The gas column ignition unit in working order prevents emergencies, ensures that the main burner is triggered when the hot water tap is opened and the flame dies out after it is closed. There are several types of columns, classified by the type of ignition, differing in the internal structure and principle of operation.

Geysers with piezo ignition

The main difference between piezoelectric ignition and flow-through boilers with manual ignition is that the pilot burner is ignited by means of a piezoelectric element built into the structure. Despite the popularity of automatic dispensers, domestic and foreign manufacturers still produce gas flowing water heaters with piezo ignition and a constantly operating ignition burner.

The principle of operation is in many ways similar to that used in columns, where the burner is ignited from matches. There are common structural elements, the same breakdowns are encountered.

Piezo ignition device

The design contains a permanently working ignition wick. To turn on the column, you must light the igniter. For ignition, a piezoelectric element is present in the structure, consisting of a power button connected to a spark electrode connected to the burner device. When the button is pressed, a spark is produced, hitting the burner, igniting the gas.

The principle of operation of a piezoelectric element is associated with the conversion of mechanical and kinetic energy into electrical energy. When pressed, a spark is generated strong enough to ignite the burner. Piezo ignition for a gas column often fails. After 3-4 years, you will need to change the unit and adjust it.

How to replace the piezoelectric element

Symptoms of malfunction: weak spark, ignition after a large number of keystrokes on the element (normally it works with 1-2 clicks).

First, you should try to repair the piezo ignition. It happens that a malfunction is caused by breakdowns in the current-carrying cable. Disconnect the speaker case to see the cause of the problem. After that, they press the piezo ignition button several times and follow where the spark is directed.

There is a gas spring in the feed pipe of the ignition burner. An additional function is to receive a spark from a piezo. The spring should be bent towards the electrode.

If the changes did not help, there is no spark, when changing the location of the electrodes, the situation does not change, the piezoelectric element of the gas column should be replaced. The key can be easily removed. Depending on the model, the housing holds a lock nut or several bolts. The wire from the electrode is folded back by removing the terminal. Works with certain skills take 10-15 minutes of time.

Choosing a gas water heater from reliable suppliers

Whatever the column, models of a number of manufacturers are credible. Their products have proven themselves with time, high-quality warranty service, reliability, and ease of selection of replacement parts. Consumers and experts have ranked the best brands in the gas water heater market. The list includes 8 companies:

Gas water heater Electrolux

- Gas water heater Electrolux... The firm is Swedish. The brand's models attract with rare additional features and exquisite design. Such water heaters are able to complement the interior without needing to be covered with a false box.

- Bosch. Gas water heaters German brands are distinguished by a number of technologies patented by the company. This makes the products unique. Even if they figured out the notions of Bosch engineers, third-party manufacturers cannot take advantage of them.By the way, the German company has the best set of low-power water heaters.

- Gorenje. The Slovenian company produces excellent speakers of the economy segment. The devices are simplified externally and technically, but reliable and accurate.

- Hyundai. A full-fledged conglomerate on the market produces not only cars. The company presents a wide range of speakers. Attention is drawn to the high-power ones. The product line includes units capable of providing hot water to several kitchens and bathrooms at the same time.

- Thermex. The brand is highly specialized, it produces only water heaters and accessories for them. The company's devices are breaking records for durability, fulfilling a 15-year warranty. You have to overpay for such reliability, but an acceptable amount.

- Ariston. Although the brand is merged with Hotpoint, geysers continue to be produced under a separate logo. The Italian concern Indesit continued to produce water heaters. Therefore, gas water heater "Ariston" remained the same: exquisite externally and internally functional.

- Neva. The only Russian company whose water heaters were included in the list of the best. Gas water heater "Neva" associated with affordability, design simplicity and reliability. However, the pluses are accompanied by minuses such as poorly machined parts made of aluminum alloys and low fineness of materials used in production. The column can last for a long time, but with several approaches for repairs.

Column gas with electric ignition Neva

Heat workers also make repair approaches. Every year consumers are left without hot water several times according to the plan. Unscheduled outages due to failures on the networks are also possible.

The water heater helps out, allowing you to enjoy the comfort even when only cold water is supplied to the house. The device is worth the money, especially the high quality one. We choose wisely, we use it with pleasure.

Electric ignition for gas water heater

Present in fully automatic boilers. The principle of operation of a continuous gas water heater with electric ignition eliminates the need for a constantly burning wick. The main burner ignites immediately. The source of electricity is a 220 W household network, batteries or a built-in hydrogenerator.

Automatic electronic ignition of the geyser occurs when the hot water supply tap is opened. After closing the DHW point, the burner goes out on its own.

Battery ignition

The device of the electronic unit for the ignition of gas water heaters is used in fully automatic water heaters. In the factory configuration, batteries are used as batteries.

Electronic ignition of a gas water heater works as follows:

- the rod in the water reducer has special legs connected to the electric ignition;

- when DHW is turned on, the membrane presses on the stem, opens the gas valve and at the same time gives a signal to generate a spark;

- after ignition of the flame, the battery-powered spark generation unit is switched off.

