With the approach of cold weather, a person becomes dependent on heating systems. After all, heat, or rather, its absence, significantly affects the comfort of living and even the state of health. And, when, instead of enjoying the comfort, you have to deal with why the gas boiler often turns off and on, then this causes a lot of negativity. Isn't that right?

But it is possible to solve the problem that has arisen quickly and without significant financial costs. And in a number of situations, the user himself will be able to return the equipment to work.

The boiler goes out in hot weather: troubleshooting

In rare cases, such a situation is observed when the gas boiler begins to go out in summer. The reason is the lack of draft for the operation of the burner. It is in the warm season that the draft deteriorates noticeably, therefore many experts do not recommend turning on the boiler for permanent work this season, it is better to do this periodically, to obtain hot water, for example. During the night, the chimney cools down, its internal temperature becomes lower than its level outside, which is why such problems arise with the performance of the equipment.

In order to eliminate the malfunction, it is necessary to warm up the chimney, that is, to insulate it. But there is another reason - equipment shutdown in warm weather. It is possible that the traction sensor is faulty, which can work normally in winter, but in summer it constantly turns off the equipment. In this case, it is useless to repair the boiler, only its complete replacement is necessary.

Any equipment requires proper maintenance and preventive inspection. This reduces the likelihood of breakdowns and malfunctions to a minimum. But if the gas boiler starts to work incorrectly, its burner constantly goes out or soot appears when turned on, then an immediate inspection, preventive maintenance or repair is required.

The boiler does not turn on

If the boiler does not turn on at all, then among the reasons for this may be:

- Burner malfunction;

- Insufficient gas pressure in the pipeline;

- Valve closed by mistake;

- Lack of voltage in the mains.

What to do in such a situation? First you need to check the availability of electricity and the supply of gas fuel. If all power is available, then it is necessary to look at the boiler burner - whether it is working properly or not. If a malfunction is detected, it can only be replaced with a new one. It is not recommended to dig into the igniter for the purpose of repairing it; the master should deal with this issue.

A drop in gas pressure may be caused by problems on a street gas pipeline or on a pipe in a cottage. In the first case, you need to contact gas workers, this is their sphere. But the in-house pipeline, like the entire heating system of a private house, is in the area of responsibility of the owner of the home. Moreover, if there is a blue fuel leak in the building, then it can be smelled with your own nose. Additives with a sharp, unpleasant odor are specially added to pipes with main methane.

The problem may be due to a drop in pressure in the central line

Problems of open-type atmospheric boilers

There are a number of reasons that affect the working process of the device, which worked properly for some time, and then suddenly begins to fade.

Traction problems

To check the device for this problem, a lighted match should be brought to the main window. If there is a thrust, then the fire will deviate to one side, in the absence - the flame burns evenly.

Checking the draft in a gas boiler

The main factors influencing the violation of traction:

- Lack of proper ventilation.The air intake is carried out from the premises; a window is required for ventilation. Natural ventilation is required to keep the flame going. Open the window to resume the operation of the device.

- Weather. Unfavorable weather conditions negatively affect the working process of the chimney. In the event that a foreign object falls into the mine, backdraft can occur, leading to carbon monoxide poisoning.

- Glaze. The accumulation of condensate on the shaft walls leads to icing of the part, and as a result, a barrier is formed for normal draft and smoke removal. Eliminate this reason as follows - knock down the icy layer, insulate the walls of the mine.

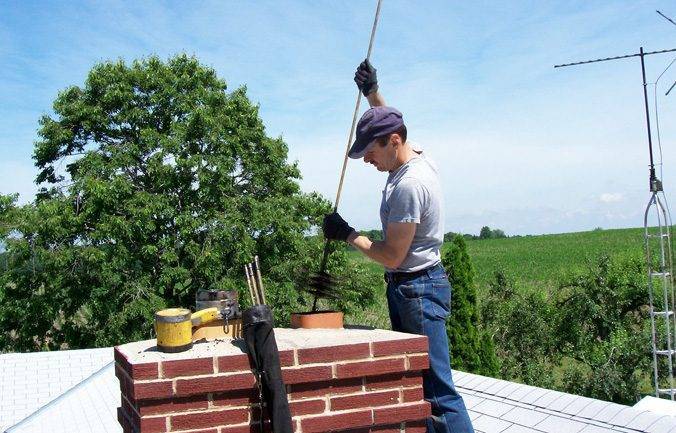

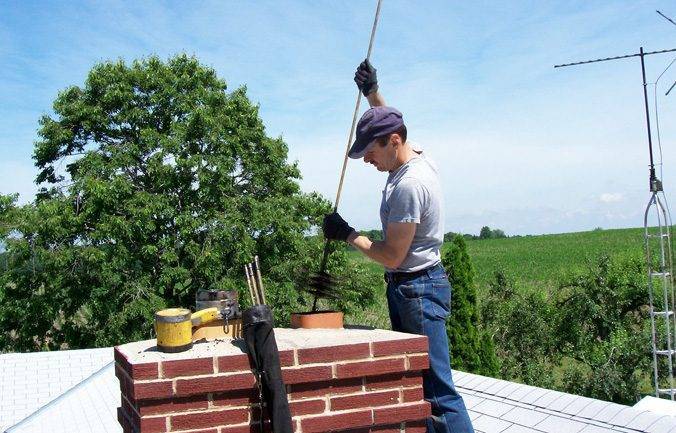

- Soot accumulation. Simultaneous connection of a gas appliance and a solid fuel model leads to a similar problem. In this situation, it is better to resort to the help of utilities.

- Burnout of the pipe. The part must be completely replaced.

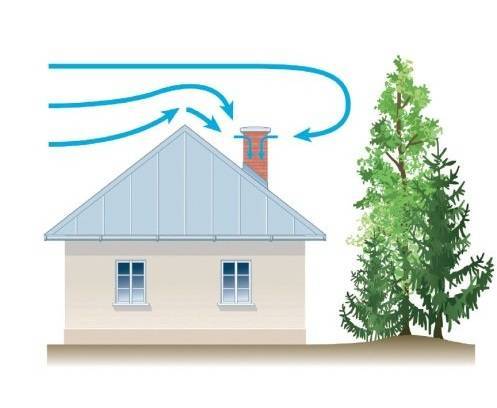

Helpful! A high-rise building located in the neighborhood can block the house, for this reason, the chimney is in the leeward area, which negatively affects its operation. The recommended height of the shaft above the roof of the structure is more than two meters.

Decrease in gas pressure in the pipeline

If there is a draft in the chimney, then you need to go to the next step of checking the unit for fuel supply. A sign of a reduced gas inlet pressure is the unreasonable extinguishing of the burner when the flame is burning at the igniter.

The drop in gas pressure may be due to problems on the street gas pipeline

The main factors affecting the reduction of the fuel supply in the highway:

- clogging, breakdown of the meter - extraneous noises may emanate. A working meter changes readings properly, in case of a failure, you will need to contact a specialist. Hand-held troubleshooting is strictly prohibited;

- triggering of safety sensors - modern models are equipped with gas control and temperature sensors. In the event of a fuel leak, the equipment is blocked. It is possible to identify an unfavorable area in a simple way: a soapy solution is applied to the joints, when bubbles appear, shut off the gas supply, open the windows to ventilate the room and immediately call the gas service;

- clogged fuel filter - you need to clean the mesh part, and after cleaning is completed, the wick and the main boiler burner are kindled.

Important! Before performing any manipulation with the gas pipeline, it is imperative to shut off the fuel supply with a shut-off valve.

Freezing of the head

The outer element of the boiler is called a head, if ice forms on its surface due to low atmospheric temperatures, it is completely impossible to knock it down. To eliminate this factor, you will need to remove the part and defrost it.

It is quite possible to start the unit in this state, however, before starting it, it should be warmed up: screw on the gas supply valve, and then gradually unscrewing it, you need to ignite the burner. The flow should be increased little by little until the entire structure heats up to thaw.

Lack and excess of air

Normal operation requires supply air from the ventilation duct or from other rooms. Drafts must also not be allowed, which could extinguish the low power burner.

With a lack of oxygen, extinction can be easily activated; in such a situation, it is enough to open the nearest window and observe the behavior of the fire. If the combustion stabilizes, then the decay passes.

