thin layer of glue, protected by a foil. Self-adhesive foam foam is easy to install without spending a lot of time. For installation, they are cut into pieces of the required length and glued to the prepared surface.

TYPE R - full match to type "A", but with a pattern on the foil. Used as a decor for walls in the room. And also with multilayer insulation, creating an air gap.

TYPE ALP - high reflectivity. This insulation is used in agriculture, for example, to insulate incubators or buildings for calves.

The NET type is analogous to the B type. Produced in a narrow roll or in reels. They are used for pipeline insulation.

2000 Type C - reduced performance. The adhesive layer is of poor quality and has poor adhesion.

Insulation from below

This type implies the process itself directly from the bottom of the ceiling itself. For him, materials made in rolls or beams are ideal.

This method is considered more difficult and labor intensive. The process itself includes the following stages of work:

- It is necessary to make fastening with the help of a filing. If it was not possible to carry out it, you can build up beams on which the installation will be carried out in the future. If it is done using foam, then the process itself is greatly simplified. It can be simply glued to the ceiling. But after that, to increase reliability, it should be additionally fixed with dowels intended for these types of work. After the installation process, the ceiling itself, if its condition requires it, can be decorated by painting or using putty.

Thus, you can carry out the fastening with your own hands. The main criterion is the presence of either a suspended frame or specially made mounts.

With a low ceiling height, it is better to opt for foil-clad polyethylene foam. The profiles on which will subsequently be attached can be made of metal or wood.After the implementation of the insulation, if desired, the ceiling can be decorated in various ways, the main of which are painting or installation of a stretch ceiling.

Today there is a huge selection of insulation materials that can retain not only heat in your home, but also provide good sound insulation, which is quite important in multi-storey panel or brick houses.

- Date: 05-02-2015Comments: Rating: 15

Warmth and comfort in the house is one of the first tasks that must be solved for a comfortable life and preservation of health. In the modern world, where the daily rise in the price of energy resources is by no means new, the issue of insulation of living quarters is an acute issue.

The scheme of insulation and sound insulation of a wooden ceiling.

To ensure the preservation of heat from below, "warm floors" are used, in order to prevent it from leaving through walls and windows - plastic structures.

But it is extremely important to pay attention to the loss of heat through the ceiling. This is due to the fact that more than 30% of all heat is concentrated at the top of the room. If the appropriate thermal insulation is not observed, this will inevitably lead to settling condensation, an increase in the amount of moisture and, as a result, the formation of mold.

How can you avoid this, you ask? Is it possible to insulate the ceiling with your own hands?

Of course. In addition, it is quite simple to do it, while not spending a lot of effort and material investments. You just need to sort out the question of how to fix the insulation to the ceiling?

Before examining the issue of fixing the insulation to the ceiling, you should pay attention to such an important aspect as the types of insulation. What is the material with which you will insulate your ceiling? After all, only having decided on this issue, you can purchase it and engage in fastening.

Answers from experts

Grandfather Ay:

ordinary food will not work - it is metal and if it can "reflect" some part of the radiation, then part of the convective flow will still heat it up, and since aluminum is an excellent conductor ... Insulation is needed under the foil! Walls need to be insulated by themselves e.g. .termoplex /korund.php?table=korund

*:

Try to glue it with your saliva ...

Marek Black:

You'd better insulate with pinoplast from the outside. and the floor can be insulated. You talk to those who do this.

Angry Electrician:

I think you need to consult in the store in the building or try the moment of installation

Novoe:

First, prime several times with bentonite, and then glue, but better with a heat-insulating layer, at least on PVA, but there is, as a self-adhesive, it is sold on a heat-insulating substrate.

Sergey Burmasov:

think maybe iron galvanized or better stainless steel because foil is weak

nina ilyina:

oh, if you stick it crookedly, half a magnifying glass, with a focus like in ancient greece they burned a fleet)

albert belkov:

I use Termoizol - foil on foam, it is easy to work: I heat insulate steel baths - they are no worse than cast iron ones, warm. And food can be glued to cardboard with slots for hooks for easy insertion.

Yuri Martysyuk:

Buy penofol, sold in different thicknesses. It can be self-adhesive, but if not, try double-sided tape!

Chuck Kazemerchak:

If the foil sticks to the glass with egg yolk, then it will definitely stick to the concrete

Dmitry Nizyaev:

Double-sided tape. He then oh? He will hold, but nothing else is required.

egor ag:

Why insulate at all? Never did it. Insulation only retains heat, but does not generate. And overnight, no insulation will keep the engine warm. Moreover, the hood is not even the very surface of the engine.