Battery power has one major drawback. Replacement of elements is required every six months. If desired, you can install an adapter and connect the speaker to a household power supply through it. This solution will eliminate the need for constant and frequent battery replacement.

Ignition from a hydrogenerator

In the columns of the new generation, the batteries have been replaced with a turbine. Geysers with a hydrogenerator are switched on due to the production of electric current through the conversion of mechanical energy.

The water heater works in a completely autonomous mode, but has several disadvantages:

- sensitivity to pressure and water quality;

- dependence of uninterrupted operation on regular maintenance.

A spark from a hydrodynamic generator is produced only when the water pressure is sufficiently high. At a pressure of 0.3-0.5 atm.the automatic column from the batteries turns on normally, and the water heater with a turbine simply does not start. To ensure the stable operation of the device with hydrodynamic ignition, it is necessary to use a booster pump and a water treatment system that includes several degrees of purification.

Should I take Bosch gas stoves

Let's go back to Bosch HGG 245255. The technical characteristics of the gas stoves are excellent. The equipment is adapted to Russian life realities. The manual clearly warns that the electric ignition does not work when the mains voltage drops below 185 V. Pleasant concern of the manufacturer for customers. The instructions clearly show how to use the grill cover. Heat-reflecting material protects the front panel, keeps the oven lid half-open. Curiously, factories are not always able to explain the principle of operation of a gas stove of their own production, although violation of operating conditions leads to negative effects.

Undoubtedly, Bosch is excellent equipment, but the correct choice of a gas stove depends on the place of manufacture of a particular instance taken. Not all conveyors produce equipment of the same excellent quality. True, Bosch strictly enforces the German quality. Since it is considered that the European assembly is better than others, in advance, inquire about where your device was produced.

Keep in mind that this model gives you the essentials, no frills. If the clock seems pointless, remember, it beeps until it is turned off. The sound signal of other timers switches off automatically after a certain period of time.

We hope the review has shown which gas stoves are better, and you can now compare specific models with a sample.

What is a column flame ionization sensor

- ionization electrode;

- photosensor.

The principle of operation is based on the fact that in the process of combustion in gas columns, flame ionization or the production of ion current is created. The amount of energy is directly proportional to the intensity of combustion. Incorrect ratio of the gas-air mixture, settling of dust, damping of the main burner will trigger the sensor. By blocking the gas supply, gas leakage is prevented if the burner spontaneously extinguishes.

How to properly light the column

The ignition is carried out as follows:

- the gas supply button is clamped;

- after 10-15 seconds, the piezoelement key is pressed or a burning match is brought up (depending on the type of ignition);

- the wick ignites;

- after another 20 seconds, the gas supply button is released.

The gas water heater with electric ignition turns on independently when you open the hot water tap. Switching on should be silent. Pops, long operation of the spark generator unit indicates a malfunction.

The gas column ignition unit in working order prevents emergencies, ensures that the main burner is triggered when the hot water tap is opened and the flame dies out after it is closed. There are several types of columns, classified by the type of ignition, differing in the internal structure and principle of operation.

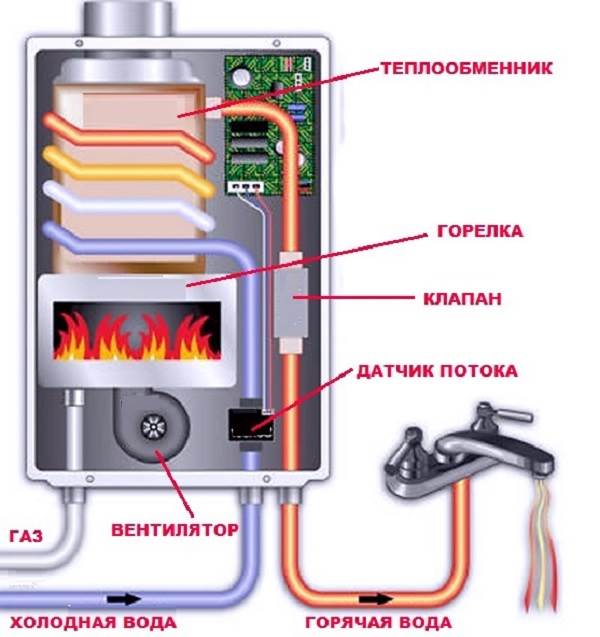

How the column works

To understand how any geyser generally works, you can follow what happens to the water that flows through the inlet pipe into the apparatus. Column heating steps:

- The user turns on the wick in the viewing window, presses the piezo ignition button, or simply opens the hot water tap.

- From the central system, H2O flows through a pipe to the heat exchanger (if the column is semi-automatic or automatic, that is, not with manual ignition.

- The burner ignites, as water appears at the inlet pipe, increasing the pressure in a narrow place and the so-called frog or water unit is triggered (in columns with manual ignition, these actions are performed by the user).

- The gas injected through the gas valve generates a large amount of heat during combustion.It, in turn, heats up a metal (namely copper) heat exchanger from below, inside which water passes through pipes folded in the shape of a snake and called a coil. While she is walking over it, she manages to get very hot.

