Advantages and disadvantages of a brick chimney

Despite the fact that the metal pipe is no longer exotic, chimneys continue to be laid out of bricks. In some ways, this looks like an anachronism, but there are good reasons why you should not abandon the classic technology of laying chimney ducts.

The main one is that the brick has a high thermal inertia. Exhaust hot gases heat it up weakly, which significantly reduces the fire hazard of the heating device. We must not forget about another aspect - the smoke temperature at the upper cut of the pipe should not fall below 60-70 degrees. Otherwise, condensation will flow through it. Brick plays the role of a thermos shell and does not allow the smoke to cool down excessively.

But there are two fatal flaws:

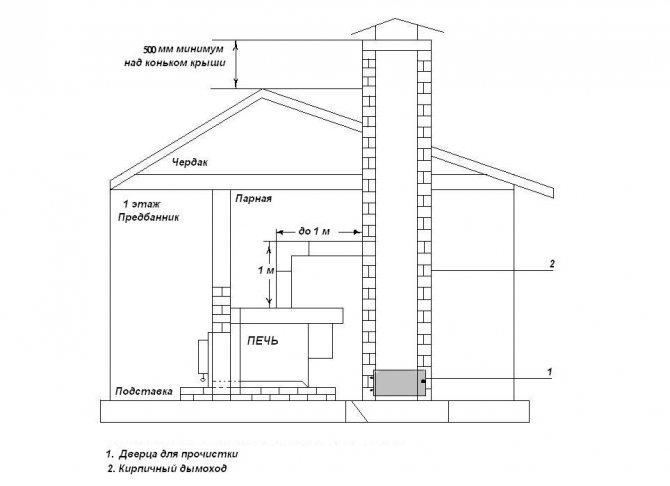

Column with a base area of not more than 0.25 sq. meter, the whole mass presses on the stove. This is a concentrated load. If the total height of the pipe exceeds 5 meters, then it is placed on a separate base, and a transition pipe is connected to the heating device.

Types of pipe structures

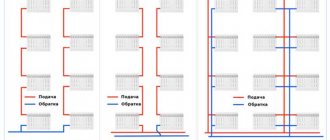

In addition to the fact that the difference between the devices depends on the materials of manufacture, they also differ in the type of construction. Stove pipes can be divided into 4 categories:

- Invisible chimneys. The main location is the ventilation ducts in the walls of the house.

- Packed. They are connected to the air outlet of the supplied fireplace or boiler.

- Outdoor structures. This type is placed on the facade of the house.

- Root chimneys. This is a vertical structure that has its own foundation. The basis for such structures is considered to be brickwork, in many cases it is part of the furnace itself.

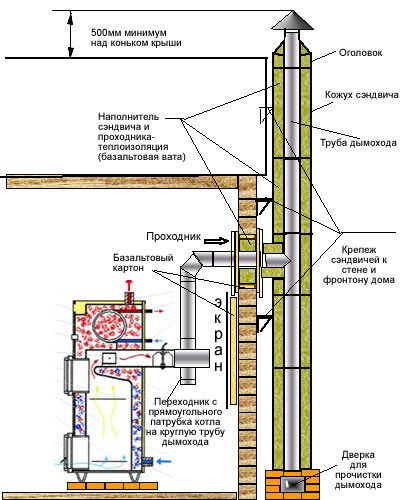

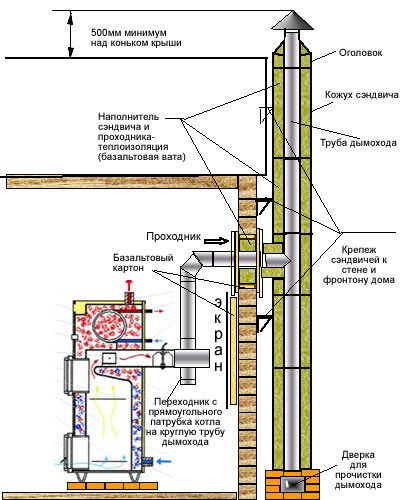

Each type asks for special installation conditions, for example, a chimney through the wall is used exclusively for the installation of external or hidden devices, and root or mounted chimneys are taken outside the house, passing through the attic room and the roof.

Brick chimney as an engineering structure

The chimney, for all its outward simplicity, is a complex engineering structure, to which serious requirements are imposed. They relate to strength, fire safety, the ability to effectively remove hot gases. Therefore, the installation of a chimney in a wooden house should begin with an acquaintance with its device.

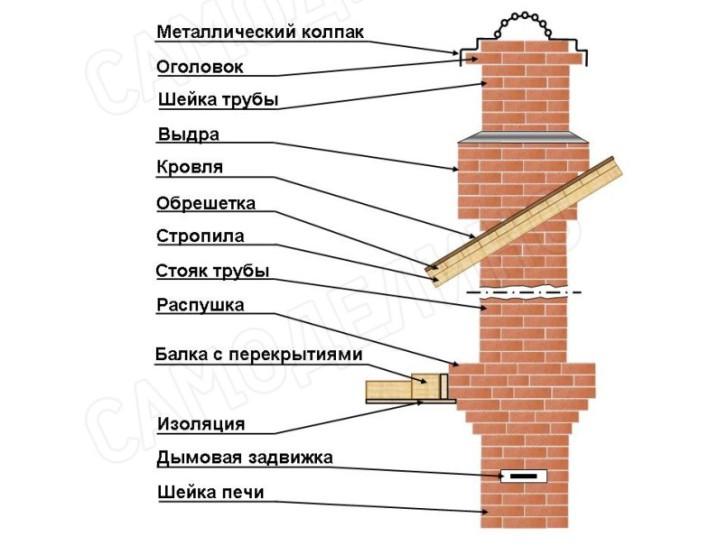

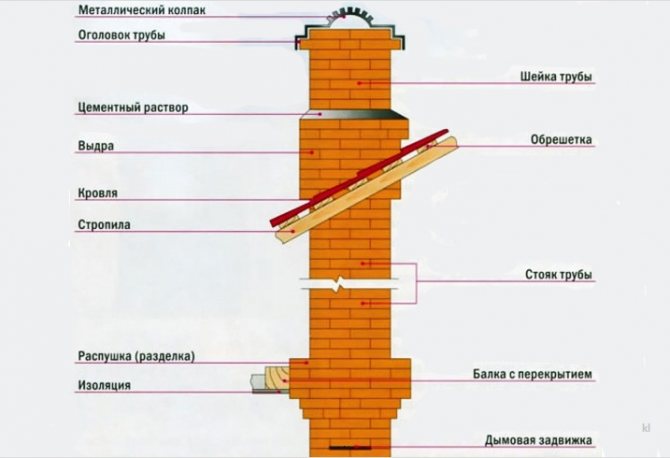

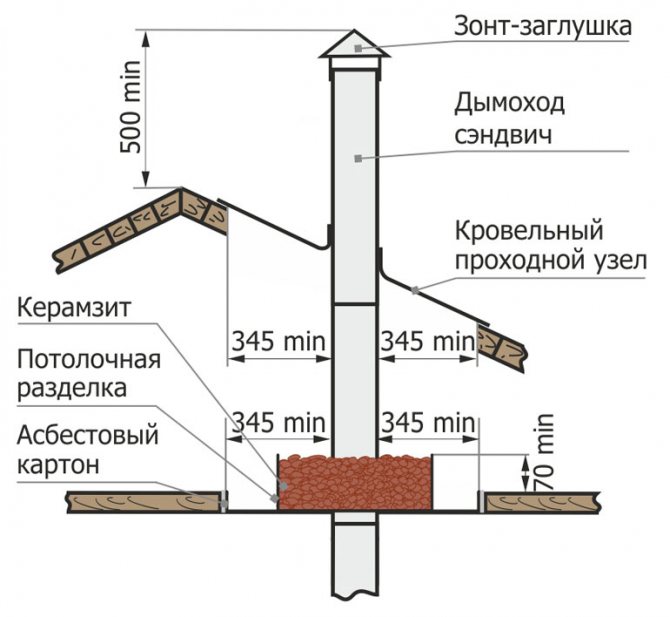

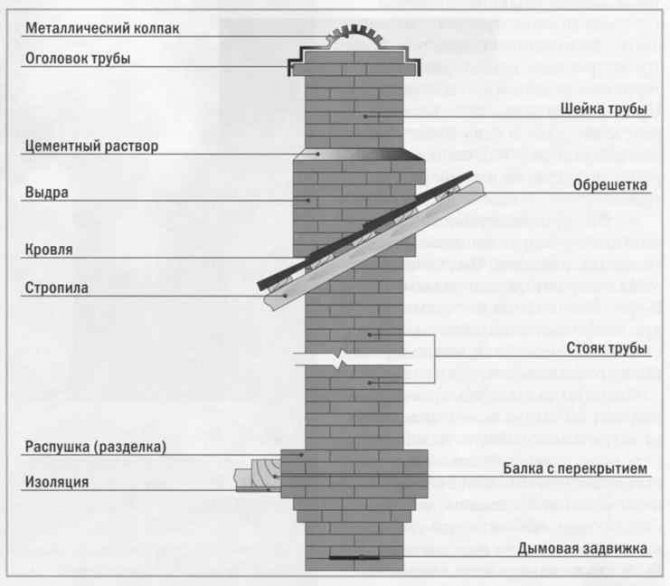

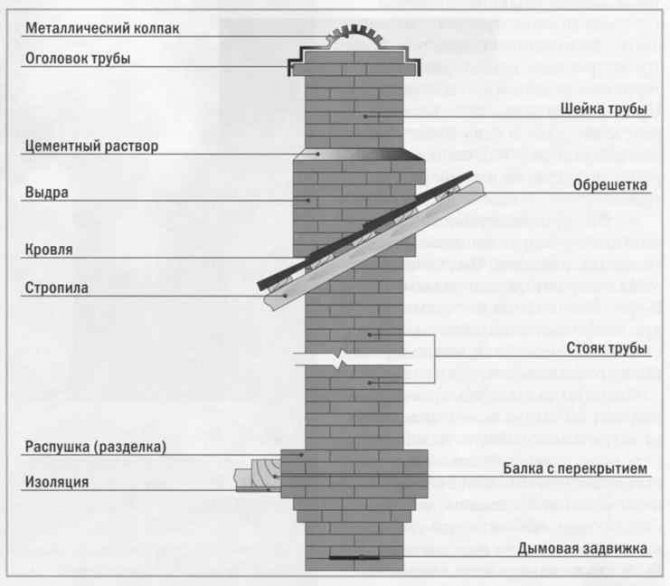

Main elements

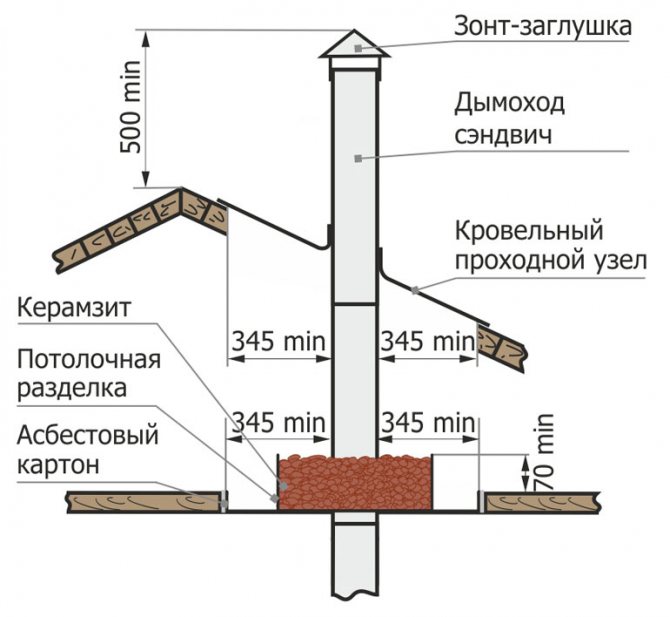

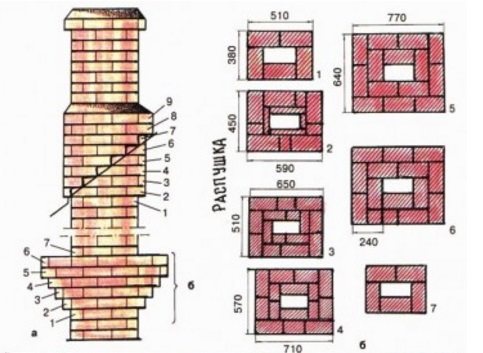

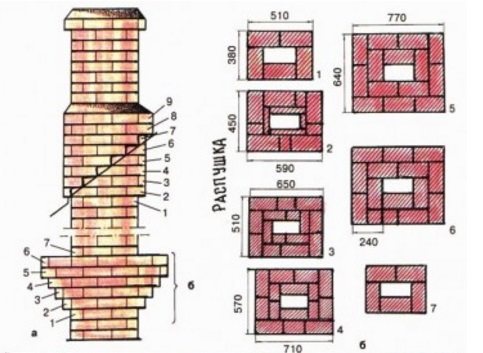

- Internal chimney - is carried out from the ceiling of the furnace to the level below the ceiling by four rows of brickwork.