The sources of this failure are:

- Sealed plastic windows stop the air flow into the room.

- The interior doors were replaced, due to which the leaf gaps were reduced, thereby reducing the passage of air.

- A powerful cooker hood draws in part of the air mass.

- A forced extractor hood was installed in the bathroom and toilet.

The installation of the exhaust devices must be compensated for by the flow of air so that the chimney draft does not decrease and does not tip over on the contrary. In plastic windows, special supply valves are installed, and in the case of forced draft hoods, a mechanical inflow is organized from the street side.

Malfunctions of an atmospheric boiler

Non-volatile floor-standing heat generators have parts that fail during operation. Breakdown signs:

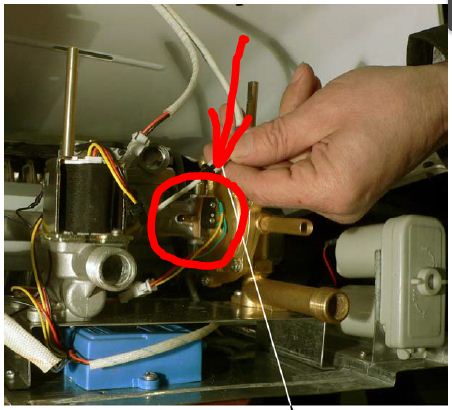

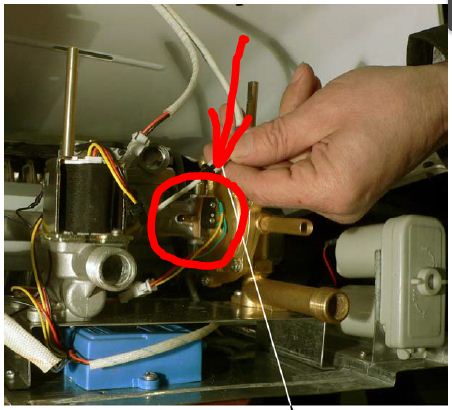

- In the process of igniting the igniter, attenuation occurs when the valve button is released. The thermocouple has stopped its normal operation. This part is heated by the wick, keeps the solenoid valve fuel in the open position.

Thermocouple - copper tube with bimetallic element

- The entire system is not ignited, even the pilot burner. This criterion indicates that there is no contact in the electrical circuit that connects the automatic unit to the traction sensor.

- The ignition of the main burner is difficult or the work is intermittent with pops, then this indicates a clogged main fuel jet.

Important! It is not recommended to personally remove the gas burner element to clean the nozzle, but in case of urgent need, remember that before carrying out this manipulation, it is necessary to turn off the gas, and then unscrew the fastener.

Insufficient ventilation or no ventilation duct

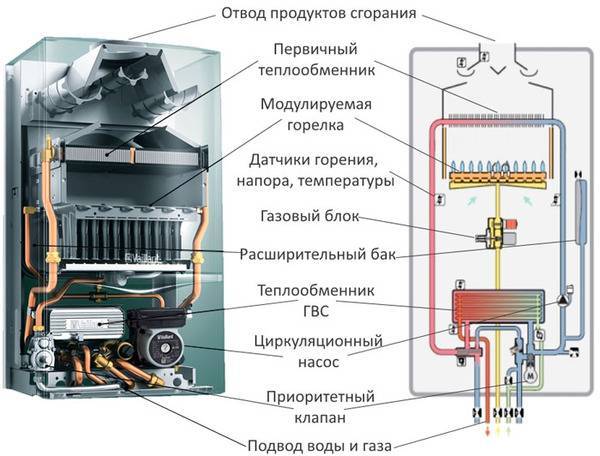

When burning one cubic meter of gas, ten cubic meters of air are burned. Accordingly, in most cases in domestic household boilers, if it is not a turbine type of boilers with a coxial pipe, air from the room is used.

And, accordingly, if you have insufficient supply ventilation: the door is not cut, or holes are not made, and your room is permanently closed, there is not enough air supply for the boiler to burn.

Either you may not have a ventilation duct, or it may simply be clogged. Again, you must either clean the ventilation duct, or provide air flow from below. This is necessary in order to burn the required amount of air in the room and your gas boiler does not go out. If you do not have supply ventilation, or there is no draft in the ventilation duct, then the boiler will start burning air from the room. When all the air in the room is burned, it will begin to draw air from the street through the chimney. Thus, reverse thrust is formed. A certain draft is formed and this draft can blow out your boiler.

Gas boiler does not light up: draft problems

In the case when the gas boiler does not work, first you need to deal with the draft, due to which it may not be possible to start the column. It is quite simple to check it: just bring a lighted match or candle to the window and see how the flame will behave. If it began to lean towards the opening, then the thrust is in order, and if the fire burns evenly and does not reach anywhere, then there is no thrust.

What to do if there is no traction:

- Open the window to the boiler room so that there is an inflow of fresh air;

- Disconnect the part of the chimney connected to the outlet pipe and check the presence of draft in the chimney itself;

- If there is a draft, then you need to clean the gas boiler directly, and if it is not there, then you will have to clean the channel.

If the outlet is not visible in the chimney, you will have to clean it too. However, the problem may be in a bird's nest at the top of the pipe or ice that has appeared, which must be removed.

Fault classification

When contacting a service center, it will not be enough to say that the equipment is not working well, you need to describe the symptoms of a malfunction as fully as possible. All breakdowns are divided into several groups, united by common signs, they can be:

- Intermittent or final. In the first case, the equipment works, albeit poorly, without reaching the operating parameters. In the second, a complete failure occurs, that is, the gas boiler does not heat the water or does not even turn on.

- Primary or secondary. Boiler malfunctions that have arisen for the first time are called primary. Secondary faults are faults that occur intermittently, provided that no repairs have been carried out.

Sudden and growing. The first group includes breakdowns that happened unexpectedly for the owners, that is, before the failure occurred, the owners did not notice any malfunctions behind the boiler. The second group included breakdowns that developed gradually, that is, the owners noticed for a long time that the unit was not working well, but did not take any measures.

Obvious and obscure nature. The obvious ones include leaks, failure of some equipment units. Non-obvious malfunctions can only be detected by a specialist with special diagnostic equipment.

Incorrect location of the gas boiler in the room

The location of the gas boiler in the room also plays an important role. In some cases, such situations were observed when, for example, the boiler is in the kitchen, which in turn is located somewhere on the second or third floor of the building and this kitchen has a balcony.

So what's going on? People open the balcony door, the draft in the chimney is excellent and ... What happens? At first we had some kind of air flow from the corridor or from neighboring rooms when opening the kitchen door and the draft was more or less stable. And then, with a sharp opening of the balcony, what happens? A huge amount of fresh cold air enters the kitchen and a very sharp strong draft is formed in the chimney.

The amount of air increases and hot air begins to go into the chimney with an even greater speed. Thus, the wick literally starts to hesitate, to walk. That is, it can simply either be blown off, or, if there are bad contacts of the safety circuit, or worn out sensors. This can also cause your boiler to go out.

It should be noted that the above reasons are the most common problems. There may be special cases when the cause of the fading and blowing out of the gas boiler can only be determined by a specialist as a result of a thorough examination.

Only one thing is important - observe the safety rules for gas supply and comply with the standards prescribed there.

DIY house

Heating system on a gas boiler Navien 16, first operating experience

After turning on the CO, I could not get enough of it, the boiler heats up, there is no need to throw firewood, but, after carefully observing the operation of the boiler, I discovered the following - the cauldron was clocked badly, the operating mode was - heats up for 10 seconds, stands for 5 seconds, it occurred to me that this mode could screw the boiler after a certain amount of time, rapid heating and rapid cooling suggested that the boiler pump has a weak head, and the water, moving slowly, quickly heated up, and also pumping cooled water from the return flow quickly cooled down, moreover, after turning off the flame on the burner, the blower kept running, intensively cooling with cold outside air boiler heat exchanger, and with it water, after reading on the Internet about gas boiler cycle, I saw that first of all it was necessary to remove air from the boiler, but I did not have it there, the second reason was called wrong hydraulics, strange, but mine worked for 5 years and there were no complaints about it, the pump of the wood-burning KChM at first speed pushed everything radiators, and at 2-3 speeds and with excess, everything was fine on the electric boiler too. First of all, I decided to put a second circulation pump to help the boiler, but, as it turned out, this is not entirely simple, when the boiler is operating on hot water supply, it is necessary that it turns off, otherwise the three-way valve of the boiler may fail, i.e.you need to feed 2 pump from the control board, which means you need to climb into the boiler, which may entail the loss of the warranty. Well, or go the other way, mount a hydraulic arrow, but I think this in the future, time will tell.

