Structural differences and appearance

Cast iron

Let's start with cast iron radiators, which today have changed their design, but, as before, have wide water channels and are made up of several cast sections. Heat-resistant gaskets made of rubber or paronite, which are placed between the sections, provide the required tightness. The length of the finished radiator is determined by the number of sections, the height varies from 0.35 to 1.5 meters, and the depth can be 0.5 meters or several centimeters. In accordance with the volume of the room, you can select the desired size of the radiator, while there is a possibility of its modification (for example, remove an extra section or add several new ones).

Varieties of cast iron heating radiators.

It is worth mentioning the models of radiators, artistically cast from cast iron. They will not only perfectly heat the room, but are also able to give it charm and charm. Such radiators with molding patterns skillfully executed on their surface are produced mainly by foreign manufacturers. Like any piece of art, such devices cost a lot of money.

Several types of artistic cast iron heating radiators.

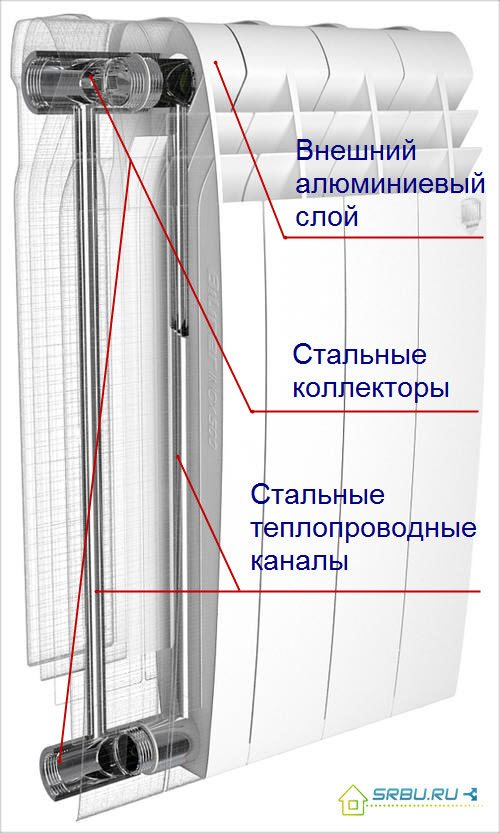

Bimetal

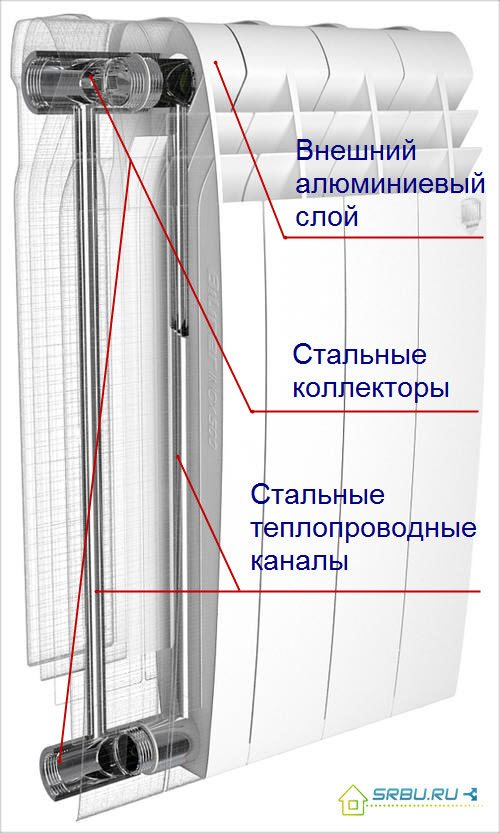

The case of bimetallic radiators is aluminum, its shape is ribbed-shaped. This is how it is designed for better heat dissipation. A strong steel core is hidden under the body - this refers to "real" bimetallic radiators. However, there are also semi-bimetallic (or pseudo-bimetallic) radiators - their difference is that only the vertical radiator channels are reinforced with steel.

The rest of it is made of aluminum. Such a device costs 20 percent less than a completely bimetallic one, and gives more heat. But it is less reliable and durable, and it is highly undesirable to use it in a centralized network.

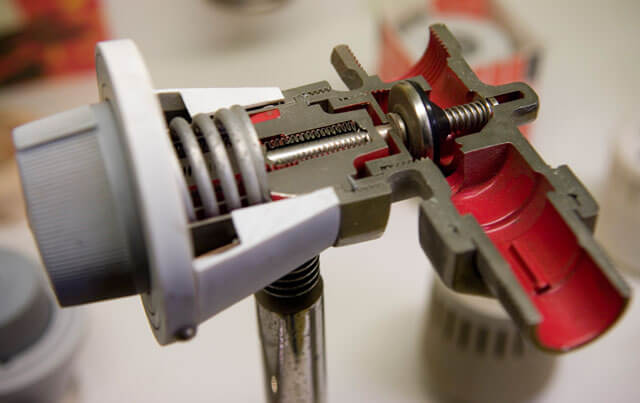

The device of a bimetallic heating radiator.