DoctoR:

Bolts or rivets

Pavel Voronin:

but why bind at all, just put in, when you need to twist and remove

zheka-zloy:

narrow stripes and reinforced tape around the perimeter, see it’s all right ... and the discarded material is used as a reflector for radiators in apartments (it is considered to be the type that increases efficiency when heating in winter)))

kurt:

called FOLGOIZOL

Engineer:

More sturdily, formos / produkciya / klej_adgezivy / klej_sprei-3m / 80-scotch-weld / If you glue-unstick, then lenta-plus m / catalog / kley / 49

kenny uncharted:

the material is penofol, the trouble is that in the collector area it will certainly melt.it is glued with liquid nails of the installation firm for products made of pvc and polystyrene.

How to glue Isolon to concrete

how to glue isolon to concrete

In the construction of industrial facilities and residential buildings, modern building materials are used to meet the most important building requirements for heat and sound insulation. Such material, for example, is isolone or expanded polyethylene foam. The use of Isolon allows to reduce construction time and heating costs due to the excellent thermal insulation properties of this material.

Izolon has the following characteristics 1. Low density (light weight) and at the same time good thermal insulation properties. A 10 mm layer of isolon can replace a 15 mm layer of mineral wool, 45 mm of wood or 150 mm of brickwork.

This reduces the weight of structures and helps to save useful space, 2. Freons and other substances hazardous to humans are not used in the production of isolon. Izolon is non-toxic, does not affect the skin, and does not emit harmful substances when applied. Has a hygiene certificate, 3.

Izolon is a chemically inert material, organic solvents do not act on it. Isolone can be combined with other building materials (concrete, gypsum, cement, lime, wood). It practically does not absorb water and steam, therefore it is resistant to decay, mold and aging, 4.

Excellent shock-absorbing properties due to flexibility and uniform cellular structure. Izolon is used as a substrate for carpet, laminate, linoleum or parquet. Izolon sheets are used to separate adjacent walls, if the adjacent walls are subject to movement or vibration, 5. The operating temperature range is from -60`C to + 75`C, and if there are no mechanical loads, the operating temperature increases to + 100`C. Except for special isolon with extinguishing additives, isolon is a combustible material. But at temperatures less than + 140`C, harmful substances are not released from the isolone, 6.

Izolon is produced in different thicknesses and densities (with different foaming coefficients) and is supplied in the form of rolls, sheets, tape or blocks. This significantly increases the possibilities of using isolon in construction. Depending on the production method, isolon is subdivided into crosslinked (when molecules are crosslinked, a reticulated molecular model is formed) and uncrosslinked (there are no chemical bonds between polymer molecules).

A cross-linked isolon has improved characteristics in comparison with a non-cross-linked one. one.

For sound, steam, heat, waterproofing of walls, foundations, ceilings and roofs for country houses, cottages, garages, 2. As a seal for slate, ribbed metal roof or tiles, 3. Isolone tapes with an adhesive layer seal the joints of windows and doors, connections between the frame and glass, protect from dust, moisture and noise, 4. Strips of isolon can be used to insulate pipes for cold and hot heating, as well as ventilation pipes, 5. Isolon with a polymer metallized film is used as a heat-reflecting screen to protect against heat loss through the radiator sections of the walls. When using a combined material, a double effect is obtained.

Due to the metallized film, up to 90% of the heat emitted by radiators or other heating devices is reflected back into the room. Isolon's big advantage is its ease of use and installation. P It is easy to cut, can be glued to the surface with adhesives (pre-glued surfaces must be cleaned of dust and degreased).

To attach to a smooth surface, use screws, strips, furniture staplers. Use a building hair dryer to connect the joints. Isolon is attached to curved surfaces with double-sided mounting tape.

Thus, when using this modern material, you can significantly reduce the construction time of heating costs.

How to glue Isolon to concrete

How to glue Izolon to concrete How to glue Izolon to concrete In the construction of industrial facilities and residential buildings to ensure the most important building requirements for heat and sound insulation

Mineral wool

Mineral wool is one of the most commonly used insulation materials

The main and most popular raw material for insulation is mineral wool, which has the largest set of positive qualities. It consists of textile fibers assembled in blocks or rolls. But the best performance properties are possessed by cotton wool, which is made in the form of a track. Minvata is easy to attach to the ceiling surface, and it also has excellent soundproofing functions.

