Gas columns operate on the basis of natural and liquefied gas. Manufacturers of space heating devices equip boilers with a security system. The occurrence of a breakdown or the threat of an emergency situation provokes the activation of the protection, after which the blocking of the unit's operation is turned on. The draft sensor of a floor gas boiler (or wall-mounted) can be located in various parts of the equipment. Before turning on the unit, it is important to make sure it is working properly and to know the principle of operation of the gas boiler draft sensor.

A pneumatic relay with a membrane (draft sensor) prevents an emergency situation

The principle of operation of the traction sensor in the gas water heater

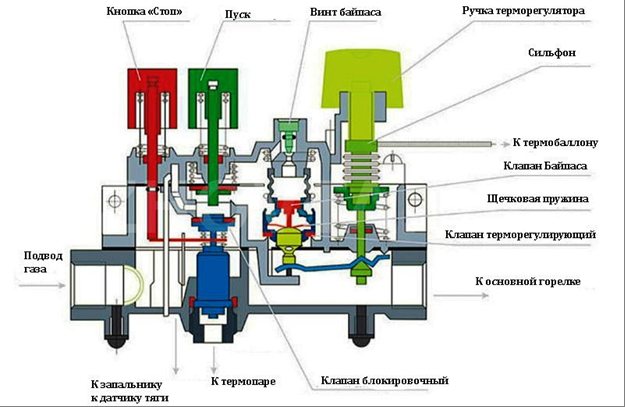

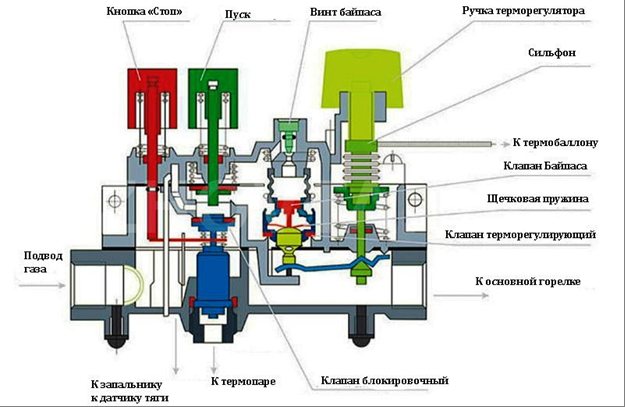

A sensor is called a bimetallic relay, endowed with the ability to start and turn off the boiler burner. In the inner part of the element, you can find a strip made of metal, which reacts to temperature changes. The manufacturer sets it to 75-900 ° C (in cases where natural fuel is used) or 75-1500 ° C (for liquefied gas). In situations where there is a deterioration in the draft in the chimney, the degree of concentration of the flue gas increases, against which the temperature indicator rises. The main function of the pneumatic relay of a gas boiler is to control and transmit signals about a change in the temperature indicator to the control unit. After the signal has reached the block, it enters the area of the gas valve. The supply of liquefied or natural gas is shut off. Sensor operation is also possible in cases of a violation of the draft in the chimney, which brings combustion products to the street.

The AOGV gas boiler draft sensor does not allow poisonous vapors to enter the house.

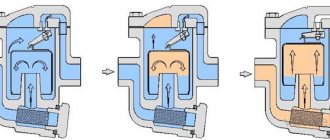

In boilers with closed combustion chambers, products are removed through a coaxial channel using a fan. A pneumorel with a membrane serves as a sensor that does not respond to a change in temperature, but to a change in flow rate.

At the moment the speed is within the normal range, the membrane looks curved. The contacts are closed. As soon as the flow rate indicator weakens, the contacts begin to open. The membrane is gradually straightened. The gas supply valve is closed.

Sensor design and principle of operation

Considering the variety of versions of gas boilers, it should be noted that traction control sensors are also found in different designs. If we consider their design in an extremely generalized way, we will talk about a fairly simple mechanism of devices.

The basis of almost any sensor for controlling the traction of a gas boiler is a bimetallic element that changes shape when the temperature background changes. In fact, it is a simple bimetallic plate that bends when heated or cooled.

The change in the shape of the plate is controlled by the contact group, which translates the state of the contacts to "on" or "off". The switching signal of the contact group is transmitted to the gas boiler controller or to a simpler gas control mechanism.

