Table of contents:

- Why is it wet in the basement

- Why do you need internal waterproofing

- Types of waterproofing

- What materials are used for waterproofing

- Penetrating insulation

- Cement-based waterproofing (cement mixtures)

- Roll insulation

- Liquid insulation (coating)

- Membrane waterproofing

- Liquid glass

- Polyurea

- How to order waterproofing on poliol.ru

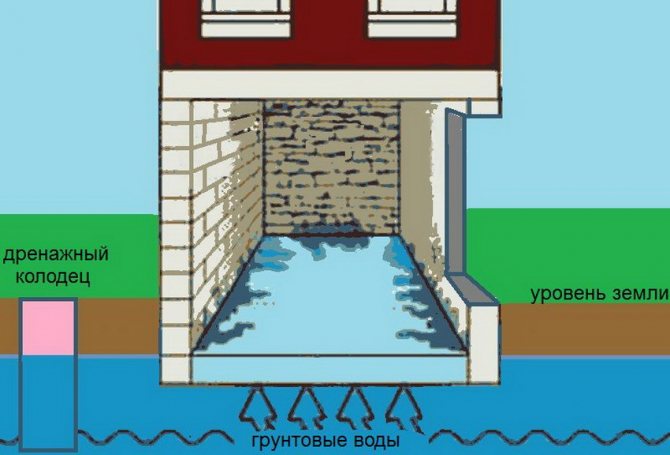

80% of buildings without waterproofing begin to collapse in the first years. The foundation and basement of the building are in contact with the soil, which means with groundwater and moisture, as a result of which:

- Water corrodes metal and erodes support structures.

- If dampness enters the basement, the temperature regime is violated, mold, fungus, insects appear.

- With periodic flooding of the foundation, cracks and surface faults are formed.

Drainage and protection of the interior of the building from moisture ingress can prolong the life of the house.

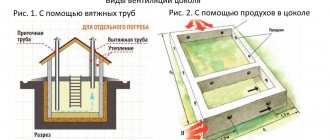

Drainage systems

There are many types and types of drainages. In low-rise construction, local drainages are mainly used:

- annular;

- wall-mounted;

- reservoir.

Reservoir drainage

settles down at the base of country houses directly on the aquifer. At the same time, it is hydraulically connected to a tubular drain located on the outside of the foundation at some distance from the plane of the building wall. The reservoir drainage system protects the structure both from flooding by groundwater and from humidification by capillary moisture.

Reservoir drainage is widely used in the construction of underground structures erected on poorly permeable (dispersed connected) soils (Kf ≤ 5 m / day), as well as in the presence of a thick aquifer under the foundation.

Ring drainage

(most often these are tubular drains) located around the perimeter of the house or the entire garden area. The action of the ring drainage is based on lowering the groundwater level inside the protected circuit, which provides protection against flooding. The depth of this lowering depends on the depth of the pipes, or the filtering part of the wells relative to the groundwater level, as well as on the size of the protected circuit.

Ring drains are located at some distance from the structure, due to which they can be installed after its construction. In this respect, ring drainage compares favorably with stratal drainage, which can be arranged only simultaneously with the construction of the structure.

Wall drainage

consists of drainage wall structures (dumped, glued, installed) and tubular drains, laid on the outside of the structure and serving at the same time collecting and removing drainage water by a pipeline. Wall drainage is used, as a rule, in almost all cases, both independently and in conjunction with other types of drainage.

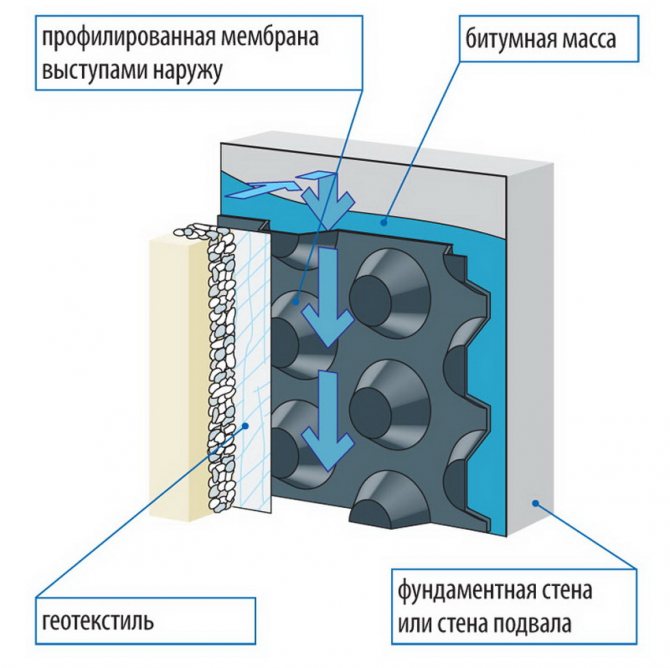

Currently, special geocomposite drainage systems are mainly used for wall drainage. Geocomposites consist of a profiled plastic membrane (PVP) and geotextiles glued to it. Geotextile allows water to pass through, while retaining soil particles, and a plastic membrane freely diverts water to drainage pipes.