Let's take a closer look at how to attach mineral wool to the ceiling. Installation is carried out using dowels with a wide head. Self-tapping screws and adhesive tapes are used as additional fasteners. In addition, you will need: a tape measure, a sharp knife, a stapler, wooden slats, a metal profile. Installation of mineral wool on the ceiling takes place in the following stages:

- measure the dimensions of the ceiling with a tape measure;

- prepare sheets of mineral wool in an amount corresponding to the size of the ceiling;

- holes are drilled in the ceiling surface for plastic dowels;

- they install metal profiles to the base;

- prepared sheets of mineral wool are laid on the profiles;

- the structure is fixed with dowels;

- to support the mineral wool, wooden slats or wire stretched between the ceiling beams are used;

- the remaining slots are sealed with polyurethane foam.

The mineral wool is fixed with wire

Ceiling insulation with mineral wool has a number of advantages:

- the material is quite environmentally friendly;

- does not cause allergies;

- has a long service life;

- does not deform;

- it is characterized by fire safety, therefore, mineral wool is suitable even for warming a sauna;

- has a high vapor permeability.

Before fixing mineral wool to the ceiling, it should be borne in mind that it must be placed close to the ceiling, but at the same time, possible deformation should be avoided. To extend the life of such a heater, it is necessary to cover the ceiling with an anti-fungal agent.

Read more in our article on how to insulate the ceiling with mineral wool.

Best Answers

% username%:

Pat doesn’t stick to anything at all, you need to accept this

Roman Shved:

double-sided tape

Dmitry Dved:

there is a special adhesive foam like Penoplex in building stores, but not Penoplex, it is specially for this. Cylinders of red (more precisely, cyan) color. I bought cylinders for a pistol with a capacity of 750-800g in Castorama. I don't remember the name, it can be used as glue and as foam. Dissolves with foam cleaner. On the packaging it is indicated that before applying the foam, it is worth sprinkling with water from a spray bottle. Water does not improve adhesion, but is a catalyst for hardening.

Vladimir Nikitin:

88 (such glue ... ask the shoemakers)

Useful video

https://youtube.com/watch?v=RgKvM3-JFRU

Penofol was bought to insulate the loggia. How can you reliably glue penofol to a concrete wall so that it sticks?

Do you want to be insulated from the inside? You can use penofol of all three types "A", "B", "C"

It can be glued both on the mill itself immediately and on insulation. In this case, ceresite, dragon or titanium glue is used.

But it is better to leave a gap (air), such insulation improves air exchange and prevents condensation from accumulating.

The mounting method is as follows.Rails (lathing) are attached to the wall and penofol is attached to them with a stapler. I advise you not to leave penofol as a finishing layer, but to cover it with panels or drywall.

Can be glued with glue from the "liquid nails" series, for example, "Moment-Montage",

There are "liquid nails" of this brand for wet rooms (baths, saunas), there are for outdoor, for indoor work.

Also consider the material of the surface (metal, brick, concrete, etc.).

In general, the very idea of gluing penofol is not entirely correct.

If some air ducts are insulated with penofolm,

If the wall is insulated, then penofol is attached with an air gap (up to 2 cm, this is enough), that is, at the beginning of the crate, then penofol, fastening with brackets (you need a stapler), then counter-crate and finishing finishing material.

The joints are glued with foil tape,

It is not necessary to glue penofol at all, it is fixed differently, without an air gap there is no benefit from it.

On the loggia you need penofol type "B", this is penofol with double-sided foil, one layer of foil (do not forget that penofol is reflective insulation) will not release heat from the room, the other will not allow the sun's rays to overheat the room in the summer (this is important for the loggia ).

Penofol type "B" is not glued, it is attached with a gap on the staples (see above).

In your case, the glue method will not work, just spoil the material and do not insulate the loggia, fix the penofol according to the technology described above (crate, gaps and so on).

Choosing exactly the glue method for strengthening penofol on insulated surfaces, you will do the right thing, since it is technologically uncomplicated, it does not require professional tools and skills, the least costly in terms of money / time

One thing is important: take into account the bearing capacity of the glue in order to reliably, having determined the maximum weight of the coating, to attach it. But since foil-clad penofol (and its analogs too) is a very light material, the main requirement for glue is its adhesion

This is the name given to the ability of the adhesive to penetrate the fine pores / irregularities of the material, providing adhesion to it. Any material on an organic polymer (including penofol) has low adhesion if it is not porous. Therefore, it is clear: for gluing penofol, water-based adhesives are absolutely useless. The composition should contain an organic solvent, it kind of "dissolves" the surface a little, thereby increasing adhesion.