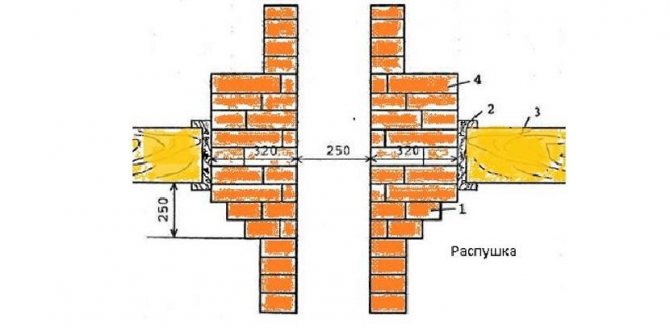

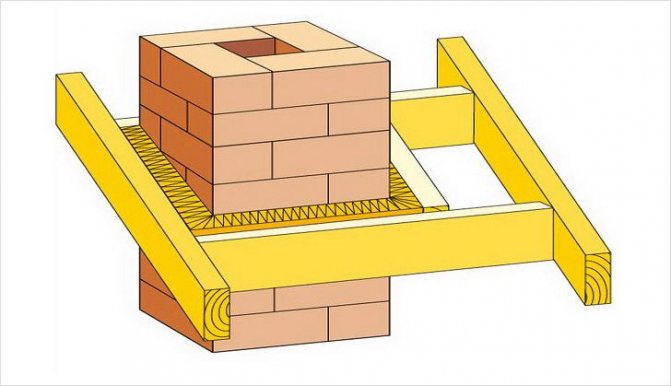

- Cutting (fluffing) - expansion of the pipe wall thickness as it passes through the ceiling.

- External chimney - is carried out through the attic to the level of the roof.

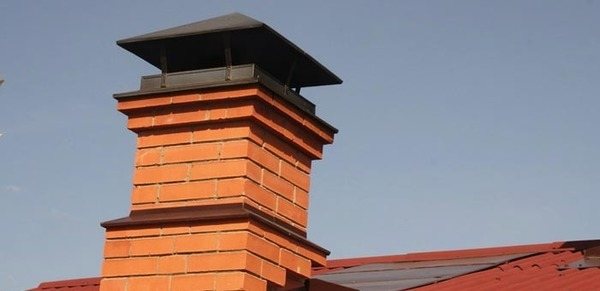

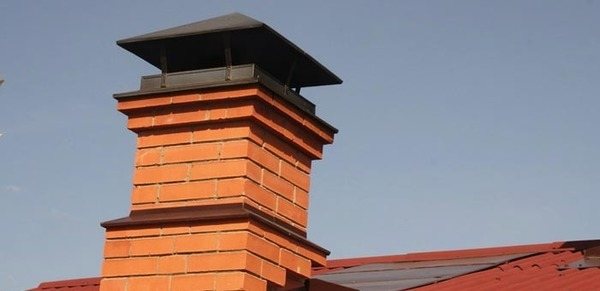

- Otter - another expansion of the thickness of the chimney walls, arranged to cover the gap between it, the roof lathing and its covering.

- Neck - continuation of the external chimney.

- Head - thickening of the walls, playing the role of a deflector.

Requirements for a brick chimney

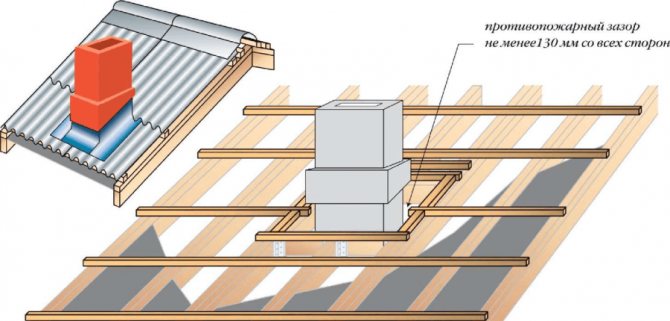

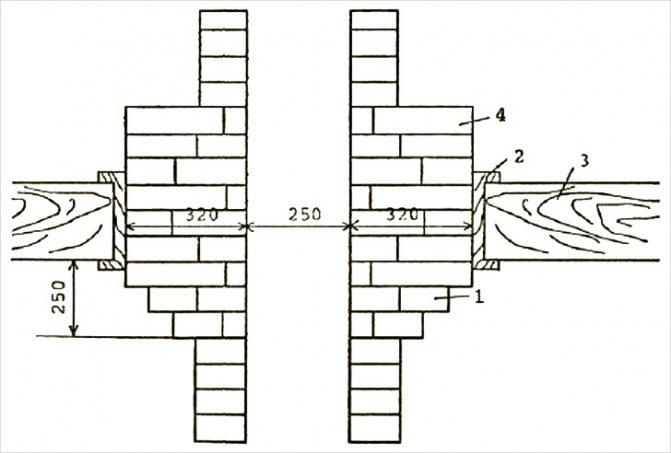

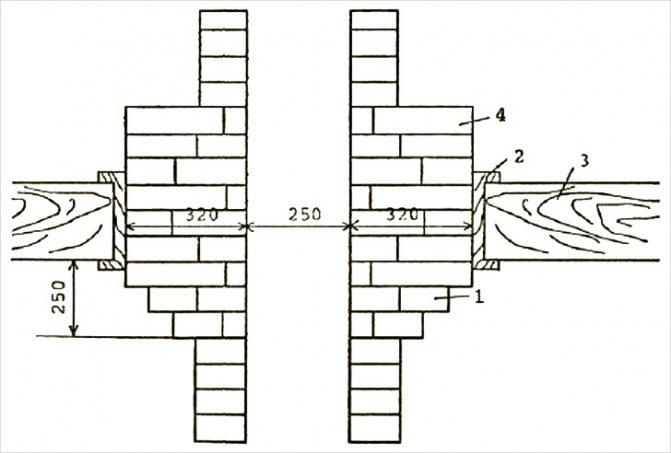

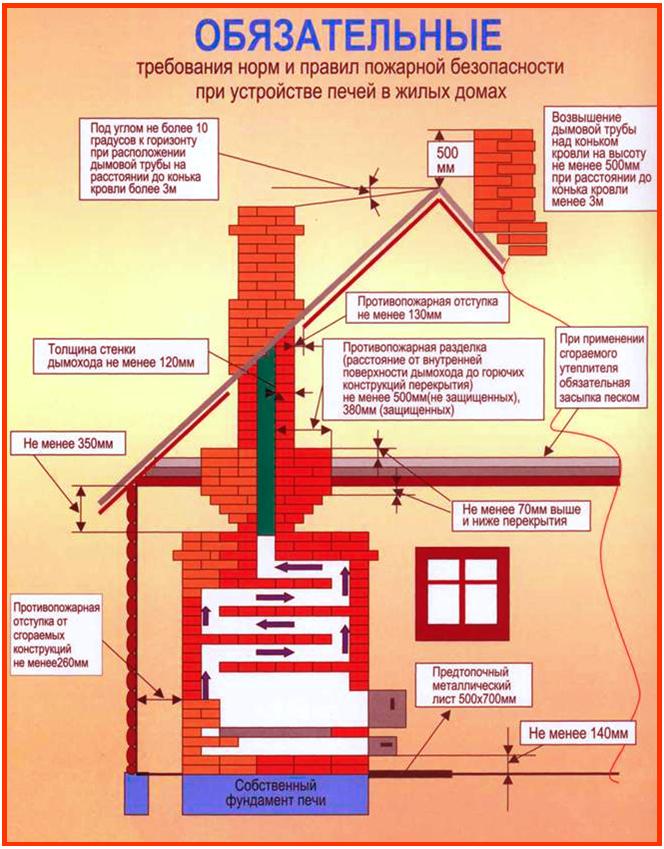

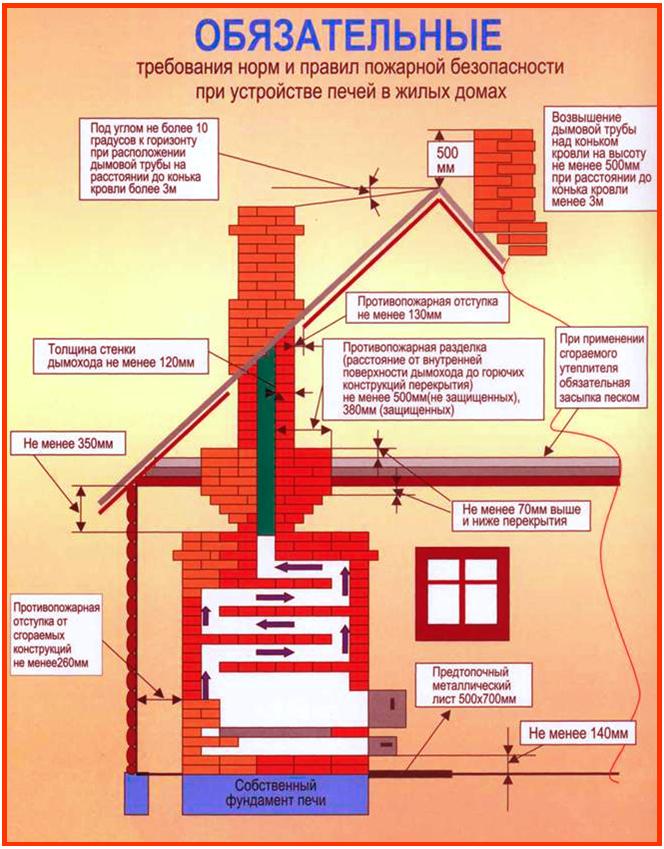

The main one is the distance "from smoke" to combustible structures. It is equal to 250 mm - this is the full length of a ceramic solid brick.

The second requirement is the strict verticality of the structure. A deviation from it by more than 3 degrees (per one meter of height) is not allowed. Also, there should be no through cracks in the brickwork.

Chimney calculation

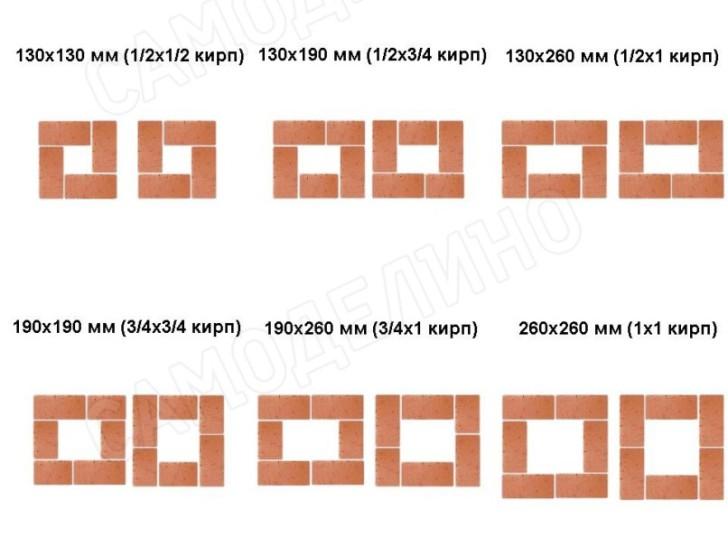

The main criterion is the inner section. The ability to remove hot gases mainly depends on it. The more powerful the stove, the wider the chimney should be. There are three standard sizes used for each type of heating device.

- "Quartet" - a row of which is formed by four bricks. Section 125 x 125 mm. Used for low power cookers or heating stoves.

- "Five" - a rectangular chimney formed by a row of five bricks. Section 250 by 125 mm. Used for heating and heating-cooking stoves. It is not recommended to make chimneys for fireplaces smaller than this section.

- "Six" - a square tube, a row of six bricks. Section 250 by 250 mm. It is used for fireplaces and Russian stoves - wherever minimum resistance to the movement of hot gases is required.

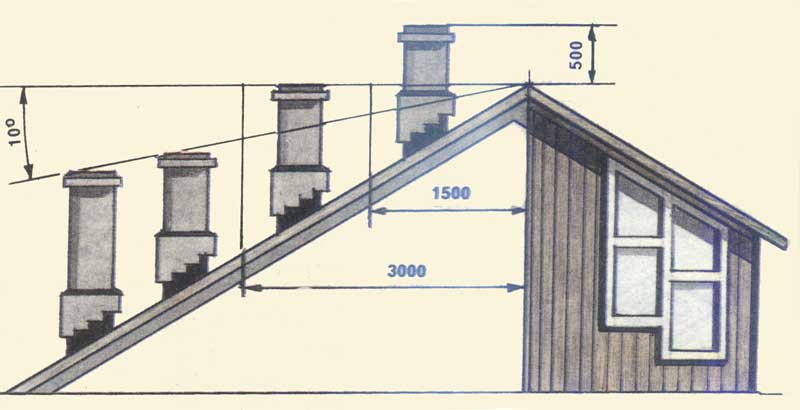

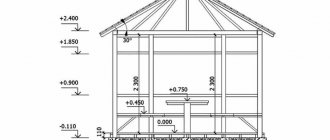

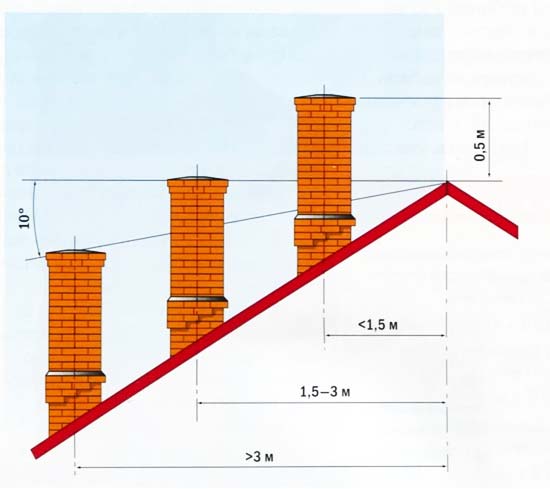

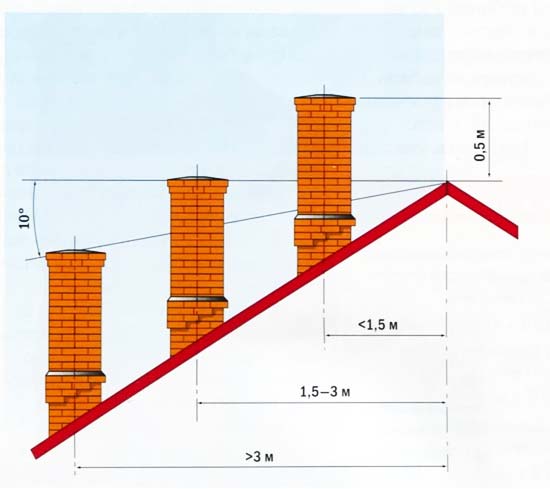

The second most important criterion in the calculation is height. It depends on the place of its output to the roof relative to the ridge:

- Pipes installed on the ridge or at a distance of no more than 1.5 meters from it rise 0.5 meters above the roof.