In conclusion, we will summarize some of the results. What can a complete waterproofing system look like using modern waterproofing materials?

For clarity, you can use the systems developed by TechnoNICOL specialists.

Why is it wet in the basement

Heavy rainfall, wind, temperature changes - all this affects the foundation and basements in houses. Moisture is contained in the surface layers of the soil, melt and rainwater collects in the upper layer of the soil.

The reasons may be as follows:

- poor ventilation;

- microcracks and faults in the foundation and supporting structures of the building;

- overload: the building presses on the soil, groundwater penetrates through loose joints and increases the amount of moisture.

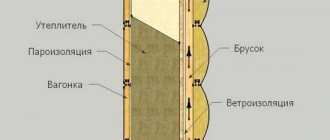

Wall waterproofing

The walls of the house gradually collapse under the influence of moisture. Water can penetrate through the pores of the wall material, through the foundation, due to poor waterproofing, etc.

When water penetrates through the foundation into the basement, it begins to rise higher along the wall along the capillaries, sometimes reaching the second floor and causing dampness in the premises. The so-called capillary suction occurs.

To avoid this, it is necessary to waterproof the walls according to all the rules. The method of its application should be chosen depending on the material from which the walls are built, as well as the reasons that cause an increase in their humidity.

Wall waterproofing methods

Wall waterproofing can be external and internal. As an external one can serve as coating, painting, penetrating, sprayed, injection waterproofing, etc.

Helpful advice

Painted waterproofing "seals" the pores of the stone wall and thereby protects it from moisture penetration from the outside.

Of the lubricants, first of all, those created on the basis of expanding cement are used, which, during the hardening process, increase in volume and neutralize the effect of shrinkage. Such material can protect walls from external moisture when groundwater rises, flooding and other unfavorable external factors.

Video: Do-it-yourself waterproofing of a private house:

(No Ratings Yet)

Types of waterproofing

There are several ways to isolate the cellar from groundwater. To choose the best option, you need to take into account the climatic conditions of the region, the features of the structure and communications inside, the level of melt and groundwater.

- Vertical protection walls from the inside are required if the groundwater is very close or there are no drainage systems around the house. Waterproofing is arranged along the perimeter inside the building.

- Horizontal insulation it is necessary if we are talking about clay soil, which prevents steam exchange, and the base is adjacent to the places where groundwater is released. As a rule, vertical and horizontal foundation insulation is combined with each other. This helps to enhance the protective properties of the materials.

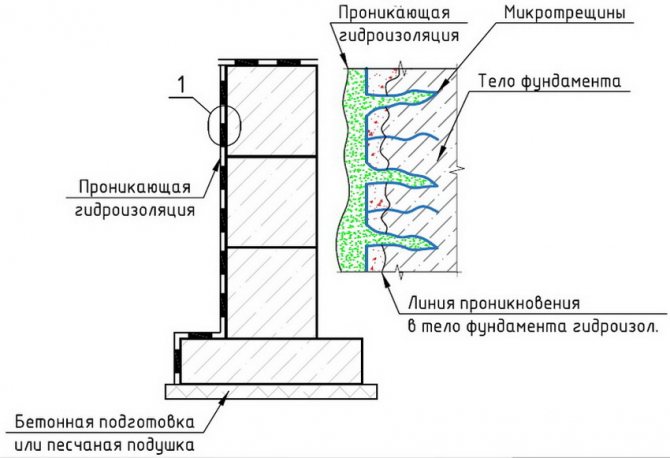

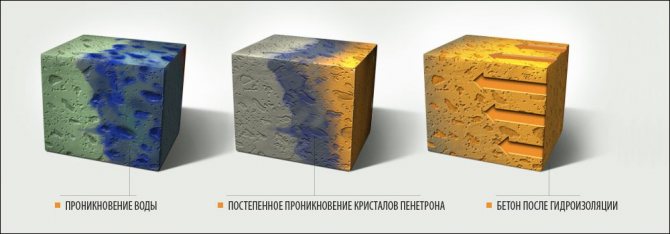

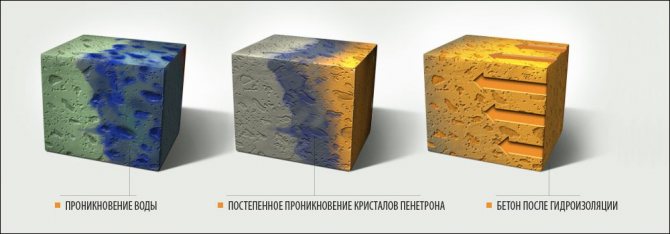

- Penetrating waterproofing relevant when it comes to groundwater pressure and lack of drainage. The idea is to use water pressure, which pushes the protective material harder against the surface of the house. Penetrating waterproofing is designed to fill cavities that appear in walls and help stop moisture from entering. For example, concrete has a porous structure, if it is impregnated with a special hydrophobic solution, then it will repel water.