And since absolutely universal solvents have not been invented, it is necessary to look for a special glue for penofol. Adhesives, called "universal" most often glue everything, but badly. Or they are incredibly expensive.

Insulation of the ceiling with stone wool

- Joint cream for arthritis and arthrosis - Arthrade

- Means Bioliposactor abdomen for weight loss in the abdomen and hips

- How to enlarge breasts by 2 sizes with Upsize cream at home

Insulating the ceiling with stone wool is an inexpensive way to prevent heat leakage through the ceiling by installing it from inside or outside the room. The quality of work depends on competently performed operations, therefore in the article we will consider the rules for placing and attaching an insulator to the surface in various situations. Using our recommendations, you can avoid unnecessary financial costs and common mistakes when insulating.

Features of thermal insulation of ceilings with stone wool

Stone wool is a fibrous insulator made from basalt. To improve the characteristics, various substances are introduced into its composition, including hydrophobic ones. The material is rather loose, saturated with an inert substance that does not allow heat to pass through.

- To avoid skin irritation, wear thick, long-sleeved clothing and gloves. Wear goggles and a respirator to protect your eyes and respiratory system. Change after work.

It is often said that vata is very dangerous, but this statement is not true.Modern technologies completely isolate the coating from the living space, and it will not bring any trouble to anyone.

Advantages and disadvantages of thermal insulation of the ceiling with stone wool

The fibrous material possesses unique characteristics, due to which it is considered the best among the products for similar purposes.

- Very low thermal conductivity, which creates a comfortable indoor environment.

Users should be aware of the problems that sometimes arise when using a room insulated with cotton wool:

- Unscrupulous sellers can sell a low-grade product with a high percentage of toxic elements.

Advantages and disadvantages of the method

Insulation with foil has a number of features and a minimum of negative sides. Benefits:

- Foil reflects heat. Thus, the heat stays in the house, from the back side, does not let the heat into the house in the summer.

- Increased durability.

- Partially applicable as a waterproofing material.

- Easy assembly, light weight, easy disassembly.

- Insulation keeps cold wind out. Isolates as much as possible from external influences. Does not lend itself to deformation with sudden changes in temperature.

- Blocks out noise from the street.

- Does not rot or mold.

- This material is thinner than others, but 20-30% more efficient.

- The insulation does not emit substances harmful to health and prevents the smallest irritants and allergens from getting inside.

- There is no rigidity, therefore, it cannot be covered with plaster or wallpaper on top.

- For fixing, special adhesives are required.

- Sometimes insulation with foil is not enough to insulate a room.

Despite the disadvantages, foil-clad material is widely used for various purposes.

Warm ceiling is a guarantee of health and comfort

- Insulation from below: how to fix

- Stages of work

Keeping your home warm is one of the top priorities for a comfortable and healthy life. A system of “warm floors” is used to retain heat from below, and various plastic structures are used to prevent heat from escaping through walls and windows. But it is especially important to eliminate heat loss through the ceiling. And because about thirty percent of the heat goes through the top of the room (due to the convection effect), and because the lack of thermal insulation leads to the formation of condensation on it (due to the temperature difference on both sides of the ceiling) and an increase in humidity in the room, which means to the appearance of fungus and mold.

Polyfoam has zero vapor permeability. In addition, this material is easy to install and a fairly budget option for effective insulation.

Fastening of insulation to the ceiling can be carried out both from above (from the attic side) and from below (in the room).

If for some reason it is impossible to insulate the ceiling from above, then for insulation from below the best option is to use the following non-loose (expanded clay, sawdust) materials:

- polystyrene (expanded polystyrene). It is produced in the form of squares measuring 1 × 1 m, with a thickness of 2 to 10 cm. It is non-hygroscopic (does not damp), which means that the thermal insulation does not change with fluctuations in the level of humidity. It is easy to fix with glue to the rough base of the ceiling, therefore it is also used as an intermediate insulation for suspended frames;

- mineral wool (glass wool, basalt wool, ecowool and other varieties). Supplied in rolls (carpet) and bales (blocks). In the roll type, one side of the mineral wool can be covered with foil, which increases the effect of thermal insulation. Fastening to the ceiling is carried out using a wooden or metal frame made of profiles. Cheaper than polystyrene with the same good thermal insulation. More environmentally friendly, as mineral fibers do not emit harmful substances. Possesses high fire safety and retains all its properties at temperature extremes. It is not subject to decay and is not a breeding ground for insects;

- foamed polyethylene foam - foamed polyethylene glued to aluminum foil. Available in rolls 100 cm wide and 1 to 20 mm thick. Often, thin insulation is used in combination with mineral wool to increase the power of the thermal barrier and protect against carcinogens that can come from certain types of wool. It is convenient to fix it with glue and construction fungi-dowels;

- polyplex. It is obtained from expanded polystyrene by extrusion (forcing through special forms of polymer melt). It is produced in sheets with a size of 60 × 120 cm with a thickness of 1 to 20 cm. It has a high density, and therefore is often used both as insulation and as a rough base for ceiling putty. Can be fixed with dowel mushrooms or U-shaped holders.