And, always thinking about what is the easiest thing to do, he began to look at his CO, i.e. its hydraulics, first of all I was strained by the fact that from the boiler I mounted a 3/4 inch pipe with a footage of about 3 meters, to a 2-inch comb, this slightly deteriorated the hydraulics, and slowed down the boiler pump, then I began to carefully feel the work of the radiators at home, and , which was strange for me, I found out that the last in the radiator circuit have a temperature much lower than the first ones, so I think they sailed, the pump presses weakly, and the water circulates only through the nearest radiators, returning back.

I had to run a little, gradually tightening up the nearest radiators, I achieved equal temperature on all radiators, I had to press in the attic radiators directly on the CO comb, since the contours there are short, and the radiators are large, having reconfigured the coolant relatively evenly, noted serious improvements in the boiler operation, the operating time increased up to 5 minutes, and the rest time up to 1.5 minutes, and it turned out that the boiler can stop the blower after a minute of inactivity, and enable flame modulation, when the temperature in CO approaches the set one, it was noticeable by the smoke coming out of the chimney, then a more precise adjustment of the radiators went, tactilely by the temperature difference between the top and bottom of the radiator, the setting added a couple more minutes of boiler operation and half a minute of rest.

Further, in the boiler room, I carefully measured the temperatures of the return from the circuits and the return to the boiler itself, found that the return from the circuits is cooler than the return of the boiler, strange, I thought, where does the hotter come from? And, cursing, I saw that the indirect heating boiler, having heated the hot water supply, gives back heating water with the same temperature that it receives, the analysis of hot water was not great, the temperature in CO was high due to frost, the boiler eventually took little heat energy for heating, I had to press the supply from CO to the boiler to a minimum. After a couple of hours, the outputs from all parts of the CO circuits became approximately the same, after looking at the operation of the boiler, I found that the operating time of the boiler burner has increased to almost 10 minutes! Of course, this was partly due to the low temperature outside, the frosts fell below 25 degrees. But the joy was short-lived, I was able to enjoy the work of the boiler without clock cycles and managed to have the same temperature for about 5 hours :-), at about one in the morning, my wife woke up with a message that the batteries were cold, and something got cold at home! A little dazed asleep, he ran into the boiler room and saw that the boiler has stopped, the red lamp is on, and there is an error 10 on the display.

I tried to reset the error by disconnecting the boiler from the network, but when firing up, it again displayed an error and did not work. First, as a child of modern technology. I wanted to open the Internet and see what kind of nonsense, but I remembered that the manual contains error codes, it turned out to be error 10 - a problem with the smoke exhaust system, it dawned on me - the boiler coaxial pipe is frozen, (condensation was already dripping from the chimney and a decent-looking stalagmite grew on the ground).

collection of icicles from the cauldron

But this is not surprising if a good temperature was recorded on the street in the morning.

frost on the street

I jumped out into the street, but it turned out that it was not the flue gas outlet pipe that froze over, but the air supply pipe to the boiler, all the holes in the air intake were clogged with frost! Grabbing a broom, he quickly cleaned the holes, but the attempt to start the boiler was again unsuccessful, the pipe was clogged with frost and further. Then it was decided just remove the corrugation of the air duct from the boiler, and give it air from the room, the boiler caught fire, the heat went off, blowing for decency in the opposite direction into the corrugation, began to wait for the hot gases to melt the ice plug in the outer pipe of the coaxial chimney, it took a couple of three minutes, and a small stream of air went from the corrugation into the boiler room, carefully putting it on back to the boiler, watched it work, but the frost had already melted, and the boiler worked without problems. As a result, half an hour of dancing at the boiler, I went to bed closer to 2 o'clock in the morning, but it was warm!

But, not only this problem, additionally worried me, from a short boiler pipe, not only the main pipe of the coaxial duct was blocked with ice, but also overwhelmed the hemming at the roof of the house, which could lead to irreversible consequences for the paint, i.e. spoil it, which I don't like at all

the roof is covered with frost from the boiler

Thus, only one thought came to me, it is necessary to lengthen the boiler exhaust, this will kill two birds with one stone, the roof will not be touched by frost, and the air inlet pipe into the boiler will not be clogged with ice, for this I did the following, broke the end cap on the exhaust pipe, and put on a piece of extension nozzles, thus slightly removing the exhaust from the boiler

the pipe from the boiler is slightly longer

But this turned out to be not enough, frost continued to grow on the roof, and again at night the boiler stood up along the frozen air inlet pipe, so I had to throw off the air from the boiler and live while supplying air from the boiler room, I had to go to the store and buy a 1 meter extension cord, he gave a real effect to the exhaust

the pipe from the boiler is even longer

The result was pleasing, there is no frost on the roof, the inlet is not clogged with ice, but another problem almost formed, this is the freezing of the exhaust pipe itself, since it is not isolated, but since the frost is almost over, it seems to have relieved my heart, but. plans to insulate it and loosen it with ties so that it does not fall off under its own weight

But, the adventure continues! Read on!

- Next, setting up the Navien boiler

What are the malfunctions

To repair the heating boiler Navien with your own hands, you need to familiarize yourself with a special manual. It will help not only to decipher the type of breakdown, but also to eliminate it in the most effective way.

List of codes for problems with the Navien boiler and their decoding:

- 01E. The device overheated and this one was detected by a temperature sensor.

- 02E. Indication of an open circuit in the flow sensor and a drop in the level of the coolant in the circuit.

- 03E. The signal to confirm the presence of a flame has disappeared. In this case, combustion can continue.

- 04E. This code has a completely opposite meaning of the previous designation: in this case, there is a flame confirmation, although in fact it is absent. E

- 05E. Breakdown of the circuit responsible for controlling the degree of heating of the coolant in the heating system.

- 06E. This code also indicates a malfunction of the temperature sensor (closed circuit).

- 07E. Signal about the failure of the temperature sensor in the DHW circuit.

- 08E. Malfunction of the gas boiler Navien in the same unit due to a short circuit.

- 09E. Fan failure alarm.

- 10E. The appearance of malfunctions in the smoke exhaust system.

- 12E. Attenuation of the flame in the burner.

- 13E. The heating circuit flow sensor has closed.

- 14E. The gas from the mainline stopped flowing, which is why the Navien boiler does not turn on.

- 15E. General indication of errors in the operation of the control board, without specifying the problematic element.

- 16E. The equipment is overheated.

- 18E. Occurrence of malfunctions in the smoke exhaust sensor.

- 27E. Interruptions in the operation of the air pressure sensor (APS).