- Combustion products fly out through a special hood located on top of the column, connected to a separate pipeline.

- The heated H2O continues on its way out through another pipe leading to the tap in the bathroom, toilet or kitchen.

Despite the fact that the design of a gas column can be quite complex, the principle of its operation is simple: water, passing through pipes heated due to gas combustion, becomes hot.

Electric ignition for gas water heater

Present in fully automatic boilers. The principle of operation of a continuous gas water heater with electric ignition eliminates the need for a constantly burning wick. The main burner ignites immediately. The source of electricity is a 220 W household network, batteries or a built-in hydrogenerator.

Automatic electronic ignition of the geyser occurs when the hot water supply tap is opened. After closing the DHW point, the burner goes out on its own.

Battery ignition

The device of the electronic unit for the ignition of gas water heaters is used in fully automatic water heaters. In the factory configuration, batteries are used as batteries.

Electronic ignition of a gas water heater works as follows:

- the rod in the water reducer has special legs connected to the electric ignition;

- when DHW is turned on, the membrane presses on the stem, opens the gas valve and at the same time gives a signal to generate a spark;

- after ignition of the flame, the battery-powered spark generation unit is switched off.

Battery power has one major drawback. Replacement of elements is required every six months. If desired, you can install an adapter and connect the speaker to a household power supply through it. This solution will eliminate the need for constant and frequent battery replacement.

Ignition from a hydrogenerator

In the columns of the new generation, the batteries have been replaced with a turbine. Geysers with a hydrogenerator are switched on due to the production of electric current through the conversion of mechanical energy.

The water heater works in a completely autonomous mode, but has several disadvantages:

- sensitivity to pressure and water quality;

- dependence of uninterrupted operation on regular maintenance.

A spark from a hydrodynamic generator is produced only when the water pressure is sufficiently high. At a pressure of 0.3-0.5 atm. the automatic column from the batteries turns on normally, and the water heater with a turbine simply does not start. To ensure the stable operation of the device with hydrodynamic ignition, it is necessary to use a booster pump and a water treatment system that includes several degrees of purification.

What is a column flame ionization sensor

- ionization electrode;

- photosensor.

The principle of operation is based on the fact that in the process of combustion in gas columns, flame ionization or the production of ion current is created. The amount of energy is directly proportional to the intensity of combustion. Incorrect ratio of the gas-air mixture, settling of dust, damping of the main burner will trigger the sensor. By blocking the gas supply, gas leakage is prevented if the burner spontaneously extinguishes.

How to properly light the column

The ignition is carried out as follows:

- the gas supply button is clamped;

- after 10-15 seconds, the piezoelement key is pressed or a burning match is brought up (depending on the type of ignition);

- the wick ignites;

- after another 20 seconds, the gas supply button is released.

The gas water heater with electric ignition turns on independently when you open the hot water tap. Switching on should be silent.Pops, long operation of the spark generator unit indicates a malfunction.

If there is no hot water supply in your house, or if you constantly turn off hot water, then life becomes completely uncomfortable. But that's not a reason to give up a warm shower on a cool autumn evening, right? This problem can be solved by installing a gas column, as many users do. But how does such a miniature water heater work and can it cope with its task?

We will talk about all this in detail in our publication - here we consider the principle of operation of the gas column, the diagrams of its device. It also focuses on the main equipment malfunctions and ways to cope with them. The presented material is supplemented with visual illustrations, diagrams and videos.

Choosing a gas water heater according to technical parameters

The main technical indicator of a gas water heater is power. It indicates the volume of water heated per minute. High power is justified in the presence of several points of connection of the water heater and at least several consumers.

The principle of operation of the gas column

If one person lives in the house, it is more logical to purchase a low-power speaker. However, with plans to let someone else into your house, you can look ahead in the acquisition of a water heater. In terms of power, it can be:

- Low-power with the output of 18-19 kilowatts.

- Medium-power with an indicator of 22-24 kilowatts

- High-power with an indicator from 28 to 31 kilowatts.

A low water pressure in the system can get in the way of the need for a powerful apparatus. How to heat the maximum volume of liquid in a minute if it does not flow? An additional pump can be installed. However, this will further reduce the pressure in neighboring apartments.

Gas water heater Oasis with electric ignition

Problems with water pressure, by the way, are typical for buildings connected to worn-out Soviet-style networks with small throughput pipes or for apartments on high floors. In order for the water to reach them, several times more pressure is needed than to provide the first floors.

The general structure of the household column

The geyser is a flow-through water heater. This means that the water passes through it and heats up along the way. But, before proceeding to the analysis of how a household gas water heater is arranged for heating water, we recall that its installation and replacement are associated with a centralized gas supply system.

Therefore, it is imperative to submit documents to the gas service of your region along with the corresponding application. You can read about the norms and necessary documents in our other articles, and now let's move on to the device.

