Cravings as a physical phenomenon

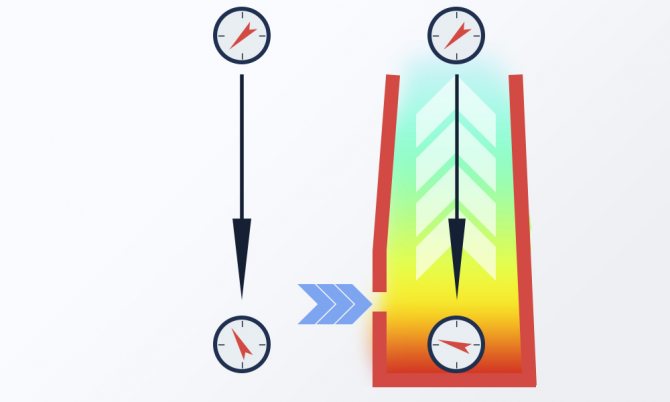

Before considering the design features of the firebox, you need to understand what a vacuum in the firebox is. Vacuum or draft is a decrease in the pressure of combustion products, air, due to which the inflow of the medium through the channels of the structure into the low pressure zone is ensured. It is customary to distinguish between two types of traction: (See also: Do-it-yourself furnace furnace repair)

- natural - carried out under the influence of the Archimedean force. Air enters the furnace or boiler directly to the burner or grate. Hot air is generated during combustion. It is partly cooled by the influx of new air, and partly by contact with the walls of the firebox. Hot air will rise up the pipe. The longer the pipe, the stronger the thrust.

To control the process, you can close the hole through which new air enters. Very often in small home boilers and stoves, the natural draft is so good that it even needs to be reduced. The only drawback is that the higher the ambient temperature, the lower the vacuum. And also with poor regulation of the cold air there will be so much inside that the stove will not warm up;

- forced - with the help of special mechanical devices. Usually, smoke exhausters are used to create it - blade mechanisms, fans. The disadvantage of such a device is that the vacuum decreases with distance from the mechanism, and the advantage is that by controlling the rotation speed, you can change the thrust.

(See also: Briquettes for heating stoves)

The smoke exhauster requires a lot of electricity, makes noise during operation. For small stoves and boilers, it is better to choose options with fans. Usually, along with forced traction, natural traction will be present in any system, but they are not always co-directional.

The choice of material for the chimney

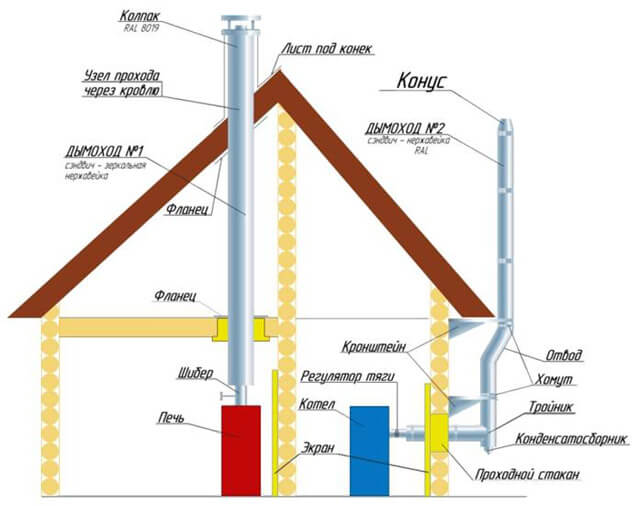

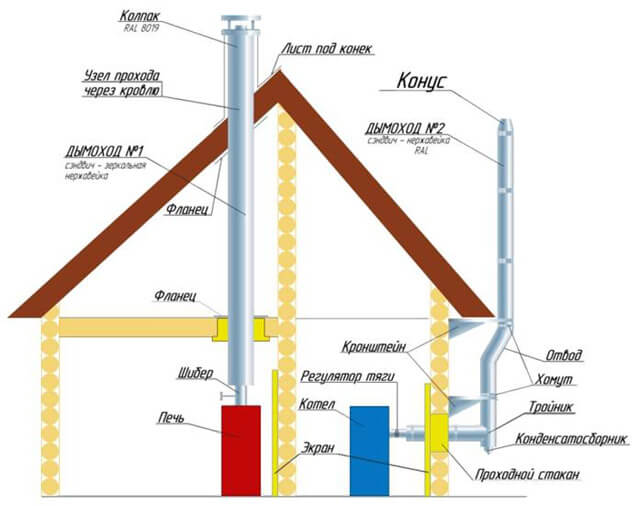

When arranging chimney systems, metal, ceramic and coaxial pipes can be used. It is necessary to decide which pipe is needed for a gas boiler in accordance with the requirements of a specific boiler model. If there is no such information in the documentation, then you will have to study the characteristics of each of the materials presented.