Motan Boiler Operation Tips - Basic Troubleshooting Methods

Can anyone help me on how to reduce the pressure at the Motan boiler? And is it allowed to reduce the gas pressure? Does the unit have a regulator that adjusts the pressure of the gas mixture or is it not recommended for them to make any adjustments? The regulator should adjust the pressure of the fuel entering the device. If it is sufficiently reduced, the gas-burner device will not ignite, when it is enlarged, then it is possible to fix the separation of the torch from the wick, and the burner goes out immediately after ignition. Here are the procedures for correcting. Warm up the machine intensively. Open the entire smoke exhaust duct. Turn on the main burner to maximum, at this moment the flame will turn blue-yellow. By closing the intake valve, we eliminate the yellow tint of the fire.Then check the actions of the device in different modes. The device noticeably began to emit a hum and heat up, besides, the safety valve was leaking. What's the problem? If you are in no doubt that the boiler unit was connected correctly, first of all it is necessary to trace the expansomat tank. A situation may arise that it is more expedient to put it in another place. In addition to this, the boiler unit itself is adjusted. In particular, they inspect the circulation of the coolant or correct the gas valve, since its incorrect setting is a factor of just such functional complications. We had a gas boiler Motan placed in our country house. After a year and a half of satisfactory functioning, the pressure began to decrease. The expansion tank was emptied, then air was pumped in and water was added. Maintenance was carried out in accordance with the instructions, but after about a day, the pressure drops again. No leaks were found. An attempt was made to change the nipple, but failed. Why did the device fail to maintain the correct pressure? How exactly to check and adjust the expansion tank? There is no need to drain water from the heating system. We terminate the operation of the device. Next, the nipple is removed, which is fixed at the top of the expander. If liquid is flowing, then a replacement tank is expansomat. When the air began to flow, we turn off the filling valve and open the drain valve, through which the liquid is removed from the boiler. When the water stops pouring, connect a pump with a pressure gauge to the nipple and pump the pressure recommended according to the passport. Perform the process several times, because when pumping, a little water usually flows out, therefore the pressure drops. It is required to pump until the pressure drop and the flow of the coolant stop. Then the cap is screwed on, the taps are opened and the liquid is poured into the system. We turn on the unit and, using the air exhaust valve, release unnecessary air from the system. What are the reasons for the crackling noise during heating? Suppose the burner is ignited, the temperature starts to rise, then a strange metallic knock is heard. However, if you unscrew the bolts of the front paneling, in this case there is no knocking. What does it mean? Occasionally the machine produces crackling and humming sounds in most cases when the main burner is turned off. A significant reason for this deterioration in performance is the uneven heating of the heat exchanger fins, due to blockages or limescale deposits. We recommend that you clean the heat exchanger as soon as possible. Motan boiler, it is impossible to start. The burner block ignites when the power button is pressed. But the device fades out if only the key is released. What could be the reason for the breakdown? The problem is presumably a thermocouple failure or a gas valve. Otherwise, the input main. contains low gas pressure or the voltage of the electronic board is insufficient. The flame smokes significantly and the burner burns constantly without extinguishing. The temperature cannot rise above the set level, and at the same time the fire burns. There is a lot of soot in the device. In the gas service they say that there is insufficient traction. How do I fix the problem? Probably weak air flow. Full prevention should be done. Remove the burner assembly, clean and wash the burner and nozzles. The heat exchanger must be cleaned from the outside. Yesterday I found a malfunction with the start. For some unknown reason, the main burner unit does not burn, but there is a fire on the igniter. Can anyone explain what could have happened? Most likely, the ignition mechanism is out of order. The unit must be serviced and the igniter must be cleaned. The house has a Motan Start BT boiler. He recently had a breakdown. It goes out when the wind blows on the pilot burner.I changed the thermocouple several times, but there are no changes. What is the problem? When the main burner begins to work, this serves to reduce the supply of fuel to the igniter, that is, the safety automatics are started. You should increase the flow of fuel to the igniter. This happens regularly due to the low pressure in the system. In some cases, there may be a weakening of the chimney draft if it is installed incorrectly. Why does the unit fail to start and the E1 error is displayed? Normal pressure, no leaks. Tried unplugging but the problem persists. What is the cause of the problem? This situation often occurs when the pressure of the liquid in the heating system decreases. In this case, you need to check the pressure sensor. It must be damaged. Why does the unit not shut down when the set temperature is set? Heating occurs up to 89C, followed by a malfunction. With a restart operation, everything starts again. Presumably, the board is out of order, the boiler water temperature sensor is damaged, the safety sensor button has a problem. It is possible that the automatic adjustment has failed. In the middle of this year, he installed the Motan gas boiler. About six months later, there was a failure. I set the temperature cycle, but it does not hold it. Explain what it is? Apparently, there were some problems with the automation, and at the moment the temperature rises by 67 degrees, the nozzles stop working. It is required to configure the automation for the correct performance of the functions. Also, the reason may be that you have chosen an inconsistent capacity of the unit in proportion to the areas that need to be heated. Why does the Motan boiler not turn on? Also, the E3 error periodically flashes. What to do? This malfunction may appear due to some problems with the thermostat, temperature sensor, and in addition, if the main circulation circuit is malfunctioning. Most likely, the heat exchanger is overheated. If the temperature sensor and thermostat are not damaged, then the problem is in the control board. It needs to be replaced. Can anyone help sort out the chimney? Soon the second day, as there is a return thrust, in which the smoke penetrates immediately into the room. The chimney was made by myself. It is a steel pipe. It looks like there is some discrepancy. The main factor may be the incorrect configuration of the chimney. There may be soot contamination that severely impairs its performance. In addition, it is required to check the hood in the house. Please tell me how you can diagnose the operation of a three-way valve? I think that this part does not fully complete the opening. The extreme batteries cannot pump for heating, and on the hot water supply the pipe for heating water supply under the boiler unit heats up. Indeed, it is necessary to inspect the 3-way valve for stem hanging in an intermediate state. In turn, we advise you to check the heating system itself. The boiler works for about four to five minutes, after which the burner goes out, and an E5 error is issued. It blinks for about a minute, the burner starts working again, and the device performs well for another five to six minutes, and so on in a circle. This failure, judging by the instructions, indicates that the draft sensor is triggered, although the chimney is clean, the combustion products are removed well. I just can't figure out what is the cause of the problem? In your case, the probable reasons affecting the lack of thrust are: breakdown of the pneumatic thrust sensor. Poor contact between the electronic board and the draft sensor. There is condensation, as well as incorrect connection of the pipes to the pressure switch. Damage to fan components. Presumably, it runs at low revs.The device buzzed during the switch-on period, and now it rumbles even stronger. At first, the sound was not heard for long, but now it is heard longer. Has anyone observed this issue? The appearance of an excessive unpleasant sound can be explained by the presence of scale on the inner walls of the heat exchanger, the heating of which proceeds unevenly due to the different wall thicknesses. The more the heat exchanger is clogged, the stronger the rumble, which reduces heat transfer. The same unit is in operation. Today, when starting up, the wick ignites for a few seconds, the main burner does not pick up the flame, and because of this, the unit begins to extinguish. What is the best way to get out of the situation? It looks like the automatic igniter is out of order or there is a problem with the burner. Just in case, you need to check if the phasing is not lost when connected to electricity. The gas boiler Motan is in operation. In the last month, almost every day it gives an E2 ignition error. After rebooting with the reset key, the boiler occasionally starts up normally, but this is quite rare. A few days ago I removed the air intake cover and it worked much better. What is this breakdown? When knocking out an error related to flue gas discharge, it is imperative to open the protection covers. This will help draw air out of the room. Then inspect the flue for the presence of ice and, if necessary, clean it. In the event of a combustion accident, it is advisable to check that gas is supplied to the room. The unit quickly sets the temperature over 98C, but then it blocks with overheating. Subsequently, when it cools down, it starts to start on its own. How to fix the breakage? An overheating alarm indicates a problem with the circulation process. Beforehand, it is necessary to control the position of the valves on the radiators. They need to be opened. After that, an inspection is made for clogging of the filter, and it is also recommended to make sure that the heat exchanger does not contain dirt.

Why does the device go out?

There can be several reasons for the burner decay:

- Gas cut off. Switch off the boiler, wait for the supply to resume.

- Unstable or absent voltage in the power supply network (for volatile boilers Lemax).

- Failure or actuation of the draft sensor. It is necessary to check if it is there, if the chimney is not clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts are oxidized and do not close. Should be cleaned with fine-grained emery paper.

- Reverse, insufficient or excessive thrust. The draft sensor reacts to all situations by switching off the burner.

Traction problems are most common in non-volatile installations, where the stability of the unit depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous due to the possibility of flame blowout on the burner, which will provoke gas supply into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency case, leading to a stoppage of the boiler.

Pressure switch for a gas boiler: principle of operation, symptoms and causes of malfunction

The pressure switch (pneumatic relay) for gas boilers works on the principles of electrical resistance. It is equipped with contacts associated with two control circuits, which are alternately closed during operating or standby mode. During normal operation of the fan, which removes flue gases from the combustion chamber, a vacuum is created, which acts on the sensitive membrane. The diaphragm bends and the smoke pressure switch switches the microswitch to the operating position for the gas supply to the burner. When the pressure in the system rises, the electrical resistance drops and the pressure switch transmits a signal to turn off the gas supply. An increase in pressure in the combustion chamber can occur for a number of reasons: deterioration of thrust, overheating of the coolant, fluctuations in the gas supply.