Insulation from below: how to fix

To create a frame from transversely and longitudinally located profiles, cells are made, attaching them to the ceiling with nails, dowels or screws.

For any insulation, either special fasteners or a suspended frame will be needed. The easiest way is to fill the space between the suspended and main ceilings with a thermal insulator. In this way, it is convenient to fix the insulation in high rooms. For rooms with a small space, it is more convenient to use penoplex or polystyrene, the sheets of which are glued to the ceiling with ordinary tile glue, and then fastening with special construction fungi-dowels is performed for greater strength.

Given the popularity of such insulation as mineral wool, in view of its durability, environmental friendliness, fire resistance and low prices, let us dwell on its ceiling installation in more detail.

Stages of work

Ceiling insulation scheme with mineral wool.

We use mineral wool in the form of slabs, wooden beams (metal frame can be used) and drywall sheets.

- A layer of waterproofing, any insulating material (film, glass beads, etc.), is attached with a stapler to the rough base of the ceiling. Cloths of the film with a stele overlap a few centimeters.

- The assembly of the frame, wood or metal, is fixed with a puncher and dowels.

- Laying of mineral wool: we glue the wool slabs to the ceiling using tile adhesive (provides quick adhesion of the ceiling and wool surface).

- On top of the insulation, we again lay the waterproofing material.

- We mount plasterboard ceiling sheathing using self-tapping screws.

Tools and materials other than cotton wool:

- knife, hacksaw, hammer;

- self-tapping screws, screws;

- grinder, electric drill, screwdriver;

- construction stapler (fix the film to the ceiling);

- waterproofing film, wooden beams or metal profiles, drywall, polyurethane foam.

For any owner who knows how to hold tools in his hands, insulating the ceiling in his house on his own is quite a feasible job. And realize your tastes, and save the budget!

The most popular type of insulation with foil for finishing from the inside Aluform

Bestizol or alufom is a bubble base, consisting on one side of aluminum foil (outer layer) and polyethylene (inner). Foil acts as a reflector for solar and heat rays. The polyethylene interlayer has a cellular structure and neutralizes sound waves and shocks. The advantage of this material is its low thermal conductivity.

You can use bestizol both in frost and heat. Due to its small thickness (1 cm), the material is used for hard-to-reach places:

- for winding ventilation pipes;

- pasting of air ducts;

- insulation of pipelines and other outgoing communications.

Where is the method of insulation with foil insulation applied?

Foil insulation reflects infrared rays, which are, in fact, thermal. But, you do not need to apply the material everywhere. In some places, it will not work as expected.

Basically, it is mounted at sources of thermal energy:

- heating devices - batteries, air heaters. The insulation is mounted on the wall with foil into the room;

- boiler, fireplace stove.

And also it is used when installing a "warm floor". The reflective layer will direct the heat in the desired direction.

Small rooms, where every centimeter plays a role. Here, thin insulation will be appropriate on the walls and ceiling.

In the attic. Here the insulation is mounted on the roof. Apply 2 coats to combat heat and cold.

In baths and saunas. Heating of the room is not constant, the foil material is suitable for such purposes.

Garages, hangars, outbuildings - an installed radiator or potbelly stove.

They also insulate heating pipes, air ducts, wells and wells.

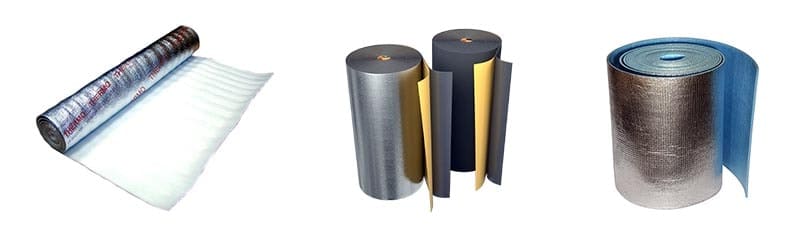

Features of thermal insulation with foam foam ceiling

Penofol is a multilayer synthetic material, the basis of which is a canvas made of foamed polyethylene foam. It is considered not quite an ordinary insulator due to its specific principle of operation. Outside, the sheet is covered with aluminum foil up to 10 microns thick to reflect heat in the direction where it is needed. The presence of a mirror surface retains 97% of the heat.