The most popular material for making chimneys is metal. Most often stainless steel is used, but there are also options from galvanized steel. In any case, the operating temperature in the chimney of a gas boiler when using metal pipes can reach 800 degrees, which is quite enough for arranging a combustion product removal system.

The construction of metal chimneys includes an inner layer made of stainless steel, a thermal insulation layer of basalt wool and a thin metal casing. Such devices are quite reliable, have high durability and have acceptable visual qualities.

The next option is ceramic chimneys, designed for operation at temperatures up to 1200 degrees. Such devices have a three-layer structure, which includes a ceramic layer, thermal insulation and an outer shell of expanded clay concrete. The main advantages of ceramic chimneys include simplicity of design and installation, reliability and high fire safety.

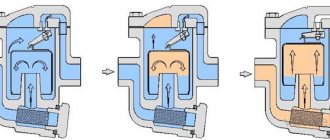

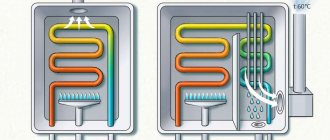

The last type of chimneys is coaxial, which looks good and has very good performance characteristics. Thanks to the two-layer construction, coaxial chimneys are reliably protected from condensation.In combination with gas boilers, this quality manifests itself especially clearly, therefore, the choice of a coaxial chimney in this case will be most justified.

There are also brick chimneys, but they were originally designed for use with solid fuel heating equipment. In order for it to be possible to connect a gas boiler to a brick chimney, the latter must be re-equipped by inserting a metal part into it and performing thermal insulation work.

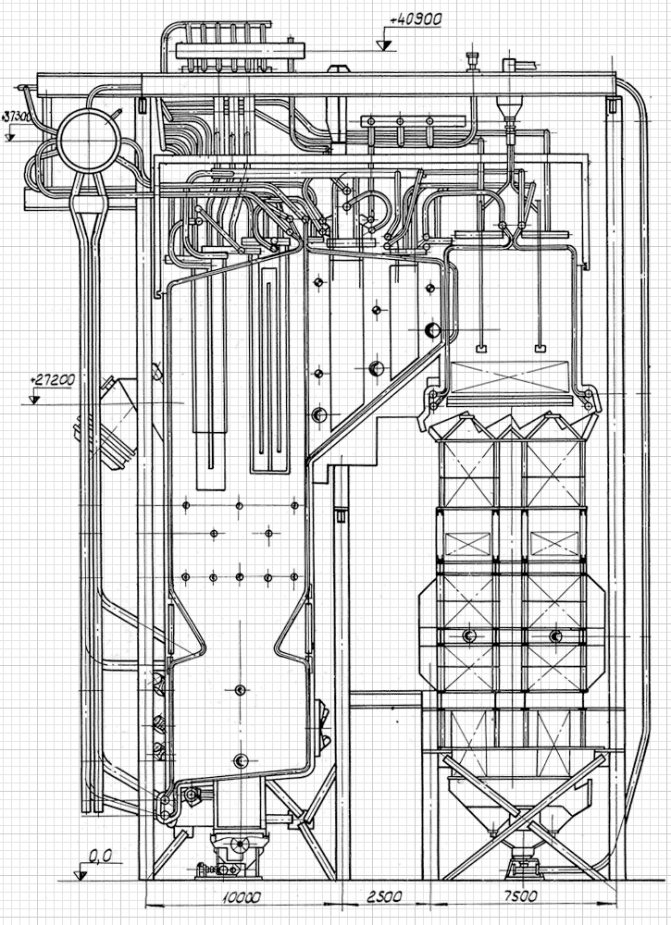

Furnace dimensions for excellent combustion

When laying out the stove yourself, you need to know how to properly arrange the firebox. Also, this knowledge may be required when choosing a firebox. The firebox is a rectangular chamber inside which fuel is burned. There are always very high temperatures, and therefore special materials must be used. The standard dimensions are 25x38 cm. The height is about 80 cm. Most often, the chamber is used for burning firewood, peat, coal.

