Cast iron radiators have been the most sought after for half a century. Nowadays, they are also very popular, but, nevertheless, their popularity among competitors is growing every year:

- bimetallic;

- aluminum;

- steel radiators.

Pig-iron heating battery of the times of the USSR

It should be noted that during the Soviet Union, such "retro" radiators were used everywhere, and there was no particular alternative to them. Please note that cast-iron heating radiators are installed in all buildings of that era.

Installation of heating batteries: tips, secrets, instructions - only here.

pros

- Reliability and durability. Cast iron is unpretentious to the coolant, it will not be damaged even by large fractions or aggressive chemical impurities, often contained in water from Russian thermal power plants. The maximum allowable coolant temperature reaches 130-150 degrees. With regular flushing, this battery can last for decades.

- High heat capacity and thermal inertia. Such batteries give off heat for a long time, which after disconnection can remain in them up to one third of the original volume. However, the same feature of the material is also its disadvantage - more on this in the corresponding section.

Replacing heating batteries in an apartment with your own hands or through a housing office

An example of a claim against the management company for the replacement of heating radiators. back to contents If the batteries have leaked after the heating is turned off If the heating radiators are leaking after stopping the supply of heat to the MKD, the malfunction should still be eliminated, but not in such a harsh mode. A battery leak indicates that the water has not been drained from the system. The procedure is as follows:

- Residents report the problem to the Criminal Code.

- The employees of the Criminal Code eliminate the leak, if possible, or change the battery at the expense of the funds donated by the owners.

Only a specialist servicing the MKD will quickly be able to block the riser or cut off the entire entrance from the heating.

You can learn how to replace the heating riser from housing and communal services from the video: back to content Who is responsible in an emergency? In an emergency, all responsibility lies with the technical service of the UK, HOA or ZhEK.

Minuses

- Great weight. Cast iron is a very heavy metal, the weight of one section of a cast iron radiator can reach several kilograms. On average, this is 2-3 times more than the weight of a bimetallic battery section, and 4-6 times more than the weight of an aluminum radiator. ...

- Price. One section of a cast-iron radiator is noticeably more expensive than a section of a bimetallic or aluminum battery similar in size and heat transfer.

- Impossibility of installation in a system with automatic adjustment. The design features of the battery and the properties of the metal will prevent the sensors from receiving up-to-date information on the temperature of the coolant and surface. When choosing which is better to put heating batteries in an apartment, be sure to take this nuance into account.

- Low efficiency. Due to the thermal inertia, much more energy and coolant will be spent on heating a square meter of area than in the case of other types of batteries. This can be completely unimportant if your heating is centralized and you pay based on the square of the house.But if you have a gas boiler, you will have to spend more of your own money, and they will go mainly to heat the battery itself, and not to increase the temperature in the room.

- Unaesthetic appearance. Note that this applies only to old batteries, but if you have just such - they are unlikely to harmoniously fit into the modern environment. Cast iron batteries of the new model in this regard are no different from bimetallic or aluminum "brothers" - they look modern and stylish, they will perfectly fit into the interior of any apartment.

The secret of popularity

Perhaps, among Soviet citizens there is no person who would know little about cast-iron heating radiators. They witnessed two revolutionary uprisings, a world war. Today this type of heating equipment can be safely called “legendary”. Their popularity peaked in the last century.

It was impossible to imagine a Soviet communal apartment without cast-iron batteries, which performed not only the role of heating the premises. With the help of them, meat was defrosted, wet shoes, washed linen were dried. They served for a long time, did not cause trouble in operation. The whole care consisted in the fact that the surface was painted with white or brown paint in order to give freshness.