In geysers with forced smoke removal, the situation is similar.They are also equipped with pneumatic relays, which begin to operate when the pressure rises, the reason for which may be associated with poor flue gas discharge due to a clogged pipe or unstable fan operation. The device reacts to all these emergencies and gives commands for its instant shutdown.

Why does the pressure switch fail?

- Oxidation of contacts on conductive circuits of a circuit that does not close it due to an oxide film

- Wear of the flexible sensing membrane, resulting in reduced mobility and inability to apply pressure to the microswitch.

- Clogging or the appearance of a water blockage in the tube with the condensate collector, as a result of which the pressure sensor of the gas boiler does not work abnormally during changes in operation.

- Reducing the fan power, which does not create the necessary vacuum for the membrane pressure on the microswitch.

What irregularities in the operation of a gas boiler indicate a malfunction of the pressure switch?

- Gas cut off

- When the fan is turned on, the "turn on" click from the microswitch is not heard in the relay

- The boiler does not start, and the display (if any) shows an error code: "The relay is off, but the fan is running"

What to do next? Before proceeding with the repair or replacement of the pressure switch, it makes sense to carry out more detailed diagnostics.

- turn off and de-energize the boiler, remove the casing, connect the contacts as indicated in the instructions in the "work" position. If after this the boiler starts up, then the relay is broken and needs to be replaced.

- check tubes for wear, blockages, water and dirt. If the whole thing is a blockage, then it will be enough to clean everything. If the tubes are slightly worn, you can try to repair them, but it is better to replace the device.

A few tips on how to extend the life of your smoke pressure switch. In order to prevent condensation from forming inside and contacts being oxidized, it is advisable to reinstall the pressure switch for the boiler away from the cold circuit. If, nevertheless, the contacts have oxidized, it is necessary to open the case and clean them with an emery cloth. At the same time, try not to touch the adjusting screws, so as not to knock out the factory settings.

External factors affecting unstable performance

But why does your boiler go out if it is completely serviceable? One of the main external factors is insufficient, excessive or reverse draft (overturning) in the chimney.

The reason for this process is the lower density of warm combustion products compared to the density of cold air, or the use of smoke exhausters and fans for forced gas exchange. So, the possible situations:

- Insufficient traction. In this case, the corresponding sensor is triggered and the gas burner goes out (the sensor heats up, turns off the boiler, the sensor cools down and turns on the unit again).

- Excessive cravings. It is formed in the presence of additional ventilation ducts, incorrect location of the chimney, etc. As a result, the speed of the exhaust combustion products increases, which leads to the damping of the boiler.

- Reverse thrust (rollover). In this case, the direction of movement of the flow of combustion products changes to the opposite, the flue gases are not removed through the chimney, but returned to the furnace. This causes damping of the flame and increased gas content in the room.

The sources of these troubles can be design flaws and current chimney malfunctions:

- inaccurate calculation of location and height, unfair installation;

- structural defects;

- leakage (blowing outside air). It is necessary to seal the connections;

- lack of supply air for the combustion process;

- malfunction of the fan (smoke exhauster) with the forced removal of combustion products;

- clogging (ingress of foreign objects into the chimney, a large layer of carbon deposits);

- damage or lack of insulation.This contributes to increased formation of condensation - the chimney must be warm.

The draft also deteriorates due to unfavorable weather conditions: the gas boiler often goes out in wind or heavy rain. Low atmospheric pressure and humidity, high outdoor temperature can also reduce the rate of outflow of combustion products.

In strong winds, an unsuccessful chimney design also contributes to the fact that the boiler igniter goes out when it is switched to standby mode.

Therefore, if a gas boiler goes out, first of all, it is necessary to check the design of the gas outlet (size compliance, connection method, etc.), the state of the thermal insulation and, if necessary, clean it.

Having considered the main reasons for the constant attenuation of a gas boiler, we can summarize: independent attempts to restore its normal operation can be life-threatening and end in failure, not to mention the possible failure of the entire boiler. Therefore, in the situation "the gas boiler goes out and what to do" the most correct solution will be to call the gas service masters to find out and eliminate the causes of troubles.

Methods for eliminating the causes of shutdown of units

Incorrect unit power

If the gas boiler is often turned on and off, then this indicates that the power of the unit is too large for this room. As a result, the device quickly picks up the desired temperature and turns off. Frequent switching on and off leads to increased wear of the boiler parts. Therefore, before buying a gas device, it is important to calculate the optimal indicator of its power based on the area of the heated room, its insulation and other factors.

For a large private house, floor-standing gas boilers with a capacity of 35 kW or more are suitable. For apartments and small cottages, it is better to purchase compact wall-mounted models that fit perfectly into a small kitchen or hallway.

If the boiler has already been installed, then the problem of overpower can be solved by the following methods:

…

- installation of four-way valves;

- readjustment of the gas burner to the minimum mode;

- connecting a boiler or other systems so that part of the boiler's power is spent on them.

Low line pressure

Typically, the reasons for low gas pressure are the following factors:

- Fuel meter problems. Suspicious sounds or noise may be emitted from the device. On a faulty device, the readings change in jerks or the arrow does not move at all. To fix the problem, contact a specialist.

- Safety sensors have triggered - if the system has noticed a fuel leak, then the operation of the unit is blocked. The leak also smells like gas. If such a problem occurs, you should turn off the gas boiler and call the gas service master.

- The filter is clogged - it should be cleaned.

Reverse thrust

If a reverse draft occurs and the flame goes out, the gas boiler protection system is triggered and it turns off.

The situation can be corrected only by eliminating the reverse thrust. To do this, it is necessary to identify the cause of its occurrence. For example, adjust the design of the chimney, install a deflector, etc.

Backdraft also occurs when there is poor ventilation in the room. It's easy to check - the flame will burn well when you open the window. The following factors impair ventilation:

- sealed plastic windows;

- hermetically closed doors;

- too powerful hood in the kitchen.

In this case, measures should be taken to improve ventilation.

…

Chimney problems

A common problem for open and closed gas boilers is frost that forms at the exit from the chimney. Hot combustion products come out of the pipe and are converted into condensate, which freezes at the head. This frost prevents air from entering, the fire is extinguished and the boiler shuts down. The ice needs to be cleaned and the air flow will resume.

If ice builds up regularly, then you need to insulate the chimney.

The classic chimney is more prone to all kinds of blockages. It can get there:

- rubbish;

- pipe elements;

- soot, soot, dry leaves;

- sometimes even birds and the remains of their nests get into the chimney.

Voltage drops in the network

If the voltage in the mains falls below the indication provided for by the operating mode of the unit, the security system will turn off the gas boiler. When the voltage returns to normal, the unit will start up again.

To avoid this problem, you should install an uninterruptible power supply.

Find out here why the gas boiler smokes

Why the gas boiler is buzzing - reasons and methods of solution

What to do if the gas boiler blows out?

Fan malfunction

In turbocharged gas boilers, air intake and combustion products are removed using a fan. If a failure occurs in this unit, the boiler will shut down.

In this case, it is necessary to diagnose the fan, clean it from the blockage, replace the damaged parts, inspect the wiring.

Pump problems

If the pump malfunctions, the coolant does not circulate well through the system. As a result, the radiators do not heat up, and the automation turns off the gas boiler.

If the circulation pump was recently included in the system, and after that the unit began to turn off, then, perhaps, mistakes were made during its installation.

Burner problems

If the gas boiler switches off all the time, then the functioning of the burner should be checked:

- If the ignition does not occur and the flame goes out immediately, then, most likely, the problem is in the nozzles - they should be cleaned of soot and excess air released. It is also advisable to check the position of the ignition electrode and, if necessary, clean it.

- If the flame goes out after a short burning, then the diagnosis of the ionization electrode should be carried out.

- The flame breaks off and the nozzle makes noise - it is necessary to adjust the gas supply. This is sometimes due to excessive traction.

The boiler is dying out

Among the common reasons why a gas boiler goes out are:

- Drop in pressure in the gas pipeline;

- Chimney problems (clogging);

- Breakdown of the gas meter and sensors in the boiler;

- Gas leaks and lack of traction;

- Blowing wind into the chimney.

The chimney inevitably becomes clogged with soot, debris and even birds that have flown in over time. It should be cleaned regularly. However, even if it is absolutely clean, traction can simply disappear in the pipe due to a sharp gust of wind or improper installation of the chimney as a whole. The wind blew strongly and the torch in the firebox goes out, heating of the coolant stops.