Waterproofing materials

For waterproofing the basement from the inside from groundwater, different materials are used. It can be liquid glass, bitumen, cement, penetrating agent, metal. The choice depends on the level of the aquifer, its pressure, geological conditions, and structural features of the building. According to the application technique, there is a coating, gluing, injection, penetrating moisture insulation. A video review of modern waterproofing materials will help you make the right choice:

Liquid glass

When the surface is covered with liquid glass, its components penetrate into micropores and cracks in the concrete foundation and turn into crystals there. Due to this, the structure acquires increased strength and moisture-proof properties.The penetration depth depends on the number of layers. With a single coating, liquid glass diffuses by 1-2 mm. A multi-layer penetrating coating makes it possible to increase this depth up to 2 cm.Additional advantages of waterproofing a basement with liquid glass include:

- low cost of material and work;

- ease of preparation and application of the product;

- low material consumption per 1 square meter;

- resistance to destruction by microorganisms;

- high waterproofing properties.

The application of water glass requires expansion of the cracks for better penetration of the substance.

Cement mixtures

Cement-based waterproofing is characterized by high adhesion. According to the level of adhesion of the material to the base, this type is considered the best. For waterproofing the basement, two types of cement coating are used: rigid and flexible. The first variety goes on sale in the form of loose powders. Flexible cement mixture consists of a dry part and a polymer emulsion.

Plaster as a method of protection is used alone or in combination with other types (penetrating, roll, injection). A cement layer with a thickness of 30-80 mm is applied after preliminary cleaning of the surface. This material is convenient to use when there is a need to level the walls and floor for further finishing.

Coating waterproofing

Liquid compounds for coating consist of bitumen, latex, polymers. After being applied to the surface, the mixture turns into a film that is waterproof to groundwater. Such a waterproofing agent at the same time has the property of protecting the structure from steam coming from the inside of the basement. Some mastics require warming up before application, while others require dilution with water or organic solutions.

Bituminous mixtures are suitable for coating both vertical and horizontal surfaces with external and internal waterproofing. Before application, all existing cracks and fractures are sealed with cement. It is necessary to take into account the fact that "liquid rubber" does not contact well with finishing materials. The walls of the basement room, treated in this way, cannot be sheathed with plasterboard, since the fastening parts violate the tightness of the moisture-proof layer.

Roll insulation

Bitumen-impregnated glued materials are intended for floors. On vertical surfaces, roll products are rarely used due to their poor compatibility with the finish. In practice, three types are used:

- Roofing material.

- Hydroizol.

- Linocrom.

Roofing material is an inexpensive and affordable canvas, which, however, has low protection against a strong pressure of underground moisture. Hydroisol is more expensive, but its price justifies its moisture-proof properties. Linocrom is considered an excellent material, as it meets the price-quality ratio.

Membrane waterproofing

Despite the fact that the membrane material belongs to roll varieties, it is considered an independent type of internal waterproofing of walls and floors. The coating has an insignificant thickness - less than 2 mm and is fixed to the surface with bitumen glue. There are three types of membrane sheets:

- PVC. They contain polyvinyl chloride, which is highly fire-resistant.

- TPO. Thermoplastic polyophene is an expensive membrane containing rubber and propylene.

- EPDM. The composition includes a synthetic rubber that does not lose quality at low temperatures.

Membrane materials can be film or profiled. The former are used when the aquifer is low, and the latter is used when the aquifer is high. The choice of the membrane is also influenced by the depth of the foundation. If it is located at a depth of 10 meters, then a 1.5 mm thick film is sufficient. With a deeper foundation, a material of 2 mm is required.

Penetrating compounds

For penetrating waterproofing, products containing Portland cement are used. When applied to the surface, there is a gradual filling of all micro-voids in a concrete or brick base. The slab turns into a reliable protective shield in the path of moisture. Penetrating waterproofing is relevant at a high level of groundwater.

The popular material in this category is Penetron. The technology of its application is simple and convenient. The dry powder is diluted with water and applied to the base with a brush. Such insulation does not require special preparation of the walls and floor inside the basement.

Injection protection

A reliable way to stop the diffusion of water molecules through the foundation in high groundwater conditions. However, injection protection is considered a labor-intensive option for internal waterproofing. According to the technology, it is necessary to make a large number of holes in the slab, which are filled with a hydrophobic composition. The introduction of the solution is carried out using a special injector device. Gels of different compositions are used as a filler:

- cement;

- polyurethane;

- methyl acrylate;

- epoxy.