The popularity of heating devices is due to their technical characteristics. The qualities for which they are valued:

- reliability of use

- durability of operation

- corrosion resistance

The main advantages

They have a number of advantages that play an important role in their operation:

- anti-corrosion resistance. The chemical composition of the alloy reliably protects the product from corrosion. The material is not destroyed by moisture and various atmospheric precipitations. The corrosion process ends for them with the appearance of a layer of "dry rust" on the surface;

- temperature "immunity". Cast iron is able to withstand high temperatures. It does not respond to temperatures reaching 150 degrees above zero. Such a plus is a clear trump card "in the hands" of steam heating systems;

- "Loyalty" of the material to the quality of the heat carrier. Strongly alkaline fluid, rust particles, small grains and stones are not able to affect the material in the inside of the radiator. Cast iron is resistant to mechanical damage. The material does not dissolve even in the strongest solvents, it is impossible to scratch it;

- thickened product walls. This design feature is the determining factor for the long service life of the device;

- high rates of accumulating capacity. These numbers are impressive. Already after an hour, the switched off batteries have a residual heat transfer of about 30%. Batteries and steel have 15% residual heat transfer, which allows them to be used for systems with periodic heating;

- the large size of the internal section, which allows you to clean the sections very rarely, which cannot but please the owners;

- long service life. Manufacturers set a borderline value for their reliable operation, which ranges from 10 to 30 years. This limit is not a postulate, therefore, you can find cases when the service life of a cast-iron battery reaches fifty years. Which is also not a limit.

Note! Correct assembly, high-quality water and liquid filling prolong the life of cast iron heating radiators.

The main cons

An overview of the shortcomings comes down to operating limitations:

- cast iron alloy batteries are extremely heavy, which slows down their installation on a number of surfaces. This indicator makes these products not competitive against aluminum, bimetallic and steel samples. Cast iron heating radiators are large in size, weight, which does not always coincide in style with the interior. Battery geometry is sometimes a barrier to its use;

Interesting! Battery manufacturers are increasingly focusing on the aesthetic side of their products. There are models on the market that are retro or hi-tech.

- if the working pressure in the system is 15 atmospheres, cast iron radiators are an excellent choice. But, if the pressure is higher, this type will have to say "no" for heating. The question arises: "Which are better cast iron or bimetallic?" Bimetallic batteries will come to the rescue in resolving the pressure issue, the pressure for which is 30 atmospheres is not yet the limit.