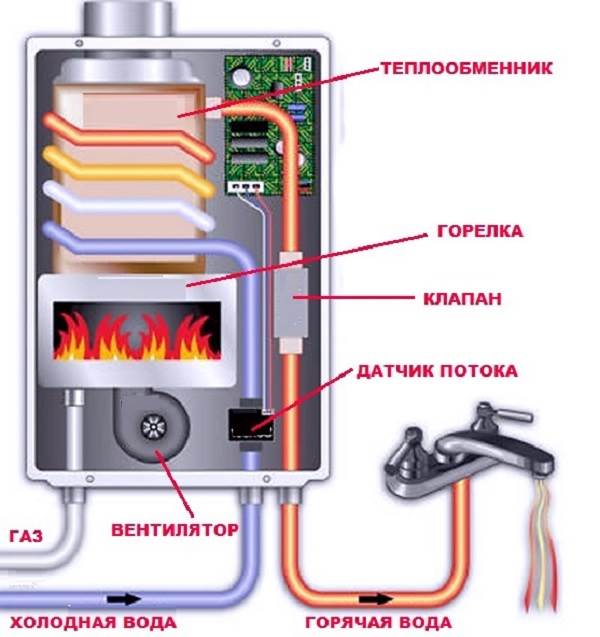

Various models of gas water heaters differ among themselves, but the general structure of a household gas water heater looks like this:

- Gas-burner.

- Igniter / ignition system.

- Exhaust hood and chimney connection.

- Chimney pipe.

- The combustion chamber.

- Fan (on some models).

- Heat exchanger.

- Gas supply pipe.

- Water node.

- Water inlet nozzles.

- Hot water outlet.

- Front panel with controller.

The central element of the column is gas-burner, in which the combustion of gas is maintained, which contributes to the heating of the water. The burner is installed in the body, it collects hot combustion products, the purpose of which is to heat water.

Column with a closed combustion chamber

In addition to the open system used in most home gas water heaters, there is also a closed system. It is also called turbocharged. It differs from atmospheric (open), but not significantly.

What is the difference between a closed gas water heater system from an open one:

- A conventional burner in non-atmospheric columns is replaced by a fully automatic one, which itself regulates the gas supply so that the flame is always not too small and not too large.

- The air, so necessary for the combustion process, is supplied in a turbocharged column by a special fan. This element is absent in ordinary open columns, since such a necessary element as O2 freely enters from the outside by itself.

- The ignition system in the turbocharged column, as well as the gas supply, is fully automated. An electric current or a hydrogenerator is used.

- In a closed system, there is one element that is missing in an open system - it is the water temperature sensor. It controls the degree of heating: if the temperature is more than sixty degrees, the sensor is triggered.

How does a gas water heater work?

Let's get acquainted with the principle of operation of a gas column in the form of a simple algorithm:

- when water flows through the water assembly, the membrane strains and moves up the stem connected to the gas valve;

- then the valve opens the gas supply to the main burner;

- the gas is ignited from an electrode or igniter, burns out and heats up the water that flows through the pipes of the heat exchanger;

- the heated water flow is supplied to the tap through the left branch pipe;

- gas combustion products are removed through the chimney or exhaust hood - there is a fundamental difference between open and closed columns, which will be described in detail below.

At the same time, the power of the flame and the power of water flow through the column can be adjusted using the controls on the front panel.

And now let's take a closer look at how the burner is ignited and how the already mentioned water unit is connected with this.

Gas ignition method

In general, gas water heaters are based on three methods of gas ignition. As can be seen in the diagram, in all three cases the reaction of the water unit (frog) serves as a signal to ignite the main burner.

There are three ignition methods:

- using a piezoelectric element;

- from batteries;

- from the rotation of the hydraulic turbine.

Ignition with piezoelectric element - this is a manual ignition, and assumes the presence of a button on the front panel. Pressing the button causes the piezoelectric element to close, which ignites the igniter. He, in turn, ignites the main burner after a signal from the rod, which is moved by the water membrane with an active water pressure.

The igniter continues to burn with a small flame until it is manually turned off. This leads to increased gas consumption and increased scale formation in the pipes. One of the gas instantaneous water heaters with manual ignition is Bosch Therm 4000 O W 10-2 P.

Geysers of some models work on batteries... In this case, ignition occurs from an electric spark after the signal from the rod. Thus, instead of an igniter, electrodes are present here, which directly ignite the main gas burner.

But the batteries need to be changed on average once every 10 months, and with constant use - once every 2 months, so that there are no unforeseen circumstances. One such battery-powered speaker is the Zanussi GWH 10 Fonte Glass La Spezia.

Sometimes ignition occurs from rotation hydro turbines (with water flow). Ignition also occurs from an electric spark, but the batteries do not need to be changed, because the turbine itself generates electricity during the flow of water.

But for the operation of the hydraulic turbine, a high pressure in the pipes is required, at least 0.3 bar. Not every home has this kind of pressure. In Russia and other CIS countries, it is not advised to buy such columns due to the unstable water pressure. An example of such a model is the Bosch Therm 6000 O WRD 15-2 G gas water heater, which is noticeably more expensive than the above two models.