Injection products are economical, do not require surface preparation and allow surface treatment even in hard-to-reach places. The flowing consistency of the mastics ensures deep penetration into the solid base and simultaneously pushes the water out.

Metal cladding

Steel waterproofing is advisable when there is a strong pressure of groundwater. For this, metal sheets with a thickness of several millimeters are used. They are fixed to the base with anchors. The holes made of small diameter are poured with cement, and then covered with small plates and welded.

This method is generally applicable for a basement room. In some cases, instead of cladding, a metal caisson is used, which ensures complete sealing of the underground from underground moisture in the soil.

What materials are used for waterproofing

Most often used:

- penetrating insulation - a mixture of sand, cement and polymers;

- cement mixtures - cement and polymer additives;

- roll insulation - bitumen, roofing felt, roofing material, brizol, waterproofing;

- liquid glass - an aqueous alkaline solution of sodium and potassium;

- membrane insulation - molding rubber for a snug fit to the surface;

- polyurea - sprayed two-component polymer.

For example, penetrating insulation is suitable for concrete surfaces; for buildings in regions with frequent and heavy precipitation, a bitumen-based coating mixture is used.

Let's consider in more detail in what conditions and how to use each material.

Soil waterproofing materials

Soil waterproofing is carried out using different types of materials: roll and film, based on bitumen and polymers. The work is carried out in several stages, each of which requires an attentive and competent approach. Initially, the soil is tamped with a special device to prevent cracking and subsidence during operation. Next, a pillow is created from a layer of sand, expanded clay and crushed stone, which is poured from above with cement mortar and, after drying, is treated with bitumen.

Only after completing the above steps can you start laying waterproofing - it can be a roll material, a polymer-bitumen membrane or surface treatment with penetrating or coating compounds.

Membranes

Waterproofing in the form of a membrane is made on the basis of high-density polyethylene. The material has perforations and protrusions on the outside, intended for locking connection when overlapping each other.The main feature of the membrane is its ability to cut off the aggressive effects of acids, minerals in groundwater and create a dry air layer under the surface of the foundation, while water does not penetrate to the building structure.

Films

Waterproofing films are a type of flat-type membranes that are laid in several layers when waterproofing the soil. The material is made from polyvinyl chloride, polyolefin or high and low density polyethylene. Among its advantages are high strength, water resistance, low cost and preservation of hydrophobic properties for a long time.

Roll materials

Waterproofing with roll materials is the most proven and reliable method used for decades. Today, in addition to the traditional roofing material, there are materials on the market based on:

- cardboard - rubemast, glassine;

- polyester - fibers made from polyester resins;

- fiberglass - a material that is maximally resistant to aggressive environments;

- fiberglass - an inexpensive product with a small resource.

Penetrating materials

Today, the market leader in coating materials is the brand "Penetron", among the products of which there is a waterproofing primer, a variety of dry mixtures intended for adding to concrete and preparing penetrating solutions. Thanks to the use of penetrating compounds, the strength and hydrophobic properties of concrete and other building structures are significantly increased.

Penetrating waterproofing

Such basement waterproofing is used if the groundwater is high enough. Penetrating insulation is an umbrella term for a mixture of several components. It includes sand, cement and polymers. As a rule, such mixtures are diluted in water and then applied to the surface to be protected from moisture. It is also a concrete or brick building. The liquid composition penetrates into cracks and capillaries, fills the concrete structure and crystallizes, leaving no chance for moisture to penetrate inside. At the same time, the ability to pass steam at the concrete remains, which avoids the appearance of condensation.

How to apply penetrating waterproofing

Remove grease and dirt from concrete. If there are cracks on the surface, they must be repaired with a putty and a homogeneous structure of the material should be achieved. This will help to avoid the formation of fractures and premature deterioration of the concrete. Then rinse the surface with water, prepare a waterproofing mixture and apply it on damp concrete in 2-3 layers. It is worth starting work from the corners and joints of the joints. After completion, we recommend moisturizing the treated surface for several days, this will promote uniform hardening.

Why you need to waterproof your basement

Due to the fact that there is constantly high humidity in the basement, this leads to the formation of fungus on the walls, and this, in turn, adversely affects both the structures of the structure and the health of the person himself. To keep it dry in the basement, you need to properly organize waterproofing on the outside of the walls.

The organization of the drainage system laid underground, as well as the blind area around the entire house, can completely protect the basement structure from groundwater. A well-made waterproofing of the walls inside the basement should protect it from the penetration of filtration groundwater.If you notice that it is damp in the basement, then you need to take a number of sequential actions to improve the conditions, namely:

- Examine all walls, floor and ceiling of the basement for cracks and open joints that allow water to pass through.

- Inspect the blind area around the structure, if there is damage, then be sure to close it up.

- Found cracks and open seams that let water into the basement must be repaired with a waterproofing mixture.

