The main plus of instantaneous water heaters is compactness. But at the same time, these household appliances consume a large amount of electricity. Such a consumption is due to a large power, sometimes reaching 15 kW. Instantaneous water heaters belong to the class of reliable and durable devices, breakdowns rarely occur (sometimes due to a defect in production). You should know that repairing a flow-through water heater can be done by hand, it is enough to know the algorithm for finding them and purchase the necessary tools.

DIY water heater repair

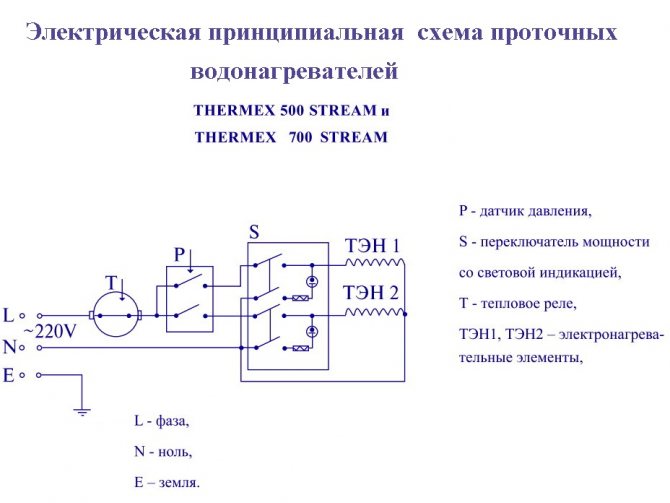

Basic control systems of instantaneous water heaters

Before proceeding with the repair of an instantaneous water heater with your own hands, you should understand its structure and principle of operation. The main elements of an instantaneous water heater:

- Heating element - heating element.

- Pressure switch.

- Temperature sensor.

In addition, the circuit must have wires with different markings, as well as a button to turn on the device and adjust the water temperature (in more expensive models). Manufacturers of water heaters very often use a standard control scheme, including new elements in it.

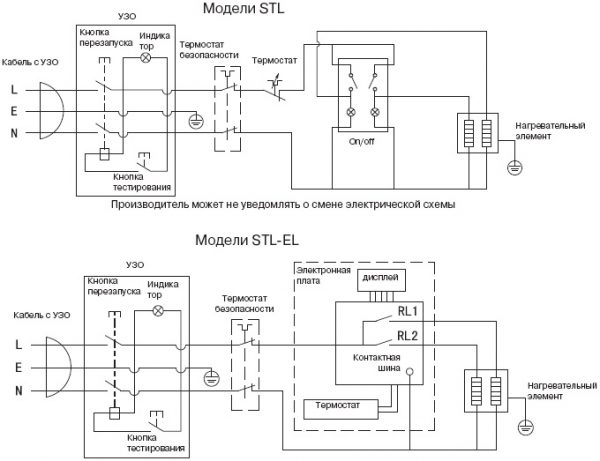

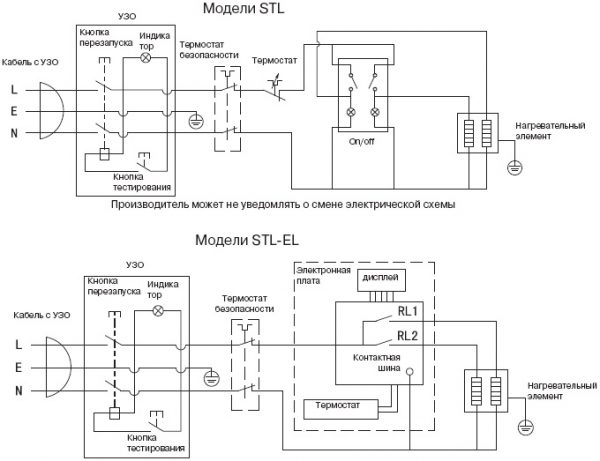

2 water heater control schemes

Above are the diagrams of devices of different models of instantaneous water heaters. As you can see, in these water heaters, heating elements are provided, to which the electric current passes through a temperature control relay, a pressure switch and a switch. Both relays in the circuit have a protective function, and trip the network if any of the parameters are not correct. The switch is used to adjust the working power of the device.

