Advantages and disadvantages of corrugated chimney pipes

The positive aspects of using corrugation for such purposes include the following points:

- The circular section of the chimney is the most favorable for the passage of gases. The flow rises along it in a spiral, which is why stagnant zones are created in the corners of a square or rectangular channel, in which moisture present in the smoke is actively condensing. It becomes a "trap" for unburned fine fuel particles. This mixture becomes soot, which can block the smoke channel completely, which makes it impossible for the further operation of the heating unit in the house.

- Simple docking of individual elements of the chimney. A simple adapter and a pair of clamps are sufficient for this.

- Simple and affordable repair associated with simple dismantling and easy assembly of the new flue duct.

- The need for various components is minimal, since corners, turns and other similar elements are not used.

- Convenience of laying a chimney with direction changes if you need to bypass obstacles in the form of rafters and other structural elements.

At the same time, there are several negative aspects of their use:

- Small wall thickness (0.1 mm), which leads to active cooling of the chimney and is accompanied by the formation of a large amount of condensate, and therefore soot. The flue duct made of heat-resistant corrugation needs careful and high-quality insulation.

- Roughness of the inner surface of the corrugation walls, contributing to the increased formation of condensation and soot.

Most often, corrugated pipes are used to insert a liner into brick or other channels in the shape of a rectangle,

as well as in the places where the boiler is connected to the smoke exhaust duct.

Pros and cons of corrugation

The corrugated pipe is suitable for all flue gas systems, even at very high flue gas temperatures.

Another advantage of the corrugated pipe is the ease of connecting two sections to each other.

She shows resistance to:

- humidity;

- high temperatures;

- chemically aggressive environments.

Such a pipe is used not only for the chimney, but also in air conditioning and ventilation systems. Its flexibility allows you to easily install a chimney in the presence of complex architectural structures: sloped ceilings, floor beams, built-in columns, etc. This feature of the stainless corrugation for the chimney reduces the cost and labor intensity of installation work.

No expensive components (adapters, corners, bends) are required for installation; this is important if the budget is limited. Among other advantages, it is possible to note the possibility of connecting pipes of different diameters into one structure. For this, special adapters are used.

There are few disadvantages of corrugated pipes: a short service life and the need for insulation to combat the formation of condensate. In addition, the thrust in the corrugation is much lower than in a smooth pipe, therefore it is not recommended to make a vertical channel from such a product along the entire length.

The diameter of the boiler nozzle must match the size of the pipe to be installed.

The procedure for installing a chimney for a gas boiler

The manufacture of chimneys for gas heating devices using a corrugated pipe is popular. In this case, a heat-resistant aluminum corrugation can be used. At the same time, the basic requirements for the smoke exhaust device remain the same:

- reliability;

- durability;

- tightness throughout the entire service life.

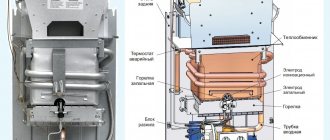

The chimney consists of the following elements:

- The pipe is crowned at the upper end with a head. This can be a simple protective cap or a deflector. In more detail about what types of deflectors are and which one is better to choose based on their characteristics.

- It is attached to the main flue duct, which consists of individual links 1.0 - 1.5 meters long. They are connected to each other using spacers of the appropriate size. At the junction, two screw clamps are installed - one for the abutting ends of the pipe. It can be operated without external thermal insulation, but its insulation should still be considered necessary in order to avoid planting.

- When installing a chimney of an internal structure at the intersection with a ceiling or roofing pie, special bushings are installed to ensure fire safety.

- The outdoor fume hood is mounted on the wall during installation using brackets. The distance between them should be no more than two meters.

- A tee is installed at the transition from the boiler to the chimney.

- A condensate trap with a device for discharging the outflowing condensate is attached to its lower outlet. As it accumulates, it must be drained and disposed of.

- An indispensable element is a viewing window for monitoring the state of the smoke channel.

