Frequent operation and shutdown of the heating boiler is a fairly common problem. It appears in different models of boilers from different brands. The main thing is to detect and eliminate it in time. We offer you to see why the gas boiler is often turned on and off and how to act if the unit does not work correctly.

Malfunction is often the result of improper installation, non-observance of operating rules. If you see that the equipment starts randomly turning on / off at a high frequency, you need to carry out diagnostics and repair. Otherwise, the service life of the equipment will be greatly reduced due to the rapid wear of the parts.

The most common reasons for incorrect operation of heating equipment

Even systems from leading manufacturers can malfunction for various reasons: Navien, Ariston, Bosch, Vaillant, BAXI and others. A common reason why the "Navien" boiler often turns on and off (like models of other brands) is incorrect installation. The system starts to turn on / off every 5-7 minutes or even more often.

If you see that the triggering occurs more often than normal, this is a reason to contact the master. He will be able to more accurately diagnose the problem and find the answer why the malfunctions occurred.

Here are a few more common reasons:

- The model has been selected incorrectly. For example, if a model is installed with too much power for such premises. We have repeatedly said that you need to choose units with a power reserve, but not too much. Usually, + 10% of the recommended power is sufficient.

- Circulation pump incorrectly installed. If the coolant does not move as expected, this can also cause errors in operation.

- Wrong temperature range specified. Modern models of heating equipment allow you to accurately indicate the temperature range that they must maintain - to prevent overheating of the room and its hypothermia. If the owner incorrectly sets these values and the temperature difference is too small, this may be the root cause why the boiler often turns on and off.

- A thermostat is not installed in the room, and the equipment operation is adjusted according to the temperature of the coolant. This solution does not give an objective assessment of the room temperature and the system does not work properly. It is more efficient and reliable to install a thermostat.

Most of these problems are not critical and difficult to solve. But if you do not pay attention to them, the system will wear out much faster due to incorrect operation and will require replacement. And this is already expensive. We will talk about these problems and their solutions further.

Excess power

A powerful wall-mounted or floor-standing gas boiler in a small room is overkill. First, it's expensive. And secondly, the power must be calculated accurately, and not in excess. Too much power is not recommended, as well as insufficient. If you cannot perform the power calculations on your own, we recommend that you contact a master who will do everything.

By the way: if you install a unit of insufficient power, there may be no problem of frequent switching on / off, but condensation will constantly collect in the chimney. Clogging and wear of system elements is accelerated. Plus, it will be impossible to fully heat the premises.

We have already written how to make calculations of the power of the heating system for a house. The choice is influenced by many factors:

● climate in the region by seasons; ● total area of heated premises; ● materials used for the construction of the house, and the quality of insulation; ● type, size of windows and doors, other.

Study in the instructions how often your boiler should be activated. These values differ for different models. You should be alerted not only by too frequent shutdowns, but also by its different frequency - after five minutes, after three, then again after five (the intervals may be different).

If your boiler has excess capacity, this is not a reason to buy a new one. There are several ways to resolve this issue:

- Install 4-way mixing valves in the hydraulic system. This is the most effective method, but also the most expensive.

- Lower burner. This method is only applicable if a multi-stage burner is installed.

- Install and connect the boiler. Thus, you will reduce the boiler output and at the same time provide the house with hot water.

What will happen if the boiler power is incorrectly selected

In cases where a mistake is made, and the choice of the boiler unit is not made correctly, you need to understand how to get out of this situation correctly. In fact, there are 2 options for incorrectly calculating the heat output of the heating unit.

The first is that the thermal performance of the unit in relation to the total heated area of the house is chosen very small in order to be able to compensate for the heat losses of the facility, and the second is when the heating unit is purchased with a significant margin. In the first variant, even when the device is operating at full load, the temperature in the rooms remains unacceptably low and does not rise. An emergency situation does not arise here, the only negative is the cold in the house.

In order to solve this problem, it is nevertheless necessary to calculate the required size of the heat output of the unit, and only then it will be possible to choose the right solution.

If the power deficit is not large, it may be compensated by additional insulation of external walls in the house with the replacement of window blocks.