The lower circuit is additionally equipped with an electronic board that controls the device. In both schemes, a residual current device is provided

In addition to the phase and neutral conductors, a ground connection is also provided here. The circuit is simple, you can connect it yourself using an indicator screwdriver to determine the incoming phase and zero.

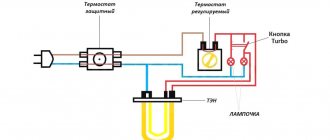

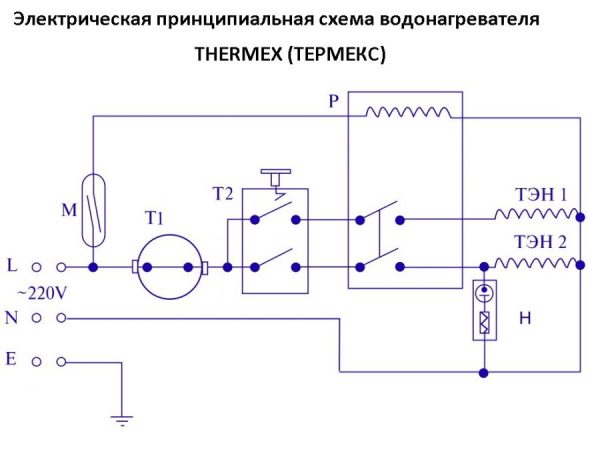

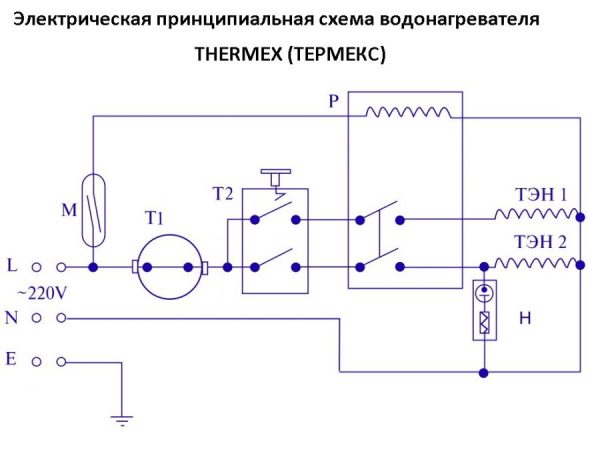

Thermex water heater control circuit

The above scheme is practically no different from the previous one. A slightly different arrangement of the element, but the functionality remains the same. 2 heating elements allow you to heat the liquid more or less. The relay is responsible for their operation, the signal to which is sent by the previously installed thermostat.

An additional element in this circuit is the readout sensor, which is connected to the relay. The heating elements can be turned on in automatic mode.

Prevention of boiler breakdowns

In order for the boiler to serve you for a long time, it, like any complex technique, requires competent care, which means that you will:

- drain water from the boiler during long periods of inactivity

- timely replace the anode

- do not turn on the water heater empty

- do not use the water heater always at the maximum temperature (it is enough to set the thermostat 5 degrees below the maximum)

If all these precautions did not help and your boiler does not turn on or does not heat or does not perform any other function assigned to it, call right now and call water heater repairmen:

8(499) 899-15-12

8

Troubleshooting Algorithm

Before you fix a malfunction, you first need to find it.Troubleshooting involves the supply of electricity to some parts of the circuit, so all work must be carried out carefully, wearing appropriate protective equipment (gloves, goggles).