When completing and installing the chimney, the following circumstances must be taken into account:

- You must carefully read the rules for constructing a chimney for a gas water heater or other heating device.

- In accordance with them, the appropriate design of the smoke exhaust device is selected.

- Along the entire length of the chimney channel, no narrowing of the channel cross-section or its sagging in areas where it is located horizontally is allowed. Their length should not exceed one meter.

- The distance from the boiler furnace to the chimney head must be more than 5 meters.

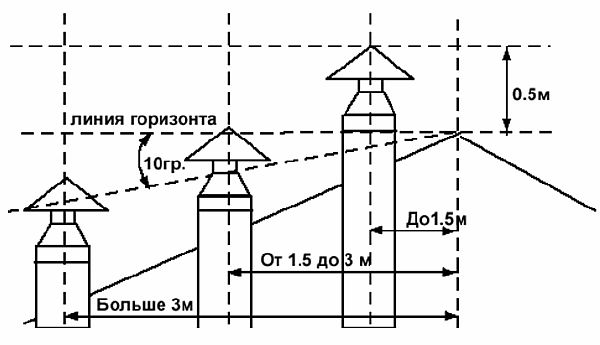

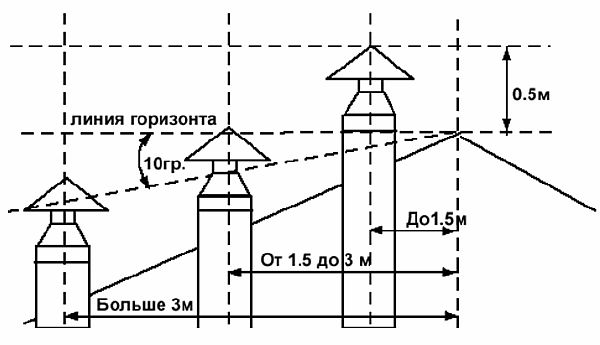

- The distance from the level of the roof ridge should be:

- not less than half a meter, if the pipe comes out at the same horizontal distance from the ridge;

- the head can be at the level of the ridge, if it is 1.5 - 3.0 meters from it to the chimney;

- deviation from the horizon is possible up to 10 degrees if the pipe is located at a distance of more than 3 meters from the ridge.

Failure to comply with these requirements is fraught with insufficient draft in the chimney with all the ensuing consequences.

- The chimney diameter is directly proportional to the boiler output. The most commonly used corrugation is 110 or 130 millimeters. But it is best to use the recommendation of the technical passport of the heating unit, where this parameter is indicated without fail.

- Climatic conditions for the operation of the gas unit in terms of the magnitude of the temperature difference in the boiler room and outside.

Chimney corrugation installation

The assembly of this simple structure must be done in the following order:

- Select a location for the heating unit so that the chimney is straight and vertical. This means that on its way the chimney should not meet obstacles that need to be bypassed. This mainly applies to transfers on the interfloor overlap and rafter system.

- Install the elbow at the outlet of the boiler or gas water heater. Instead, flexible corrugations made of aluminum or stainless steel are allowed. It should be noted that this area is almost never insulated from the outside, since the temperature of the furnace gases in this place is high and condensation does not occur.

- Next, the installation of the straight section is carried out with the installation of clamps and fastening to the brackets (for a wall chimney).

- The outer part, which rises above the roof, is advisable to be made of a heat-insulated sandwich pipe, if necessary, install braces made of stainless or galvanized wire.

- Install a safety device in the form of a head on the pipe.

- Install the condensate trap.

Important! To ensure that condensate collects and does not get back into the firebox, the vertical part of the chimney must not be placed directly above it.

Design and types of corrugated pipes for chimneys

Corrugated chimney pipes are produced by cold forming on a special mandrel. Two types of materials are used for this purpose: aluminum-based alloys and stainless steel.

The workpiece is a tape about 50 millimeters wide with a thickness of 0.1 - 0.5 millimeters.