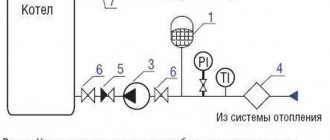

Column water assembly device

The device of the water unit is of particular interest. Its structure can be seen in the diagram below, detail captions are below the diagram. The rest of the designated elements are used for fasteners.

The main working details are stock and diaphragm, under the influence of which it moves when the flow of water begins in the lower part. The stem opens the valve and allows gas to flow into the burner, which is then ignited.

Another work item is pvc ball, which serves as a fuse. It shuts off the gas flow during sudden pressure drops in water pipes - hydraulic shocks, which we will also talk about later.

Combustion chamber type

According to the design of combustion chambers, there are two types of gas columns: open and closed.

Columns with open combustion chamber have open air access to the burner, and the combustion products go into the hood.

Such models are simpler than turbocharged ones, which will be discussed below, their operation is almost silent and in most cases they do not require electricity. However, due to the open connection between the combustion chamber and the room, air pollution in the room is possible if the hood works poorly.

Columns with closed combustion chamber are turbocharged. The combustion chamber in them is hermetically sealed, in addition to the channels for the injection and outlet of air. It is pumped there by a fan through coaxial pipes and goes outside through the chimney, together with the combustion products.

Such columns are usually fully automated, they do not have manual controls, and the thrust and temperature sensors in them are more sensitive. These speakers are “modern” and more secure.

The illustrations above showed a gas column with a closed combustion chamber. For comparison, in the following illustration, you can see the arrangement of two types of speakers side by side. You will find many similar elements with them, but the principle of removing combustion products is noticeably different.

Pros and cons of a smokeless gas water heater

Gas water heaters that operate without a chimney have the following advantages:

- They can be installed in any room. For example, in a new house, where the presence of a chimney for a gas water heater is not provided for by the project. Or in a country house, in a country house, where there is no specially built chimney;

- Such a device does not dry the air inside the room, which is typical of a standard gas water heater;

- The air in the room does not heat up, which is especially noticeable during hot weather;

- The efficiency of the water heater is increased by the forced removal of the exhaust air. Unlike this type of water heater, in a standard gas water heater, combustion products are removed by gravity through a common pipe;

- The combustion chamber of the column is completely insulated, so there are no extraneous odors characteristic of combustion products in the room.

However, this equipment also has certain disadvantages:

- Installing a column of this type is more difficult than a conventional water heater. It is required to drill a hole in the wall, and then carefully close it up, leaving a special nozzle outside;

- For gas turbocharged columns, prices are set higher;

- The presence of a fan requires the device to be connected to the mains. If the electricity in the network goes out, the column cannot be used;

- It is required to coordinate the installation of gas equipment with the relevant authorities, since the fact of the presence of such a column will be impossible to hide;

- The turbocharged column creates an increased noise effect due to the operating fan and high-speed air currents. This is noticeable both within the premises and on the street;

- Your neighbors upstairs, if any, may not like such a device, because they will partially get the smell of exhaust gases, and they will periodically be noisy outside the windows.

External view of the coaxial chimney

Key features of the speakers

Now let's talk about the aspects of the practical use of the column. One of the main characteristics - performance... It directly correlates with the power, which is indicated in kW and shows the volume of water heated at 25 ° C per minute.

The characteristics are usually indicated in the passport of the device.An ordinary column heats 10-20 liters of water at 25 ° C per minute, although this value can fluctuate significantly.

Another characteristic of modern speakers is power modulation... It shows how the column power can change depending on the water flow and is measured as a percentage of the initial power.

For modulation, the columns are equipped with special fittings with a membrane, which changes the gas supply to the burner depending on the flow. Modulation is considered normal in the range of 40-100% of the device's power.

Application

Any piezoelectric element can be used in modern technical devices for various purposes. They are used as quartz resonators, miniature transformers, piezoelectric detonators, high stability frequency generators, and many other places. Each device is designed in such a way that it can use not only crystalline quartz, but also elements from polarized piezoelectric ceramics.

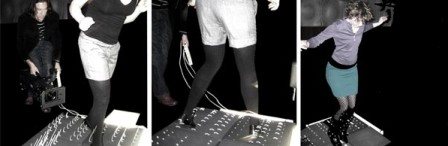

However, the piezo is not limited to lighters. Currently, work is underway to solve the problem of how to make the use of these materials more productive. This principle has been used for a long time on dance floors and car parks, where mechanical energy is converted into electrical energy under pressure.

In the future, it is possible to build more powerful energy production systems. Currently, generators are being developed with small dimensions, based on aluminum nitride, which has successfully replaced the traditional lead zirconate titanate. This device is essentially a wireless temperature sensor capable of accumulating energy from various vibrations and transmitting the received data at set intervals.

Currently, piezoelectric transducers are being installed on jet aircraft. This technical solution makes it possible to save up to 30% of fuel resources, using the oscillations of the wings and the fuselage itself. Experimental traffic lights have been created that work from batteries, which are charged from air fluctuations caused by city noise.