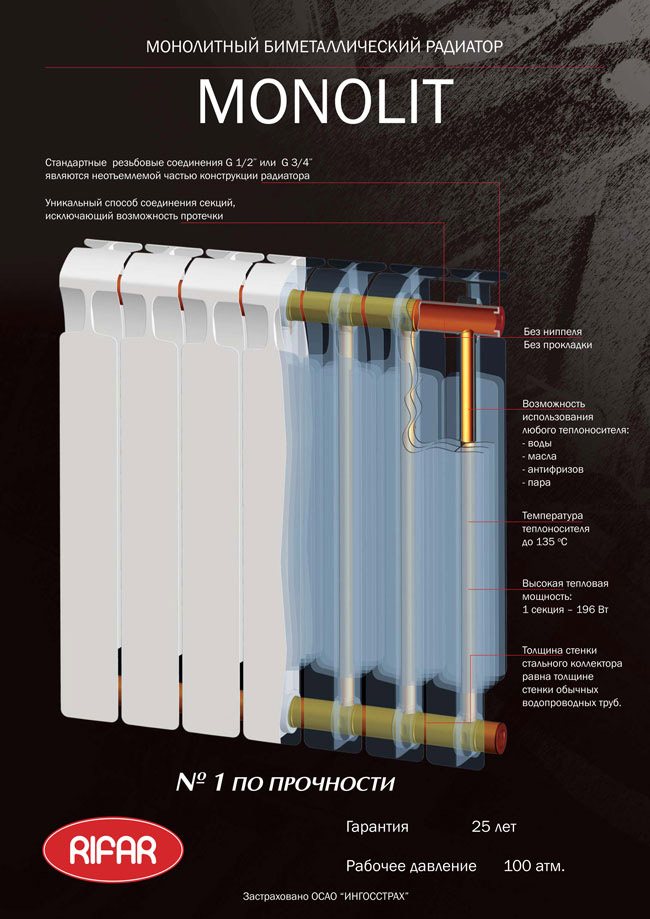

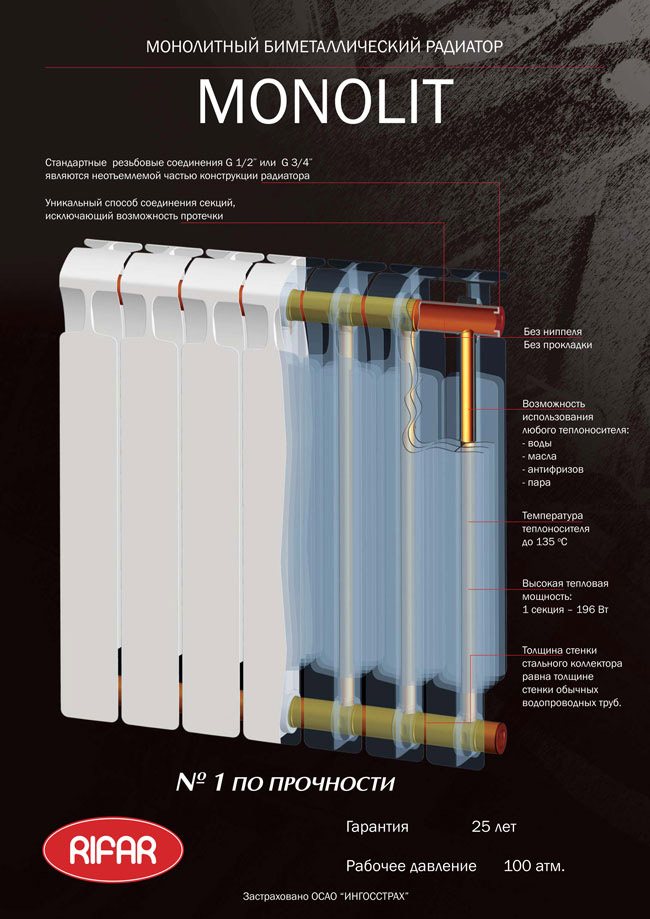

Like cast iron radiators, their bimetallic counterparts are usually sectional, which allows them to be modified. Models are usually sold with an even number of sections. A small segment of the market is occupied by monolithic models, which cannot be disassembled, assembled and improved. The design of all bimetal radiators is very attractive.