Troubleshooting algorithm and elimination of the cause:

- Ensure that internal damage is not mechanical. For example, low outlet pressure is a common problem. This can happen due to a simple clogging of the watering can, which is installed on the water tap. Also, the fluid inlet and outlet pipes may become clogged. They must be cleaned with a special solution at least once every six months.

- If the mechanical part is working properly, then you should start with the input voltage. To do this, you need to purchase a multimeter - a device that allows you to make electrical measurements. Having set the appropriate value on the device (alternating voltage), one probe must be put on a phase in the terminal box, the second - to zero. A value of 220 V should appear on the screen of the multimeter. The tolerance is a value greater or less than 10 V.

Inexpensive multimeter for home appliance repair

In this way, you can check the incoming voltage on any component of the device.

- To check the temperature sensor, it is necessary to measure the voltage at the output of the device and in parallel control the temperature of the liquid. If the temperature rises above the set value, and the sensor does not break the circuit, then the element is faulty. If the voltage comes to the input of the sensor, but does not leave it (even when the water has not yet heated up), this also means a malfunction of the element.

- The next element in the circuit is a relay that switches the power supply from one heating element to another. It is enough to force the operating voltage to its input, and the relay will let it pass through itself. If there is no voltage at the output of the element, then this means a relay malfunction.

- The last and most important element of the electric circuit of the water heater is the heating element. The heating element is a curved tube with a metal spiral inside, on top of a ceramic body. An electric current flows in a spiral, it heats up and transfers some of the heat to the liquid. To check the heating element, it must be removed and checked for resistance. Too much resistance means a breakdown of the element, respectively - its replacement.

Heating element with a power of 1500 W

Sometimes the highest quality and most reliable way to determine a malfunction is a visual inspection of a household appliance. For example, the reason for the pressure drop may be a simple tank leak caused by a long service life and poor quality water.

I have artesian water / water from a well / from a well ...

This is certainly not a question, but a very large number of disputes begins with these words. The fact is that the failure of the heating element due to the formation of scale on it is not the rarest phenomenon. Putting on this peculiar fur coat, the heating element gradually stops heating the water and begins to overheat itself. As a result, it breaks down and requires replacement. Basically, owners of wells and wells face this problem. The water from these springs is rich in minerals that are beneficial to health, etc. etc., but for household appliances it is often destructive, precisely because of its composition. Water treatment can help to save heating elements, removing excess impurities and timely cleaning of heating elements.

What is thermal protection in an instantaneous water heater

Instantaneous water heaters are equipped with thermal protection elements - temperature control sensors. If the sensor malfunctions, the water in the device quickly reaches a high temperature, and the pressure increases accordingly. Both the water heater itself and the heating elements - heating elements - can be damaged.

Example of a temperature sensor for a boiler

The temperature control sensor works by interrupting the electrical circuit when a certain water temperature is reached. The most common overheating sensor (both electric and gas) is triggered at 60 ° C. After which the water cools down, the sensor turns on the electrical circuit, and the heating of the liquid begins anew.

In addition to the main sensor that monitors the temperature, an additional one is also installed. It carries the function of back-up shutdown of the circuit if the main sensor does not work. The reserve element will open the circuit at 90 ° C. It should be remembered that the backup sensor must be switched on manually, as it does not work in automatic mode. Usually it is turned on by replacing the main one.

How to replace a temperature sensor

The temperature sensor is usually installed as close as possible to the water outlet. Attaches to body with four bolts or Allen screws. Some models of thermal sensors have a collapsible housing, which allows you not to buy a new sensor, but to restore the old one yourself.

Temperature sensor replacement procedure:

- Drain the water.

- Remove four bolts or screws. For screws, you need to use a hexagon or a shaped screwdriver, for bolts, an appropriate wrench.

- Remove the wires, having previously marked them with a marker. The wire is attached to the sensor terminals with screws. It should be remembered that before starting work, the water heater must be disconnected from the network.