The type of sensor that controls the draft in the flue gas duct depends on the boiler used.

So, there are two types of gas boilers and are used in practice:

- Constructions equipped with a simple chimney (natural draft).

- Constructions equipped with a chimney with a turbine (with forced draft).

These designs differ from one another and the thrust sensors used for them also differ.

Devices for natural draft boilers

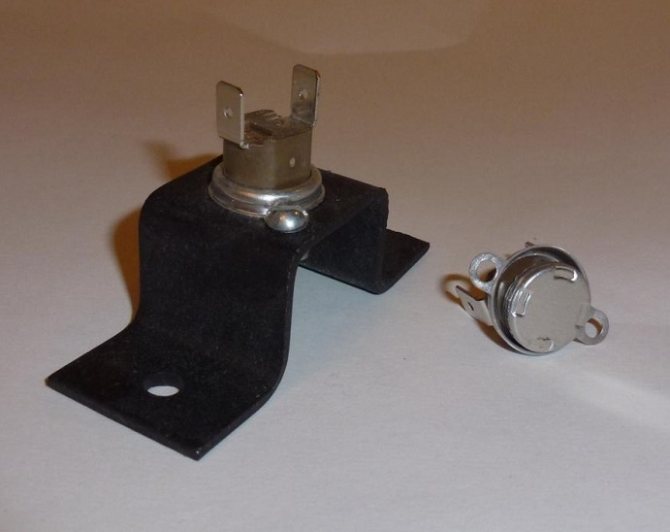

Natural draft boilers use a so-called flue gas hood, in which a simple miniature thermostat is built into the body, as shown in the picture below.

A thermostat of a simple design in a miniature version is usually endowed with a corresponding temperature mark directly on the body (on a metal shell). This mark (for example, 75º) indicates the temperature limit of the sensor contact group response.

A thermostatic device of this type is installed, as a rule, as part of the structures of hinged gas boilers, where a flue gas hood built into the chimney line is used.

The operation of such a device is simple. If the flue gases passing through the hood with the installed sensor heat the device above the set temperature parameter (which indicates a violation of the draft mode), the contacts are open.

Accordingly, due to an open circuit, the gas supply system to the boiler will be shut down (blocked). The equipment will restart only after the sensor has cooled down and the open contact has been restored.

Turbine boiler sensor designs

Boilers equipped with a chimney with a turbine have a slightly different sensor for detecting the draft of a gas boiler with an operating principle that differs functionally. First of all, the difference is that the sensor actually controls the boiler turbine fan. In other words, the optimal flue gas draft is controlled by the fan.

That is why the device of the draft sensors of turbine gas boilers is made not under the control of temperature, but under the control of the volume of passing carbon monoxide gases.

Such sensors work on the fact that there is an optimal vacuum inside the combustion chamber, they have a contact group of three elements:

- COM pin;

- normally open (NO);

- normally closed (NC).

Structurally, the devices are made different in shape, but their principle of operation remains unchanged. Upon the formation of operating conditions inside the gas boiler chamber (optimal vacuum), the supplied air pressure closes the contact group, sending a signal for gas supply.

A slightly different type of sensor elements designed to control the draft in the boiler - designs whose principle of operation is based on the pressure difference of the outgoing flow

Where in gas boilers is the draft sensor installed

The design of the pneumatic relay may differ, depending on the type of combustion chamber that the manufacturer has installed on the boiler.

Cameras on sale can be of two types:

- open combustion;

- closed combustion.

Each manufacturer is obliged to install a pneumatic relay with a membrane in gas appliances with an open type of combustion chamber. As a rule, the place for installing the sensor is located in the area of the smoke extractor.

Important! As soon as the normalized temperature indicator inside the boiler rises, the fuel supply to the column stops. The functions of the pneumatic relay in this case are similar to the operation of the overheating sensor. It is better to entrust the replacement of pneumorel to a specialist.

What is overheating sensor

In addition to the draft sensor, there is also an overheating sensor. It is a device that protects the water heated by the boiler from boiling, which occurs when the temperature rises above 100 degrees Celsius.

Temperature sensors for the boiler are one of the auxiliary elements of automation for controlling the heating system, which allows you to determine the temperature of the environment

When triggered, such a device turns off the boiler. The overheating sensor only works properly if installed correctly. An increase in the temperature of the water without this device would threaten the failure of the gas boiler.