Appearance: Cast iron + — | Bimetallic +

Cast iron batteries: pros and cons

For many consumers, parting with old cast iron radiators is alarming. Although they are tired and often make noise, they have warmed apartments for decades without requiring special care. Today, the parameters of cast-iron heating radiators are such that they are qualitatively different from their Soviet "counterparts", still not claiming the attention of the owners.

- If the old "accordions" weighed more than 7 kg per section, then modern cast-iron batteries - 4 kg, which greatly lightens the load on the wall and clamps.

- The volume of the Soviet counterparts was 1.5 liters, while the new models - 0.8 liters, which is almost two times less.

- Their price is still the lowest on the market. Although aluminum is also considered an inexpensive metal, a comparison of cast iron and aluminum radiators will show that the former are more cost effective.

- Modern cast iron batteries consist of sections that have become much easier to mount, add or remove.

- Their thermal power is still capable of effectively heating apartments, therefore, when it is necessary to change old Soviet structures, many consumers wonder which radiators are better: cast iron or bimetallic, aluminum or steel? Or replace them with a new cast iron version?

It is unlikely that such questions and doubts would arise if people knew the features of a centralized heating system for apartments and the technical parameters of modern radiators.

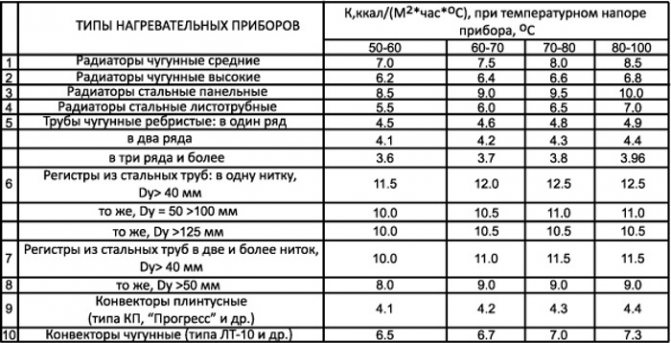

Let's compare the heat dissipation of radiators

Cast iron. Let's start again with traditional cast iron radiators. They are so slow that you can sometimes freeze while waiting for a cold room to warm up. But on the other hand, such radiators take a long time to cool down - and this is a completely different matter. After all, there are often cases when the heating is turned off once. Because of an accident or repair, for example. And near the cast-iron battery you can still warm up for a long time.

A great advantage of cast iron products is that they heat the room not only by convection, but also by radiation. That is, when they are turned on, in addition to air, objects close to the batteries also become warm. As for the thermal power, it is usually given for one section and ranges from 100 to 160 watts. These are average values and may vary from model to model.

Bimetal. The good thing about these radiators is that they just heat up instantly. However, they cool down just as quickly, alas. Heating in them is carried out mainly according to the principle of convection - the radial component is much smaller. This is some disadvantage. The thermal power of sectional models is comparable to cast iron products. This figure ranges from 150 to 180 watts (on average). If we compare the heating rate of the room, then they certainly outperform the cast iron ones.

Heat dissipation: Cast iron + — | Bimetallic +

Advantages, disadvantages of aluminum models

Advantages of aluminum radiators:

- Light weight.

- Easy to install.

- Large thermal power.

- Low temperature inertia in the system.

- Design.

- Large selection of models.

Negative characteristics:

- High cost in comparison with cast iron.

- Low chemical resistance.

- Short service life.

- Resistance to mechanical stress.

- Rapid cooling.

- Demanding on the pressure mode in the heating system of the house.

- Inability to resist corrosion, mechanical wear.

- Installing additional devices to ensure battery operation.

Aluminum radiators have more negative characteristics than positive ones.

Durability of heating devices (comparison table)

Ability to hold pressure

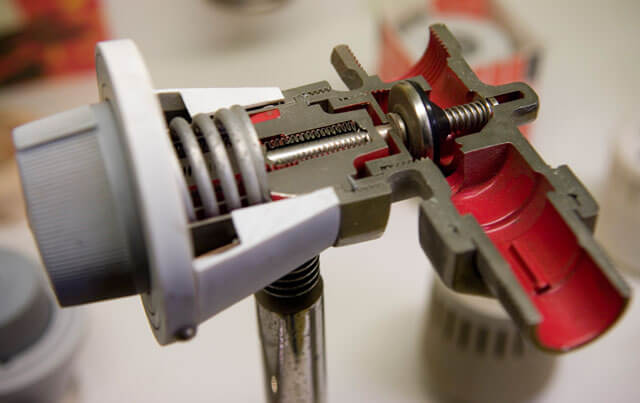

In a traditional central heating system, typical of multi-storey buildings, the pressure is by no means stable. Sometimes even water hammer occurs. After all, the cranes of circulation pumps, according to the rules, should turn on smoothly, but often workers do not follow these rules. And with a sharp shutdown of hot water, its pressure in the entire system jumps so that many batteries burst. Therefore, apartment residents should definitely choose radiators with a good pressure margin.