- The ventilation in the basement must work properly.

Cement-based waterproofing

This type of protective coating is also called plastering insulation. It adheres well to the surface, is durable and is applicable not only to concrete surfaces, but also to wood and metal. There are many options for cement-based waterproofing mixes, but the most resistant are those containing polymers. Chemical elements add elasticity to classic cement.

How to apply the cement mixture

Remove dust, soil residues, grease from the basement surface, brush with a steel brush or water. This is necessary in order to open the pores of the concrete for the mixture to penetrate inside. After that, prepare the cement mixture, mix thoroughly until it begins to resemble sour cream in consistency. Apply the solution to the surface with a brush in two layers, first lay it horizontally, after two hours - vertically. The composition will completely harden after 24 hours.

Roll insulation

Roofing material, roofing felt, waterproofing - all these are roll materials. They are used when it is necessary to protect the floors and walls in basements from the inside from moisture. The easiest way is to lay the rolls on the floor using an adhesive or bitumen mastic. If the house is located in a region with abundant floods, waterproofing should consist of 4 layers, if not, 2 is enough. Roll insulation is chosen because it is affordable and you can install it yourself. However, at low temperatures, it becomes brittle and cracks.

How to make internal waterproofing of walls in a basement with your own hands

When water flows along the walls of the basement, waterproofing cannot be done, you need to wait until it stops flowing, most often this is due to natural phenomena - melting snow or precipitation. First you need to establish where the water comes from on the walls and make marks. When the water stops seeping, the basement must be dried with a heat gun. In order for the evaporating water to leave the basement without problems during the drying process, the ventilation must be in good order.

Now we begin to seal the seams in the walls, and for this we need to remove the old solution from them and treat all the walls with an antiseptic. When they dry out, we use Penetron - a deep penetration waterproofing for the basement based on a cement-sand mixture with polymers. We fill all the seams and cracks with it.

Then, with the same mixture, only of a more liquid consistency, we process all the walls of the basement as a whole. For three days, it is necessary to moisten the walls abundantly with water - this contributes to the fact that the sealant applied to them becomes more durable.After 2 weeks, you can apply the finish to the basement walls. The floor will be ready in three weeks and it will be possible to put the floor covering you want on it.

Penetrating basement waterproofing from the inside from groundwater

Is a good way to protect your home from dampness. You will be able to do all the work yourself if you watch the video and read the step-by-step instructions. With your own hands, you can extend the life of any structure in the country.

Waterproofing of the strip foundation of a residential building is necessary to prevent moisture from the concrete and reinforcing elements included in the foundation structure from sediment and groundwater. The wetting of concrete provokes the destruction of the foundation when the frozen water expands in the capillaries of the concrete tape and leads to corrosion of the steel reinforcement, reducing the strength properties of the base of the house. Owners of individual buildings are able to independently correctly carry out work on the arrangement of waterproofing the foundation of their house, having certain knowledge in this area.

The destructive effect of moisture on the foundation of a building occurs when water interacts with the materials of the foundation structure.The porous structure of concrete, saturated with capillaries, contributes to the constant absorption of moisture by concrete from the environment and groundwater. In order to make the strip base of a residential building as protected as possible from a humid environment, it is necessary, in accordance with (previously SNiP 2.03.11-85), to provide its water protection by methods of primary and secondary protection against corrosion (clauses 4.5, 4.6 and 4.7). Foundation waterproofing belongs to the category of secondary protection based on the use of protective coatings or treatment with special compounds.

Strip foundation waterproofing scheme.

Builders with their own hands or with the involvement of specialized organizations carry out measures to apply waterproofing materials to the foundation, taking into account external factors affecting the base of the house:

- Atmospheric precipitation and melt water;

- Groundwater.

For guaranteed protection of the foundation from the penetration of sedimentary and melt water, it is enough to make a high-quality blind area around the perimeter of the entire building. To implement hydroprotection from ground moisture, it is necessary to take into account a set of initial data, among which the main ones are:

- The type of groundwater near the building;

- The depth of the groundwater passing near the building;

- Inhomogeneity of soils in the area of construction;

- Purpose and planned operation of the house.

Let us consider how these factors affect the choice of a method for waterproofing the foundation.

Groundwater type

Groundwater has a direct impact on the formation of the groundwater level (GWL) in the area of the construction site and on the degree of soil moisture near the foundation. The diagram below shows the distribution in soil of the two main types of groundwater:

- Verkhovodka - local centers of water formation, which have a seasonal nature of existence. The upper water lies near the earth's surface, is formed and exists only during high humidity of the environment, disappearing during dry periods;

- Ground waters occurring near the earth's surface and having a territorial regional distribution. The groundwater table is susceptible to seasonal fluctuations.

As mentioned above, in order to protect against perching water, it is enough to make a good blind area and downpour. Protection from groundwater will depend on its depth. This dependence is discussed below.