The chimney may be clogged and needs to be cleaned.

In some cases, the smoke channel will have to be increased in height. The chimney must not be blocked by trees or roof ridge. At the same time, it should also not rise too high above the roof. There are hard and fast rules. They must be accurately performed when installing the chimney, otherwise the newly installed gas boiler will not even work. The chamber will not have the necessary traction, and, accordingly, oxygen. And without it, methane does not burn.

The gas boiler often goes out, simply because it is turned off by the automation. This is possible due to the detection of a leak by a gas analyzer, triggering of a thermocouple and a malfunction of the meter. That is, protection is triggered to prevent fires and breakdowns of heating equipment.

Here you need to look for the root cause - why the protective elements are activated. And only then think about what to do in a particular situation. And often only the master of the company servicing the gas equipment is able to identify and eliminate problems. This pumping station for a private house can be serviced by hand. Gas-powered equipment must only be checked and repaired by specialists. These are the requirements of the laws in this area.

Insufficient gas pressure

With low gas pressure, the boiler cannot function normally, the burner flame goes out. If the problem is outside the house, in the highway, gas services will take care of it.

Internal problems include

:

- Failure (or actuation) of the sensor of the monitoring and protection device of the boiler unit - this causes the boiler to stop. The faulty sensor is replaced by specialists.

- Failure of the gas meter. A possible malfunction is indicated by extraneous noises during the operation of the meter, the absence of a change in readings when the gas supply is on.

- Violation of the tightness of the gas pipeline inside the house. The automatic protection system is triggered by a gas leak and the boiler burner goes out. When leaking, a specific odor spreads. To check the tightness of the joints of the mounted system, a soap solution is used, which is applied with a sponge. In places where there is a fistula, a soapy film begins to bubble up.

How to repair code malfunctions of the boiler

Boiler overheating error

A malfunction of a gas boiler in the form of overheating may occur due to a lack of circulation. In this case, you need to check the pump and filter. The overheating thermostat may also have broken.

Low system pressure

If the pressure does not rise when the boiler is warming up, then the tightness of the system may simply be broken and the connections need to be tightened, and then the pressure should be slightly added. If this problem arose almost immediately after installing the boiler, then you just need to remove the air through the automatic air vent and add a little water.

There is no draft of the gas boiler

If the boiler is with an open combustion chamber, it is enough to see if it is clogged with something. If the combustion chamber is closed, then condensate drips from the outer pipe, getting into the inner pipe and freezing, in the winter season, it turns into an icicle, blocking the access of air to the boiler. To eliminate this problem, it is necessary to pour hot water over the resulting icicle. Another foreign object can also get into the chimney.

The boiler does not ignite the flame when ignited

This indicates a malfunction of the gas valve in the boiler. To verify this, you can unscrew the hose and see if gas is supplied. If there is gas, then you should call a specialist who will replace this valve.

The boiler ignites, but the flame goes out immediately

In this case, the panel may indicate a malfunction of the gas boiler in the form of a lack of ionization current. You need to check this by turning on the boiler again, turning the plug over, thereby changing the phases. If nothing has changed, then the work of the ionization current may be disrupted due to any electrical work in the house. If the boiler periodically extinguishes the flame, then this is due to voltage surges and a stabilizer is needed.

The panel displays incorrect errors

Errors of the electronic board can sometimes occur. This happens from poor electricity and poor quality power supply. From this, some parasitic charges appear on the boards, due to which such errors are observed. To eliminate this, you need to disconnect the boiler from the network and let it stand for about 30 minutes. During this time, the capacitors will be discharged and these unnecessary charges will disappear. The boiler should then work well.

In general, that's all. If the material was useful, do not forget to share it by clicking on the social media buttons below this text.

Also find out how to choose the right gas boiler so that there are no problems in the future:

Meaning of errors of Monlan boilers

_________________________________________________________________________________________

Error with E1 code Difficulty firing up. Gas does not flow to the burner. Apparently the shut-off valve is closed. Open the valve located on the gas supply line. During the initial start-up, air will need to be vented from the pipeline. Check the pressure indicator of the gas supplied to the gas burner block. Required pressure 18-21 Mbar.In the future, check the rate of setting the minimum and maximum fuel pressure on the injectors. The installation characteristics are given in the instruction manual. If required, we make adjustments to the boiler. The gas valve is damaged. If faults are identified, change the gas valve. The ionization electrode is not working properly or is damaged. Check it for contamination. Correct the gap between the burner and the ignition electrode if required. Gas fittings are inoperative. Inspect the coils on the gas valve for a possible open or short. If there are any faults, install a new gas valve. The gas valve is stuck. Attach a piece of hose to the union located on the front of the valve and provide increased pressure. There is not enough power to ignite. Correct the ignition power using the service menu. Functional failure or defective electronic board. The ignition transformer has stopped working. Reset the unit. If the error persists, the electronics board needs to be replaced. Perform a grounding check. The cladding should have no potential. Excess moisture serves as a source of blocking the boiler. Clean the combustion chamber, ionisation electrode and gas burner from moisture. Failure of the ignition electrode functions. The electronics board has detected a flame, but no combustion is observed. Diagnose flame control electrode wiring. There may be bad connections and breaks. The electrical circuit from the ignition electrode to the electronic board is diagnosed for the presence of a short circuit. The ionisation electrode can touch the gas burner. Defective electronic board. It needs to be changed. Error code E3 / E4 Overheating of the Monlan boiler has been detected. The emergency thermostat has a temperature of more than 105 degrees. If there are currently no ignition messages, the error is not detected. The burner goes out as a result of the increased temperature of the heating line, but the heat exchanger continues to heat up. For the heating cycle 90 degrees, for the hot water supply phase 95 degrees. Automation turns off the boiler, if in the interval of 15 seconds. the temperature of the safety thermostat will reach over 105C. If the thermostat registers a temperature of more than 105C in heating or frost protection mode, the boiler automation module measures a pause for an average of 30 seconds. If within such a time period the temperature of the thermostat and NTC heating sensors does not drop to 100C, the boiler automation will notify of an error. The device is switched off at the stage of the request for ignition of the burner device. If, during the ignition phase, the temperature of the emergency thermostat becomes more than 105C, the boiler will go into standby mode for 10 seconds, and only then will it signal an error. The temperature sensor of the heating system or the overheating thermostat has started, turning off the unit. The emergency thermostat will start after a temperature rise of more than 105 degrees. Wait for the boiler to cool down and restart it using the on / off button. Defective or functional failure of the emergency thermostat. We advise you to replace it. Difficulty in the circulation of the coolant in the heating circuit. Perform a pressure test on the main circuit. Its performance in the cooled system corresponds to 1.2Bar. There is air in the heating pipes. Drain excess air from the system through an automatic drain. No circulation. Fully open the stopcocks that impede the required water circulation. Unstable operation of the circulation pump. The pump stopped giving the required speed. Inspect the parameters and the rated voltage of the power supply. If a voltage instability is detected in the electrical network, connect to the electrical network using an autotransformer-stabilizer.Engage in diagnosing the resistance in the stator winding of the circulation pump motor for an open or short circuit. The pump is running correctly, but the pressure is not enough. The impeller appears to be wearing out. If damage occurs, the pump must be replaced. The pump does not rotate, although the flow into it is normal. We examine the pump, obviously there is a jam. Dismantle the plug, then turn the motor rotor shaft. There is no power to the water circulation pump. Damage to the electronics board. You must restart the boiler. If the failure continues, replace the electronic board. Overheating of the flue gas thermostat. wait for the thermostat to cool down, then reboot. E7 code The heating system thermal sensor is out of order. There is a damage to the circuit or a short circuit of the NTC sensor of the heating system. If the NTC sensor circuit breaks down, the signal disappears, respectively, the electronic board gives the command to interrupt the functions of the burner unit. Error with code E5 / E6 Hot water temperature sensor malfunction. In the event of an open or short circuit in the electric circuit of the NTC sensor of hot water with a cycle of 4 seconds, the gas burner device will not burn in the hot water supply mode. The Monlan boiler will not stop functioning in the heating cycle. The hot water temperature sensor is damaged. E9 code Signals about low pressure in the system. The main reasons contributing to the appearance of this malfunction: low pressure of the coolant in the heating circuit. There is no contact between the electronic board and the pressure switch. The pressure switch is out of order. You should first look at the readings of the pressure gauge. As a rule, the problem can be eliminated by using a make-up valve, which is installed to fill the system with coolant. If the accident recurs, there is most likely a water leak. The hydraulic pump, main heat exchanger, overpressure relief valve, damaged seals and gaskets, make-up valve and other components can leak. Leaks can be found when inspecting the hydraulic components. Error code E2 Lack of traction. For the correct and uninterrupted functioning of the Monlan gas boiler, it is necessary to organize a traction for the exhaust gases, so that they do not get into the room. This is monitored by the automatics, and when any malfunctions appear, the thrust sensor-relay will work, and the device will be blocked. Possible reasons for the lack of draft: insufficient diameter of the flue duct, inconsistency in the design, clogging with dirt, icing of the inner wall. A decrease in the diameter of the flue duct can lead to a weakening of the draft. The length of the flue pipes has been exceeded. The instructions for use of the device must be read carefully and the relevant requirements must be followed. A very long horizontal chimney bend can cause a lack of draft. The thrust pressure switch is broken - If a vacuum occurs in the inlet tube, a slight click will be noticeable. Poor contact of the control board with the draft sensor, the presence of condensation, as well as an incorrect connection of the tubes to the pressure switch. Fan paused - The fan impeller is clogged. There is not enough lubricant on the fan shaft, so it has a low torque. Lost contact between control board and fan. E8 code Problems related to ignition. This code occurs if the ignition does not work or there is a burner flame failure. Check the contacts between the ignition unit and the flame sensor, and also between the control board and the gas valve. The main cause of flame blowout is inadequate thrust.