Cast iron radiators can withstand 9-12 atmospheres of pressure. This may be enough until a strong water hammer occurs. If it does happen, then brittle cast iron, unfortunately, can burst. Therefore, if you look from this point of view, that it is better to cast iron or bimetallic radiators, then it is better, of course, to insure yourself and take bimetal.

After all, a bimetallic radiator is not afraid of any pressure surges - in the passport it has declared indicators for this parameter up to 20-50 atmospheres (depending on the model). So even powerful water shocks are not capable of breaking a quality bimetal product. And we will also mention the models with a monolithic steel core - they can easily withstand up to 100 atmospheres. An example of such radiators can be Russian-made radiators Rifar Monolit, you can see its technical features in the photo below.

Ability to hold pressure: Cast iron — | Bimetallic +

Comparison of aluminum and cast iron radiators

Aluminum heaters were the first to replace cast iron, but in terms of their parameters, they are more suitable for stand-alone systems than centralized ones. It makes no sense to argue which radiators are better, cast iron or aluminum, since they have completely different technical parameters.

- The heat transfer of aluminum is significantly higher than that of cast iron. Heaters from it are warmed up instantly, immediately giving off heat to the room and saving energy resources. Cast iron takes time to "heat up".

- Deciding whether cast-iron or aluminum radiators are better in a city heating network is a waste of time. As a rule, the former do not tolerate strong water hammers, although there are models with a sufficient level of working pressure. But even this does not make them vulnerable in central heating conditions.

- Corrosion susceptibility at elevated Ph level of water does not allow their use in systems where it cannot be controlled... That is why aluminum batteries are installed in private houses with an autonomous type of heating. As a last resort, a filter can be installed in such a system, which cannot be done in a high-rise building. For cast iron batteries, the quality of the coolant does not matter, since this metal is resistant to increased acidity of water.

When it comes to installation, the question of which is better, a cast iron or aluminum battery, does not require an answer. It is enough to try to lift each of the radiators and make sure that the aluminum structures can be installed on their own, while for the cast iron ones, more than one pair of strong hands is required.

Summing up, we can say that in five-story buildings there are the best cast-iron batteries, while for high-rise buildings the only alternative is bimetallic counterparts. As for autonomous heating systems, both steel and aluminum radiators are suitable for them, so that the consumer must himself determine which of them are more suitable for him in price and quality.

Resistance to poor quality of the heating medium

Another disadvantage of central heating is the dubious quality of the coolant. The hot water going from the pipes to the radiators is neither clean nor chemically neutral. And it also contains a considerable amount of the smallest grains of sand and pebbles that can affect the inner walls of the battery, like an abrasive.

Cast iron is chemically absolutely "calm", so a high level of alkalis or acids in hot water will not harm it. And in the summer, when there is a general drainage of water from the system, it will not rust. But she does not like small abrasive stones - they wear out gradually. However, if the radiator walls are rather thick, this is not so critical.

Bimetal is also resistant to chemically active water during the heating season. However, in summer, when water is drained from the system for repair and maintenance work, air appears in the radiators, the steel core can be attacked by corrosion. So the bimetal is a little less durable than cast iron.

Low-quality heat carrier: Cast iron + | Bimetallic + —

Lifetime - Which Batteries Are Better

From the point of view of durability, cast iron heating devices occupy a leading position - with regular maintenance and observing the rules for operating heating, cast iron radiators can work for more than 50 years, and often this period is significantly exceeded.

Bimetallic radiators cannot last so long, but one cannot make any special claims to their durability - standard products are designed for 15-20 years of continuous operation, and monolithic radiators can last up to 25 years. From the point of view of durability, it is impossible to say unequivocally which is better - cast iron or bimetallic heating radiators, since both types have a solid operational life.

The maximum temperature of the coolant and its fluctuations

And the temperature of the coolant in our heating systems does not shine with stability. Now the pipes are barely warm, then hot, like fire. It is important for us how the radiators will behave in the latter case, whether they can withstand too hot water. For this parameter, the indicators are as follows. For a cast iron radiator, the coolant can be heated up to 110 degrees. Hot water flowing through the pipes of the core of a bimetallic radiator can have a temperature of up to 130 degrees. But in general, both types of radiators tolerate temperature changes well. The only thing is that due to the difference in the expansion of steel and aluminum, with a sharp change in temperature, small crackles can be heard at the bimetallic radiator.