If this is not enough, then you will have to buy a new device, as the main one for heating, and leave the first one for heating hot water and "standby heating", when outside temperatures are above zero or there are no residents in the house. In this way, a very efficient heating system can be obtained.

Much worse is the situation when the calculation of the heating device is performed with an excessive margin of thermal power. First of all, this will be the reason for a constant high and uncomfortable temperature regime in the premises, even when the burner is operating at the lowest load, everything in the house will be unbearably hot.

If the device has an automatic regulation principle, then the boiler cycle will begin, when the burner will constantly turn on / off. But the most dangerous phenomenon that occurs when there is an excess of power is that the device will generate several times more heat energy than the heating system needs and the water in the unit will boil, during which steam of large volume and bursting force is generated, which can lead to an explosion of the unit ...

Reasons for the private on-off of a gas boiler

It may happen that you just installed a new gas heating boiler at home, just set it up and put it into operation, and then it starts to turn on and off every five minutes. In fact, he must independently regulate his work, but too frequent disconnection and self-activation indicates that something is wrong here. In addition, this behavior of the heating equipment adversely affects the duration of the operating period, since the working parts wear out and the boiler fails.

There are several reasons why the heating boiler is often turned on. If you do not have enough experience, you should call a specialist for help, since blue fuel does not tolerate negligence. So, the main factors provoking the frequent turning off and on of gas heating equipment:

- The boiler was chosen incorrectly. Its capacity is designed for large rooms, and it was installed to heat a small room.

- Errors in the installation of the circulation pump.

- Temperature range not set correctly.

- The absence of a thermostat in the room, regulation of the boiler operation only by the temperature of the coolant.

The problem is not complex, but in some cases its solution is to replace the heater.

Problems with the ignition drive in the gas boiler

Boiler malfunctions

Typical problems with the operation of heating equipment:

- malfunction of the built-in pump;

- the heat exchanger is clogged;

- the three-way valve does not work.

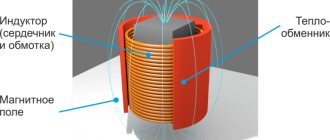

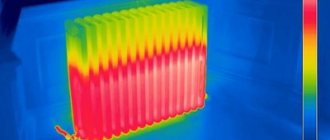

If the boiler is working, the radiators are cold, experts recommend, first of all, to assess the technical condition of the main heating element. More specifically, to establish whether the built-in device works. This detail is an invariable attribute of modern equipment and is designed to increase the efficiency of its work. Very often, after long periods of inactivity in summer, the pump can become clogged or covered with a layer of limescale. As a result, it is untimely to remove the heated coolant from the heat exchanger. The boiler is boiling and the batteries are cold.

It is strictly forbidden to repair such complex equipment as a boiler on your own. In this case, either a specialist from a service center is called to the house, or a repairman who has an appropriate certificate or permission.

Experts do not recommend using ordinary tap water as a coolant, since it is hard. Dissolved salts with an increase in the temperature of the coolant settle on the heat exchanger. As a result, the following problem arises: the boiler is working, and the batteries are slightly warm. Scale reduces the thermal conductivity of the heat exchanger, therefore, the water in the circuit does not heat up, although the heating element is constantly operating with excessive consumption of energy. You can fix the problem by changing the coolant and cleaning the heat exchanger. How to clean the heat exchanger correctly, the video will help you figure it out:

A double-circuit boiler heats water, but does not heat the batteries. Here you need to pay attention to the serviceability of the three-way electric valve. It is responsible for switching the bypass from heating circuit maintenance mode to DHW and CO mode.

Excess power

If you think that installing a powerful gas boiler in a small room is the right decision, you are wrong. The power of heating equipment must be calculated accurately, and excess power is as much a problem as its shortage. Of course, the installation of a boiler, the power of which is not enough to heat the house, is also bad, so you should carefully before buying heating equipment.

Note! The lack of capacity of the gas boiler is the reason for the accumulation of condensate on the chimney, due to which it quickly clogs up and wears out.

perform all calculations. If you cannot do this on your own for some reason, use the services of a professional.