_________________________________________________________________________________________

_________________________________________________________________________________________

- How to troubleshoot and malfunctions on the Juncker boiler

- How to troubleshoot basic problems on boilers Buderus Logano G334

- Errors and malfunctions of Rinnai boilers

- Recommendations for the repair of boilers Buderus Logano G124 / 125

- Possible breakdowns during the operation of the Beretta gas water heater

- How to correctly adjust and repair the Electrolux gas column

- Tips for adjusting and repairing gas water heaters Gorenje

- Values of error codes for boilers Immergaz

- Problems in Junkers gas water heaters - Recommendations for repair and maintenance

- How to identify and eliminate malfunctions in the Ladogaz gas column

- Recommendations for the operation, repair and settings of the Mohr gas column

- We repair the Zota Carbon boiler - Types of faults and options for their elimination

- Repair of the Zota Master boiler - What can be malfunctions and actions to eliminate them

- Celtic boiler error codes decoding

- Repair of the Buderus Logano G221 boiler - Types of malfunctions and methods of their elimination

- Causes of irregularities in the operation of Buderus Logano S131 boilers and how to repair them

- Questions on troubleshooting storage water heaters

- How to troubleshoot the operation of storage boilers

- Electric water heater malfunctions and tips for their elimination

- Electric boiler malfunctions and repair recommendations

- Boiler error codes Hermann Habitat

- Tips for eliminating basic problems in storage water heaters

- Help in troubleshooting storage boilers operation

- Possible malfunctions and breakdowns during the operation of gas water heaters

- How to repair a gas water heater in the event of a malfunction

- Ways to eliminate malfunctions and breakdowns on gas water heaters

- Errors of gas boilers Proterm Cheetah

- Elimination of breakdowns and malfunctions during the operation of gas water heaters

- Causes of malfunctions and repair of gas water heaters

- Repair of gas water heaters in case of malfunctions in operation

- Hermann boilers - Methods for eliminating errors and malfunctions

- Elimination of errors and malfunctions during the operation of Arderia boilers

- Boiler error codes Ariston Egis

Causes of boiler attenuation and troubleshooting

If you are interested in the question of why the gas boiler goes out, then, it is quite possible that the reason may lie in the ice build-ups that cover the head of the device. You cannot get rid of them quickly, otherwise there is a possibility of damage to a component of the system. If the ice is frozen on the inner walls, the air will be blocked, as a result of which the gas boiler will go out. Defrosting should be done gradually, the cap must be removed for this. Then it should be brought into the room and thawed. While defrosting is in progress, the boiler can be operated without this part.

The gas supply to the burner must be shut off, and as soon as the igniter is fired, the valve can be opened. After the main burner lights up, warm up the equipment. It should work at a low gas pressure. Warming up must be completed, only after that it is allowed to increase the intensity of the gas supply. During operation of the unit, it is necessary to control the state of the contacts of the piezo ignition elements. They should be hot. If the contacts cool down, the gas pressure should be reduced. This will eliminate the cooling of the thermocouple. Otherwise, a signal will be sent to trigger the automation.

Gas boiler goes out: what to do and how to fix it

If you have a turbine boiler and no flame is ignited in it, it is worth listening to how it works. If the sounds are heard stronger than usual, or vice versa, silence is the problem, most likely in the built-in fan, which will have to be repaired or bought a new one.

You can resume the operation of the gas boiler with your own hands, or seek help from specialists

There are usually 3 options when the boiler is not working:

- The device is completely turned off;

- The device is on, the display is on and the indicator is on, but the flame is not kindled;

- The flame ignites, but goes out quickly.

First, you need to check if power is supplied to the convector. The reason for its absence may lie not only in a power outage, but also in the operation of the machine on the switchboard.

If everything is in order with the voltage, you can start repairing. To do this, unscrew the front panel of the boiler with a screwdriver and remove it or fold it back. Then find the fuse box and check each one. If a burned-out one is found, it must be replaced with the same denomination. If, after these actions, the unit starts working - fine, but not - you will have to call a specialist.

When displaying any error on the convector's display, you can read what it means in the technical data sheet of the device.

Some problems in which the device turns off can be eliminated by yourself:

- The clogged sump can be cleaned by first shutting off the taps of the device;

- Correct the circulation pump by unscrewing the screw in the center of the pump and letting the air out;

- Pump air when the pressure in the tank is too low;

- Eliminate existing leaks and add water to the system.

This is how you can try to resume the operation of a gas heating boiler of various brands with your own hands, for example, AOGV, Dani, Weber, Aton, AGV.

Reasons for the private on-off of a gas boiler

It may happen that you just installed a new gas heating boiler at home, just set it up and put it into operation, and then it starts to turn on and off every five minutes. In fact, he must independently regulate his work, but too frequent disconnection and self-activation indicates that something is wrong here. In addition, this behavior of the heating equipment adversely affects the duration of the operating period, since the working parts wear out and the boiler fails.

There are several reasons why the heating boiler is often turned on. If you do not have enough experience, you should call a specialist for help, since blue fuel does not tolerate negligence. So, the main factors provoking the frequent turning off and on of gas heating equipment:

- The boiler was chosen incorrectly. Its capacity is designed for large rooms, and it was installed to heat a small room.

- Errors in the installation of the circulation pump.

- Temperature range not set correctly.

- The absence of a thermostat in the room, regulation of the boiler operation only by the temperature of the coolant.

The problem is not complex, but in some cases its solution is to replace the heater.

Problems with the ignition drive in the gas boiler

Why does the atmospheric gas boiler turn off

In the equipment related to non-volatile there are elements that can bring a lot of problems during operation. There are such signs of breakdown.

- If you want to light the igniter, but as soon as the button on the valve is lowered, it immediately goes out. This is a sure indicator of thermocouple failure.

- If the main burner ignites poorly and is unstable with constant popping, and the flame is yellow, this is a clear sign of a clogged fuel jet.

- If the boiler does not ignite at all and even the burner, then the power supply system is more often to blame. Cases when the element itself fails are rare.

It is best not to take risks and try to remove a piece of equipment to gain access to the clogged element for cleaning. But when the situation is urgent and there is no other way, before starting work, you need to turn off the gas and then you can start. It is better not to touch all unnecessary joints, the less interventions in the device, the better. After completing the required manipulations, you should check the reliability of the connection using a soap solution.

Why can a gas boiler leak

A leak from a gas boiler can be associated with both simple malfunctions and serious breakdowns. Insignificant costs will arise in case of loss of tightness of the connections of the water supply pipes, wear of the oil seals, seals.