Depth of groundwater

"Recommendations for the design of waterproofing of underground parts of buildings and structures" Central Research Institute of Industrial Buildings, Moscow, 1996 (supplemented in 2009), determined that the waterproofing of structures must be performed at least 0.5 m above the maximum GWL (p. Sec. 1.8 and 1.9). Since the average value of fluctuations in the level of GW in many regions of the Russian Federation, based on the results of geological surveys, was taken within 1.0 m, then for guaranteed protection of the foundation from ground moisture, it is recommended to adhere to this indicator as a reference point when choosing waterproofing of the base of the building, depending on the depth of occurrence of GW. ... In particular:

- When the groundwater level is less than 1 m below the base of the foundation, it is necessary to waterproof the foundation;

- If the groundwater level is deeper than the foundation by more than 1 m, the water protection does not need to be equipped.

It is necessary to take into account the possibility of increasing the GWL as a consequence of the development of infrastructure in the region. And also the maximum GWL for the past seasons.

With a high level of hot water, exceeding the lower level of the foundation base, in addition to waterproofing, it is necessary to additionally make drainage of a local nature to remove moisture from the foundation, as prescribed in "Design and installation of foundations and foundations of buildings and structures" (Chapter 11).

Soil heterogeneity

The heterogeneity of soils with different chemical composition leads to chemical aggression of groundwater in relation to concrete in the composition of the foundation, up to its destruction (concrete corrosion).It is required to use special corrosion-resistant concrete of the W4 brand when pouring the foundation and waterproofing of increased reliability from materials resistant to aggressive environments.

Purpose and planned operation of the house

In the presence of self-equipped basements for functional purposes such as a gym, workshop, etc. increased requirements are imposed on the reliability of waterproofing in order to prevent a deterioration of the microclimate in these rooms.

A properly equipped waterproofing strip foundation of a residential building requires compliance with three basic principles of building a waterproofing system for the foundations of buildings of any purpose:

- Continuity of each layer of waterproofing along the entire perimeter of the waterproofing;

- Installing a waterproofing layer only on the side of exposure to moisture, i.e. foundation waterproofing should be carried out outside, but in no case inside the basement;

- Preliminary special preparation of the outer surface of the foundation for the subsequent application of waterproofing material.

Liquid insulation (coating)

Protective coatings are varied in composition. The mixture can be bitumen-based, bitumen-polymer, polymer and polymer-cement. Such formulations are suitable for concrete, stone and brick surfaces. They are easy to apply and protect basements from temperature extremes, moisture and salt. The most durable are polymer and polymer-cement. By adding active chemical elements, their lifespan is extended. Bituminous mixtures lose their elasticity at low temperatures, so cracking is highly likely.

How to apply liquid insulation

Clean the surface of dust and dirt, level if it is uneven and contains cracks. Then prime the walls of the cellar to increase the adhesive force. Moisten non-primed walls with water. After that, prepare the coating mixture according to the instructions and apply in two layers. The second coat can be applied when the first coat has hardened but not completely dry.

Methods

As practice shows, for waterproofing the walls of the basement from the outside, the following methods of protection are most often used:

- Application of penetrating compounds.

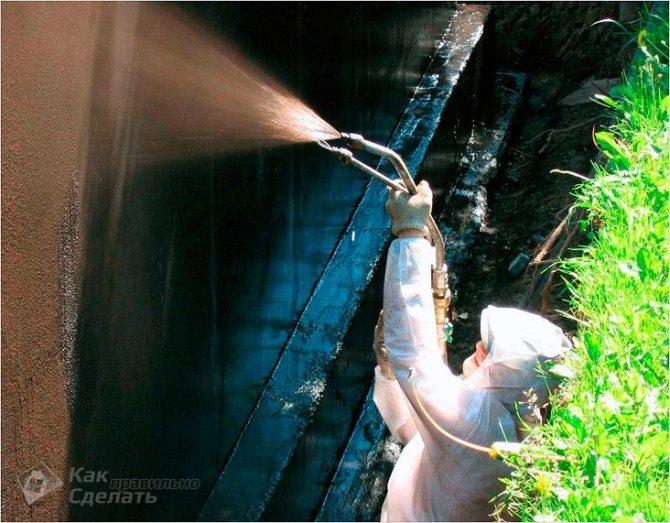

- Surface treatment with low-pressure or high-pressure mixtures.

Penetrating insulation not only protects the basement from moisture, but also strengthens the building material, making it stronger and more resistant to various kinds of stress. Compounds of this type are capable of deeply penetrating into the pores and microcracks of concrete, as well as other porous materials. Here they polymerize, reliably blocking access to water. At the same time, the penetrating waterproofing retains its hydrophobicity, i.e. it does not allow moisture to penetrate through the capillaries into the building material, but does not impair its vapor-permeable qualities.