In the future, these developments will make it possible to eliminate the capacity deficit. With the help of piezoelectric elements, it will be possible to receive electricity as a result of the movement of cars along specially equipped routes. Even ten kilometers of such a piezo road will produce about 5 MW / h. Pedestrian sidewalks will also contribute to the generation of electricity. This direction is very interesting and promising, attracting the attention of scientists from many countries.

Piezo generators are new sources of electricity. Fantasy or reality?

A thin piezoelectric film on a window pane that absorbs street noise and converts it into energy to charge your phone. Pedestrians on sidewalks, subway escalators, who charge autonomous lighting batteries through piezo transducers. Dense traffic of cars on busy highways, generating megawatts of electricity, which is enough for entire cities and towns.

Fiction? Unfortunately, so far, yes, and it may remain so. There is a high probability that the excitement around sensational reports about the wonderful prospects of power generators on piezoelectric elements will soon end. And we will again dream of safe, renewable and, to be honest, cheap electrical energy obtained with the involvement of other phenomena. After all, the list of physical effects is remarkably long.

The phenomenon of piezoelectricity was discovered by brothers Jackson and Pierre Curie in 1880 and since then has become widespread in radio engineering and measurement technology. It consists in the fact that the force applied to the sample of the piezoelectric material leads to the appearance of a potential difference on the electrodes. The effect is reversible, i.e. the opposite phenomenon is also observed: applying voltage to the electrodes, the sample is deformed.

Depending on the direction of energy conversion, piezoelectrics are divided into generators (direct conversion) and motors (reverse). The term "piezoelectric generators" does not characterize the conversion efficiency, but only the direction of energy conversion.

It was the first phenomenon associated with the generation of electricity under mechanical stress that engineers and inventors became interested in in recent years. As if from a cornucopia, there were reports of the possibilities of obtaining electrical energy, utilizing street noise, the movement of waves and wind, the loads from the movement of people and machines.

Several examples of the practical use of such energy are known today. At the Marunuchi metro station in Tokyo, piezo generators are installed in the ticketing hall. The accumulation of passengers is enough to control the turnstiles.

In London, in an elite disco, piezo generators power several lamps that stimulate dancers and ... the sale of soft drinks. Piezoelectric lighters have become common. Now any smoker carries his own "power plant" in his pocket.

Relatively recently, the world community was blown up by a message about testing systems for obtaining energy from a moving vehicle. Israeli scientists from the small firm Innowattech have calculated that 1 kilometer of the autobahn can generate up to 5 MW of electrical power. They not only performed the calculations, but also opened several tens of meters of the highway bed and mounted their piezo generators under it. It seemed that a breakthrough had finally come in the field of alternative energy. But this raises serious doubts.

Let us consider in more detail the physics of the processes occurring in a piezoelectric. To get acquainted with the principles of energy generation by piezoelectric materials, it is enough to understand several basic mechanisms. Under mechanical action on the piezoelectric element, atoms are displaced in the asymmetric crystal lattice of the material. This displacement leads to the appearance of an electric field, which induces (induces) charges on the electrodes of the piezoelectric element.

Unlike a conventional capacitor, the plates of which can retain charges for a long time, the induced charges of the piezoelectric element are retained only as long as the mechanical load is applied. It is at this time that energy can be obtained from the element. After removing the load, the induced charges disappear. In fact, a piezoelectric element is a source of current of negligible magnitude, with a very high internal resistance.

Since the specialists of the Innowattech company did not find it necessary to share the results of their experiment with the general public, we will try to make rough numerical estimates of the efficiency of piezoelectrics as an energy source ourselves. As an object for calculations, we take an ordinary household piezo lighter - the only product that is now widely used.

From the abundance of technical characteristics of piezo materials, we need only a few. This is the value of the piezoelectric modulus, which for common (and still the industry does not produce) piezoelectrics is from 200 to 500 picocoulombs (10 to minus 12 degrees) per newton, and characterizes the efficiency of charge generation under the influence of force.

This characteristic does not depend on the size of the piezoelectric element, but is completely determined by the properties of the material. Therefore, it is pointless to try to make more powerful converters by increasing the geometric dimensions. The capacity of the lighter piezoelement plates is known and is about 40 picofarads.

The lever system for transmitting force to the piezoelectric element generates a load of approximately 1000 Newtons. The gap in which the spark slips is 5 mm. The dielectric strength of air is taken to be 1 kV / mm. With such initial data, the lighter generates sparks with a power of 0.9 to 2.2 megawatts!

But don't be intimidated.The discharge duration is only 0.08 nanoseconds, hence such huge power values. Calculating the total energy generated by the lighter gives a value of only 600 microjoules. At the same time, the efficiency of the lighter, taking into account the fact that the mechanical force is completely transferred to the piezoelectric through the lever system, is only ... 0.12%.

The energy extraction schemes proposed in different projects are close to the operating modes of lighters. Separate piezoelectric elements generate high voltage, which breaks through the discharge gap, and the current flows to the rectifier, and then to the storage device, for example, an ionistor. Further energy conversion is standard and of no interest.