The following parameters affect the determination of the power of a gas boiler for a private house:

- climatic conditions of the area;

- area of premises;

- what materials the house is built from;

- how and with what is the house insulated;

- what windows and doors.

In order not to calculate the value yourself, you can use a special program that will help you determine with accuracy what power the boiler should have in order for it to function well in your home.

Breakdown of the gas boiler mechanism

How to solve the problem

If you have already purchased heating equipment for your home, but its capacity is off scale, you need to look for adequate solutions to the problem. First of all, you should familiarize yourself with how often the gas boiler should be turned on. This parameter is not the same for different models. But if the installed unit turns off for five minutes, then turns on for three and then turns off again, it's time to take some measures.

- The optimal operating mode of the boiler, in which there is an excess of power, can be achieved by installing four-way mixing valves in the hydraulic system. This option is effective but costly.

- Lowering the burner. This is only possible if the burner in the device is multi-stage.

- Boiler connection to the boiler. This method will help not only reduce the power of heating equipment, but also provide the house with hot water.

Gas boiler connection diagram

Determination of the power of a single-circuit and double-circuit boiler is carried out according to different schemes. Experts recommend choosing boilers with the minimum power required to heat your home.

Note! An alternative to the mixing valve can be a thermohydraulic distributor. It is quite expensive, but it optimizes the power in the heating boiler, which allows not only that,

how to make the boiler turn on less oftenbut will also help reduce fuel consumption.

Boilers with automatic ignition.

The water circulation in the heating circuit is interrupted.

Due to the slow movement of the coolant in the heating system, the water in the heat exchanger overheats, and the boiler stops in emergency mode. The speed of fluid movement in the system can be affected by reduced performance or breakdown of the pump, contamination of the filter installed on the "return" of the heating circuit, incorrect operation of the three-way valve.

The performance of the circulation pump is reduced due to contamination of the turbine blades or internal cavity.

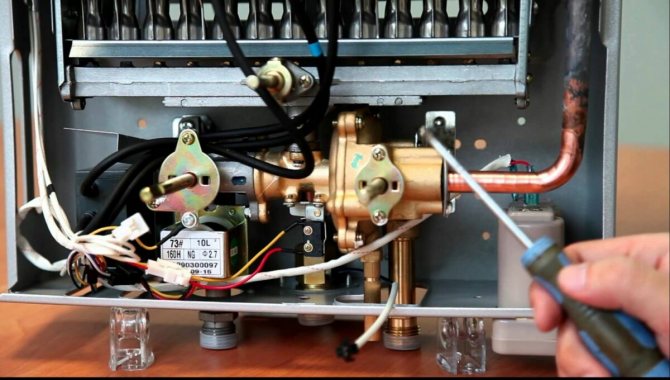

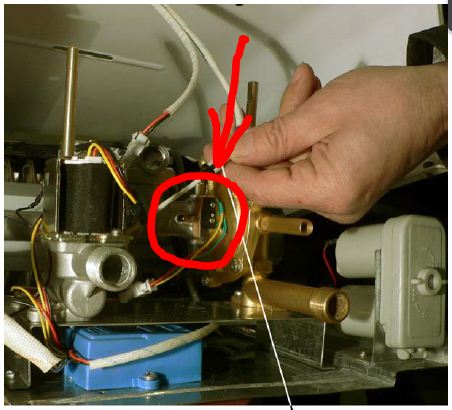

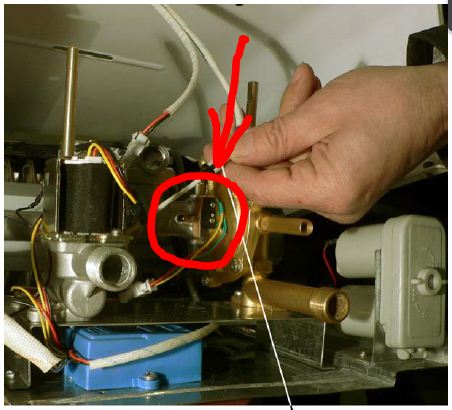

Photo 1 - gas boiler circulation pump module with automatic ignition.