There are several modifications of the product, which differ in the placement of the metallized shell on one or two sides and the presence of a sticky layer.

The insulation has unique properties that prevent heat leakage through convection, conduction and infrared radiation. Other modifications do not have such a wide range of protection. It is able to replace several different insulators or one, but thick. For reference, the standard material thickness is 2-10 mm. There are more massive samples, but they are inconvenient to work with.

Penofol is used in household and industrial premises as the main and additional insulation. In addition to the main function, it solves the issue of vapor barrier. It is often used in baths, saunas, steam rooms.

The material cannot be fastened with nails or self-tapping screws due to a significant loss of reflectivity when the foil is damaged. Therefore, manufacturers recommend fixing it with an adhesive solution. The result is improved if there is a gap of 15-20 mm between the ceiling and the panel. Usually, after installation, a decorative ceiling is made under the panel, but in basements, garages and industrial buildings it is left “naked”.

Often used with other insulators such as foam. In such structures, the foam is first attached, then insulation is glued to it, and the whole "pie" is covered with sheets of drywall. The room will perfectly keep the temperature: cold does not penetrate from the inside, and heat does not come out.

What glue to use for gluing polyethylene composition

The easiest way to get a structural adhesive from a store is methyl acrylate. Its properties provide fast softening of polyethylene and its further adhesion. The glue also contains inorganic and organic acids and xylene, chromium anhydride and various additives.

The advantage of using a mixture is that no additional processing of the material is required. However, glue for polyethylene is quite toxic, so it is recommended to carry out work in the open air. The glue acquires its best properties at a temperature of + 35C, it is not afraid of moisture, but it is highly flammable. It is better to buy it in specialized stores so as not to run into a fake.

This technique allows you to obtain a strong, inseparable seam. Among the disadvantages of the method, it is worth noting the deformation of the edges of the product.

On sale are mixtures for combining polymers, similar in consistency to a thick paste. The kit includes an activator. After adding it to polyethylene glue, it acquires the required consistency, and it can be used in the near future.

We glue polyethylene - step-by-step instructions

To glue polyethylene, no special knowledge and skills are required. Even beginners will cope with the task at home.

The order of work is as follows:

- Clean the surface and degrease it. Some manufacturers argue that this step is optional, but experts still recommend taking a few minutes and never skipping it.

- Apply glue to the treated material. It will take only a few minutes to solidify, so the parts need to be attached to each other, without delay.

- Leave the glued polyethylene elements for several hours until the glue has completely set.

In general, this algorithm is similar to working with any glue. However, it is worth taking care of the use of protective gloves, since the glue can cause allergic reactions and is quite toxic.

It is more convenient to apply the adhesive with a glue gun, which can be charged with ready-made cartridges. The mixture of them is distributed evenly, so it is easy to achieve the desired dosage. If you are planning a large amount of work, this unit is worth the investment.

VIDEO ON TOPIC

How to glue foamed polyethylene

Foamed polyethylene has a porous structure, therefore it provides high-quality heat, steam and waterproofing.

Due to its low price, ease of operation and installation, it is actively used in construction. The most popular brands are Izolon, Vilatherm, Energoflex, Polifom, Temaflex.

If it becomes necessary to glue foamed thermal insulation, experts recommend two-component methyl acrylate-based adhesives. Such compositions are distinguished by high adhesion and are suitable for working with polyvinyl chloride, polyethylene, polypropylene. An example is the well-known Easy-Mix PE-PP adhesive from WEICON.

Usually, in order to achieve high results in gluing foamed polyethylene, the following procedures are additionally required:

- surface treatment by sandblasting or grinding,

- physical treatment, such as thermal fire,

- chemical treatment (usually the fluorination method is used).

But when using "Easy-Mix PE-PP", you can do without additional preparation and surface treatment due to the "primer" included in the composition, which changes the structure of the materials to be glued, after which they easily adhere.

The use of Easy-Mix PE-PP glue for working with foamed polyethylene both on a production scale and at home allows you to reliably and quickly bond materials, while it is ready to use immediately after opening the package, it is easy to dose and mix, as well as to apply.

The glue has a soft pasty consistency, is not afraid of conditional "aging" and retains its properties for a long time even in open areas.