- Remove the old sensor and install a new one in its place, fasten with bolts or screws. It is necessary to purchase exactly the same item, otherwise the attachment points may not match.

- Connect the wires and tighten the contact points properly.

- Fill in water and turn on the water heater. Check its functioning.

Service of water heaters

Surely every user is worried about the question: what needs to be done in order for the boiler and the entire heating system to function as long as possible, and the need for such a service as boiler repair arises as rarely as possible ...

The answer is simple: it is required to carry out timely service maintenance of the boiler, radiators, and other components of heating and water heating systems.

There are works that only an experienced master can do. For example, debugging automation, cleaning the boiler tank and heating element, replacing the magnesium anode, diagnostic work of the gas system and electrical.

Unskilled intervention can easily not only lead to breakdown and more expensive repairs, but also to fire, flooding, and many other not very pleasant things. Fortunately, it is we who can offer our services for maintenance and repair.

It is also prescribed to strictly follow all the recommendations from the manufacturer. Since there are many equipment models, each of them has its own characteristics, it is simply impossible to list all the requirements here. But the following can be distinguished as universal tips:

- Avoid turning on the maximum temperature regime;

- If possible, use softened water as a heat carrier in the heating system;

- Apply filters;

- Regularly clean the equipment from dirt outside and - if possible - inside;

- Closely monitor all suspicious sounds on the system.

Service annual maintenance will avoid frequent repairs of the heating and water heating system. We can:

- Make a service drain of water from the tank;

- Inspection of the heating element for integrity and the presence of lime;

- Replace the anode with a new one.

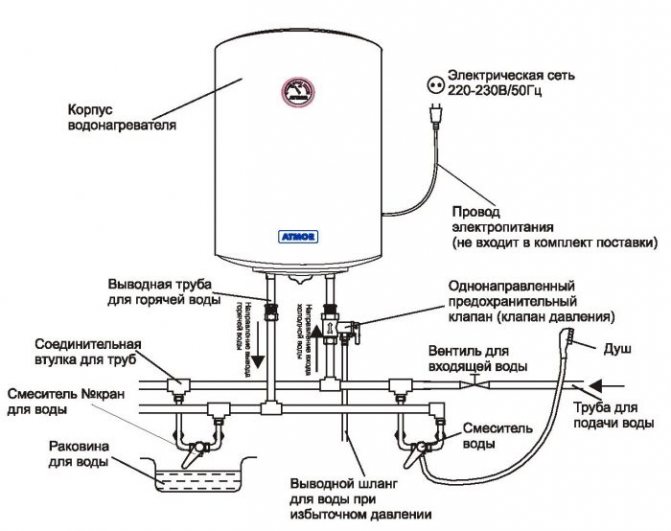

In addition, regular inspection of the check valve is required. If it turns out to be inoperative, the boiler will need to be repaired in the form of replacing the heating element. In the presence of automation, it is necessary to carry out its diagnostics, commissioning and tuning in a timely manner.

We invite you to familiarize yourself with our prices -

Gas boiler repair and maintenance are significantly different from electrical models. Only a specialist with extensive experience and the availability of specialized equipment will be able to do all the necessary work at a high level of quality.

The most frequent breakdowns and how to fix them

Instantaneous water heaters are simple enough if they do not have additional electronic control units. If any malfunction occurs, you can simply turn to the list for help, in which they are all indicated. The troubleshooting list also includes remedies.

Breakdown number 1: burned out heating element

The most common breakdown in which a household appliance continues to function even when the warning lamp is on, since the electric current reaches the heating element, but does not pass through it.

Burnt out heating element of the water heater

We repair the heating element in the following order:

1. Disconnect the water heater from the power supply and drain the water from it.

2. Remove the heating element. To do this, it is necessary to unscrew several bolts securing it to the water heater body.

3. Attach the working probes of the multimeter to the two main terminals of the heating element, having previously established the resistance measurement. The working resistance of the heating element is 32-35 Ohm. If the multimeter shows one, it means that the heating element is damaged.