Low-pressure external basement waterproofing is made in cases where the groundwater level is low and there are no serious seasonal fluctuations in its value. This type of water protection includes:

- rolled bituminous, polymer canvases;

- coating compositions;

- liquid glass;

- bituminous mastics.

High quality low pressure insulation has good adhesion, corrosion resistance, long service life. At the same time, in order for the created waterproof membrane to reliably protect the basement from water, it must be uniform and continuous over the entire area of the building.

High-pressure outdoor basement waterproofing is a multi-layer structure that is strong and durable. It is used to protect the foundations and basement of buildings located in areas with high groundwater pressures.A typical method of manufacturing such insulation is to alternate roll material with cement plaster, to which bitumen or polymer compounds are added that improve the hydrophobic properties of the waterproof membrane. Sometimes, to give the structure rigidity, the waterproofing is reinforced with a polymer mesh.

You can do the waterproofing of the basement outside the building with your own hands. However, you always need to remember that it will serve for a long time and reliably, only if the structure around the perimeter is protected by a drainage system and has a wide blind area.

Ideally, waterproofing should be erected during the construction phase of the building. But if there is a need to repair or manufacture a basement protection from groundwater in a house that is already in use, you will have to open the foundation and replace the floor.

Membrane waterproofing

The membrane-type protective material is similar in principle to roll insulation. But it is lighter, produced in the form of a film with a thickness of two millimeters. To protect the interior of the house from moisture, a PVC (polyvinyl chloride) membrane is often used. It is fire resistant. Membrane coatings are available in the form of a web with cone-shaped spikes, this helps to drain water. They are also easily attached to any surface due to the adhesive backing.

How to apply membrane insulation

The walls and floor in the basement or cellar need to be cleaned. If there are cracks and chips on them, putty and prime. Apply bituminous mastic, for better adhesion, fix the membrane to the surface with dowels, install an insulating material.

Waterproofing options

There are 2 methods to protect the foundation from water:

- the creation of a drainage system around the residential building;

- protection of foundation elements with waterproofing materials.

The foundation must be protected from the harmful effects of moisture.

Consideration should be given to the options for foundation waterproofing and the materials used for such purposes. In the process of waterproofing strip or prefabricated foundations for residential buildings, a set of measures is carried out that are associated with the application of waterproofing materials to structural elements.

Horizontal waterproofing of foundations and basements is performed in 2 levels. Typically, this is done at the top or bottom of the basement slab. Before waterproofing the foundation, the surface of the floor slabs is cleaned of dust and debris, and the joints of the walls and slabs are well sealed with cement mortar.

When the solution dries, a roll-up waterproofing is glued to the entire area of the slabs. A gas burner is used to waterproof the foundation with guided materials. But self-adhesive waterproofing materials are also on sale. The protective film is simply removed from them and tightly pressed against the insulated surface.

Important! Such materials are more expensive, but in quality they are not worse than guided roll materials.

The disadvantage of glued and deposited materials in the production of a foundation waterproofing device is that the joints may not provide the necessary sealing.

Vertical waterproofing is done along the walls of the basement. It also prevents moisture and fungus from entering the concrete blocks. Basically, it is performed with coating materials based on polymeric materials and bitumen.

The implementation of the coating waterproofing of monolithic and prefabricated foundations is carried out using liquid compositions. Bituminous mastics can be diluted with gasoline and applied with a simple brush to concrete blocks. It is important that the consistency of the liquid allows it to fill all small cracks and pores.

Recommended to apply in 2 coats. In this case, the first layer hardens in 4-6 hours, and the final coating should have a thickness of at least 1.5-2 millimeters.

In winter, waterproofing requires high attention to the use of frost-resistant additives and the quality of applying insulation materials to foundation blocks, especially at their joints.

When waterproofing foundation slabs, special care is required because it is closer to the groundwater. Here, filtration waterproofing is needed, which is carried out with a bituminous solution before laying it in the pit.

If the groundwater is not close to the foundation of the house, then you can restrict the treatment of foundation blocks with primers - this is a liquid solution of gasoline and bitumen.

Plastering waterproofing of foundation walls is based on the use of cement-containing mortars with the inclusion of polymerizing components. After mixing with water, they become a composition that penetrates into the pores and cracks of concrete blocks and after a while increase in size, filling all the voids.

Particular attention is paid to sealing the joints between pillows and foundation blocks.

Important! Do not use ordinary plaster mix of cement and sand. It is not intended for waterproofing.

Vertical and horizontal waterproofing of slab foundations must be joined without gaps, because this will break the sealing. The drainage system is a network of storm drainage channels and drains that carry wastewater to a distance from which they cannot affect the foundation structures.

The distance from the foundation belt is 4-5 meters. Downpipes and trays for joints from the roof, various sidewalk paths with rain trays with a slope of 1.5-2 degrees from the residential building are what you need.