Penofol ceiling insulation technology

The product can be laid on a floor made of any material, but the operations must be performed in a specific sequence. A deviation from the technology of installing foam foam on the ceiling will reduce the expected effect. In addition to insulation, you will need glue to fix the insulator and metallized tape at the joints. The rules for choosing the components of the insulating "pie" are described below.

Select consumables

For reliable insulation, together with penofol, they buy glue for fixing to the surface and adhesive tape for connecting parts of the canvas.

There are several modifications of penofol that can be used to insulate the ceiling:

- Type "A"

... Foil on one side only. It is usually used with other heat insulators as additional insulation. - Type "B"

... Foil film is located on both sides. It has proven itself well as the main heat insulator. - Type "C"

... There is a sticky layer that makes it easier to attach. - Type "ALP"

... The metal cover is protected with plastic wrap. Often they are laid on the floors of specialized premises - greenhouses, incubators, chicken coops. Foil-reinforced insulation is used in basements where it is not protected by a suspended ceiling.

It is not recommended to buy Penofol-2000. Its cost is low, but it retains heat poorly.

Before insulating the ceiling with penofol, check the quality of the product. Pay attention to factors such as:

- The goods must be manufactured in accordance with the requirements of TU 2244-056-4696843-98.

- The material is sold in rolls, the length of the product depends on its thickness.

- Tears and through holes are not allowed on the canvas.

- The winding of rolls is tight, without distortions. The goods are packed in plastic wrap, the edges of which are fixed with adhesive tape.

- Make sure the item is stored on racks or pallets at 20 degrees and 50 to 70 percent relative humidity. Storage of material closer than 1 meter from heating devices is not allowed.

Products must be labeled with the main data:

- Manufacturer's name;

- Basic dimensions;

- Date of issue and warranty period, usually the manufacturer allows storage of the material for no more than 1 year;

- Thermophysical indicators;

- Scope of the material;

- The protective layer on type “C” specimens should be easily peeled off.

For gluing to the ceiling, special or universal adhesives are used. The requirements for their composition are as follows:

- The tool is intended for indoor use. In the certificate of conformity for the glue, the degree of toxicity of the composition is indicated.

- Ability to withstand large temperature fluctuations.

- The solution contains antiseptic additives.

- Retains its properties for a long time.

- The composition does not contain solvents that negatively react to the material from which the ceiling is made.

- The tool takes into account the operating conditions of the room. For example, a sauna adhesive must be able to withstand heat and humidity. Such properties are possessed by MV-40. In residential premises, it is necessary to use a solution that is non-toxic and completely safe for humans. Usually they use “Universal” or “Express” adhesives, they dry quickly.

- Welcon Easy-Mix PE-PP 45 is intended exclusively for penofol. The only drawback is the complete drying time for 1 day.

For fixation it is also allowed to use the following solutions: 88Luxe; Nairit-1 (88-P1); Foam rubber-2 (88-P2); 88 Metal. If the area of insulation is large, take large packages of "Facade" and BOLARS substances. They are sold in bags from 25 kg.

To reliably connect the pieces of cloth to each other, the adhesive tape must have the following properties:

- The product is reinforced metallized with a sticky layer with a thickness of at least 20 microns.

- The instructions for use indicate its purpose - sealing and thermal insulation of the surface.

- The tape does not lose its properties when interacting with water and dust, it resists bacteria well.

- The tool has great strength and durability.

- Retains qualities in the temperature range of -20 + 120 degrees.

Gluing penofol to the ceiling

The use of glue allows you to significantly reduce the time of insulation of the ceiling with foam foam from the inside. This method is inexpensive, since it does not require special devices, and is easy to implement. The sample is very light, so there is no need to calculate the strength of the adhesive bond. If the insulator is used as the main insulation layer, choose a thick product.

Perform the following operations:

- Remove loose plaster and decorative coat from the floor. Make sure the surface is level, if necessary, rework it with plaster.

- Scrape off mold and mildew, dry the area with hot air and treat with an antiseptic.

- Wipe oil and grease stains with solvents.

- Seal cracks in concrete slabs with cement-sand mortar.

- In wooden ceilings, fill small gaps with caulk, large ones with tow and foam.

- Cover all wooden structures with special means to protect against fire and decay. Apply new protective layers only after the previous one has completely dried.

- Remove any sharp items that could damage the foil.

- Treat the ceiling with a primer that matches the adhesive. The fulfillment of this condition will allow you to create the most durable connection.

- Prepare an adhesive solution. If the material has a sticky layer, it is sufficient to remove the protective cover.