The element is installed in the reverse order. Also, do not forget about the rubber gasket under the heating element. If the gasket has become unusable, then it should be replaced.

Breakdown number 2: clogging of the household appliance

A clogged water heater can result in too low outlet water pressure. An incomprehensible noise is also heard, similar to the passage of large debris through the pipes of the system.

With such a breakdown, all the working elements of the electrical circuit remain in good order, therefore, it can take a lot of time to find the malfunction. A clogged water heater does not require repair, it should only be cleaned with high quality.

Clogged water heater

The procedure for cleaning the instantaneous water heater:

1. De-energize the device and drain all water from the system.

2. It is necessary to remove 2 wires from the heating element: phase and zero. Then undock the heating device and rinse it thoroughly in hot water. Do not use hard objects to remove scale and rust, as this could damage the cell body.

3. Flush the water intake and discharge pipes under low pressure. For the best effect, it is allowed to use household chemicals with a mild effect, without active elements.

4. Install the heating element in reverse order. Switch on the device and check it for functionality.

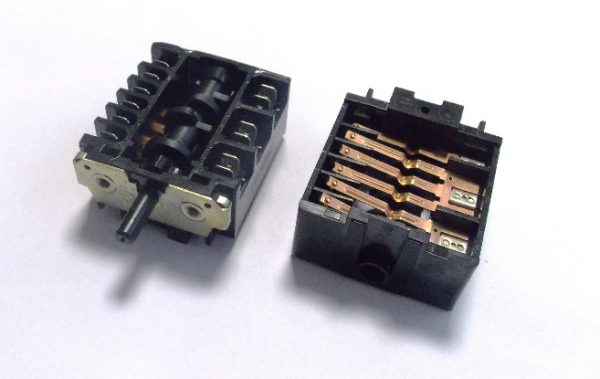

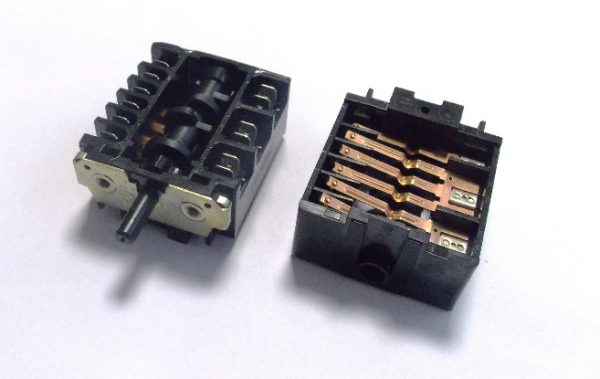

Breakdown number 3: the power switch does not work

Multistage power switches are mainly installed on models of the latest generations of boilers. This allows you to precisely control the water temperature and save energy costs. The consequence of a breakdown of the power regulator: the device does not react in any way to the rotation of the operating mode switch knob. There may be a slightly heated liquid at the outlet, while the pressure remains normal.

Standard power switch

Most often, the power switch is a variable rheostat, which can be checked with a multimeter. It is necessary to connect the probes to the terminals of the element and smoothly rotate the adjusting knob. If the resistance changes, then the rheostat is working, if not, then it should be replaced. When replacing, it is necessary to mark the wires and connect them to the corresponding switch terminals. It is better to buy an original switch rather than a cheaper analogue.

Breakdown No. 4: the external tank is punctured

With a long operating period, the water heater tank may leak.The quality of the heated liquid also affects the integrity of the material - very often, after several months of operation, scale forms on the surface of the heating element.

Damage to the external tank

When the body is punctured, the fluid pressure at the outlet drops sharply, the body of the device may be covered with fluid leaks. This malfunction is determined quickly by visual inspection.