To revise it, you need:

- Stop smoothly by moving the knob of the water temperature regulator to the extreme zero position and wait until the process is complete, disconnect the boiler from power.

- Dismantle the front part of the housing.

- Determine where to install the pump.

- Close the shut-off valve (No. 2, No. 3, No. 4, photo 2) of the supply, return, and cold water supply.

- Drain the boiler through the drain cock and leave it open.

- Loosen the pump fasteners until air enters the circuit to drain the residual fluid from the system.

- Dismantle the mount, power plug and remove the module (engine with turbine).

- Clean the blades, inner cavity and rubber seal of the mechanism from dirt.

- Assemble the pump.

- Open the cold water inlet tap.

- Open the make-up valve slightly to check the tightness of the hydraulic part of the boiler.

- Open the flow and return valves.

- Fill the system with water to a pressure of 1 bar.

- Turn on the boiler in recirculation mode to remove air.

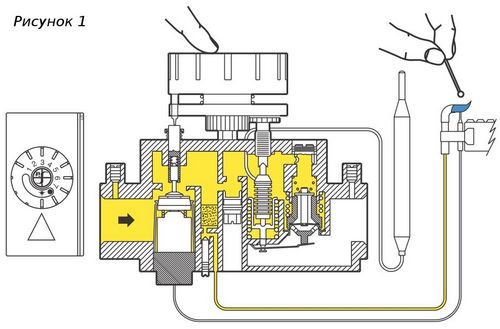

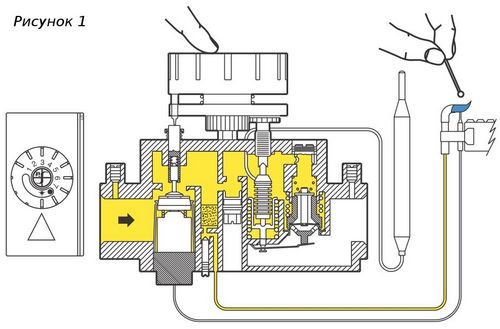

Photo 2 is an example of the piping of the heating system.

In boilers with electronic control, in the event of a pump breakdown, the corresponding fault code will be displayed on the dashboard, which is deciphered using the boiler passport or electronic catalogs posted on the manufacturer's website.

Checking and cleaning the filter:

- Stop the boiler smoothly.

- Using the taps (No. 1, No. 2) installed in front of the filter and behind it, shut off the water supply.

- Using the filter drain valve, drain the water from the isolated area.

- Unscrew the flask and clean the strainer.

- Collect all filter components.

- Open previously closed valves.

- When the system pressure drops, recharge the circuit.

- Switch the boiler on to the venting position.

Checking the three-way valve.

In double-circuit wall-mounted gas boilers, switching from heating mode to the position of hot water supply is carried out using a three-way valve. It consists of a servo (gear motor), stem, rubber seals, valve and body with inlet and outlet ports. A malfunction of this device can lead to the cessation of the circulation of the coolant and, as a consequence, the overheating of the heat exchanger is formed.

To check the condition of the three-way valve, it is necessary to smoothly stop the boiler and disconnect the system from power. Check the serviceability of the engine, and for this, connect the ohmmeter probes to the power terminals. If it shows 80 - 300 Ohm, then the engine is in good order, and if other readings (0 or 1), then it is faulty.

The three-way valve may not switch due to a jammed actuator gearbox or deformation of the valve itself. If a valve malfunction is detected, it is changed to a serviceable one, or it is subject to revision.

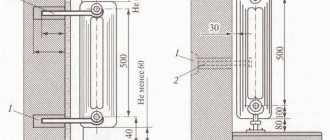

Incorrect installation of the circulation pump

The natural circulation of the coolant is not always effective, so the owners decide to install a circulation pump. It is especially important if heating of a two-story house is required. Appliances force water to circulate correctly through the heating system, ensuring that it works properly.

The pump must be installed in accordance with all the rules. Their violation can lead to malfunctions in the system, which will be the reason why the gas heating boiler is often turned on.