In a situation where a heat exchange chamber becomes the cause of a leak, the owner in most cases will face serious material costs, since this unit has an extremely low maintainability, and its cost can be up to 50% of the total cost of the boiler.

The built-in circulation pump can also cause a leak.

Important: If signs of leakage appear, turn off the power supply immediately to avoid other damage.

Heavy leakage sometimes occurs as a result of a failure of the water pressure safety valve. This unit is designed to release water when the pressure in the system is exceeded. If it malfunctions, there is a direct flow of water from the make-up system (water supply system) into the room.

Motan boilers - Operation and adjustment of equipment

The Motan boiler is a wall-mounted unit that serves as a source of heat throughout the house. Gaseous products are used as fuel, which, by means of combustion, are converted into heating energy. The boiler operates in automatic mode. Equipped with control and safety systems. Motan products are available in a wide variety of modifications: Max Optimus, Optimus, Start BT and Plus.

Gaseous fuel enters the boiler bypassing the branch pipe and the pressure level controller, which is set at 20 Mbar for G20. When using certain types of gas (a mixture of propane and butane, as well as pure propane), the pressure values are set at 37 Mbar. The fuel bypasses the flap that regulates the gas flow to the burner.

Ignition takes place due to the action of the ignition electrode and the auxiliary aid of the transformer. The ionisation sensor monitors the presence of the combustion process. Variants of boilers with installed forced draft are equipped with special fans that serve as a system for removing by-gases. At the start of the start-up, the fan is used to ignite the boiler.

With a long break without operation, at start-up, there may be extraneous noises caused by gas accumulation. The unique shape of the combustion chamber, made in the shape of a polyhedron, allows the heat to be transferred from the used gases to the liquid with maximum yield.

In boilers with a bithermal type heat exchanger, the heat generated during the fuel combustion period passes through the heat exchanger, in which the water is heated, with its subsequent transfer to the heating circuit. In the same way, the temperature of the hot water supply water rises.

In boilers with paired heat exchangers, the energy produced in the process of fuel combustion is supplied bypassing the primary heat exchanger to the heat carrier - water. After that, the feed mechanism transfers the water to the heating system.

If the transfer detector detects an increased flow of liquid in the DHW circuit, then a special valve will be automatically turned on, which will redirect the flow from the heating section to the hot water supply system through a plate-type heat exchange mechanism.

Waste generated as a result of fuel combustion is carried away by a powerful forced draft fan, as well as due to pressure differences at the beginning and end of the pipe. System protection and control is carried out in a fully automated mode. It is advisable to set the required parameters using the control panel.

Motan Optimus forced draft boiler

- Consistently high efficiency.

- Minimal power consumption.

- A unique combustion control system, the Optimus model is 5 percent more economical.

- The small size of the boiler allows it to be installed in small rooms.

- Electric system for ignition and control of the state and intensity of the flame.

- Gas shutter with constant modulation.

- A device for controlling the intensity of movement of warm water.

- In the DHW system, resistors with a negative temperature index with high reactivity.

- LCD screen on the control system.

- Ease of installation and maintenance.

- Possibility to connect a temperature timer or an external temperature sensor.

- Drainage equipment.

- Comfort mode allows you to supply warm water from a hot system, without mixing it with cold water.

Security device

- A safety device that takes effect when the pressure rises above 3 bar.

- Temperature detectors on the heating circuit.

- Air control system, which is triggered when the ventilation system does not work correctly.

- Protective thermostat against high temperature on the heat exchanger.

- An automatic control mechanism that processes information from various nodes.

- Advanced self-control equipment.

- Anti-freezing mechanism.

- Anti-scale system.

- Function that excludes blocking of the pump when the frequency of operation is every day.

Motan Start BT boiler with forced draft

This model is used for heating and hot water supply of residential buildings that have a chimney for blowing out.

- Bithermal heat exchanger.

- Circulating pump for the circuit.

- Current production of warm water.

- Closed tank for receiving excess liquid.

- Ignition and control of the state of fire using electronic systems.

- Exhaust system that removes processed gas products.

Classification of possible errors that occur during the operation of Motan boilers

E0

- an error caused by a minor malfunction of the boiler, when the indicator lights up again, you should pay attention to the main board. It must be turned off and then restarted using the Stop and Start buttons. After several such reboots, if the error display does not stop, it is worth turning off the device completely.

E1

- signals that there is no water in the heating system. Fill the container with liquid up to the working marks with your own hands. If this measure is not effective, turn off the boiler and call specially trained foremen.

E2

- such an error occurs when the ionization electrode is not sensitive to the presence of a flame. The malfunction can be caused by the lack of gaseous fuel in the system or a breakdown of the gas valve. Use the system restart button. If the unit does not work in normal mode after several repetitions, then disconnect it from the electrical network and contact the service center masters.

E3

- an error arising from a breakdown of the temperature fixing sensor in the heating circuit. In this case, you need to turn off the equipment.

E4

- an error similar to the previous one, only in this case a malfunction occurs in the hot water supply circuit.

E5

- the malfunction is caused by the lack of gas removal. It is necessary to inspect the chimney, make sure that there is an influx of air masses. If the channels are clogged, carry out cleaning work.

Other system malfunctions

Switching off the device, the absence of an image on the panel - a malfunction of the electrical network. One of the possible options is a fuse failure.

The device operates at regular intervals, there are extraneous sounds and vibrations (error E2 is displayed on the panel) - there is no gas supply or the inlet pressure is not adjusted properly.

Operation with a variable temperature of the heated liquid - the water pressure is extremely low (less than 1 bar).

The boiler starts up, but the flame does not ignite (fault E2 is displayed) - the gas valve is closed.The pressure in the system is too low due to an incorrectly set pressure controller, the pressure level is below 0.5 bar.

The flame ignites, but then quickly extinguishes (fault E2 is displayed) - zero and the phase are reversed.

Inefficient operation of the pump or lack of signs of functioning - replace or unblock the pump.

Fault in the pressure measuring sensor - conversion with a new sensor.

The control valve does not open or the pressure drops below the required level - replace the valve.

Temperature detector (error E3 or E4 is displayed on the panel) - incorrect operation of the heating unit or breakdown of the detector. Change the block design or replace the detector.

Gas fuel valve (malfunction E2 is displayed) - does not function, or it functions extremely poorly. A new valve is being installed.

Heat exchanger - replace if defective.

Expansion tank - the pressure level drops. It needs to be replaced.

The burner is not able to ignite. Clean it, if this measure did not help, replace it.

Pressure meter - in case of defective operation, it will be replaced.

Central control element - does not execute specified commands, does not display current readings. Hand over for repair or replace.

Electronic board - frequent occurrence of code E0. Install a new board.

Ignition system - if damaged, it must be replaced.

Ionizing electrode (fault E2 is displayed) - there is no ignition spark or its loss due to poor insulation. Insulation monitoring or installation of a new electrode.

Smoke detector (error code E5) - if malfunctioning, it must be replaced.

Ventilation system (error code E5) - if damaged, it must be replaced.

Pressure Meter (Error Code E5) - If a problem is identified, a replacement is required.

Functional dysfunctions and repairs

Motan Optimus MT gas unit is installed. The error code E5 is displayed. Give advice on how you can fix it? What actions need to be taken?

Violations of the exhaust gas extraction system. Turbine - you need to study the degree of contamination of the blades and the presence of defects on the bearings. Exhaust Pipe - Make sure there are no foreign bodies on both ends of the pipe.

Do not activate DHW in a Start BT series device after the heat exchanger has been changed, since the previous one had a crack and the incoming water heated up excessively, although it should normally remain at a low temperature. Perhaps the reason is this, but what exactly is the case? The heating circuit operates in standard mode, but stops working when hot water is supplied. The flow sensor is in excellent condition, as it was removed from a functioning apparatus, but no effect.

It is necessary to seek help from specialists.

Motan Plus displays malfunction E9. Can you decipher this error or give a general list of possible errors?

Code E9 - Occurrence of a huge number of E5 errors in a short period of time. Press the reset button to clear the error. If the violation is eliminated after several reboots, it is worth turning off the boiler and calling the wizard. Code E5 - excessive smoke that cannot be removed, thermostat breakdown. This breakdown is eliminated by the owner manually using the Reset button.