- Chimneys passing through the roof at a distance of one and a half to three meters to the ridge are made with a height equal to it.

- If the distance is more than three meters, then the angle between the ridge and the upper cut of the pipe should be 10 degrees.

What you need to consider when constructing a chimney

The pipe must be laid so that there is sufficient distance between it and the outside of the load-bearing wall - see the table with dimensions.

| External wall thickness in bricks | Gap in bricks |

| 2 | 1,5 |

| 2,5 | 2 |

| 3 | 2,5 |

It is forbidden to lay chimneys in the corners of rooms and in areas where walls intersect. If the building is residential, the pipe wall thickness must be at least 10 centimeters. Complete tightness of the structure should be ensured, it should not allow combustion products to pass through.

Often the house is made of concrete, slag and foam blocks, silicate types of bricks. In this case, the sections of the walls along which the chimney will pass must be laid out of red brick. Their minimum thickness should be 12 cm. This requirement also applies to walls, partitions between smoke exhaust ducts.

Watch the video

Before you lay out the brick chimney with your own hands, you should take into account the fire regulations:

- the gap from the outer plane of the chimney to the walls made of flammable materials should be at least 40 cm.

- in the sections of the chimney passage through the ceilings, it is necessary to make thickenings (edge).

The chimney channel along its entire length should be assembled so that the dimensions of its internal space are constant.

Chimney masonry

There is no fundamental difference between the brickwork of the stove and chimneys. It is carried out on a clay-sand mortar using the same tools - an oven hammer-pick, a trowel and a plumb line. However, items such as fluff and otter are laid out using a large number of pieces of bricks in the size of 1/8, 1/4, 1/2 and 3/4 of the whole.

To avoid splitting and cracking, which are accompanied by clouds of brick dust and rarely give the desired result, it is worth using a "grinder" with a diamond wheel for ceramics. This guarantees the accuracy of work, eliminates tedious work and a lot of useless brick fighting.

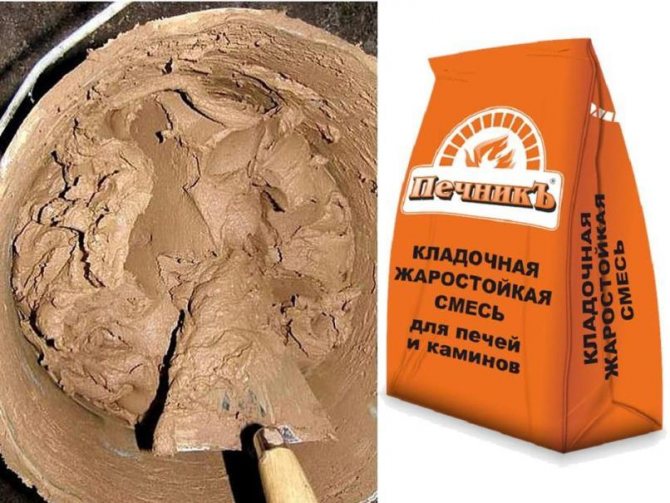

Solution

For masonry up to the level of the roof, a mixture of sand and clay is used, since it has a coefficient of linear expansion similar to that of a brick, which is a certain guarantee against cracking.

Pure clay used as a binder can be oily or skinny. In some places, there are deposits where the proportional ratio of the amount of clay to sand is optimal by nature: one to three or four.

With an increase in the volumetric part of the clay, the solution cracks after drying, and with a decrease, it crumbles. To determine the optimal ratio of volumetric parts, you need to knead the ready-made solution in your fingers. It should be neither perceptibly slippery nor rough like sandpaper.

The excavated clay is soaked in an iron container for 3-4 days.The result should be a homogeneous clay pulp without stones, similar in consistency to liquid sour cream.

Clay and sand are mixed in volumetric parts in a ratio of one to three or four. Water is added gradually, in small portions. The finished solution should leave traces on the trowel (but not stick to it) and not drain from it.

To avoid errors in proportions, it is better to buy a ready-made dry clay-sand masonry mixture. Please note that the one marked "fireproof" is not suitable for masonry.

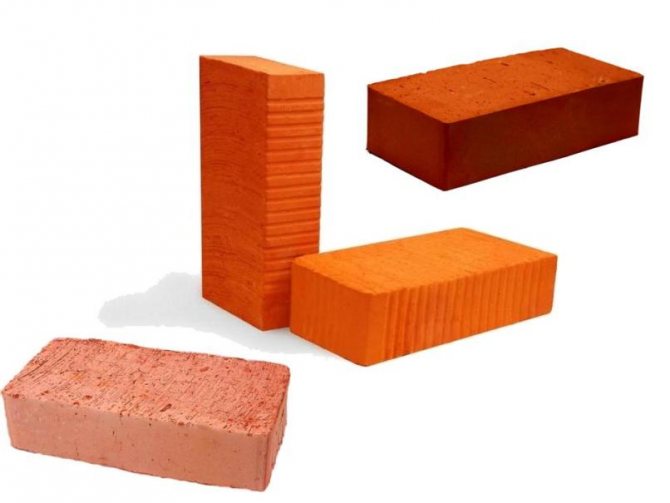

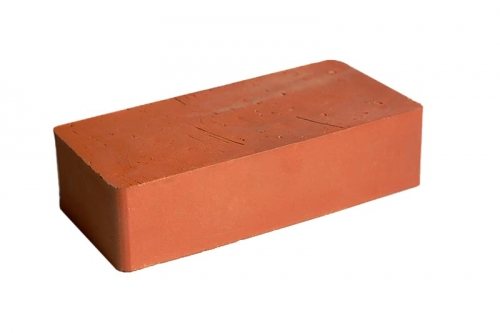

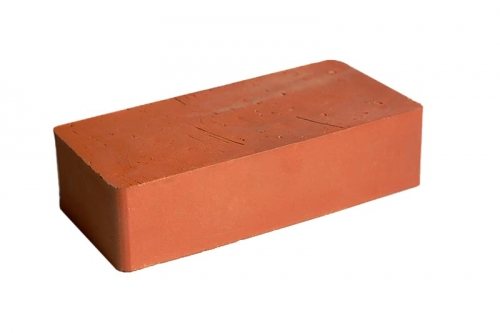

Brick

Used solid red fired brick.

Its edges should be smooth, without cracks, and the sound made when lightly hitting it with an oven hammer should be resonant.

The standard size used for masonry is 250 mm long, 125 mm wide and 75 mm high.

Internal chimney masonry

It begins immediately after the damper is installed and the stove overlap is completed. Masonry techniques are the same - applying a layer of mortar, laying bricks, shaking it with your hand and lightly tapping with a pick. The verticality and horizontalness are checked after laying each row. They finish it four brick heights to the ceiling.

Do you want to know how to quickly and inexpensively make a reliable chimney from asbestos? Read here.

Find out how to make a septic tank from concrete rings with your own hands from this article:

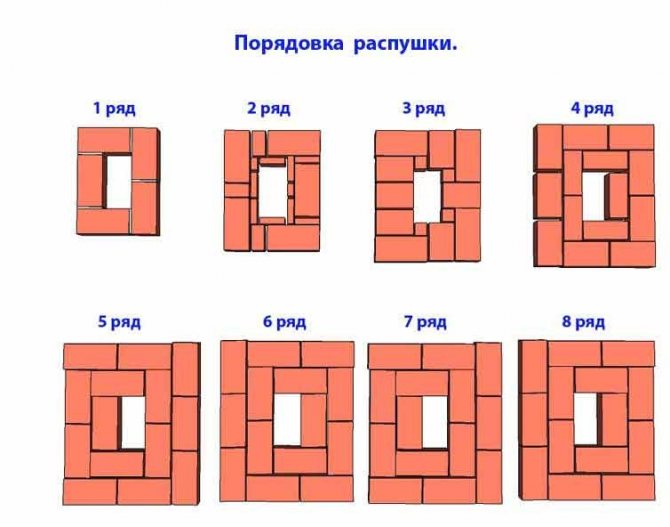

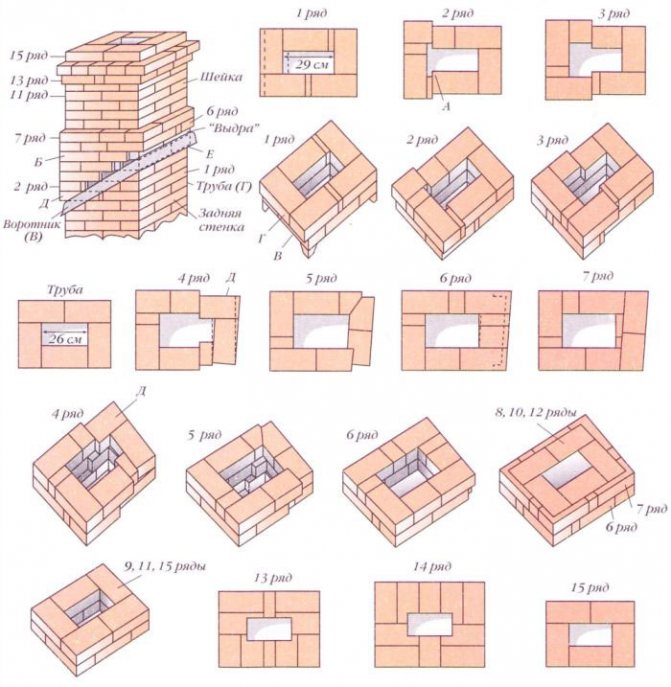

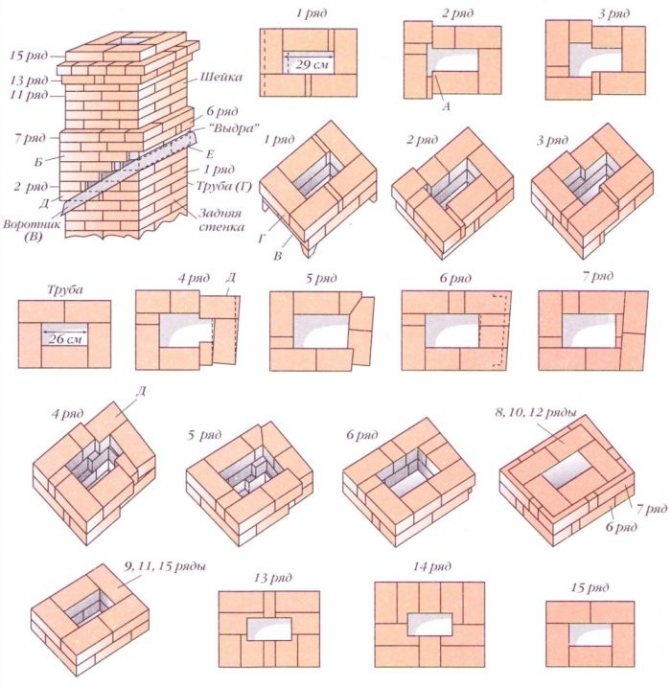

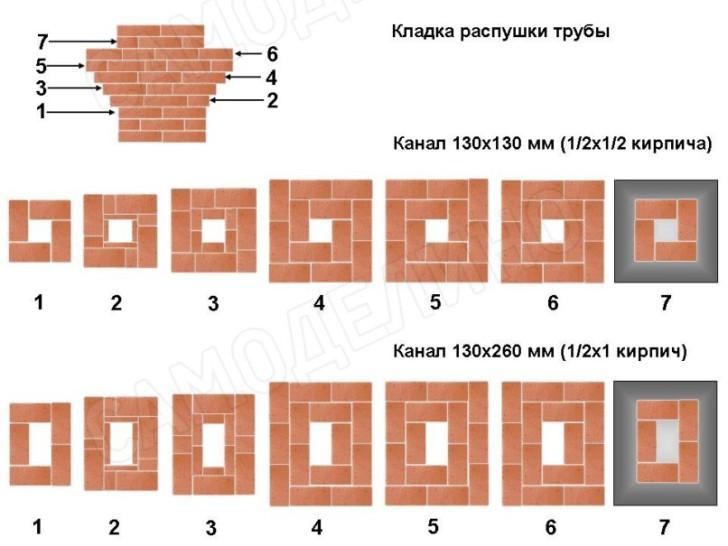

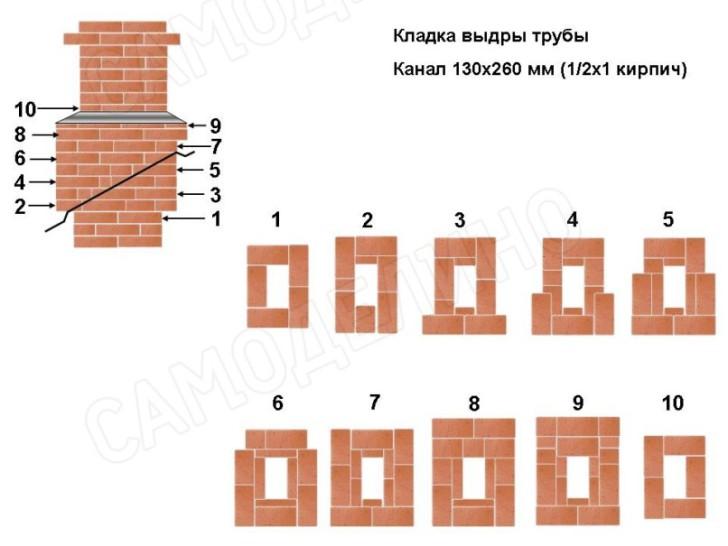

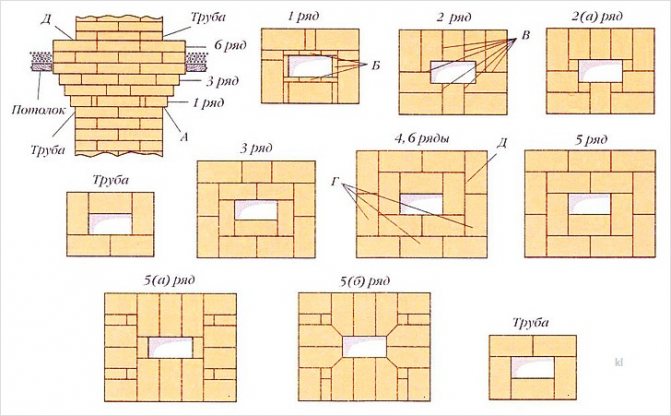

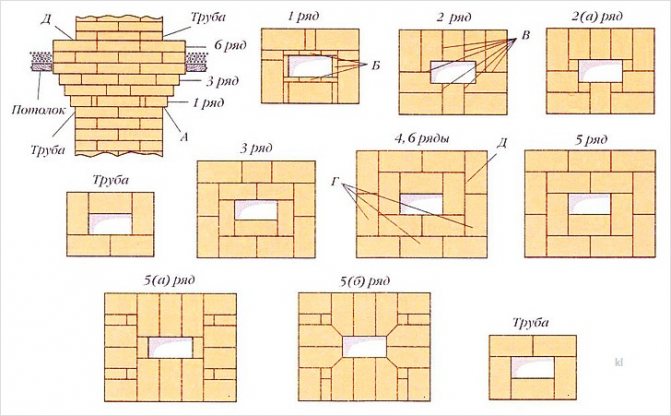

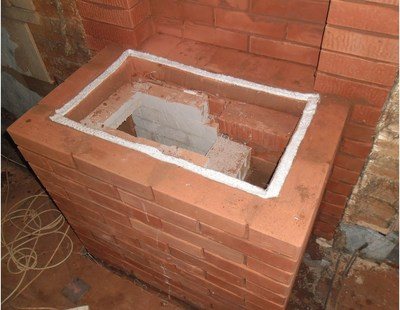

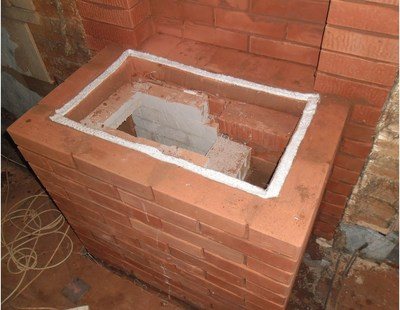

Laying fluff

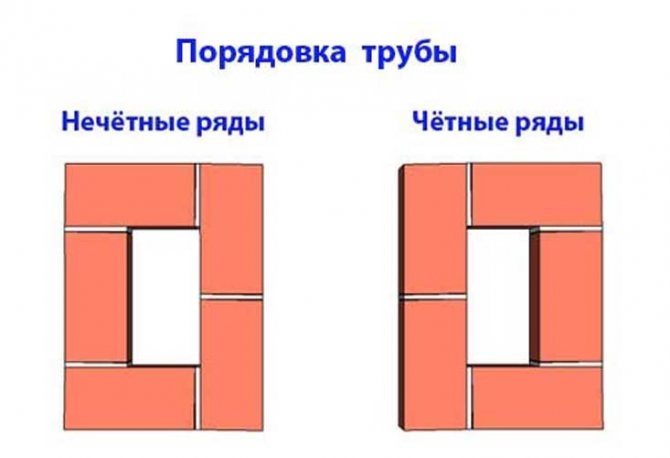

Expansion of the chimney wall thickness is performed to comply with the requirement to locate combustible structures at a distance of 250 mm "from the smoke". The usual wall thickness of the chimney is 125 mm. To double it, it is required to fold four rows, each of which is shifted outward by 1/8 of the width of the brick relative to the lower one - just the amount that allows the brick to lie without being thrown over. The masonry principle is the same for all three sizes:

- The inner surface (to smoke) of the first row is laid out in 1/8 pieces. The gaps between the outer bricks are filled in 1/4 pieces.

- In the second row, the parts increase, respectively, to 1/4 and 1/2.

- The third row uses 1/2 and 3/4 pieces.

- The outer belt of the fourth row of fluff is laid out with whole bricks.

Having reached the ceiling, they put it, observing the dressing of the seams, another two or three rows higher. A gap of 2-3 cm is left between the ceiling slab and it to eliminate the pressure of the structure on the masonry. It is covered with mineral wool slabs. Laying up to the roof is carried out in the usual way - with bandaging of vertical seams and control of verticality.

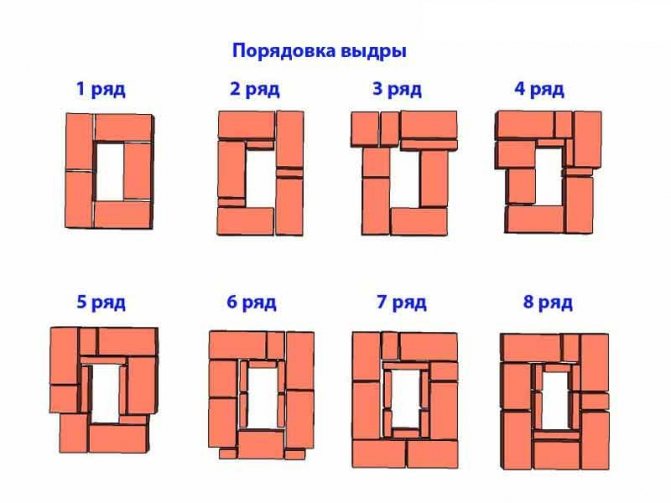

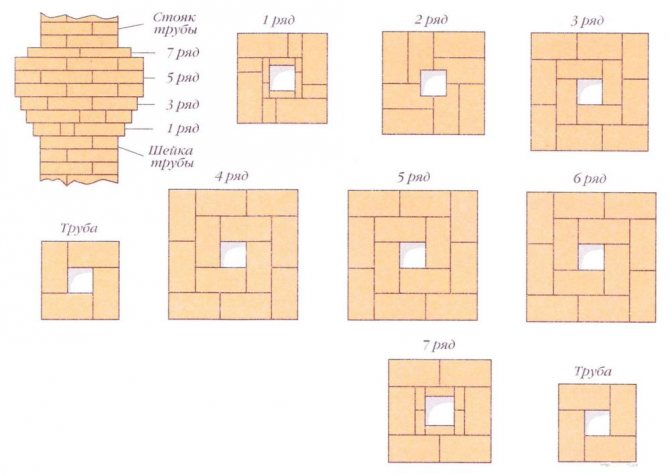

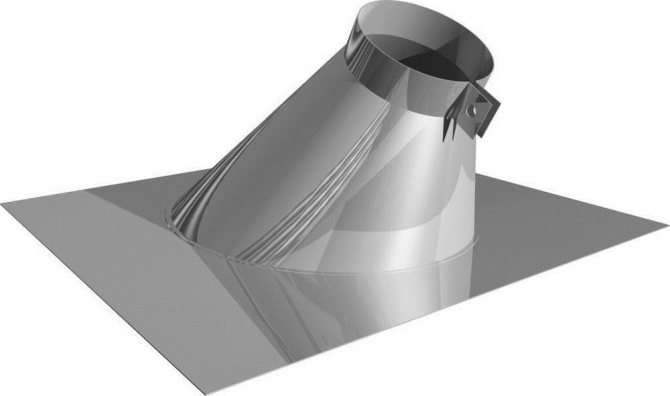

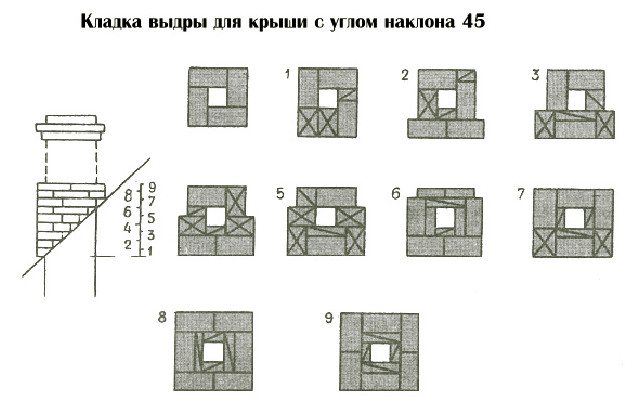

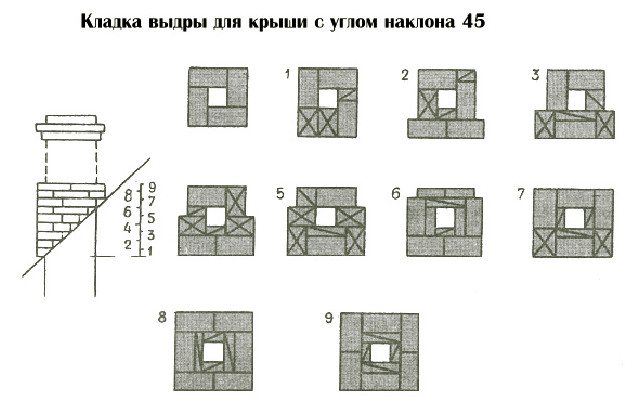

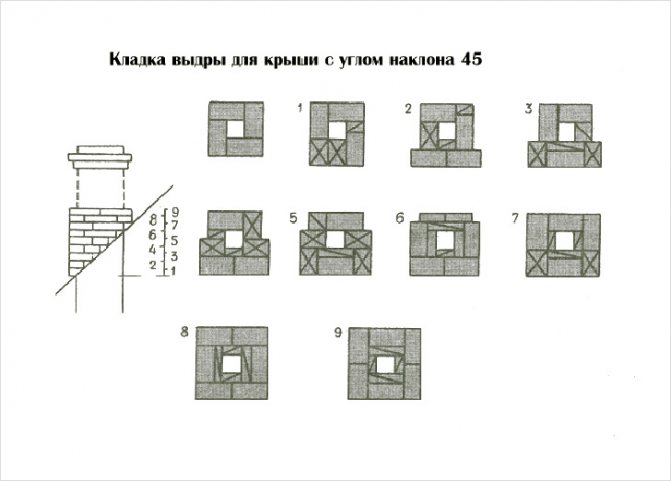

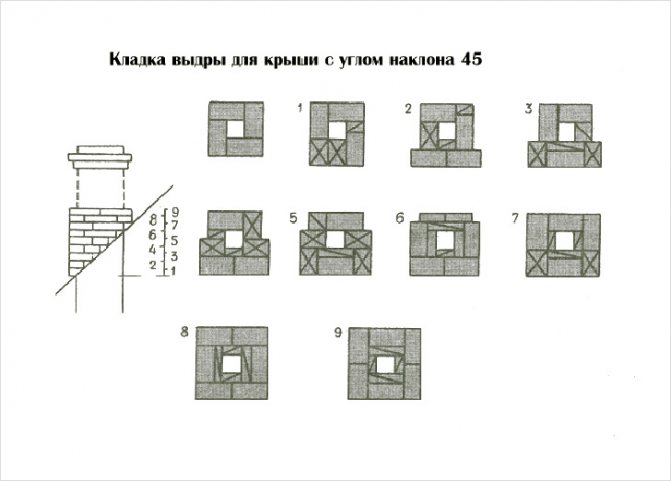

Otter clutch

It begins after the edge of the chimney brick has risen above the roof. It is conducted outside, in compliance with all safety measures when working at height. You can use cement mortar. They start it from the edge that is lower along the slope. The distance from the smoke on each row is equal to 1/8 of the brick width. There should be six rows in the otter. After it, a neck is placed - the usual continuation of the chimney. The slots between the roof and the chimney are closed with a “collar” made of sheet roofing steel.

What solution is used for masonry

During work, the stove-maker can use different masonry mixtures:

- For laying red bricks, a clay-sand mortar is used. Its proportions are 1: 2. If the clay is very oily, then 3-4 volume fractions of sand are added.

- When installing refractory blocks, masonry mortar from refractory clay, chamotte and sand is kneaded. The proportion of the mixture is 1: 1: 2.

- For the installation of the chimney in the attic, you can use a cement-lime-sand mixture in a ratio of 1: 1: 2.

- For the roof top, you can use a cement-sand mixture in a 1: 2 ratio.

After mixing with water, the mortar for masonry of the stove chimney should have a creamy consistency.

Masonry rules

The cross-section of the structure must be a multiple of the dimensions of the bricks. The thickness of the outer pipe walls of the mounted structures must be at least half a brick.For greater stability, the thickness of the outer walls of the bottom of the main structures should be equal to a whole brick with a transition at the top in half a block.

Air ducts inside the structure should be placed in a vertical direction. Do not mount the hogs horizontally at the level of the attic floors. This is required by fire safety regulations.