Let's move on from lighters to the task of obtaining energy on an industrial scale. Let the most efficient cells be used, generating 10 milliwatts per cell. Collected in clusters (groups) of 100-200 elements, they are placed under the roadbed. Then, to obtain the declared power value of the order of 1 MW per kilometer of the road, only ... 100 million individual elements with individual energy removal schemes will be required. There remains the task of summing it up, transforming it and transmitting it to the consumer. In this case, the currents of the elements, taking into account the changing load on the roadway, will lie in the range of nano or even picoamperes.

Getting acquainted with such projects of obtaining energy from the piezoelectric effect, one involuntarily suggests an analogy with a hydroelectric power station, in which turbines operate from the moisture of the morning dew, carefully collected from the surrounding fields.

But what about the experiment of an Israeli company? The report on the results of the "sabotage" never appeared on the highway. But ahead is the fulfillment of the contract for obtaining energy from the Venice-Trieste highway, which was concluded by the Innowattech company.

On this occasion, there is one version: this, i.e. with a high risk of investment capital. Having received more than modest preliminary results of the researchers, its founders decided to justify the money spent by investors and turned a great marketing ploy - they conducted a spectacular test with the participation of the press. And the whole world started talking about a small company. And in this noise, the main question was lost: where are the megawatts of cheap energy?

Summing up, we can only draw one conclusion: piezoelectric elements will never become alternative sources of electricity on an industrial scale. The range of their applications will be limited to low-power (micro-power) power supplies and sensors. It's a pity, it was such a beautiful idea!

Safety sensors and their meaning

A gas water heater can be dangerous, because it is connected simultaneously with the water and gas mains, each of which, individually, can pose a threat.

In case of problems with the gas or water supply, safety sensors turn off the column, and special valves will shut off the water or gas supply.

Usually, gas water heaters can withstand a voltage of up to 10-12 bar, which is 20-50 times higher than the usual pressure in pipes. Such sudden jumps are possible with the so-called water hammer.

But if the pressure is lower than 0.1-0.2 bar, then the column will not be able to work. You need to carefully study the instructions and characteristics before buying in order to understand whether the column is optimized for low water pressure in the pipes of the CIS countries and whether it will work properly. And vice versa - will it withstand sudden pressure drops, which, alas, is also not uncommon in our conditions.

In general, a modern gas water heater contains many safety sensors. All of them, in case of breakdown, can be replaced.

More details about the purpose and location of the sensors are in the table below.

| Sensor name | Location and purpose of the sensor |

| Chimney draft sensor | Located at the top of the device, connecting the column to the chimney. Turns off the column in the absence of draft in the chimney |

| Gas valve | Located in the gas supply pipe. Turns off the column when the gas pressure drops |

| Ionization sensor | Located in the camera of the device. Turns off the device if the flame goes out when the gas is on. |

| Flame detector | Located in the camera of the device. Shuts off the gas if the flame does not appear after ignition |

| Relief valve | Located on the water inlet. Turns off water at elevated pressure in the pipeline |

| Flow sensor | Will turn off the column if water stops pouring from the tap or if the water supply is turned off |

| temperature sensor | Located on the heat exchanger tubes. Blocks the operation of the burner in case of significant overheating of the water in order to avoid damage and burns (it mainly works at + 85 ° C and above) |

| Low pressure sensor | Will not allow the column to turn on when the water pressure in the pipes is reduced. |

Bosch cookers

Let's note the features of the translation of the Instructions for the operation of gas stoves. The feeling that companies - world brands do not respect the Russian consumer, an indicator - the low quality of operating instructions. The choice of goods is carried out according to documents posted on the Internet. Clear instructions are the face of the firm.

Gas cooker Bosch

The difference between inexpensive gas stoves is minimal, let's discuss expensive models. Modern cooker Bosch HGG 245255 is completely gas, electric ignition, automatic, on all burners and oven. The spark is triggered by pressing the knob in ignition mode, the gas control mechanism is cocked within 10 seconds. retention.

The design is not perfect, but the control panel is not overloaded with buttons. The product card on the Yandex market contains information about the price - only 35,000 rubles. At the current jumped prices, it is acceptable, given the electronic (automatic) ignition of four burners and an oven.

Gas grill. There is an opinion that electric is better, but there is no substantiated evidence. The grill and the oven are switched on with one knob, the operating mode is set mechanically by the position of the gas supply regulator: two ignition positions on opposite sides of the neutral:

- for the oven;

- for the grill horn.

It is difficult to make a mistake with the gas supply. When the oven is fired up, the handle is shifted to the right to an asterisk (spark), then turned in the same direction until the start of the temperature scale. The grill turns on in the same way, but there is one temperature setting, indicated by a stylized grill icon. There is only one gas supply valve, the adjustment candles are switched on in parallel - the first into the lower burner, the second into the grill horn.

The grill and oven are equipped with gas control thermocouples, triggered by solenoid valves, giving out a voltage of 10-50 mV when heated. The risk of using the device is minimized. Burners with separate valves The total power of the four burners is of the order of 10 kW, a separate parameter is not indicated, although the buyer is guided by differentiation, not total costs. The exact parameters of the gas stove Bosch HGG 245255:

- economical burner and quick heating, respectively, 1 and 3 kW;

- two ordinary burners in the second row, 1.75 kW each;

- the remainder is on the cabinet.