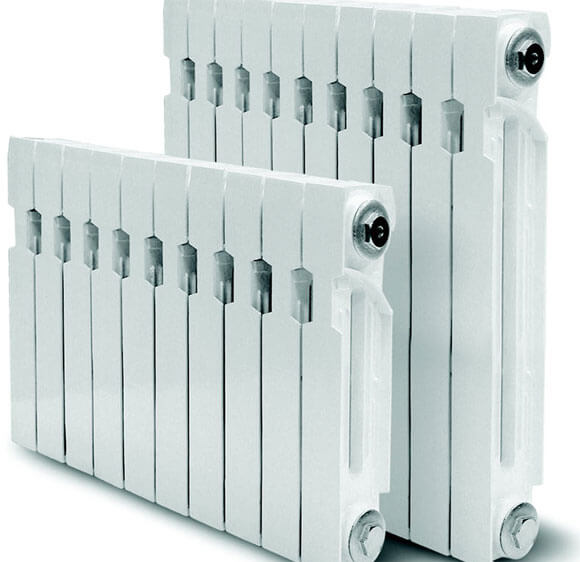

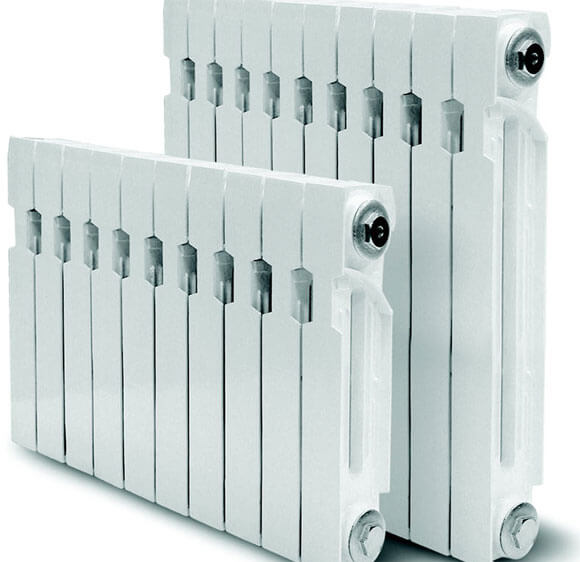

New cast iron batteries

If the advantages of a cast iron battery outweigh its disadvantages for you, we can recommend you high quality modern cast iron batteries. In the Santechbomba store you will find several practical options - the STI Nova 500 and STI Nova 300 models are presented to your attention. They differ from each other in size and power characteristics - for example, the "older" model 500 has a heat transfer of 150 W per section, the weight of the section at the same time it is 4.2 kg, volume - 0.52 liters. For the 300 model, these indicators are respectively 120 W, 2.9 kg and 0.3 liters, while it is 20 cm lower. Both radiators differ in their original design, a heat-resistant polymer coating is applied to the surface.

For those who prefer the familiar design, the classic MC-140 model is perfect. Consisting of 7 sections of 150 W each, it looks almost the same as the "very" Soviet batteries. And, of course, it is still heavy as it is made of real cast iron. However, you have not forgotten what advantages this material has?

Varieties and design features of cast iron radiators

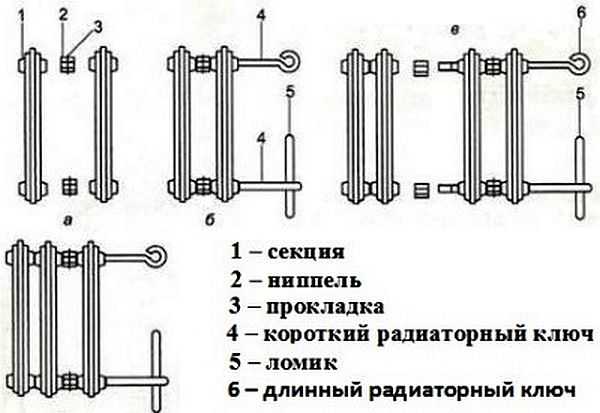

Each battery consists of several cast sections. They are made from gray cast iron. Inside the sections there are channels through which the coolant moves. The cross-section of the channels is round or elliptical. The sections are interconnected by nipples. To prevent the joints from leaking, they are additionally sealed with special gaskets - usually paronite or rubber.

Depending on the number of channels within the sections, several types of batteries are distinguished:

- single-channel;

- two-channel;

- three-channel.

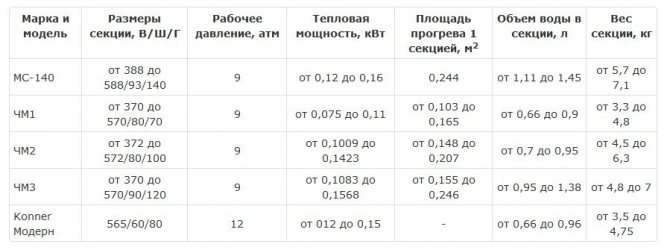

Manufacturers produce heating devices of various standard sizes, with a different number of sections. The main technical characteristic - power - depends on the parameters of the radiators. The height of the devices ranges from 35 to 150 cm, the depth is 50-140 cm.

As for the location and type of attachment, cast-iron radiators are mainly wall-mounted, they are mounted under the windowsills on powerful brackets. But in recent years, manufacturers are increasingly supplying floor models to the market that are equipped with legs. This is a convenient option, because cast iron is very heavy, it cannot be mounted on all types of walls.