An overheating sensor monitors the temperature rise in the heating circuit. It is installed at the outlet of the heating circuit heat exchanger.When the critical temperature is reached, it opens the contacts and turns off the boiler.

Reasons for triggering the overheating sensor:

- Such a device can work if the water in the column is too hot;

- With poor sensor contact;

- Due to its malfunction;

- If the sensor has poor contact with the pipe.

In order to make the heating sensor more sensitive, a heat-conducting paste is used. In case of overheating, the sensor blocks the operation of the boiler. Modern devices are capable of indicating a breakdown code on the display.

How to install a gas boiler draft sensor

There are times when it is required to replace the draft sensor of a floor-standing gas boiler (or mounted). The process of installing a pneumatic relay with a membrane is simple. It is enough to fix the regulator in the chosen place and connect it to the gas column. For the correct fixing of the temperature regime, it is important to position the regulating element, adhering to the recommendations of specialists:

- the indicator of the minimum height from the floor surface reaches 150 cm;

- the maximum height from the floor is 170 cm.

Any heating devices, household, climatic appliances that distort the temperature indicator inside the gas appliance should be located at a distance of 100 cm. It is important to prevent drafts. Installing the boiler in a cold room is not permissible.

It should be borne in mind that you should not allow the sensor to be too tightly fixed to the body of the equipment. The installation is carried out on paronite gaskets, which helps to reduce the heating of the sensor through contact with the column body and makes it possible to achieve a gap between the hole in the area of the gas duct and the plane of the sensor.

It is important to make sure that the thermostat contacts are firmly attached to the housing. The presence of traces of oxidation on the device is unacceptable.

Step by step installation process:

- After the device has been fixed in the chosen place, you should start laying the wire to the heat source using hidden or open methods. One part of the end of the cable is connected to the contacts on which the COM and NO markings of the thermostat are displayed. For wireless versions, you will find the terminals in the area of the relay box.

- The front panel of the gas appliance must be removed as it prevents access to the control board and connectors. The jumper located between the terminals is removed.

- The wires that go from the contacts of the regulator are connected to the freed terminals. Polarity is optional.

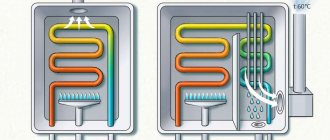

Increased power boilers

Separately, it is worth talking about what a condensing boiler is. In fact, this is the same device, only it has an additional heat intake system. The principle of operation of condensing equipment is simple. During the combustion of gas, the products are not immediately thrown out, but fill a special chamber. It cools down to 55 degrees and water appears. That is why such a boiler is called a condensing boiler.

The energy that results from this process is sent to the heating system. But at the same time, she does this through the operation of a three-way valve. This mechanism is simple. It is not used often. The element resembles a tee, but at the same time it performs completely different functions. The principle of operation of the three-way valve is simple: it mixes water from the system and the chamber. As a result, much less energy is spent to create the desired temperature in the room.

Due to all this, the assembled device makes it possible to save up to 35% of the energy carrier. And this is a significant indicator for today.

It should be noted that the condensing boiler has its own sensor, which is adjusted in a special way. The fact is that the outlet temperature is lower, which means that the thermocouple will react differently.

How to check the draft sensor on a gas water heater

In some cases, during normal operation of the smoke exhaust system, the column may turn off. The reason for this phenomenon is a malfunction of the pneumatic relay with a membrane. In this situation, it is worthwhile to check the thrust sensor, the step-by-step process of which is described below:

- A mirror is installed in the sensor placement area for 10-20 minutes.

- After a specified period of time, it is necessary to check whether it fogs up during operation.

- If the mirror is not fogged up, you don't have to worry, the device works. A fogged mirror indicates a breakdown. It is important to identify the cause of the malfunction as soon as possible and take steps to eliminate it.

To use the second method of checking the pneumatic relay, partially cover the chimney with a damper. In cases where the device is fully functional, the boiler is turned off.

You can also check the gas boiler draft sensor with a multimeter. After connecting the probes of the measuring device, you need to wait for the readings. In cases of normal switching, the multimeter needle will display the minimum resistance level. In the absence of a response from the device, we can talk about a violation of the switching channel.