Another reason for water leakage can be a worn-out rubber gasket under the heating element - the so-called flange. To replace the gasket, it is enough to drain the water, disconnect the water heater from the mains and remove the heating element. Having taken out the old gasket, it is necessary to put a new one in its place and assemble the device in the reverse order.

Qualified home repairs

Boilers are considered reliable and unpretentious devices, but with errors in operation and long-term use, problems may even arise with them. Under conditions of hard tap water, scale and limestone deposits form inside the tank on the heating element, which requires immediate preventive measures in the form of cleaning all internal components and assemblies from salts with a high calcium content. Our engineers quickly and efficiently carry out full diagnostics in order to identify problems and quickly eliminate them.

When ordering an urgent repair of EVN at home from us, you will receive a number of advantages:

- Masters will arrive at your address as quickly as possible;

- All diagnostic work is carried out at home;

- We will select the most rational way based on the technical documentation;

- We issue a document that is a guarantee for the work performed;

- Upon completion of the repair, we conduct testing in different operating modes;

- Competitive prices;

- We are ready to provide discounts for some used components;

- Experts will give recommendations regarding the correct use of the equipment, its care and maintenance, so that you do not face new breakdowns for as long as possible.

Boiler repair: elimination of frequently occurring faults

There are several of the most common problems that occur when using a water heater. Some of them can be eliminated on their own. To eliminate others, you cannot do without the help of a professional:

Damage to the integrity of the inner tank or outer shell

Such a malfunction may occur during careless installation or careless use of the device. For example, a chip or crack can occur if you accidentally hit the boiler or drop a heavy object on it.

As a result of such a breakdown, the destruction of the heat-insulating material will begin and the deterioration of the heat-insulating properties of the device. The active development of corrosion is also possible. It is almost impossible to eliminate such a malfunction on your own. You will either need to contact a specialist or buy a new drive.

Soldering the resulting holes will only solve the problem for a short time.

Replacing the gasket

In the event that a leak has formed at the location of the protective gasket, you just need to replace it by performing an independent maintenance. maintenance of the device.

Breakdown of heating element

One of the most common malfunctions is the breakdown of the heating element.

If the water has stopped warming up, or it takes much longer than usual, then the heating element is out of order.

Before starting to replace the heating element, you need to make sure that the power is supplied to the drive. This can be done using a tester:

- The scale of the measuring device is set within 220-250 V

- We fix the voltage at the terminals of the tester connected to the mains

- Lack of voltage means boiler breakdown

- In the event that there is voltage, the test should be continued.

- The boiler must be disconnected from the mains

- Then we disconnect the thermostat from the heating element and remove the insulation from the contacts of the heating element

- Using a measuring device, we take readings on open contacts

- The presence of voltage indicates the health of the heating element and vice versa.

A situation is possible when the heating element is serviceable, but the water does not heat up. Perhaps the reason is the thermostat:

- The tester should be set to maximum. We check the voltage at the input and output of the device

- In the absence of indications, it is necessary to replace the part (the presence of a positive reaction also does not give one hundred percent confidence in the serviceability of the device. It is necessary to continue measurements)

- We set the measuring device to a minimum and carry out a check on the thermostat contacts for a short time

- We try to warm up the thermal sensor with matches or a lighter and watch the thermal relay. In the event that heating has caused the thermal relay to open, the device is working properly. In the opposite situation, it will need to be replaced.

Other boiler faults

In cases where the heating element and the thermostat are working properly, but the water does not heat up, the possible reason lies in the boiler settings. If that doesn't work, the control board may be faulty. In this situation, you need to contact the service center.

If a breakdown of a particular part is detected, it is necessary to replace it with exactly the same one that meets all its characteristics (not only in appearance). Disassembling the drive for maintenance should be done very carefully and gradually. In the event that the flasks of the device are broken, most likely it will be necessary to completely change the thermostat.

In situations where you are not sure of your ability to check or replace one or another part, it is better to contact a specialized service so that you do not have to buy a new drive.