This approach allows you to calculate the operating time from a gas cylinder. The Bosch cooker is designed for 3 types of fuel supply. On the back of the Bosch cooker, a plate is reinforced with options, an asterisk marks the set of factory settings. Pure methane is rarely found in the fields, so Bosch thoughtfully designed the cooker to work with a mixture of natural gas (85%) and nitrogen (the rest).

Gas burner

- Gas mixture G20 is an analogue of natural gas, supplied at a pressure not exceeding 20 mbar. If the threshold 25 is exceeded, you have to turn off the equipment, because performance is not guaranteed. We are talking about methane, the G20 standard provides for its 100% content. Delivered to homes through yellow pipes running along the surface of the ground.

- The second type of gas fuel Bosch considers the mixture G30, the equivalent of bottled gas, butane, more precisely, a mixture of n-butane and isobutane in equal proportions.Due to the high pressure, the fuel liquefies with an increase in temperature, with a flow rate during the cooking process, the bar will drop even below zero. It is recommended to use cylinders in pairs to avoid negative points. A pressure of 30 mbar is normal, the limit value is 36 mbar.

Household gas for cooking

- G31, or LPG - liquefied petroleum gas. From a chemical point of view, 100% propane, pumped into cylinders at a gas station. The pressure is higher: 37 mbar - working, 41 mbar - emergency.

If the network limits are too high, Bosch recommends using pressure regulators, reducers. To work in such conditions, Bosch completes the plates with two sets of nozzles: with small holes, they are designed to work with bottled gas, the second set is designed for networked natural gas.

Consider the rest of the options and functions of Bosch HGG 245255 gas stoves. The stainless steel table looks amazing, but housewives recommend washing it carefully, the mirror surface is scratched and loses its attractive appearance. This also applies to enamel, to a greater extent. The best coating is considered to be tempered glass, ceramic is relatively fragile (it is afraid of shocks, withstands significant static pressure). The stainless steel is optimal, its authenticity is checked with a magnet. If it doesn't stick, the alloy has a high percentage of nickel. Such stainless steel is expensive at the reception point.

Kitchen stove Bosch HGG 245255

The product card of the Bosch HGG 245255 stove is silent about the purpose of the timer. A number of models are controlled from it, i.e., we have a multicooker in a huge case. Bosch assures that the electronic display on the front panel with buttons does not affect the operation of the equipment. Separate alarm clock that will sound an alarm at the right time.

Basic problems and how to fix them

Speaking about the structure and principles of operation of a household gas water heater, as well as the sensors built into it, it is worth briefly mentioning possible failures and malfunctions. Here we will not dwell on the complete repair or replacement of the column, but will quickly go through all the elements listed in the description of the burner and describe their problems, as well as how to cope with them with our own hands.

As mentioned, the main column element is - gas-burner... Often, the burner goes out due to the activation of the safety sensors, which we have already mentioned. Common problems that lead to this scenario are fouling of the heat exchanger soot and scale.

Cause weak pressure — scale formation in the pipes of the heat exchanger. In this case, you need to remove the heat exchanger and rinse the pipes with special descaling liquids.

If the combustion of gas does not occur completely, or the column is used for a long time, it accumulates in the chamber soot from the outside, which significantly reduces the thermal conductivity and quality of water heating.

To learn more about the causes of low pressure and the intricacies of cleaning, please follow this link.

If the gas valve does not open due to the low pressure of the supplied water, remove filter, check how much it is clogged and, if necessary, rinse. If there is an insufficient pressure of water or gas, you will have to contact the appropriate state service.

If water flows directly from the column, this means that the tightness is broken in the pipes. It is necessary to disassemble them and replace the sealing elements. If necessary, the pipes themselves will have to be replaced.

Separately, it is worth recalling faulty water membrane... If the column is in operation for a long time, the membrane of the water unit wears out and its sensitivity drops significantly. It stops responding to low water pressure, and, accordingly, does not give a signal that the burner needs to be ignited. In the best case, it should be changed every 5-6 years.

Sometimes the problem is also in the stock, which moves by the membrane, it can also be replaced if necessary, because there are special repair kits for this.

To better understand the device of your geyser model, you need to carefully study the instructions for use and the passport of the object. This will not only save you time and hassle, but in itself will improve your understanding of how the device works.

Conclusions and useful video on the topic

To consolidate the understanding of the structure of the gas column, you can watch a video review, which explains in detail the location of all elements of the column using a live example:

In this article, we have studied the device of a household gas water heater, the principle of its operation. Then we examined the work of the main elements. And knowing the main components and elements of gas equipment, the sensors of its security system, you can diagnose a breakdown on your own. And if the cause of the malfunction is the contamination of individual structural elements, then perform your own service of the gas column.

Would you like to supplement the above material with useful recommendations or ask questions that we have not covered here? Ask our experts and other site visitors for advice - the feedback form is located below.

Post Views: 6