The reason for the operation of the pneumatic relay with a membrane may be the occurrence of a blockage in the chimney

Diagnostics of errors of the smoke exhaust system of traditional gas boilers

There are a number of basic reasons why a diesel fuel will be able to give a signal to cut off gas. They appear regardless of the type of combustion chamber installed in the gas boiler. Users should not rely on the performance of the sensor in everything and it would be more correct to understand the reasons for the emergency operation of the boiler and monitor these parameters. Thus, the owner of the boiler will be able to prevent the possible development of negative events in advance, eliminating their root cause.

The main reasons for the emergency operation of the boiler:

- The draft or resolution does not correspond to the permissible parameters set by the boiler mode card. This is the main reason for the trigger sensor. This problem can appear due to erroneously mounted blast air supply systems and gas ducts. The problem may also be associated with a violation of the integrity of the flue ducts, in the case when the individual parts of the pipes are poorly connected to each other. After compaction work is completed, the thrust or vacuum is restored.

- Backdraft is a dangerous form of low quality vacuum. This situation also occurs if an air lock forms in the smoke ventilation system, which prevents the exhaust gases from being discharged into the atmosphere. This problem is quite common as a result of poor-quality thermal insulation of the chimney system.

- Chimney clogged. Such a failure occurs when its outlet is not fenced and protected from external blockages. In this case, various atmospheric and natural debris, for example, foliage, can get into it. Protection against this drawback is the obligatory annual cleaning of the smoke ventilation ducts, before the start of the heating period.

- Strong wind pressure. If the traction controller does not work in such a case, then the gas will flow uncontrollably into the boiler unit, but combustion will not occur, which means, possibly, the formation of an explosive gas mixture in the room. In order to prevent such a development of the accident, it is necessary to buy a stabilizer and install it in the system at the point where the pipe exits into the atmosphere.

- If any of the above-mentioned draft sensors in the gas boiler did not work, it must be replaced.

Indicators of the need to change diesel fuel:

- The controller switches off continuously if there are no breakdowns in the boiler flue gas system.

- The gas boiler unit operates for no more than 30 minutes, after which it switches off on its own and can be restarted only after the heating surfaces and combustion chamber have completely cooled.

In the case when one of these signs is found, it is better to invite a service technician, especially if the boiler is under warranty service.

Thus, it can be summed up that the principle of operation of the draft sensor of a gas boiler running on gaseous fuel consists in giving a signal when the parameters in the flue system are overestimated, set by the equipment manufacturer. The signal will go to the electromagnetic type gas shut-off valve, which will instantly cut off the gas supply and the boiler will stop. In cases where the unit is under warranty service or the user cannot repair the thrust sensor on his own, it is better to contact the service center.

How to turn off the draft sensor in a gas boiler

Frequent actuation of the draft sensor causes outrage. Property owners are starting to look for ways to turn off the regulator, but such actions are unacceptable, since:

- systematic triggering of the sensor indicates a poor draft of the chimney, against which the fuel will not be able to burn out and will begin to accumulate in the house;

- there is a risk that the situation is triggered by the reverse thrust indicator, which has arisen against the background of the formation of an air lock (in this case, the exhaust gas, having reached the plug, returns back).

The formation of a reverse draft arises from a lack of natural vacuum in the area of the chimney of the gas column. A similar problem arises in boilers with an open combustion chamber. Disruption of the air flow prevents carbon monoxide from escaping, so it enters the living space and causes poisoning.

If necessary, you can still turn off the sensor. For example, if it stopped working and needs to be replaced. To do this, it will be enough to remove from the circuit the communication wires with the thermocouple breaker and the electromagnetic valve. However, when disabling the sensor, it is important to understand that this is a safety violation. In case of an emergency, the unit will not shut down, but will continue to work. It is not worth the risk, it is better to invite a specialist who will help eliminate the cause that triggers the sensor.

Gas heating boiler automation

The main thing that owners need to do when using explosive equipment, which includes a gas-fired boiler unit, is the rules of safe operation. In accordance with the requirements of PB 12.368.00, all gas units are necessarily equipped with safety automation, the list of regulatory control parameters includes a thrust sensor.