The corrugation was originally intended for use on air ducts of ventilation systems, where to this day it regularly performs its work. Attempts to use such pipes for chimneys were crowned with success, and since then this application has become more and more popular.

Technical indicators of stainless steel corrugated pipes

Among the important technical indicators of corrugated stainless steel pipes are:

- working temperature: -50 ° С - + 110 ° С;

- pressure at an operating temperature of + 110 ° C: 15 bar;

- possible bending radius of the product depending on the pipe diameter: 25-150 mm;

- thermal conductivity coefficient: 17 W / (m * K);

- linear expansion: 17;

- roughness coefficient: 0.008.

The corrugated pipe is resistant to pressure drops (limit value 50 atm). The maximum breaking pressure is 210 atm. Other pipe parameters are shown in the table.

Table 1

| Indicator | Value | |||||

| steel grade | 304 | |||||

| Diameter in mm | 12 | 15 | 18 | 20 | 25 | 32 |

| Outside diameter in cm | 1,62 | 1,81 | 2,0 | 2,56 | 3,2 | 3,76 |

| Inner diameter cm | 1,18 | 1,41 | 1,78 | 2,1 | 2,7 | 3,2 |

| Wall thickness in mm | 0,3 | |||||

| Weight of one running meter corrugated pipes, kg | 0,13 | 0,156 | 0,164 | 0,2 | 0,23 | 0,28 |

| Corrugation step in cm | 0,425 | 0,476 | 0,5 | 0,5 | 0,526 | 0,56 |

Aluminum corrugation for chimneys

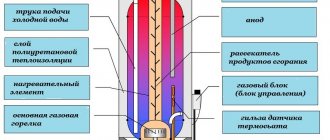

Aluminum alloys used in the manufacture of this type of product can withstand temperatures up to 500 degrees, after which the thin walls of these pipes burn out. But not only the temperature is important, but also the aggressive environment, represented by condensate, which is a weak solution of sulfuric acid.

In this regard, it is obvious that their use for this purpose is very limited. It is not recommended to install a corrugation on the chimneys of solid fuel boilers, where the temperature of the furnace gases is much higher and high-temperature agents are used to remove soot from the chimney. Corrugation is not used for fireplaces and solid fuel stoves on coal and wood.

Aluminum corrugated chimneys for gas boilers are still used quite actively, but specialists in gas and fire services are increasingly inclined to prohibit such structures.

Watch the video

A more loyal attitude to the corrugation on the chimneys of gas water heaters and electric fireplaces, since the temperature of the gases removed is lower than that of similar boilers.

Corrugated stainless steel

Heat-resistant corrugation is made of stainless steel using the same technology as aluminum. These pipes use a high-carbon steel reinforcing insert that is wound in the form of a spring. The spiral in the chimney increases the lateral strength of the products and prevents them from collapsing.

One of the features of corrugated products is their compactness. In the transport position, the length of the branch pipe is 65 centimeters, and after stretching along the longitudinal axis, it can reach three meters.

Watch the video

The temperature that the heat-resistant stainless steel corrugation can withstand is 900 degrees, which allows you to confidently use it for chimneys with any kind of boilers.

Pipes are produced in a range of diameters from 100 to 150 millimeters, the most commonly used are sizes 110 and 130.Of the first, chimneys are mounted for boilers up to 19 kilowatts, large ones can be used for any more powerful heating units.

During installation, the corrugated pipe can be bent in the desired direction at an angle of up to 180 degrees, which is an undoubted advantage, since it allows you to do without the use of a large number of fittings.

To increase the service life, the stainless steel is treated from the inside with special compounds. Reacting with metal, they form a strong, chemically resistant cladding film on the surface. In this state, the corrugated chimney can serve up to 20 years. Fireproof corrugation is the most reliable material for fume extraction.