Each stove must be equipped with its own chimney. Rarely, a project allows two heating devices to be connected to one channel. They should have a single-level arrangement, with a high-rise cut from 75 cm and more.

Watch the video

When installing two heating devices (or a stove and an exhaust network), two channels can be connected in one riser. Their sizes remain the same. However, the installation of a two-channel chimney with a cross-section of half-brick channels on a half-brick is done in incomplete blocks. Five solid and two ¾ bricks are placed in each row. In this case, a reliable ligation of the masonry is achieved.

Installation of a double structure (chimney and ventilation duct) with a channel size of half on a single block is made with eight bricks. If it is carried out with the alternation of even and odd levels, it will not be possible to connect the delimiting partition with the masonry of the outer wall. Therefore, the alternation must be done in three rows.

The first level is assembled from eight solid blocks. The second contains five whole and four ¾ blocks. With this layout, the reliability of the structure increases.

Design features and pipe sections

Before you start laying a brick chimney with your own hands, you should study its design:

- The first part of the chimney is the lower neck of the structure. It is placed on the shoulders. A gate valve is mounted in it. When installing the neck, the bricks are tied up.

- At a distance of 5-6 levels of bricks from the ceiling, fluff is laid. This extension goes up to the attic.

- The part of the device laid out with your own hands in the under-roof space is called a riser. He goes to the base of the roof.

- An otter is laid out from the roofing. It expands on all sides by at least 10 cm. This element of the device prevents precipitation from entering the house.

- Next, the neck is laid out. Its dimensions are the same as those of the main pipe barrel.

- Then the head is placed. A deflector is mounted on it, which protects the chimney from precipitation.

Stages and process of laying a brick chimney

You should have on hand a chimney diagram with its order. On it you must carry out construction.

Watch the video

Here is a step-by-step process for laying a stove chimney:

- Prepare tools, materials and solution.

- Take measurements to the gate and fluff.

- Start laying blocks (mortar thickness should be 5-10 mm) of pipes from the stove. Check the evenness of all rows with a level on all planes. After 3-4 levels, clean the canal from excess solution.

- Fix the frame at the gate mounting point. It should not disturb the position of the top of the bricks. Therefore, cut a recess in them to fit the frame.

- Continue erecting the structure to the level of the fluff. Calculate the number of rows that will need to be laid out before bringing the fluff to the required size. Please note that in one row, the perimeter of the pipe becomes larger by ны the width of the block. The fluff should fit tightly with the floor beams. When they are located at a distance from the chimney structure, make a stop frame.

- Next, in order, mount the fluff. It can be made square or rectangular.

- For the calculated number of rows, go from the fluff to the main dimensions of the riser. Bring it to the roof.

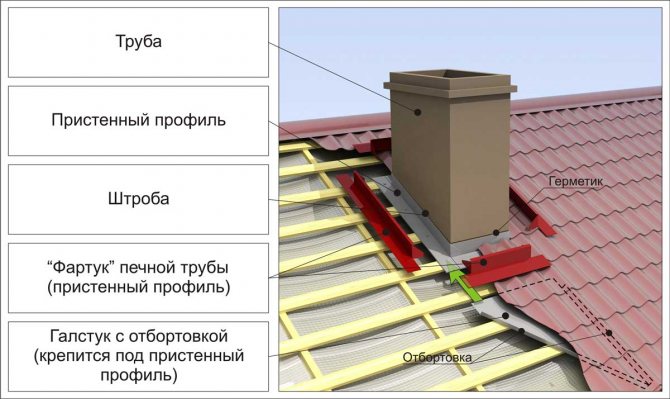

How to make a hole for a chimney in the roof

The dimensions of the hole in the roof covering must be calculated accurately. Having laid out the chimney to the roof, using a plumb line and a hammer with a nail, mark the angular dimensions of the structure on the roof. Do this from the attic side.

Connect the holes punched with a nail with a pencil.This will give you a rectangular cross-sectional projection of the structure onto the surface of the roofing. Then count 10 cm from all sides of the figure and draw a small rectangle inside it.

Connect the corners of the shapes and cut out the smaller one by sawing the cover along the lines that connect the corners. Unscrew the resulting four strips on the leaning board. Do this so that they almost reach the vertical. Then the roof covering will press tightly against the wall of the chimney device.

The remaining unprotected triangular gaps between the strips at the corners of the chimney, coat the inside with a solution, leaning bricks against them. Do the same outside.

Chimney placement above the roof

At the level of the roof covering, begin to mount the otter. The instruction says that it is more difficult to lay it than fluff. The construction should be expanded carefully and gradually. Taking into account the pitched slope. When laying a brick chimney with your own hands, it is required to increase the stability of the structure. Therefore, brick the steel plates into the otter and fix them to the rafters.

File the ends of the blocks. This will reduce the gaps between the otter and the roof. Alternatively, place sheet metal between the bottom of the tubular and the roof cladding. It will not allow sediment to seep into the rafters and into the attic.

The installation of the chimney is completed by arranging the head and installing a deflector on it.

How much will it cost

The brick chimney on the roof has become a visual constant in three centuries. And a building with such a finish looks, according to subjective estimates, much more attractive.

It remains only to determine how much it will cost you to comply with the canons. If you attract third-party craftsmen, then the price of the work will be added to the cost of the brick. And she is rather big. In St. Petersburg and the region, for example, laying one brick will cost from 50 to 90 rubles.

The solution, if you prepare yourself, is free.

Five kilograms of ready-made masonry mixture cost 60-70 rubles. One package is enough for 10-15 rows of a pipe with a section of 125 by 250 mm (sixes).

Let's compare the cost of a meter of a metal sandwich pipe with a diameter of 250 mm and a brick one with a cross section of 250 by 250 mm. Just the kind that can be used for chimney flues.

| Brick (at a price of 15 rubles per piece) | Masonry mix | The work of the master | Total, rubles | |

| Brick chimney | 900 rubles | 70 rubles | 3000 rubles | 3970 |

| Metal sandwich pipe | – | – | – | 3800 |

As you can see, the prices are almost the same. Of course, it is worth adding the price of fluff, otter and head masonry. But, given the best performance characteristics of brick pipes - no corrosion, high thermal resistance, it makes sense to spend money on such an acquisition. And if you are going to lay a brick chimney with your own hands, then it will cost almost half the price of metal sandwich pipes.

Methods for installing chimneys

Attention! This remedy saved my marriage, and it made me feel young again. It was only necessary. Read more.

When compared with the recent past, stove heating is not considered a popular heating method, but, nevertheless, it looks very important in cottages or summer cottages. Thanks to this, the installation of a chimney on the roof for a stove or fireplace requires special attention and approach.

Not so long ago, chimneys made of bricks, asbestos pipes, or non-galvanized ferrous metal were popular.

At this time, there are many different production technologies for furnace equipment, using certain materials, each of them has its own disadvantages and advantages.

Chimneys, chimneys, boxes

To understand which device to give your own preference, you need to analyze all the options. So, chimneys are:

- Asbestos-cement.

- Made of bricks.

- Ceramic.

- Iron.

- Concrete.

- Vermiculite.

Non-pressure asbestos pipes

The following advantages are inherent in asbestos pipes:

- Low price.

- Durability of operation.

- Not resistant to high temperatures.

- Exposed to soot in the middle of the chimney due to the rough surface.

For pipes made of bricks, the following advantages are inherent:

- Durability.

- Fortress.

- Beautiful view.

- Fire safety.

- Laying a brick structure requires a specialized mortar that is resistant to the combustion process, as well as plastic and heat-resistant characteristics.

- The finished structure needs periodic repairs.

- The impressive weight of the structure asks for its foundation.

- Finished structures are susceptible to soot contamination.

- Big sizes.

Ceramic pipes have the following advantages:

- Acid resistance.

- Durability.

- Not prone to the appearance of soot, due to the smooth surface inside.

- Resistance to temperature extremes.

- Chemical resistance.

- Does not rust.

- Has heat-absorbing characteristics.

Ceramic chimney

- Awesome construction weight.

- Separate foundation.

- The cost is too high.

For pipes made of metal, the following advantages are inherent:

- Heat resistance.

- Acid resistance.

- Does not contribute to the formation of condensation.

- Prevents accumulation of soot.

- Low weight of the structure.

Iron chimney pipe

Dear visitors. Save yourself a link to this site in social. networks. The moment will come when the house becomes cold and we will help you :) Share!

- They do not have anti-corrosion parameters.

- They do not have the qualities of thermal insulation.

For concrete pipes, the following advantages are inherent:

- Good enough value.

- Durability.

- Possibility of renovation.

- No seams.

The following advantages are inherent in vermiculite pipes:

- Lack of condensation.

- Heat resistance.

- Lightweight construction.

Vermiculite chimney cut

Secrets of the skill of stove-makers

- Before laying, the brick must be soaked - immersed in water and wait until the violent eruption of air bubbles stops. Wet ceramic blocks adhere more firmly to the mortar.

- For splitting and cutting bricks, use a grinder with a diamond disc for stone.

- When laying in the attic, hang a plumb line on the rafters, between the future pipe and the workplace. This saves you the hassle of touching it for verification. To control the verticality of the angle, it is enough to change the position of the head.

Do not forget that a chimney in a private house is not only a convenience, but also a technical device that requires proper operation and maintenance. Clean it from soot, inspect it for cracks, heat the stove or fireplace with dry wood and it will serve well for many years.

The wood-fired oven works thanks to the traction principle... Hot gases released during combustion rush up the chimney, giving off heat along the way to the heat exchangers.

For the formation of traction, a correctly calculated chimney is needed. For a long time, ceramic bricks have been used for this purpose, due to the properties burnt clay.

When designing a heating system it is very important to check compliance pipes and stoves - brick is not suitable for all systems.

Chimney cleaning and repair

Both traditional methods and modern ones based on technological advances are used to clean the pipe.

From time immemorial, people were engaged in the maintenance of stoves, whose profession was called a chimney sweep. Today, finding a professional chimney sweep is problematic. They were replaced by chemical agents, which, however, are also often called "Chimney sweep".

It is very difficult to find a professional chimney sweep today, this profession is a thing of the past.

So, a tool called "Log Chimney Sweep" has proven itself well.It contains copper sulfate salts and other active chemical compounds. Burning in the furnace, the vapors of these substances interact with carbon deposits that have settled on the pipe walls. Under the influence of heat, the reaction continues for several weeks and leads to the fact that the solid structure of soot crumbles and, once again in the furnace, burns out.

claim that its application twice a year allows you to completely clean the chimney from soot

From folk remedies, one can note such effective prevention methods as burning salt or soda once every 2 months (about 0.5 kg per one furnace). The powder is poured into the combustion chamber at the moment when the firewood is well heated and the temperature is maximum. After that, you need to tightly close all the doors, as the reaction can be quite violent.

Dry aspen firewood helps to clean the chimney well. The fact is that aspen burns with a large release of heat, the tongues of flame are long and penetrate deeply into the passages.

If there is no aspen or soda, you can use potato peelings. To do this, you need to accumulate about half a bucket of potato skins. When burned in a firebox, the released substances bind the soot and force it to burn to the end.

The combustion temperature of aspen wood reaches 800 degrees, so the soot on the walls of the chimney burns out

When carrying out work on the installation of chimneys, especially in the area where the neck, otter and head are installed, safety standards should be carefully observed. If you work carefully and follow the necessary instructions and technologies, you can easily fold the brick chimney with your own hands.

Chimney types

To build you need to decide with pipe type... Depending on the location, there are:

- Indigenous pipes. They have their own foundation - they rest directly on the foundation. They can be both inside the house and outside. Advantages - connectivity several heaters, as well as construction "in reserve", with the subsequent connection of not yet purchased heating equipment. This option is perfect for any type of metal stove.

- Mounted pipes. They rest directly on the stove itself, which stands on the foundation.

For metal stoves, it is better not to use a top-mounted chimney - too large a mass leads to deformations.

- Suspended pipes. They are supported by a special bracket attached to the wall or ceilings.

Such a chimney cannot be built from brick; it is better to use metal light pipes, thermally insulated and sewn into the case (sandwich chimneys).

- Wall pipes. If the outer wall or partition is made of bricks, a smoke outlet can be designed in it. This technique has been used in the construction of stone buildings since the days of the Roman Empire.

This saves material and does not hide free space, the pipe can be made several floors without loss of strength. Cons - when soot ignites, the wall turns into a hot pillar, which leads to a fire, and with constant soaking from condensate, the pipe can collapse.

If only brick is available from the materials for the chimney of an iron stove, it is worth stopping at the option of a root or wall pipe. It does not put pressure on the oven itself, you can connect at different levels and is not difficult.

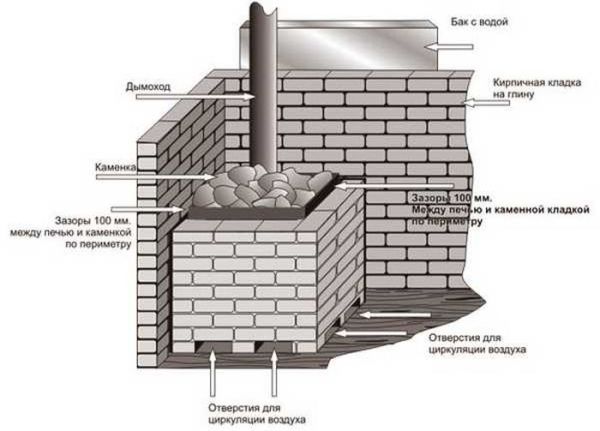

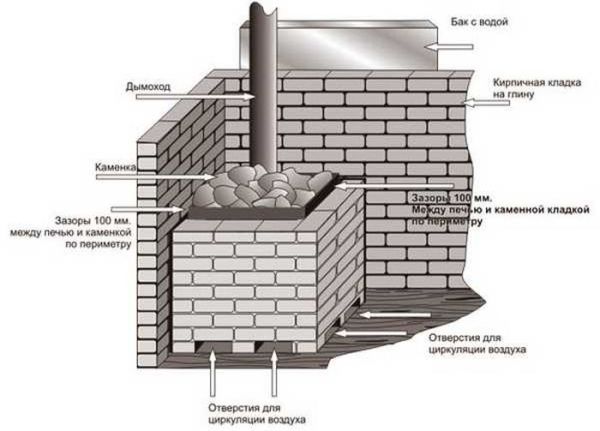

Expansion of a pipe in a ceiling opening

Before the start of the increase (cutting) of the pipe, you should check the horizontality of the masonry, determine the number of rows remaining to the ceiling, taking into account the cutting height and house draft. In new buildings, taking into account their probable draft, cutting must be started at a distance of at least 7 cm below the ceiling. It must be borne in mind that any material has a wide variety of sediment. Cutting should start a couple of centimeters lower or higher, depending on the height of the house and oven.