Maximum coolant temperature: Cast iron + | Bimetallic +

Device, principle of operation of cast iron radiators

Radiators have a simple design, proven over many decades. Cast from gray iron. Internal gaps are large. The flow of water inside is not hindered, even with significant pollution.

Individual sections of cast-iron heating radiators are connected with fasteners. To prevent leaks, they are sealed with heat-resistant rubber gaskets. A common design is of the MC type. Collapsible, available in different sizes. Rare - solid cast. More often these are designer expensive models.

The internal volume of cast iron heating devices exceeds the volume of aluminum structures. This slows down full heating, prolongs the period of heat release in the event of a shutdown of the centralized heating system. Cast iron is less heat conductive. Advantageous features are chemical inertness, resistance to corrosion, temperature drops in the system.

With the correct connection to the system, the batteries of the brownie, the centralized heating made of cast iron will last a long time, without repair or replacement of parts.

Unlike aluminum, cast iron can withstand the freezing of the coolant. With careful, competent defrosting of the system, there will be no consequences.

Cast iron, aluminum models

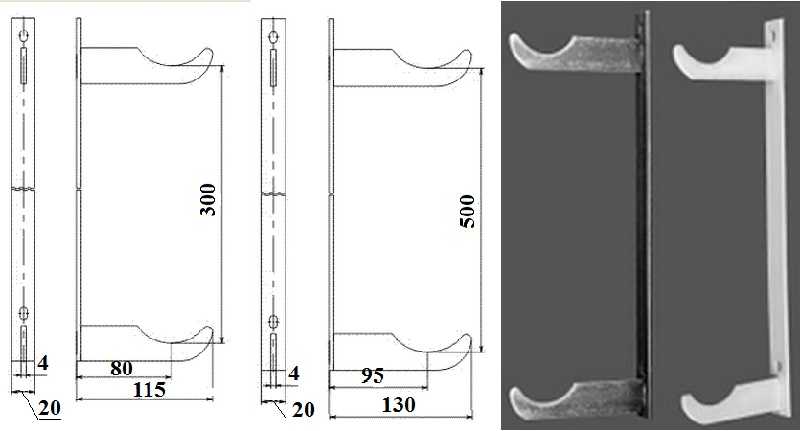

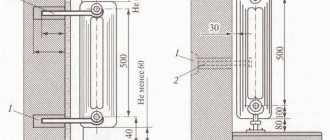

Which radiators are easier to install

There is nothing to argue about - naturally, there will be more problems with cast iron during installation and transportation. And it is beyond the power to lift such a battery alone, and special brackets are needed for it - especially strong, and the plasterboard wall will not withstand it.

And one more thing: when purchasing cheap domestic radiators, one must be prepared for the fact that they will additionally need painting and broaching.

But working with bimetallic radiators is, one might say, a pleasure. They are so light and neat that hanging them (and on any surface) is not difficult. And if in the first place you have ease of installation, then the answer to the question of which is better - bimetallic or cast iron radiators, is unambiguous. Of course, bimetal.

Ease of installation: Cast iron — | Bimetallic +

Installation and equipment cost

If we compare in terms of installing radiators, then there are more problems with cast iron batteries, they are very heavy, so not everyone can lift them alone. Strong fasteners are needed for them, and in addition to the brackets, the wall must also be strong, drywall will not withstand such a load.

Bimetallic products are light in weight and pleasant to work with, they can be attached to any wall surface. In this case, the bimetal wins.

If we take domestic-made cast-iron radiators, then they are inexpensive in terms of cost. Now there are models in retro style, this option will cost much more, since they are made using artistic casting.

Domestic bimetal is more expensive than conventional cast-iron radiators, and the price of Italian batteries is even higher.

Let's talk about the difference in the price of radiators

Pig iron is undoubtedly cheaper, especially domestically produced. So, the cheapest section of the MC model, for example, costs only about 300 rubles. However, only classic models will have such a "tasty" price.But radiators in the "retro" style, made by the method of artistic casting, are several times more expensive. Such models of the Konner brand cost from 2000 rubles (for one section).

Sectional models of bimetallic radiators will be somewhat more expensive than similar cast iron ones. For example, one section of a radiator from the Rifar company (Russia) will cost at least 500 rubles. The price of a section of the same Italian radiator starts from 600-700 rubles.

Price: Cast iron + | Bimetallic —