The design is such that the discharge in the boiler furnace is uniform. The firebox has an obligatory part - a grate, as well as a blower. The grate is located slightly below the fuel filler door. Firewood, peat, combustible materials will lie on it. Holes are made in it to allow air flow. The blower is a hole in the furnace below the firebox, which is needed to improve traction. The lower part of the firebox under the grate is an ash pan where waste will be collected. (See also: How to increase chimney draft)

There are three subtleties that determine the size of the furnace firebox:

- Creation of maximum temperature. The higher the temperature in the firebox, the more efficient the combustion will be. Temperature varies greatly with size. A wide firebox is bad in that the combustion products in the form of soot will quickly rise up and settle on the pipe walls, impairing the draft, and it will also not have time to warm up. Efficiency is calculated for both furnaces and boilers. Modern designs allow up to 90% for wood-burning stoves. To reproduce such conditions, you need to make the firebox about 25 cm wide, and the length that is necessary for the log. Typically, the depth ranges from 50 to 63 cm.

- Use of refractory bricks for the inside of the firebox. It is easy to create a structure of any size from this material, and the material also withstands high temperatures well.

- Firebox height. It should be as high as the flame is possible. Usually the fire from the wood is higher than the coal. If the stove is used as a stove, then the height of the firebox does not exceed 40 cm, and for heating the room it is better to choose 70 cm.

SNiP requirements for chimney installation

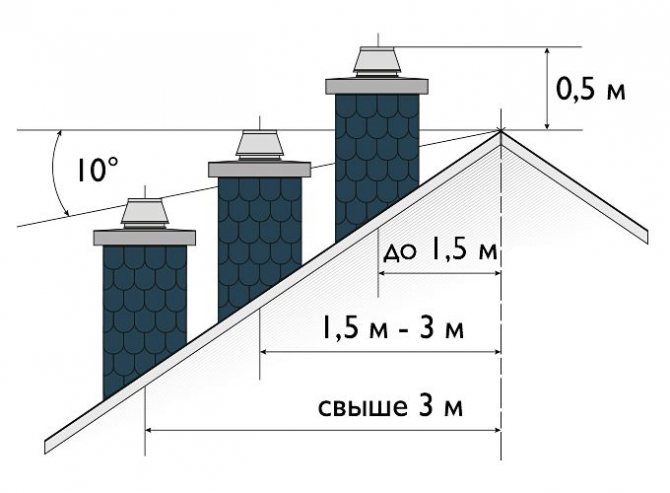

Any chimney, regardless of design features and material of manufacture, must be installed taking into account the requirements described in SNiP 2.04.05-91. The norms specified in this document are primarily aimed at creating a secure system. In addition, compliance with these standards will make it possible to put the boiler into operation and not have problems with the local gas service.

The chimney arrangement of a gas boiler in a private house must be carried out in accordance with a number of requirements:

- The chimney for gas heating equipment must necessarily provide good draft.

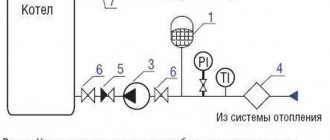

- The system must be equipped in such a way that there is a condensate collector in it. This design allows you to prevent the destruction of the chimney, which occurs due to the accumulation of aggressive condensate on its walls.

- The chimney cap must not be equipped with fungi, deflectors and similar devices that prevent the normal removal of gas combustion products.

- When installing the chimney, it is imperative to pay attention to the quality of the fastening of individual elements. The entire structure must be assembled securely enough to withstand the operating conditions.

- The chimney of a gas boiler for heating a private house in each of its sections must be sealed.Of course, we are talking about the points where the individual elements of the chimney are connected.

All chimney norms for a gas boiler are aimed at creating a high-quality system that can do its job.

Discharge measurement

In boiler rooms, emergency situations are extremely undesirable, since a lot depends on them, there may be casualties among the service personnel. But even in a small house, a stove or boiler must work properly. Many sensors constantly monitor the operation of the device. There is a vacuum sensor in the firebox. There are several different designs of the sensor, the main thing is that it works properly.

The sensor can measure resolution, or respond when a certain value is exceeded. At enterprises, the signal is transmitted from the sensor to the notification device: light, sound, electromagnetic. And employees or automatics take measures to stabilize the situation. For example, the flow of air or fuel can be reduced. The measures taken depend on the design of the particular boiler or furnace.

First furnace firing and draft check

After the stove has been folded, two things need to be done: let it dry and determine the quality of the draft. It takes a week for the oven to dry. For this period, all doors are left open, the furnace was blown. You can burn small amounts of paper and wood chips. If you do not allow it to dry properly, it is possible that the material will crack in the future.

To find out how much heat the stove will give, a draft check is carried out. It depends on:

- smoothness of the inner walls, including the walls of the furnace and chimney;

- pipe height - at least 5 meters. Usually they use the recommendation that the higher it is, the better.