If you do not know exactly the draft of the house, it is better to do the cutting below the ceiling.

It is more convenient to expand the pipe in 4 gaps up to 3 cm according to the template, starting to lay down corner bricks and leveling it from the side and top of the row with the rule. The flue in the cut must have the same size as at the beginning of the laying, thanks to which the initial row inside is made of quarters flush with the flue. Sometimes it is advised to make gaps of 6 cm, but at the same time the brick can simply turn out of the masonry under pressure from above.

Brick pipe insulation scheme.

In another row, the stack is connected to the middle of the pipe. It is better to start the next 2 rows from the gas duct, in this case the bricks near it will connect to the lower row, and it will be easier to lay the outer bricks, however, it is still better to maintain the inlet part of the masonry for a couple of seconds until the moisture is absorbed into the brick. Cutting is done for fire protection purposes, thanks to which the seams must be quite thin. The chipped or hewn part of the brick must be sanded with an emery stone. Before breaking off a part of the already chipped brick, you need to equalize the place of the previous chipping. In the first three rows, the gaps must be 32 mm. This makes it possible to make a gradual expansion of the chimney on each side in half a brick. Laying 4 rows starts from a whole brick flue.

The other row has 6 seams from the edge of the cut to the flue. This row is located below the ceiling slabs, thanks to which these seams are not dangerous. But if this installation is carried out in the middle of wooden floors, then with incomplete joints there is a danger of fire. To prevent this, near the combustible parts of the ceiling, the cutting is performed in rings (3-6 rows) so that the seams from the gas duct overlap with the middle of the brick of the second outer ring. The clutch is completed as indicated in the usual orders. On top of the last row of cutting, a pipe begins, securing its masonry. An even pipe stand is laid up to the roof.

to come back to the beginning

What does a brick pipe consist of?

Brick stove pipes are of various designs. But any chimney necessarily has the following elements:

- Door or a knockout brick for cleaning. They are located at the bottom of the channel and in the turns of the hog, if there is one.

- Base with a view or catch. The most even bricks without cracks are selected - the entire chimney will rest on them. If possible, the base should be wider than the pipe on a brick and form a "heel" - a large support area.

- The pipe itself. Smooth, with smooth inner walls, seams without voids and cavities.

- Fire-fighting fluff when passing overlaps - expansion of the pipe for 1 brick. It is needed to reduce the temperature of the edge in contact with the heat-insulating box.

- Waterproofing "otter" - optional element, expansion of the pipe when laying outdoors. It plays the role of a dropper - raindrops do not flow along the root of the pipe, but flow down the walls of the thickening.

Photo 1. It looks like a brick pipe with a waterproofing "otter" and above it - a metal "umbrella" to protect it from moisture.

- Top protection against rain and snow. It can be a metal or concrete "umbrella", or finishing the top row of bricks with waterproofing fiber cement mortar.

Laying the pipe over the roof

Brick chimney diagram.

At the point where the chimney exits to the roof, it should be surrounded by roofing material to avoid moisture penetration under the roof. To do this, an otter is made above the roof on each side of the chimney - a recess in which iron for the roof is supplied to the pipe. Deepening is done by overlapping rows of masonry on each side of the pipe. The overlap must be at least 25 mm. According to the number of rows in the fluff, overflow protrusions are made. Due to the fact that each roof has its own slope, it is impossible to make an exact drawing of the order of the fluff.

It is easier to lay the masonry along the formwork from a board with cut edges 10 cm wide. Such formwork in most cases is installed on the roof batten. The entire pipe on top of the roof is placed on a solution that is resistant to precipitation, one row below the roof. If the rise of the roof allows, the initial row is let in on three sides, just like the second. The rest of the laying of the 1st row is carried out flush with the riser. All laps must be 3 cm each. From the other row, laps above the walls on the sides will begin. The height of the gaps above the roof must be at least 5 cm.

The 3rd row is built on top of the 2nd, observing the dressing. Gaps above the walls on the sides are lengthened, internal protrusions are made on the side walls to increase the gas duct. The size of the gas duct increases with each row in places with overflows. Then continue laying with a constant overlap of incomplete bricks. Rows 4-5 will be the last before the overlap over the back wall. They are located above the roof, where a metal collar will be made at the back of the pipe. To extend the working life of the collar in such 2 rows, it is recommended to make one of the walls on the sides longer by 3 cm.

Brick laying scheme.

The back wall is built obliquely. At this wall, after laying, one of the corners in the roof will be higher, and a trough with a slope will form around the pipe, the debris from which will be washed off by rain. At the same time, laying the back wall is somewhat difficult, since it is necessary to cut straight parts of the brick into oblique ones. It is also possible to build this part of the chimney in the traditional way - without lengthening the wall, then the chute will come out without tilting. On the 6th row, the laying of the overlaps above the back wall is completed. The next one is executed exactly the same as the previous one. The 8th row is poured inside the chimney above the flue. Starting from here, the laying is carried out vertically along the riser. Construction of the pipe neck begins with five bricks in a row to the required height.

The brick pipe ends with a head with 2 overlaps of 3 rows - 13-15 rows. In most cases, this part of the chimney is exposed to gases, cold weather and precipitation. Wet seams freeze in winter, and thaw in spring, thanks to which the styling can collapse. The construction of the head implies the use of brick quarters with thick seams. They can get wet and grow from frost, which makes them weak and leads to a rash of solution. To increase the service life of a brick chimney, you need to reduce the number of quarters used and make the vertical seams thinner.

On the ledges of the head and bedside tables, an inclined filling is made from a solution of cement, sprinkling it with dry cement and smoothing it with a trowel for good reliability. It is needed for the rainfall. The neck of the chimney will have sharp corners, thanks to this, if there is a desire, you can chamfer the chamfer at the corners of 4 cm.If you shave less, then the beauty of the brickwork will not be clearly visible. Laying in this case can be performed in order. Chimney angles are prone to strong winds. The thickness of its walls is about 12 cm, and in places where it is squeezed, it will be at least 14 cm.

The cutting of the corner begins in the 11th row with an indent from the bottom of the corner by 2 cm. 12-16 rows are made with the same dressing and are laid out of bricks with cut corners. In the 17th row, squeezing is performed, similar to that performed in the 11th, with an indent of 2 cm from the part on top of the corner. The remaining 2 cm in this row will make the corners more beautiful and will give better support and significant strength of the masonry for the inflated rows of the head. The neck of the pipe will have 8 rows, but for a greater height of the pipe, the laying can be continued. The next 2 rows are stacked in the same way as 13-15 in the version without constricting the corners. The corners will be chamfered, and the cap head will receive two overflowing rows.

Before laying the head, it is necessary to unfold dry row 20 so that the masonry can be divided into halves of the brick. The seam should be 5 mm. If on top of the structure that turned out to be laid the last, 21 row of five bricks, a protrusion of 6 cm should come out.This 6 cm must be divided into 2 parts, as a result, it turns out that in each row an overlap of 3 cm should be made. and whole bricks, which makes it much easier. The overflows are carried out according to the previously laid out scheme.

Sometimes bricks can fall off from the plastered pipe. This is due to the fact that dense plaster does not allow air to pass through, which leads to the accumulation of condensation due to temperature differences. Condensation destroys both brick and plaster, thanks to this, the pipe should be covered only with mortar, it contains slaked lime.

DIY chimney construction for a metal stove

It requires skills to build it. bricklayer... In the old days, the most experienced stove-maker was always invited to build a pipe. A self-confident person will fully cope with this task if he has patience and will lay each brick carefully.

The construction of a chimney consists of a number of important stages - design, foundation preparation, purchase of materials, pipe laying, finishing.

Attention! Neglecting technological nuances will lead to serious consequences! Bad cravings will cause smoke inside the room, carbon monoxide poisoning.

Poor quality materials or non-compliance with masonry technology leads to the destruction of the chimney.

Project selection

In order not to be mistaken, the following factors are taken into account:

- Boiler type and fuel combustion mode.The main enemy of brick pipes for the furnace is condensate... It is formed when the flue gases from the boiler cool down below a certain level. For pyrolysis boilers and long-burning furnaces of the type "Stropuva" or "Buleryan"the temperature of the exhaust gases is low, the condensate settles on the walls of the chimney, and the brick gradually gets soaked and destroyed.

Type of fuel. Wet wood, even with a "hot" fast burning, emit a lot of moisture. It evaporates and penetrates into the pores of the brick.

The condensate contains sulfuric acid, which has a detrimental effect on masonry. You need to heat with well-dried wood with moisture no more than 15%.

Brick dimensions. The inner diameter depends on this. The smallest pipe, a four, is formed of four bricks and has a wall width of half a brick - 125 mm, six - 250 mm.

The more powerful the firebox, the wider the smoke outlet should be.

The choice of material for laying a brick chimney

An important point in the construction of a chimney is the choice of bricks. At different stages of the construction of the smoke exhaust duct, you can use different types of bricks:

- Red corpulent shmatt or ceramic brick - well fired. The material has smooth edges and a clear rectangular shape. When tapping red brick, a characteristic “metallic” sound is heard.This type of brick is recommended for laying any part of the chimney. The minimum mark for a brand is 200.

- Pink brick - unburned. During a knock on such a brick, a dull sound is heard. Usually it is used for laying less important areas.

- Dark brown brick (burnt) is the best option for laying the foundation of the chimney.

- The size of the brick for arranging the chimney is 25 * 12 * 6.5 cm.

Important! Porous, lightweight and hollow bricks are prohibited for use in the construction of a chimney.

The laying of different parts of the structure is marked by the use of a working solution of a different composition:

- the chimney area above the roof is laid out on a cement-sand mixture;

- masonry under the roof is carried out with lime or cement-lime mortar.

Chimney foundation device

A separate foundation is required only for pipes belonging to the main group. For example, a foundation for a boiler room chimney.

The foundation is laid in the same way as the foundation for the furnace, in the same ways and taking into account the same requirements.

And the actual installation of the boiler room chimney is carried out according to the previously calculated order.

Difficulties during construction

When building, a novice bricklayer can face several troubles:

- The solution is constantly falling inside pipes. To avoid this, you need to put the solution in carefully dosing. If it is not possible to achieve, we plug the pipe with a large rag, which we constantly "raise". It will prevent the solution from remaining in the chimney.

- "Filling" pipes. Not worth putting more than 10 rows in one day - the building does not withstand the load and sags. Therefore, we put in 3-5 receptions, constantly monitoring the level.

- "Crooked" brick... Plastic molding brick sometimes sins in size up to 0.5 cm. Therefore, it is worth monitoring the horizontal level and the level inside the chimney. Protruding "teeth" and edges can lead to "ghosts" - the hum of air at high thrust.

How to assemble a chimney correctly?

Fire safety rules when installing a chimney prescribe the observance of certain standards. For wiring a sandwich pipe through wooden structures, high-quality thermal insulation of metal parts from wood (or any other combustible) is required.

In the case of a finished metal pipe, it is possible to purchase ready-made structures that insulate the roof from the effects of heat (pass-through unit) and atmospheric precipitation (oblique pad and protective corrugated flange).

Rules for assembling a sandwich part of a chimney:

- The assembly of the structure is carried out from the bottom up.

- Metal parts are inserted into one another according to the principle of socket connections. The joints are sealed with a special non-flammable compound and reinforced with clamps (special clamps).

- There should be no joints in the pipe section through the floors. This is a fundamental fire prevention rule when assembling a chimney structure.

- If the roof is made of flammable material, it is necessary to install a spark arrestor on the pipe head. In any case, a protective cap is required.

- To secure the high structure, I use tension cables.

General rules for installing the transition:

- The metal part of the pipe can be partially recessed into the brick part according to the sleeve principle.

- It is unacceptable to reduce the inner part of the channel or install mechanical barriers (protrusions, fittings) for the passage of combustion products.

- To ensure tightness, a black oven sealant with a resistance of up to 1500 degrees is used. If the pipe is not supposed to be disassembled, then the sealant passes through the inside of the pipe. If the structure will (in the future) need to be disassembled, then only the outer seam is sealed. Later, during disassembly, the sealant is removed by mechanical action (broken).

- To switch from a square shape to a circular section, a support platform (square) and a branch pipe (cylinder) are required.Better if it is a one-piece construction.

We recommend that you familiarize yourself with: Using paint for the surface of galvanized pipes

There are several options for switching from a brick chimney to a sandwich pipe. Each of them has its own advantages.

Finishing and design solutions

Children will always draw a pipe on the house. The appearance becomes "warmer" and more comfortable, the house looks well-lived and neat. A crooked or collapsed pipe indicates a bad owner, so when laying a chimney, you should also think about design.