- Apply a thin layer of the mixture to the surface without foil, spread it evenly over the surface. Passes are not allowed. Spread the edges of the sheet very carefully. Allow 5-60 seconds to thicken the mortar for better adhesion.

- Press the canvas tightly to the ceiling (or other insulation) and gently smooth it until it sticks. Glue the joints with reinforced tape. If not, you can use a silicone sealant. It is forbidden to leave the joints untreated.

- When stacking, make sure that the sheets do not end in the corners of the room. Do not overlap the pieces. Also monitor where electrical wires and foil touch. Aluminum conducts electricity well, so check the insulation of the wires close to the insulation layer.

- Install the false ceiling.

Laying penofol on a wooden crate

This option is significantly more effective than simple gluing to a flat surface due to the presence of an air gap. The gap also allows air to move between the ceiling and the insulation and remove accumulated moisture, preventing condensation from forming.

The work is performed in the following sequence:

- Fasten penofol to the surface with 15-20 mm thick wooden slats. The distance between the bars is no more than 100 mm. Glue the joints of the sheets with reinforced tape. Make sure that the bottom of the rails is in the same horizontal plane.

- Fasten the second layer of foam foam from below to the bars using a furniture stapler. In this case, sheets with double-sided foil are usually used.

- Fit the second row of battens.

- Install decorative finishes such as MDF panels, plastic paneling, etc.

Combining penofol with mineral wool

When insulating in this way, most of the time will be spent on creating the lathing and aligning it in a horizontal plane. If the overlap is even, you can stuff wooden slats, if not, use metal hangers for plasterboard sheets.

The procedure for insulating the ceiling with penofol is as follows:

- Assemble a framework for the mineral wool slabs on the ceiling.

- Install fiber insulator into the cells.

- Fasten Penofol to the rails with self-tapping screws.

- Seal the joints of the insulation in any way.

- Sheathe the frame with plasterboard sheets.

- You can use two layers of penofol. Fasten the first with foil upwards, the second towards the room. This option will protect the mineral wool from moisture.

How to insulate the ceiling with penofol - watch the video:

[media = https: //www.youtube.com/watch? v = zx8WiU-qxvI]

Having studied the characteristics of penofol, we can conclude that the insulation of the ceiling with the help of this product helps to effectively protect the home from cold, moisture and external noise. Also, the owners will be pleased with the minimum cost of purchasing the components of the insulating "pie" and a slight decrease in living space.

How to mount penofol

Fasten penofol with the foil side inside the room. A greater effect of thermal insulation is created by an additional air gap with a thickness of 1-2 cm (with the help of a substrate - lathing).

You will learn more by watching the video:

https://youtube.com/watch?v=zx8WiU-qxvI

Adhesives of various formulations for foamed polyethylene may be ready-made or require on-site preparation. You must carefully read the instructions for the selected mixture:

the glue is applied in an even layer, paying special attention to the edges. Before sticking, it is necessary to wait up to 1 minute so that the composition has time to be slightly absorbed

This ensures a better manifestation of the adhesive properties. Attach the processed penofol to the insulated surface. Plates fasten the joint to the joint, but not overlap; the setting time varies depending on the characteristics of the glue (at least 15 seconds); smooth the surface of polyethylene foam, removing folds. Glue the seams, you can use foil tape; glued insulation in living quarters requires additional decorative finishing. The last layer of the structure (drywall or lining) is installed on the crate.

Nothing is more satisfying than a job done right and skillfully. If all the recommendations are followed, fastening the insulation will not cause much trouble.

can only be glued to double-sided tape

proven - holds firmly if you glue one strip of adhesive tape along the joints and put one strip of tape in the middle of the strip. if this does not appeal, you can try titanium glue for foam false ceilings (it is sold everywhere and is inexpensive). again proven - does not dissolve penofol and holds well. only more trouble - you need to press the penophone until it grabs

It is no longer possible to know who first came up with the idea to use expanded polystyrene instead of a building material for thermal insulation of buildings - initially its area of use was limited to furniture transportation and equipment, where it acted as a sealant. In this article we will try to figure out how to properly glue polystyrene foam to metal and concrete.

Life time

Since foil insulation has appeared relatively recently, it is not yet possible to establish an exact expiration date. However, conducting experiments, we can say that the material does not lose its properties for 200 years.

The service life of the installed insulation depends on the glue used. If the adhesive has passed the expiration date, then you can re-install it with the same heat insulator.

There are many heaters in the construction market. The choice is so wide that the question arises, which is better. To answer, you need to compare the characteristics of the thermal insulation material and the scope of application - street, living room, garage or agricultural building.