Installation instructions

The installation of a chimney is not much different from the installation of a similar device made of stainless steel pipes. But there are certain points that need to be considered:

- There is no need to think about the selection of the chimney diameter - the corrugated pipe must match the size of the boiler outlet.

- Having a thin wall, the corrugation loses a large amount of heat from the flue gases. Therefore, the chimney must be insulated along its entire length (except for the outlet pipe).

- Narrowing of the smoke channel is not allowed, its size must be stable along its entire length.

- During installation, use adapters for special purposes only. The use of other products for docking is fraught with loss of tightness, and this is the main requirement for the chimney.

- The use of a corrugation provides for the mandatory installation of a condensate collector, otherwise its inevitably quick planting.

- When connecting separate parts of the chimney, in addition to clamps, additional seals must be installed. Good results are obtained by using a high temperature sealant.

Using these rules, you can qualitatively install an effective, and - most importantly - safe in all respects, chimney.

Tips & Tricks

- It is undesirable to use an aluminum corrugated pipe for chimneys of solid fuel boilers. And for gas appliances, including a column, it is better to avoid risk and use fire-resistant stainless steel. The gas corrugation is fire hazardous.

- If the corrugation is released outside through a brick chimney, assembly is done from above. At the same time, a strong rope is tied at the lower end. In this way, working together, you can quickly and easily plug the chimney with a corrugation. A flexible stainless steel chimney is fed through the mouth of the pipe, and the second participant in the process pulls the corrugation from below.

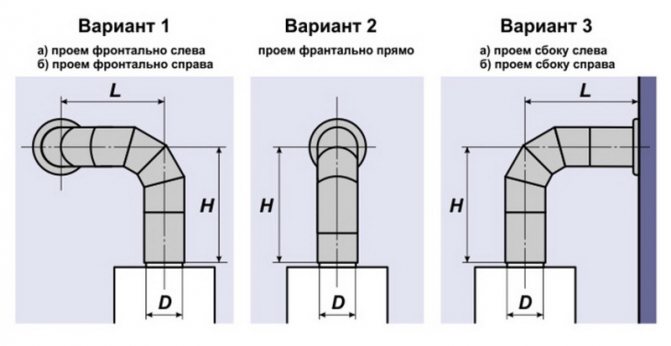

- When installing an external (wall) chimney, no more than two bends are allowed. If necessary, it is better to perform them at an angle of 45 degrees.

- When installing a steel corrugation for a boiler in an old chimney, you must carefully cover the stove with a wet cloth and close all technological holes in it. This is necessary to prevent the ingress of soot into the living area of the house.

- Before installing the pipe in the old chimney, it is necessary to thoroughly clean it from soot deposits on the walls.

What are the requirements of a corrugated stainless steel chimney

A heat-resistant steel, chimney corrugated pipe, as well as a pipe, which includes aluminum, is ideal for a gas water heater, it is enough to choose the right dimensions. However, in the process of installing a chimney, a number of important rules must be observed. Any deviation from the instructions may result in the entry of unwanted substances into the living space.

The rules are as follows:

- Fastening must be done with an adapter;

- The diameter of the duct must correspond to the section of the outlet in the heater;

- If there is an interfloor overlap, then the pipe must be placed in a fireproof material;

- The outer protective casing should be provided with double wall thickness in order to maintain the integrity of the structure in the event of damage to one of the layers;

- The fastening of the corrugated pipe to the system must be airtight, this will ensure that there is no carbon monoxide leakage;

- The radius of curvature must be no less than its diameter;

- The length of the channel from the bottom to the horizontal must be at least 500mm;

- The distance from the ceiling or wall to the pipe must be at least 50 cm, if they are covered with non-combustible material;

- If the walls are not covered with fireproof material, the distance should be at least 550mm;

- The connection to the gas appliance must be vertical;

- The total length of horizontal sections should be no more than 3 m;

- The slope of the flexible chimney can be no more than 0.01 degrees.

By observing all these rules, you will be able to achieve the perfect connection.