The brick tube for the oven is already finished art object... Using the techniques of artistic masonry and contrasting facade paints, you can get a real masterpiece even from cheap bricks. However, if such masonry does not fit into the overall design, you should think about finishing.

- Plaster... Clay brick is perfectly plastering with weather-resistant cement plasters. The seams during laying should be embroidered - this way the mortar will better adhere to the pipe.

The surface is primed, applied first, adhesive layer, beacon corners are installed. Then the main layer is pulled together by the rule and overwritten. The result is a flat surface for processing with facade paints.

- Warming solid basalt wool and device ventilated facade... The material of the ventilation facade can be any, the main thing is that it is non-combustible. Plastic or wood will not work - even an accidental spark can cause a fire.

- Device umbrella and weather vane. The chimney is the highest place in the house. A light weather vane won't harm a solid brick base, but it can dramatically improve the overall look of your home.

The efficiency of thermal energy generators, such as a boiler or furnace, is largely determined by the correct removal of fuel combustion products. The chimney lined with brick has excellent draft and excellent appearance.

In addition, a brick chimney has a significantly longer service life than pipe or metal products. You can make a brick chimney yourself if there is a scheme for laying it and at least initial skills in using the tool are present. When performing this work, it is required to observe many technological subtleties.

A brick chimney will serve as a decoration for the house

Chimney insulation

External insulation of the chimney is intended to eliminate the main enemy of the pipe - condensate, which forms in the cold season as a result of condensation of water vapor on the inner walls. A particularly large amount of moisture is contained in wood - up to 25% in dry wood and up to 60% in freshly sawn wood. Coal does not contain vapors, but since the combustion process uses air from the living quarters, its humidity can reach 8-10%.

Insulation of the chimney pipe avoids the formation of condensation on its inner walls

There are three main methods of insulation:

- Plastering. The easiest and most affordable way that does not require special skills. It consists in the fact that several layers of slag-lime mortar are applied to the chimney, which, when solidified, forms a strong protective "coat". To strengthen the adhesion of the plaster to the masonry, use a metal mesh, securing it to the pipe with anchor nails. After applying 3-4 layers (at intervals for drying) the insulated surface is covered with whitewash or lime. As practice has shown, such protection is able to reduce the heat transfer of the pipe by 20-25%. This method is fast and does not require large financial costs.

After covering the chimney with several layers of plaster, its heat loss is reduced by 20-25% - Thermal insulation with wooden boards. Boards with a thickness of 30–40 mm are required. Around the entire chimney (from the otter to the head), a wooden frame is mounted and completely sheathed with a board. From above, the wood is protected with slate.The distance between the brickwork and the boards (5–7 cm) is filled with any non-combustible insulation - earth, sand or mineral wool. In order to avoid spillage of the insulation, the gaps between the boards are closed with plastic wrap or putty with sealant. This method is effective in the regions of the steppe zone, where dry winds often blow, and prolonged rains are rare.

Non-combustible insulation is laid between the pipe and the wooden frame - The third method requires certain expenses. It consists in the fact that the walls of the pipe are insulated with mineral wool, which is resistant to the effects of solar radiation. The best option is considered to be basalt wool, which has a very low thermal conductivity. A layer of adhesive is applied to the chimney, to which the basalt slabs are attached. For good adhesion, the entire array of insulation is fixed with plumbing tape and covered with a reinforced polypropylene film. After the glue has completely dried, the cotton wool is covered with granular facade paint using a masking net. Another option is siding or cladding with profiled metal sheet. This pipe insulation allows you to save up to 50% of the heat inside the chimney. And, as a result, ensure the absence of condensation on the inner walls.

A layer of glued stone wool can be protected with sheets of profiled metal - this will be reliable and beautiful

Brick chimney properties

The main purpose of the chimney is the most complete removal of exhaust gases and the creation of good draft, without which it is impossible to maintain an efficient combustion process. The brick construction has positive properties and is not free from disadvantages.

In addition, a brick pipe gives the architectural appearance of the house a finished look, ideally blending visually with many types of roofing, in particular, with tiles. Therefore, the traditional solution in the form of a brick pipe is still popular today.

The disadvantages of such a chimney include its heavy weight, requiring the creation of a reliable base, the duration and complexity of its construction. During construction, all technological standards must be carefully observed, deviation from them threatens with very unpleasant consequences.

Brick chimneys are very different

For the delivery of structural elements, special transport is required, which will have to be ordered and paid for. In addition, the rectangular shape of the internal section is not ideal for removing exhaust gases, they swirl in the corners and impair natural draft. In any case, after a while, it may be necessary to clean the chimney, which is described in the article "How to clean the chimney, chimney and stove from soot with folk remedies with your own hands."

Work order

Layout of brickwork chimney.

It is imperative to prepare for the work. For this, it is worth choosing materials and tools. Gloves can be used to protect hands while working. Next, we get acquainted with the pipe system, consisting of a neck, a head, a riser, a metal cap and a smoke damper. Lay down a brick pipe made of bricks that will bind the solution. To insulate the pipe from wood structures, we use an asbestos-cement slab. Brickwork should not contain gaps along the entire height of the pipe.

To do this, the mortar is applied in a small layer, the bed is prepared, the brick is wetted in the water mass, the mortar is applied to the mating surface of the brick, and the brick is put in place. The installation movement is sliding with simultaneous pressure in the direction of the vertical seam. If the installation of the brick did not come out, it is recommended to remove it and repeat the operations.

Additional tapping of the brick in order for it to fall into place is not recommended. In the course of tapping, air spaces appear, which affect the draft of smoke gases.The seam of the masonry should be 0.5 cm in the horizontal position, and 1 cm in the vertical position. When laying 4-6 rows, the pipe inside is wiped with a wet cloth and the seams must be wiped off.

The shape affects the level of hydraulic resistance, due to this, very often in the cross-section of the pipe, a rectangle or square. The round shape, of course, is also considered an excellent option, but a brick is used, it is not easy to create it with your own hands.

Scheme of the construction of a top-mounted chimney: 1 - iron cap; 2 - pipe head; 3 - pipe neck; 4 - cement solution; 5 - otter; 6 - roof; 7 - frame frame; 8 - rafter legs; 9 - pipe riser; 10 - fluffing (cutting); 11 - overlapping beam; 12 - insulation; 13 - smoke valve; 14 - furnace neck.

The chimney should not have turns, slopes, since such elements form additional air resistance. If you can hardly do without turning, you can make it at an angle of 60 degrees.

The chimney section must be within 260x260 mm. The heat output of your stove depends on the selected section. For example, with a selected section of 130x130 mm, the heat output is 3500 W, and with a section of 130x250 mm - more than 3500 W. It is not better to select too large a section, just as with good traction, you lose the effectiveness of your heating, the heat transfer decreases.

Above the roof, it is necessary to remember about the headrest with which the pipe should be equipped. The headrest is laid in one brick. The upper part lies with your own hands on a mortar of cement and sand.

Diagram of the device and the constituent elements of a brick chimney

It may seem that a brick chimney has a very simple device in the form of a rectangular pipe. The scheme of its engineering structure is much more complicated. We list the parts of a brick chimney that have their own name:

- On top of the furnace, the overhead pipe is first laid out. It does not reach the ceiling for about six rows of brickwork.

- Then fluff is performed, which is an expansion of the chimney masonry while maintaining its internal section unchanged. The outer part expands at this point by about three hundred and fifty millimeters.

- After the passage of the ceiling, a flat section of pipe in the attic, called a riser, follows the fluff. It is evenly laid down to the inside of the roof covering.

- Further, another expansion of the chimney, called an otter, is performed by about one hundred millimeters. This is done to prevent rain and snow from entering the gap between the pipe and the roof.

- After the otter, the neck follows - a flat section of the pipe. He equips in the same way as a riser.

- The chimney cap is made with the expansion of the outer part of the masonry. A protective cap is installed on top of it to prevent rain and snow from getting inside.

General diagram of a brick chimney device

It should be noted that all extensions of the masonry are carried out only from the outside, the cross-section of the chimney from the inside remains unchanged throughout its entire length. Instead of fluffing, you can adapt a metal box filled with sand or expanded clay, that is, non-combustible materials. This solution simplifies the work and shortens the execution time.

The functional purpose of this structural element is the same as that of the fluff - preventing the ignition of ceiling materials. Note that the chimney can be made inside the wall, if it is equipped with non-combustible materials and has the required thickness. For a metal heating stove, it is also possible to fold the chimney out of bricks.

Required recommendations

The chimney is laid down in the same way as the stove, you can use masonry in 4 bricks, in five or six bricks.

The laying of the pipe in the attic room goes along the beacon.To do this, having laid out the first 2-3 rows in the attic, release the plumb line from the roof plane to one of the corners of the masonry. A nail is driven into the plumb line. A nail is hammered into the seam of the corner of the masonry, along which the plumb line was leveled, and a silk thread is tied between them. Laying takes place along the control corner, checking with a square every 3-4 rows.

The scheme of laying the chimney fluff.

When laying the pipe above the roof, for greater strength of the structure, you can use not a mortar of cement and sand, but clay-cement. For this, 1 liter of cement is added to the clay-sand mortar, which was used for the kiln masonry, per 10 liters of water and thoroughly mixed with a mixer.

The head of the pipe is considered more of a decoration, thanks to which it can be omitted. If you want to do it yourself, do not change the inner section. Changing the cross-section can lead to swirling of the smoke in the duct.

In order to protect the pipe from hydrometeors, a galvanized iron cap is installed in its upper part. The work on its installation will make it possible to remove the penetration of moisture into the channel.

We comply with the restrictions when planning the chimney

Laying the stove chimney with your own hands follows with unconditional consideration of the prevailing experience. When arranging a brick chimney, it is strongly recommended to comply with the requirements of building codes and regulations for the construction of such structures. The efficiency of its functioning and safety of use, the comfort of living in the house and the cleanliness of the air environment largely depend on this. The brick structure must meet the following parameters:

There should be a minimum number of horizontal sections in the chimney. In the case when it is impossible to do without them, the total length cannot be more than one meter. The elevation of the pipe above a flat roof should not be less than one meter. In the event that the distance to the ridge is less than one and a half meters, it must rise above it by more than fifty centimeters.

Rules for placing a brick pipe on the roof

In a situation where the specified distance is about three meters, the pipe head is flush with the ridge. At a greater distance from the chimney, its outlet is located along a line lowered by ten degrees from the horizon, drawn from the top point of the roof.

Construction of houses

46 votes

+

Voice for!

—

Against!

Chimney masonry is made of different materials. Some are able to successfully resist the appearance of corrosion, condensation and soot deposits. Others allow the manufacture of a complex chimney configuration. Nevertheless, as before, traditional brick chimneys are highly popular, which have proven their reliability and efficiency over hundreds of years of operation.

- Features of brick chimneys

- Structural elements of a brick chimney

- The choice of material for laying a brick chimney

- Requirements for the construction of brick chimneys

- How to make a brick chimney from a stove: step by step instructions

- determination of the shape and size of the chimney

- necessary tools and materials

- mixing of working solution

- erection of the lower part of the chimney

- arrangement of fluff and chimney barrel

- chimney outlet above the roof

- What to consider when laying a brick chimney for a boiler

- Common mistakes when cocking a chimney

Features of brick chimneys

Along with the massive construction of country houses, interest in fireplaces, stoves and boilers has increased. To organize the outflow of combustion products, a brick chimney is most often erected. An outlet structure made of this material is usually used for single heating and heating devices.

Different types of brick chimneys have gained wide popularity due to a number of advantages:

- Resistant to high temperatures.Fireclay bricks can withstand up to + 1000 ° С (the combustion temperature from the fireplace / stove reaches + 750 ° С).

- High level of efficiency. During heating, the brick accumulates heat well.

- Affordable construction cost.

- The brick chimney is suitable for different styles of the interior.

The negative qualities of a brick chimney include:

- The angularity of the structure leads to the formation of vortex flows, which worsen the outflow of combustion products.

- The inner walls of the chimney are rough, which contributes to the settling of soot. In a dirty chimney, the working space decreases and the draft decreases.

- Brick structures are bulky and weigh a lot. For the construction of such a chimney, it is necessary to lay the foundation.

Structural elements of a brick chimney

Consider a typical brick chimney design - this will help you understand the main stages of construction.

Brick chimney: device diagram

- The neck of the stove is the part of the chimney that goes directly from the stove to cutting. A smoke damper is installed here, which is necessary to regulate the draft, the intensity of combustion and smoldering of the fuel.

- The fluff (pipe cutting) is arranged at the passage of each floor. The purpose of this chimney element is to protect combustible ceilings from high temperatures. The walls of the fluff are thicker in comparison with the rest of the elements of the chimney duct. The thickness of this part is about 35-40 cm.

- The riser is a flat part of the chimney located in the attic and reaching the roof.

- The otter is located on the roof and protects the chimney structure from precipitation and condensation.

- The neck of the pipe is just above the otter. In terms of masonry, this part of the chimney resembles a riser.

- The head of the pipe is an extension above the neck. An umbrella or a cap is installed on top of the "protruding cap", which prevents the penetration of dirt and precipitation into the smoke channel. In addition, the installed vane increases the draft of the chimney.

The choice of material for laying a brick chimney

An important point in the construction of a chimney is the choice of bricks. At different stages of the construction of the smoke exhaust duct, you can use different types of bricks:

- Red corpulent shmatt or ceramic brick - well fired. The material has smooth edges and a clear rectangular shape. When tapping red brick, a characteristic “metallic” sound is heard. This type of brick is recommended for laying any part of the chimney. The minimum mark for a brand is 200.

- Pink brick - unburned. During a knock on such a brick, a dull sound is heard. Usually it is used for laying less important areas.