Around the perimeter of a cottage or house, the blind area is carried out according to the following rules: A trench is digging along the perimeter of the house with a width of 1500-2000 millimeters and a depth of 300 millimeters. 100 mm of sand are poured into it, the same amount of gravel with a fraction of 25-30 millimeters and 100 mm of clay. The last 2 layers tamp well.

Then a 100 mm concrete pad is made around the perimeter of the trench or paving slabs are laid on a sand-cement base.

Important! The slope of the sidewalk paths and blind areas with drainage trays adjacent to the structure should be at least 1.5-2 degrees.

The discharge of melt and storm drains is directed into the sewerage system provided for this or beyond the outer perimeter of the site.

After getting acquainted with the basic technologies and concepts of foundation waterproofing of private houses, it must be remembered that an integrated approach is required to study the characteristics of the soil of construction sites. No need to save on foundation waterproofing

It will also come in handy for repairs.

- How to do the job correctly

- How to properly waterproof your bathroom floor?

Today it is difficult to imagine the implementation of apartment renovation, where it would not have been carried out. Laying it is considered a very important issue, especially in apartments with high humidity. Floor waterproofing is done not only in the bathroom. Other rooms also need waterproofing.

Most often, no apartment or house can do without waterproofing, where there is a danger of water ingress, which can penetrate into the room from the surface of the earth. Everyone knows very well that rooms with constant high humidity are mainly located above basements. A humid atmosphere can cause wood to rot, and even concrete floors can be destroyed. So how do you waterproof your floor?

Liquid glass

This component contains an alkaline solution of sodium and potassium silicate. It is produced in the form of a powder, which must be mixed with water to obtain a waterproofing mixture. Outwardly, it resembles transparent rubber, which is why it got its name - liquid glass.

The composition can be prepared independently and applied too. Liquid glass protects the surface from corrosion.If the integrity of the coating is suddenly broken, it is easy to repair it. Most often, this material is used to protect concrete walls with metal inserts from moisture.

How to apply liquid glass

Clean the surface of dirt, degrease and level with a putty or primer if it is uneven. Then prepare a solution and apply to the entire surface, without bypassing joints, corners and crevices. The process should not be delayed, as the mixture hardens quickly. When the surface is dry, apply a layer of plaster.

Liquid rubber

Liquid rubber is an excellent material for making a seamless waterproofing membrane. This is bitumen with the addition of polymers and binders. It is diluted with water and applied to concrete. The liquid rubber then polymerizes and forms a smooth, seamless surface up to 10 mm thick.

This insulation has a high degree of adhesion. However, the membrane is characterized by low strength. Therefore, it is reinforced with a polypropylene or galvanized metal mesh. If you plan to make high-pressure insulation, a layer of cement plaster is applied to the liquid rubber. There may be several such alternating layers.

Polyurea

The polymer has high physical and mechanical properties, does not leave seams, unlike roll materials, dries quickly and serves for more than 30 years. It also easily adheres to concrete, metal, ceramic tiles, which makes it very versatile in many ways. It is polyurea that is used for waterproofing pipelines and swimming pools. It consists of two components that must be mixed together to obtain a spray mixture. The mixture is applied using a special installation.

How to spray polyurea

The material can be applied to the surface with a roller, brush or using a high pressure unit. It is better to use the latter method, this will allow you to spray the polymer in an even layer and avoid the appearance of bubbles. Before applying, mix components A and B from a two-component high-pressure unit, then the mixture is heated and sprayed with a gun. The surface on which the polyurea will be must be prepared in advance: clean, close the cracks and prime.

Waterproofing of the roof and roof space

Any roof, regardless of its type (flat going pitched), must be insulated from penetrating moisture into the under-roof space. Roof waterproofing must be complete, environmentally friendly and durable.

The choice of material depends on the shape of the roof and the nature of the operation of the attic space (residential or non-residential), as well as on financial capabilities.

More durable, technological and durable modern materials are polyethylene and polypropylene films and membranes. But they are very expensive.

The most cost-effective option for waterproofing flat and pitched roofs is the fusion of roll materials based on modified bitumen.

The most demanded materials from this category are hydroisol, hydrostekloizol, stekloizol, rubitex, stekloelast, profikrom and masterkrom.

Before fusing waterproofing, the surface of a flat roof must first be primed with a bituminous primer.

It is possible to glue the canvases of rolls together and fix them on the surface of the floor, as well as in the corners of the joints of structural elements, using bitumen mastic.

How to order basement waterproofing from groundwater on poliol.ru

More than 550 teams of performers are registered on the site poliol.ru, ready to help you. To use the service, leave a request on the website for free. A waterproofing consultant will contact you by phone or chat on the website. He will advise on the materials and help you choose the performers.

You can also describe the task and post it on the site.All contractors in your region will receive notifications and send preliminary quotations - you choose the one that suits you. Our service is completely free.