Modern automatic systems warn the owners of boilers about the flame breakout in the piezo igniter, the accumulation of gas in the boiler and the room, in order to protect the room from possible accumulation of explosive gas. Automation performs this work with the help of primary devices - draft sensors of heating gas boilers. The basic principle of their operation is the generation of an alarm signal, with its supply to the actuator to disconnect the boiler from the gas main, and prompt message to users about the reasons for shutdown through sound and light alarms.

The main sensors responsible for the safe operation of a gas boiler:

- By discharge or draft, for boilers with natural circulation: 20-30 PA or 2-3 mm of water. Art .;

- by external / internal ambient temperature, С;

- by the temperature of the supply heat carrier, С;

- by the presence of a torch in the furnace;

- by the minimum / maximum allowable pressure of the coolant, atm.

Reasons for triggering the gas boiler draft sensor

There are many reasons that can trigger the device to operate. Among the main reasons leading to the disconnection of the column, it is worth highlighting:

- Poor quality cravings.Often, the problem arises against the background of improper installation of the exhaust structure. Poor extraction of combustion products can lead to poisoning of people living in the living room.

- Back draft resulting from the formation of an air lock in the area of the chimney, which prevents the decay products from escaping. Quite often, a sharp temperature drop leads to the formation of air jams.

- Blockage in the chimney area. Inexperienced homeowners believe the pipe will not clog. But it is not so. Birds looking for a place to build a nest often choose a chimney. When a bird makes a nest, it can fall into a pipe, get stuck there and die. In addition to birds, foliage and soot deposits on the inner walls of the chimney can also cause clogging. When it occurs, the traction intensity decreases. The only solution to the problem is to carry out cleaning.

- Strong gusts of wind. If the pipe is incorrectly positioned, wind enters it and blows out the burner. The sensor triggering causes the fuel supply to be cut off.

- Improper installation of equipment. Incorrect calculation of the dimensions of the chimney often provokes burner damping. It is recommended to measure the chimney height indicator depending on how far the pipes are from the roof ridge. The head should be 60-70 cm higher than the ridge.

Before proceeding with the replacement of the draft sensor, it is important to familiarize yourself with the device of the gas water heater

Functionality check

All of the above can be summarized in one whole: the sensor is necessary in order to shut off the fuel supply in the event of a hazard - such as a gas leak or poor evacuation of combustion products. If this is not done, then very sad consequences are possible.

Carbon monoxide poisoning has already been discussed more than once. It very often leads to death, and it is definitely not worth joking with it. And in the event that the burner suddenly goes out, but the gas continues to flow, sooner or later an explosion will occur. In general, it is clear that the sensor is vital.

But he can fully perform his functions only in good condition. It is common for any equipment to fail periodically. The breakdown of this part will not affect the external condition of the boiler, therefore it is very important to regularly check the functionality of the element. Otherwise, you risk noticing the problem only when it is too late.

There are several methods for checking:

- attach a mirror in the area where the sensor is installed. During the operation of the gas column, it should not fog up. If it remains clean, then everything is in order;

- partially block the chimney with a damper. In case of normal operation, the sensor should instantly react and turn off the boiler. For safety reasons, do not test for too long to avoid carbon monoxide poisoning.

If, in both cases, testing has shown that everything is in order, then the item under test is ready at any time to respond to an unforeseen situation and turn off the gas supply. But there is another type of malfunction - when the sensor is triggered just like that.

If you carefully checked the draft level and other points, but the boiler still turns off, this means that the control element is not working correctly. You can additionally test this as follows.

Disconnect the element and ring it with an ohmmeter. The resistance of a working sensor should be equal to infinity. If this is not the case, then the part is out of order. There is only one way to correct the situation - it is necessary to replace the broken element.

Some homeowners in situations where the sensor suddenly begins to constantly interrupt the fuel supply in the absence of visible problems with the chimney draft, decide to simply turn off this element. Of course, after that, the column starts to work smoothly.

But such actions are a direct violation of safety measures during the operation of gas equipment. Having disconnected the sensor, you cannot be sure that everything is in order with the draft, and that carbon monoxide does not begin to fill the room. It's definitely not worth the risk. It is better to check the performance of the part using the methods described above. You can also get information on this issue from the video posted above. Good luck and a safe and warm home!