Test furnaces are carried out slowly. First, they always burn paper and wood chips, and then they set firewood on fire. Smoke may occur in the room. This indicates not very good traction. Sometimes the problem is solved by burning paper or wood chips in the chimney. A crimson flame indicates incomplete fuel combustion. A lot of soot will form, which will settle in the chimney and narrow the opening.

If the fire is straw-yellow in color and the smoke is colorless, then the stove is folded correctly. You can check traction using a special device. If it is not available, you can use plain paper. A sheet or strip of paper is carefully brought to the open door of the firebox. If it deviates to the firebox with a stream of air and is drawn inward, then there are no problems. A well-folded stove can be decorated with a mantel clock. It will not only heat the room, but also be aesthetically pleasing.

Chimney installation rules for a gas boiler

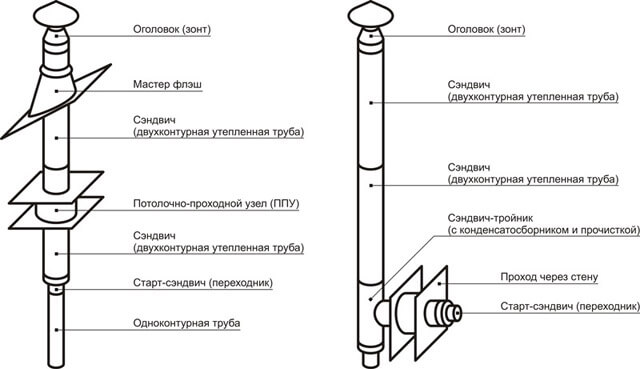

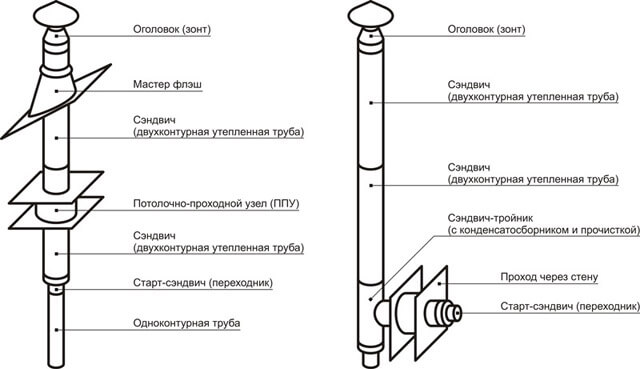

When installing chimneys for a gas boiler in a private house, you must follow a number of rules:

- Chimney elements must be installed from bottom to top;

- Structural elements can be fastened exclusively in a vertical manner;

- The pipe for the gas boiler should not be higher than 5 m;

- Bends and sagging of pipes in straight sections are not allowed;

- All pipe connection points must be sealed with a sealant;

- There should be no more than three horizontal sections in the chimney over 1 m long;

- The head can be positioned only over the zone of passage of air masses.

The chimney must be securely attached to the wall located near it. Straight pipe sections should be fixed at a distance of no more than 1.5 m, while all connections of the chimney elements themselves must be securely fastened to each other. In order for the assembled structure to be as reliable and durable as possible, its elements must be additionally reinforced with metal clamps.

From META group

As many as four options for fireplace inserts are produced by META:

- ARDENFIRE - META cast iron furnaces made in France. This model has heat-resistant glasses for monitoring the process.They have good heat dissipation and are durable. All connectors are additionally sealed with a special cord.

- EUROKAMIN - all models are assembled from parts made in Europe. They are also equipped with special glasses. The stove is distinguished by good heat transfer, resistance to high temperatures.

- METAFIRE - fireplace inserts designed for fireplaces. The base is made of steel, the chamber is additionally laid out with refractory plates. The fireboxes in these models can be adjusted in height, glass is also built-in. The price and quality of these models are well balanced.

- Caminetti is one of the new products. The cast iron firebox is lined with high quality steel from the inside. Has heat-resistant glass. It is characterized by rapid heating of the room, has a small size, and is aesthetically beautiful.

From Keddy

Swedish engineers are renowned for their ability to work with cast iron. Keddi fireboxes are distinguished by the quality of the cast iron used in the first place. The technologies for its production and processing are classified. For a very long time they have mastered the subtleties of working with this material. For this reason, each of their products is distinguished by:

- high efficiency. Heating the room starts at the moment when the fire is just kindled. In addition to cast iron, the construction uses Olivi stone, which accumulates heat and gives it away for a long time;

- reduced fuel consumption. The temperature will be maintained in the room for a long time without the need to frequently add fuel:

- durability. Any product will withstand more than one year of work, a guarantee of up to 10 years.