- Dark brown brick (burnt) is the best option for laying the foundation of the chimney.

- The size of the brick for arranging the chimney is 25 * 12 * 6.5 cm.

Important! Porous, lightweight and hollow bricks are prohibited for use in the construction of a chimney

The laying of different parts of the structure is marked by the use of a working solution of a different composition:

- the chimney area above the roof is laid out on a cement-sand mixture;

- masonry under the roof is carried out with lime or cement-lime mortar.

Requirements for the construction of brick chimneys

Home safety, comfort, fuel consumption and air purity largely depend on the accuracy of the chimney calculations. The design of the chimney of a boiler, fireplace or stove must meet the indicated criteria:

- When laying the chimney, there should be no horizontal sections of the exhaust gas passage. When it is impossible to avoid their formation, the use of channels is allowed, provided that their total length does not exceed 100 cm.

- For a flat roof, the chimney must rise at least 100 cm above the roof.

- For arranging a chimney on a pitched roof, the following standards apply:

- if the distance from the ridge line to the pipe outlet is less than 150 cm, then the chimney height must exceed the ridge structure by at least 50 cm;

- if the specified distance is about 300 cm, then the chimney is installed at the same level with the ridge;

- when the ridge is removed from the pipe by at least 300 cm, the upper cut of the chimney must correspond to a line conventionally drawn at an angle of 10 ° to the ridge horizon.

Additional requirements for chimneys in a brick house:

- The product must necessarily comply with fire safety requirements. Walls covered with flammable material should be at least 380 mm from the outside of the masonry. In the ceilings between floors, thickenings, the so-called edges, should be equipped.

- The thrust is influenced by the height of the pipe. It is believed that the chimney should be at least 5 m.

- For residential premises, the thickness of the chimney walls is at least 100 mm.

- The internal cross-sectional area of the chimney must be constant along the entire length of the chimney.

- It is unacceptable to enter more than two stoves into one chimney.

- It is permissible to arrange chimneys inside the outer walls if they are made of non-flammable materials. An additional condition is wall insulation from the street side. This measure will protect the chimney from condensation.

- For stoves with pellets, wood, briquettes, coals, etc. valves with a hole 1.5 * 1.5 cm are installed.

Important! If the roof of the house is covered with a combustible material (shingles), then the pipe mouth is additionally equipped with a spark arrester having mesh cells of no more than 0.5 * 0.5 cm

How to make a brick chimney from a stove: step by step instructions

Determination of the shape and size of the chimney

Smoke moves in a spiral along the stove / chimney. Therefore, it is optimal if the inner section of the chimney is made in the form of a circle. But it is impossible to lay out a pipe of this shape from a brick. Therefore, the brickwork of the chimney is made of rectangular shape.

It is advisable to treat the inner corners with a leveling compound. For such work, it is better not to use plaster - due to frequent temperature changes, the material can quickly crumble.

The size of the chimney is determined by the dimensions of the entire building. On a small, compact house, a chimney that is too high and wide will look comical. Chimneys with dimensions of 260 * 260 mm are being built for Russian stoves.

Advice. Economical brick consumption is achieved when laying a pipe 260 * 130 mm. This design is possible when laying each row of five bricks.

Required tools and materials

To work, you will need the following tools:

- hammer pickaxe;

- a hammer with a rubber attachment;

- roulette;

- level;

- Bulgarian;

- trowel;

- buckets for water and working solution;

- electric drill with mixer attachment;

- sieve.

Materials must be prepared in advance: brick, clay and sand.

Mixing the working solution

For the solution, clay, clean without debris and impurities, which was mined from a depth of 1.5 m, and river sand are suitable. Before work, sift the clay and sand through a sieve with holes no more than 5 mm. Two days before the start of laying, the clay must be soaked in water (for about 48 hours) and mixed.

Solution preparation procedure:

- Combine sand and clay in a 2: 1 ratio.

- Pour the resulting mixture with water in a ratio of 1: 4.

- Leave the solution for 12 hours to infuse.

- Stir the mixture thoroughly until a homogeneous consistency - the presence of lumps is unacceptable.

Erection of the lower part of the chimney

Before laying the chimney out of bricks, a nozzle pipe is arranged. It is being built with the obligatory observance of brick dressings. The shell pipe is laid out directly above the fireplace or on the stove in the shape of a rectangle about 4-6 bricks in size. A cavity is left inside the structure - a smoke well. The packing pipe ends, not reaching five to six rows to the overlap.

Arrangement of fluff and chimney barrel

The subsequent laying of a chimney made of bricks with your own hands is the arrangement of the fluff neck. The height of the cutting neck is five bricks, the size of the smoke channel is 140x270 mm.

The fluff is laid out in compliance with a number of rules:

- The outer dimensions of this part of the chimney are 590x450 mm. When laying, halves and quarters of bricks are used.

- Brick plates are installed inside the smoke channel - they "hold" the shape of the chimney.

- The third row of fluff increases, 60 mm thick plates are inserted inside. Its dimensions are 650x510 mm.

- The dimensions of the next two rows are 710x570 mm. For the strength of the pipe, bricks with a thickness of 90-100 mm are inserted inside.

- Fifth row - two solid bricks are laid side by side.

- The sixth row repeats the laying of the fifth, but with the observance of the dressing.

Previously, a hole must be made in the roof to bring the chimney out. The riser is erected in the attic and brought out to the roof, observing the bandaging of the brickwork. The height of the riser on the roof is 1-2 bricks.

Chimney outlet above the roof

The next stage after laying the riser is the arrangement of the otter. This pipe segment consists of nine rows, while the outer size of each subsequent one should be ¼ of a brick larger than the previous one.

Important! At this stage of work, special attention should be paid to the internal size of the canal - it should neither narrow nor expand

In the third row, the width of the otter is increased due to the extended bricks - the front ledge extends to the sides. In the fourth - sixth row, the side protrusions are lengthened. In the seventh row, the formation of the lateral protrusions is completed. The eighth and ninth rows complete the structure and form all the pipe protrusions.

Next, the chimney neck is formed. The height of this element is on average five to eight rows. After laying the neck, the head is equipped using the same technology as the fluff.

The final stage of the construction of the chimney is the installation of a weather vane or a hood.

Brick chimney: video

What to consider when laying a brick chimney for a boiler

When installing a chimney for a boiler, it is important to understand the features of the combustion process and the specifics of removing decay products. It is necessary to take into account all the nuances of the chimney construction technology, therefore it is better to entrust this work to specialists. Errors in chimney design and use of a chimney valve can lead to carbon monoxide poisoning.

Highlights:

- The best option is to arrange a separate room for placing the boiler. If there is no boiler room, then you can use a small corridor near the entrance to the house or basement.

- The room where the installation of a chimney for a gas boiler is planned must have the ability to ventilate and sufficient draft.

- The chimney and ventilation holes are made on the same wall - this is necessary to avoid pressure drops and back draft arising from gusts of wind.

- A slight gas leak is possible when adding fuel, firing up the boiler and completing the combustion process.

How to lay out a chimney for a brick boiler: video

Common mistakes when cocking a chimney

There may be malfunctions in the operation of the heater due to defects that were made when laying the chimney:

- Insufficient height of the pipe relative to the roof of the house affects the decrease in draft.

- A poor-quality mortar used for masonry collapses under the influence of various temperatures - the strength and tightness of the chimney deteriorates.

- Unevenness of the inner channel provokes the appearance of turbulence - soot / soot is deposited on the walls.

- The permissible vertical deviation is 30 ° С at a distance of 2 m.

Determine the size and shape of the structure

Correctly calculated chimney size is directly related to the creation of high-quality draft, the process of fuel combustion in this case occurs with high productivity. It is believed that the minimum chimney height should be approximately five meters for efficient operation.The fire safety of the structure is ensured by the thickness of its walls.

The gap between the chimney and the wall is about forty centimeters; when passing through the ceiling, special extensions of the wall thickness are performed. The dimensions and shape of the chimney are calculated depending on the structural features of the building and roof, the size of the heated rooms, and so on. The chimney should be in accordance with the general architectural appearance, so a large chimney is inappropriate in a small country house.

Pipe requirements

Chimneys of any category must be suitable for some indicators, and possess characteristics:

- Heat transfer;

- Thermal stability.

- Have a certain internal section;

- Fit the best chimney height on the roof.

- Have strength to mechanical action.

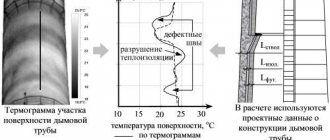

Temperature graph of the outer wall of the chimney shaft

As for the section, it must correspond to the size of the combustion chamber. The larger its dimensions, the greater its productivity, and, this means, and the dimensions of the section must be appropriate, otherwise the smoke will fall into the interior of the room. Excessive cross-sectional area will weaken traction and increase the appearance of moisture.

How to build a brick chimney with your own hands

Before you lay out the stove chimney, you need to draw up a diagram of it. Any chimney is a unique structure, and its parameters are determined by many factors. The chimney laying scheme should simplify its construction as much as possible.

Sometimes bricks are soaked before work, other craftsmen lay it dry. In the latter case, the binder is absorbed into the building material, and the masonry is less durable. Wet brick forms a more durable surface, but it takes longer to dry. Sometimes this is quite inconvenient, for example, before the imminent onset of winter cold.

We prepare the necessary materials and tools

To carry out work from building materials, only brick and a binder mortar are required. The choice of brick has already been written above, the cement mortar must also be of the highest quality. The excellent quality of the connection of structural elements under any adverse effects of the external environment is ensured precisely with its help. Parts of the exhaust system operate under different conditions, therefore, the composition of the cement slurry is different.

The fundamental base of the root pipe is fastened with a mortar consisting of three parts of sand and one part of cement, with the addition of half a part of lime to improve its plastic properties. In the section before the fluff, the temperature develops up to four hundred degrees Celsius, therefore, a solution of clay with sand is used here. The neck and the otter are fastened with a lime mortar, since here the temperature effect is low, and the wind load is high.

The clay used for the solution should not smell strongly, since such a smell indicates the presence in its composition of organic impurities that cause cracking of the dried mixture. There should also be no organic components in the sand. Mountain sand is well suited, as well as crushed sand-lime bricks. To complete the work, you will need the following tools:

- spatula and trowel;

- building level and plumb line;

- a hammer in the form of a pick.

To reduce the amount of waste in the form of brick breakage, you can use a grinder to cut the bricks. Accuracy and thoroughness are of great importance at all stages of the work.

Mixing mortar for masonry

The preparation of the binder is a very crucial moment that determines the strength and safety of the structure being erected. Before mixing the mortar for masonry, it is necessary to sift all its components through a fine sieve. Only a homogeneous material is capable of producing a good quality binder mixture.

Special mixtures for laying chimneys are widely represented on the market

With an increase in the cement share in it, the plasticity and mobility of the composition increases. The fillers are limestone, clay or sand. When mixing a solution, the quality and quantity of water, which is the main binding element of the constituent components, is important. To facilitate the work, you can use a construction mixer, and in its absence, the solution is mixed manually.

We spread the lower part of the chimney

The lower part is equipped according to the standard of brickwork used in the construction of any objects. Each subsequent row is shifted in relation to the previous one by half a brick to the side to improve adhesion. A thin layer of grout should be applied to obtain a strong and secure bond.

The first two rows set the orientation of the entire structure, so they are laid out with maximum accuracy. The entire bottom of the chimney is laid out with no less care.

Now we make the fluff and the trunk of the pipe for smoke

The fluff is an expanding stepped structure, the next row of which is laid out with an expansion of about thirty-five millimeters. The widest part is displayed at the floor level of the attic.

The order of the laying of the fluffing pipe

The first row of the chimney barrel is mounted on top. Its parameters repeat the original size before fluffing. The uprights gradually increase in height until they approach the roof overlap.

Arrangement of pipes above the roof

To lead the pipe through the roofing, a pre-marked hole is cut out in it, for example, with a jigsaw. The final row of the chimney shaft is laid out above the outer part of the roofing by approximately the size of half a brick. An insulating layer made of asbestos or other similar material is installed between the roof and the bricks.

Further, a special thickening is set up above the surface of the roof, which bears the name "otter". The functional purpose is to prevent rain and snow from entering the attic.

On top of the otter, the chimney neck is laid out with the return of the dimensions of the original section. The structure rises to the required height. From above, with an extension of about forty millimeters, the first row of the head is laid. Its height should be increased by two brick rows.

Next, the final laying of the pipe is carried out. A protective umbrella is installed on top of the structure. Around the exit through the roofing, thorough waterproofing is performed, all gaps are sealed.

Building

The installation of chimneys is actually no different from the installation of an ordinary air duct. Only one difference between these systems is in the conditions of use, in the case of an oven air duct, it will be used in a rather original environment. Thanks to this, the installation of the chimney has its own subtleties. Installation of any type of pipe is created using our own special technologies. Therefore, those. the installation process is distinguished with reference to the type of chimney device.

Invisible constructions

The device of hidden chimneys involves work when the main part of the walls is being laid. Of course, you can place these structures in the ventilation ducts, but this can be quite scary for your home. To avoid fires, plans prepared by the architect are used. An independent solution to this problem is completely prohibited, because the device of this design is associated with thermal deformation, which affect the channel, increasing it.

Chimney passage through the roof - invisible structure

Only one plus of these devices is the absence of difficulties with the insulation of the chimney on the roof.

Shell-on structures

The installation of steel devices does not require the necessary skills or impressive financial costs.

But it is still necessary to take into account certain points:

- A metal structure must necessarily consist of several sections. The nearest knee to the combustion chamber will instantly burn out, thanks to which it will not be difficult to replace it.