To install the circulation pump, you need to choose a place in the system where there would always be excess hydraulic pressure.

Violation of the integrity of the mechanism, the reason for the frequent operation of the boiler

Note! To avoid problems in the operation of the circulation system, entrust the installation of the circulation pump to professionals.

Two-pipe and one-pipe heating system: errors and their elimination

In a private house there are two pipe routing options: two-pipe and one-pipe heating systems. Previously, most preferred to install a one-pipe system, because it was believed that this was the most budgetary option. However, in this system, it is difficult to adjust the temperature of the heat exchangers as they are far from the boiler room. If in a one-pipe system the last battery remains the coldest (it is necessary to increase the sections), there is no return in such a system, therefore there will be no problems when the return of the battery is cold. Therefore, it often happens that some of the batteries are cold in a private house, since the coolant flows only through one pipe.

In the two-pipe wiring, there may be errors in the installation of shut-off valves, the boiler is incorrectly connected, the diameter of the bends is incorrectly selected. For these reasons, with a two-pipe heating system, the last battery may be cold.

Violations in the connection of heat exchangers:

- The boiler heat exchanger is clogged - a common reason, then it will need to be flushed with special chemicals.

- Incorrect installation of the hydraulics. As a result, poor circulation and low temperature of the coolant.

Now the reasons have become clear why there are cold batteries in a private house and why one battery is cold in a 2-circuit boiler. Some problems can be fixed on your own, in more complex cases it is better to contact a specialist. On our website you can find out why the battery is hot on top and cold on the bottom.

Installing a thermostat

Another reason for the frequent on-off of a gas heating boiler is that the operation of the equipment is regulated only by the temperature of the coolant.The water warmed up to the required temperature, the device turned off, the water cooled down, the boiler turned on. But the coolant cools down much faster than indoor air. Such management is not rational, as this increases fuel costs, it can be hot in the rooms, which, of course, will affect the comfort of residents.

The best way out of this situation is to install a room thermostat. The device is designed for automatic control of a gas boiler. The functioning of the heating unit becomes more efficient, it is possible to save on fuel. The system starts only when the room temperature drops, and it can remain at a level as a result of sunlight or crowds in the room.

The range of thermostats allows you to choose a model in accordance with your wishes and financial capabilities. The cheapest are mechanical products. They do not require special treatment, they are durable and reliable. It is much more difficult with modern programmers. These are devices that can be programmed, set certain options, set different temperatures depending on your needs.

Reasons for frequent shutdowns of the gas boiler

Sometimes it happens that after installing a new gas boiler, soon after its adjustment and commissioning, spontaneous switching on and off for a short time begins to occur. Frequent independent shutdowns and turns on indicate that the boiler is not working properly. In addition, there is the possibility of premature failure of heating equipment, as the degree of wear of parts increases.

There are several reasons why a gas boiler can often turn on and off:

- the equipment is incorrectly selected - it heats a smaller area than the one for which its power is designed;

- the temperature range is not set correctly;

- incorrect installation of the circulation pump;

- there is no thermostat in the room and the boiler operation is regulated based on the temperature of the coolant.

In some cases, it will be necessary to replace the boiler.

Other reasons

We can say that all cases when the radiator does not heat are unique in their own way. For example, the radiator, which is the last in the system, does not heat. This means that the coolant simply does not reach it or the heat is "lost" on the way to it. If the latter, then the system is incorrectly calculated or the diameter of the pipes is incorrectly selected and, accordingly, the ratio of the amount of water / intensity of circulation is incorrectly selected.

It is also possible that the pump is not doing the job. Perhaps it is faulty or incorrectly selected in terms of parameters. This is also not uncommon, especially when the system was implemented by beginners or just people without certain experience and knowledge.

The expansion tank can help solve many problems. For example, airing can be removed by pumping the coolant through the entire system. For this, some people cut in a valve in the lower part of the heating system, to which a tap and a fitting are connected. By putting on a hose, water can be supplied until air escapes through the expansion tank.

Only this approach is quite risky - excess water, and there will be a lot of it, will fill the tank and pour from it. In this case, act with an assistant who will monitor the water level in the expansion tank.