Cast iron radiator design

Bimetallic batteries

Should I change cast iron batteries to bimetallic ones? When the cast iron option is not suitable, bimetal batteries are an excellent solution. Usually this word means a duet of aluminum and steel (instead of which copper is sometimes used). Aluminum plays the role of an external material, while the radiator core is made of steel, since this metal is more resistant to high temperatures and other unfavorable conditions. In this respect, it has similar characteristics to cast iron, because steel is not afraid of an aggressive chemical environment, and it is also resistant to corrosion. And in terms of the maximum withstand pressure, steel even surpasses cast iron - the steel core allows it to reach a working pressure of up to 30-40 atmospheres, and it is not afraid of possible water hammer.

Aluminum, in most modern models, hardly comes into contact with the coolant, while, receiving energy from steel, it quickly heats up and transfers heat to the room.Another important advantage of bimetallic batteries is the small volume of the coolant.

So, bimetallic batteries:

- lungs;

- graceful;

- heat up quickly;

- serve for a long time;

- not subject to corrosion;

- withstand tremendous pressure;

- are characterized by high efficiency;

- have a small volume of coolant.

Speaking about specific models, we will mention Alecord 350 - one of the best options in terms of quality and price ratio. The weight of one section here is only 1.1 kg, while its heat transfer is 136 W. Working pressure - 25 bar (withstands up to 35), the capacity of the coolant is 0.17 liters per section. For example, the Russian-made Halsen 350 has similar characteristics.

An interesting version of the Royal Thermo BiLiner 500 can also be noted. 171 W of heat transfer per section with its weight of 2.02 kg and a volume of 0.2 liters was created on the basis of innovative high-tech solutions. Literally everything speaks about this - from the unusual design of the radiator to the 25-year warranty and a huge amount of insurance coverage. Country of origin - Italy.

Installation of bimetallic heating radiators: tips and tricks

One of the main conditions for the further efficient operation of heating, which should be taken into account if you, having previously estimated the advantages of the option under consideration, purchased bimetallic heating radiators: installation and testing of the system requires utmost care and attention.

Work on the installation of radiators should be carried out only after careful study of the accompanying documentation. The instructions attached to the heating system must describe in detail the entire course of the work carried out. There should also be tips and basic recommendations, following which you will certainly get a high-quality result. Do-it-yourself installation of bimetallic radiators in this case will not present any difficulties, especially if you have some experience in carrying out such work. However, it is advisable to consult with experienced professionals with the required qualifications.

The work that needs to be done before you start installing bimetallic heating radiators is the assembly of the radiators themselves. As a rule, this operation is performed by the manufacturer at the factory or in a store by qualified specialists, and you purchase a ready-to-install assembled system.

However, it is possible to assemble bimetallic heating radiators or regroup individual sections at the installation site of the system. Masters with experience in this work should be involved in this work. A special key is required for operation.

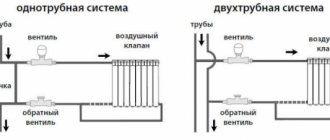

When carrying out the installation, you should pay special attention to the location of the valve necessary to release the air accumulated inside the battery (Mayevsky valve). This will eliminate the possibility of airing the heating system, which prevents a decrease in heat transfer. Before the valves, filters should be installed to clean the coolant entering the system from mechanical particles. Install a plug on the bottom of the "blind" side of the radiator.

Competent installation of bimetallic radiators requires compliance with the following points:

- It is necessary to take measurements and mark the places where the main fasteners will be located.

- In case of replacement, the old batteries are cut off, the remains of pipes are removed from the riser, in place of which taps are placed (in more detail: "Replacing heating batteries with our own hands - we will do everything ourselves").

- Fix the fasteners with suitable dowels and cement mortar.

- Performing, in fact, the installation of the radiators themselves. In this case, close attention should be paid to their installation strictly according to the level. Thanks to its low weight, the radiator is held very securely.

- Next, you need to connect the battery valve to the main part of the heating system. Radiators are connected to the pipes using sleeves, adapters and specially prepared copper pipes.

- After installing the valve, check its operation.

Installing a bimetallic radiator, video tutorial: