Solid fuel boilers have been widely used for heating for a long time due to the simplicity, reliability and relative cheapness of the fuel used - firewood, lignite and coal, coke, woodworking waste, although they have some drawbacks. The most significant drawback is associated with the fact that solid fuel quickly burns out and must be periodically added for the continuous operation of the heat generator, however, at the end of the 20th - beginning of the 21st century, new technologies appeared that significantly prolong the combustion process. In addition, the constant growth in the cost of the most common energy carrier - gas, the remoteness of many settlements from the main gas networks, allows us to consider the use of solid fuel units quite economically feasible and energy efficient.

Installation of solid fuel steam boilers

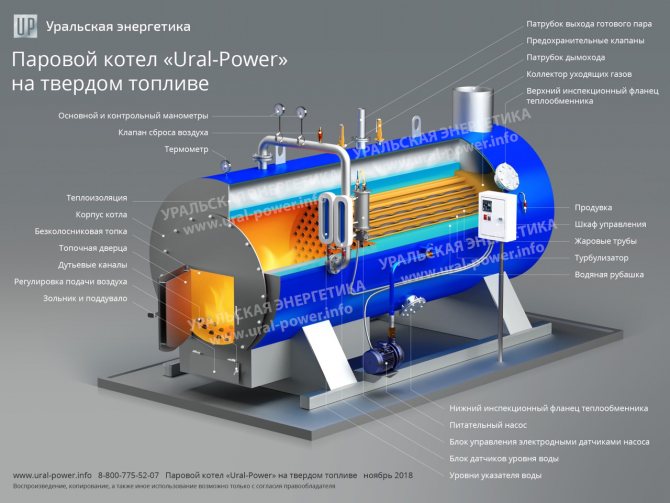

The design of solid fuel steam boilers is a single-fire horizontal box, consisting of two cylindrical sectors of different diameters. These cylinders are inserted into one another and connected by flanges and a steam collector. Thus, a firebox is located in front of the fire tube, and a bundle of pipes in the back. The principle of operation of solid fuel steam boilers is based on the heat exchange of liquid and gas. During the combustion of fuel, high temperature flue gases are formed in the fuel part of the boiler unit. Passing through the gas ducts, streams of hot smoke wash around the tube bundles in which the water circulates. Thus, gases transfer thermal energy to water, and they themselves are cooled from contact with cold pipes. As a result, the heated water in the pipes releases steam, which accumulates in the upper drum of the boiler.

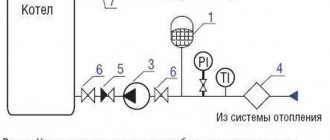

The boiler is controlled by instrumentation and boiler automation. Auxiliary devices monitor changes in water temperature and pressure, and the boiler room automation ensures the safe operation of devices due to built-in sensors.

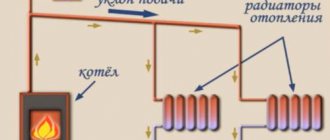

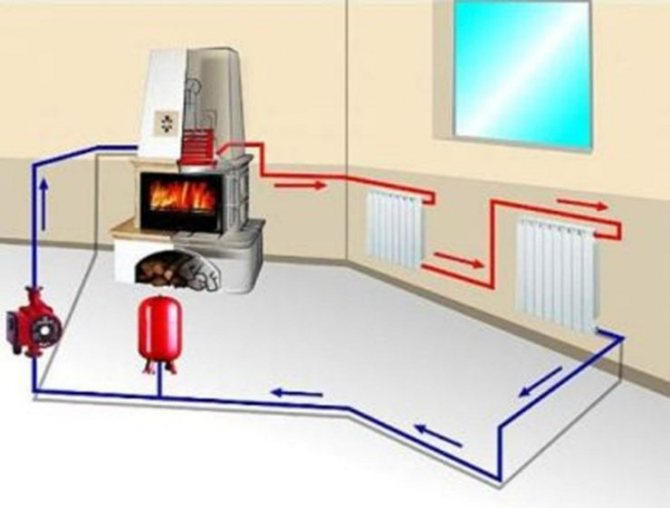

How the system works

Do not confuse water and steam heating at home. They have many functional differences, despite their superficial similarities.

Both of these types have components:

- boiler;

- radiators;

- pipes.

Steam heating is considered effective, you can get by with a small number of batteries

Steam is a heat carrier for steam heating of a private house. You can make such a system with your own hands by following the instructions for assembling and installing components. For a water system, water plays the role of a carrier. The boiler evaporates the water and does not heat it up. The coolant vapors move through the pipes and become a source of a comfortable temperature in the house. The steam cools down inside, after which it condenses. In this case, 1 kg of steam is converted into 2000 kilojoules of heat. For comparison, water cooling by 50 ° C provides only 120 kJ.

In this video, you will learn about the circulation of the system:

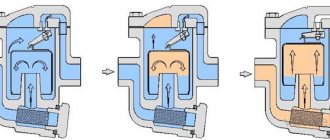

The heat transfer of steam is several times higher, which explains the high efficiency of this type of heating. The condensate formed inside the radiator passes into the lower part and moves independently to the boiler. There are several types of heating systems. In this case, the specification is carried out according to the method of returning the heat carrier, which has been transformed into condensate.

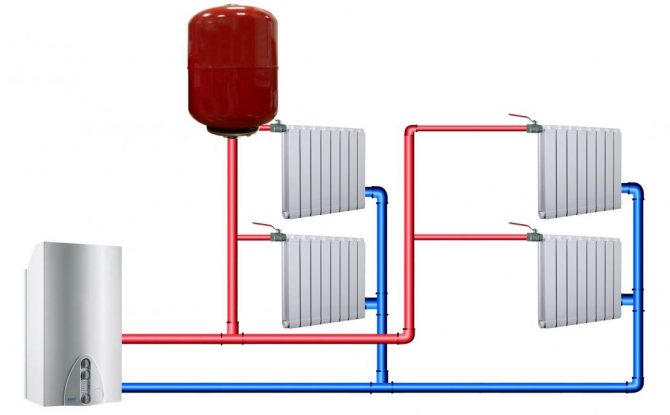

- Closed. There are no contours in this case. Accordingly, the condensate moves through the pipes, which lie at a certain angle. It goes directly into the boiler for further heating.

- Opened. There is a storage tank here.Condensate enters it from the radiators, the pump participates in its re-injection into the boiler.

Boiler types

All solid fuel steam boilers can be divided into two small groups - coal-fired steam boilers (lignite and hard coal) and wood-fired steam boilers. Depending on the fuel consumed, boiler units have their own variants of furnaces. These can be mechanical furnaces with a movable grate, with a belt grate of forward motion, with pushing grates, with inclined grates or with a fixed grate and a rustling bar.

Why is steam better

If you wish, you can make such heating in your home, but these systems are not very popular today. Rather, only a few people resort to it. At the same time, it is possible to highlight both the advantages and disadvantages of such systems..

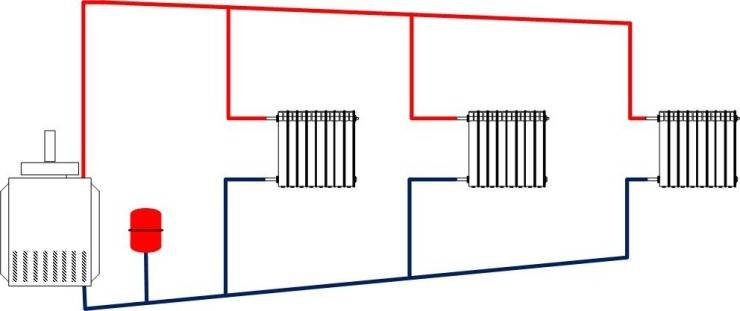

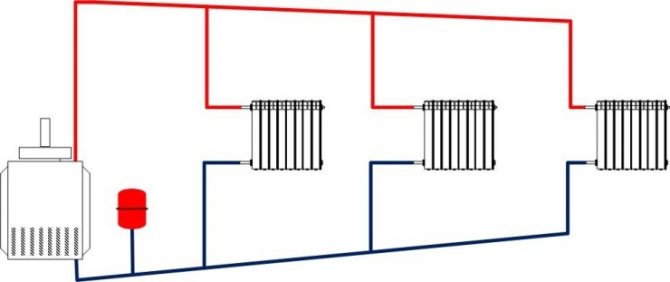

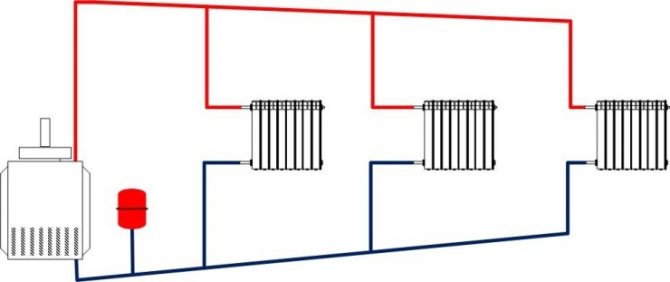

Steam heating can be single-pipe and double-pipe

The advantages can be considered:

- Heating efficiency. It's pretty high. That is why even a small number of radiators are sufficient to service large rooms. Sometimes it is possible to do even without them by installing only pipes.

- Reduced inertia. It promotes rapid heating of the heating circuits. Accordingly, as soon as a few minutes have elapsed after turning on the boiler, the rooms feel warm.

- Almost zero heat loss. For this reason, such a system is beneficial.

- The ability to use is relatively rare. There is a small amount of liquid in the pipes, so there is no need to defrost the system. Alternatively, it is permissible to use it in a country house, where they come from time to time.

Steam heating in a private house with your own hands according to the scheme can be equipped with a certain experience. The main plus here is efficiency. From the outset, the setup requires a modest cost. In the process of applying the system, insignificant amounts are spent.

Heating system overview:

But even with such an impressive range of advantages, there are significant disadvantages. They are associated with the use of water vapor as a heat carrier: its temperature can be quite high. Accordingly, all components of the system are heated up to + 100 ° C and even more.

You cannot touch such a surface, even briefly, so as not to burn yourself. Therefore, any pipes and radiators are certainly closed. The air in such a room is actively moving. When steam heating is used, the air becomes dry and you have to resort to a humidifier.

Not all finishing materials that are used indoors can withstand the proximity of extremely hot radiators and pipes, so their choice is limited. The best option would be cement plaster, which is coated with heat-resistant paint. Anything else does not guarantee security. In addition, steam passing through the pipe is a source of great noise.

The system is not well regulated. Heat dissipation cannot be controlled, so the room can easily overheat. The situation can be solved by the installation of automation, which will independently turn off steam boilers for a private house when overheating and turn them on when the room cools. Another time consuming but more realistic way is to install parallel branches that will work when needed. The main disadvantage is the emergency danger of the system.

If a pipe or radiator is severely damaged, hot steam under pressure will escape. This is unsafe; such options are not used in apartment buildings. When planning to make steam heating, the owner of a private household can obtain permission for this, but only on his own responsibility.

We make the correct calculation

The main structural element of the system is the heating device.In order for all equipment to work with maximum efficiency, it is necessary to make the correct selection of a steam boiler in terms of power. This takes into account the area of the heated premises.

There is the following dependence, which should be adhered to when calculating a steam boiler:

- power of 25 kW is sufficient for heating an area of up to 200 m2

- 25-30 kW corresponds to 300 m2

- power 35-60 kW will heat up to 600 m2

- 60-100 kW - up to 1200 m2.

The popularity of steam heating

This type of creating warmth and comfort in the house with the help of steam has been and remains quite popular in our country. Steam heating of a private house is not only affordable, simple, but also efficient. The main feature of this system is the use of water vapor as a heat carrier. In this case, the source of heat can be both purchased through a distribution network and a home-made steam apparatus.

This unit is used to produce hot water vapor at a pressure greater than atmospheric pressure. It is formed using thermal energy that is released when fuel is burned in a special chamber.

To make the creation of this system on their own, some fundamental knowledge is not needed. But, nevertheless, it is imperative to have an idea of some of the nuances.

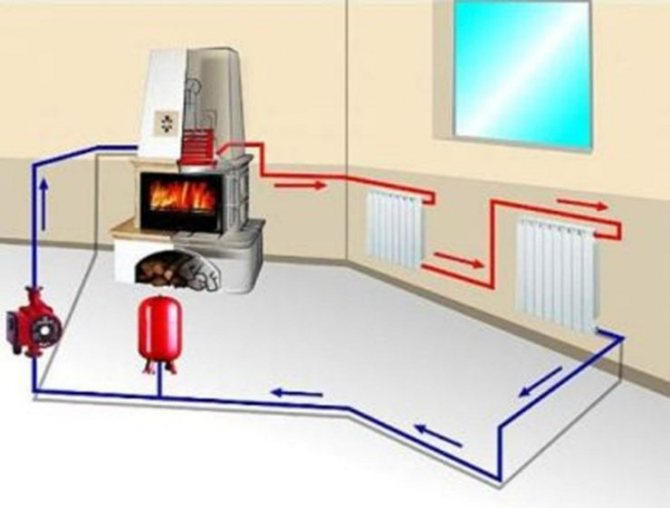

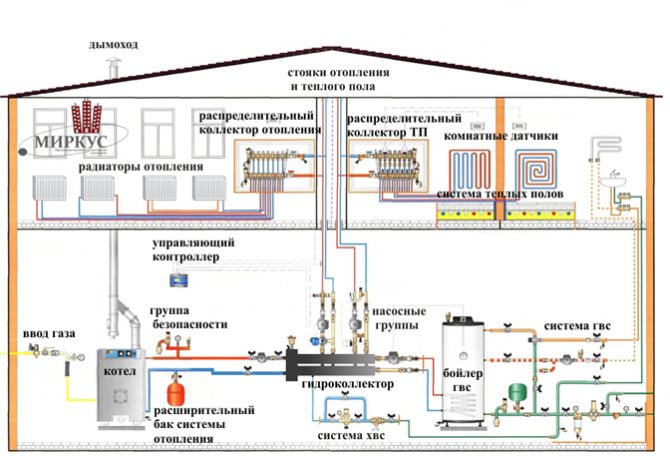

Steam heating of a residential building usually consists of the following devices and elements:

- Steam unit

- Stoyakov

- Pipelines

- Radiators

This set of components is typical for an individual heating system. It generates heat in a steam boiler, assembled and installed with its own hands, which is capable of operating on almost any fuel.

Such heating can be made single-circuit or double-circuit. In the first option, only heating of the premises will occur, the second method also involves the preparation of hot water.

The piping system consists of horizontal and vertical elements. The wiring can be bottom or top - it depends on the characteristics of the building.

Of course, before you create such a heating system in your home, you need to carefully analyze all its pros and cons.

The main advantages are:

- Inexpensive installation and compact dimensions

- Fast warm-up

- Possibility of heating large rooms in terms of area and volume

- Profitability

- High heat transfer in the absence of heat loss

- Impossibility to freeze the system

The disadvantages include:

- The inability to change the air temperature in the house

- Aggressive effect on pipes

As you can see, such heating has more pluses than minuses. And the self-made installation of the system further complements the list of the best qualities.

Assembly of the unit

The work on the independent manufacture of the boiler is carried out in a few simple steps. Follow each step of the instructions sequentially, in parallel focusing on the drawings and diagrams.

First step. Determine the optimal dimensions for the future steam boiler. Its performance directly depends on the size of the equipment. Specify this point on an individual basis, taking into account the specifics of your specific situation.

At the same stage, prepare all the necessary drawings. If you wish, you can order them to be drawn up by a professional, or you can use ready-made drawings from open sources.

Second step. Prepare the required materials. Previously, a list of required items was provided. First of all, buy pipes with a diameter of 32 mm and 12 mm. Sheet stainless steel should have a thickness of about 2-3 mm.

Step three. Prepare the boiler drum. The best option is to weld the body yourself from sheet metal. Select the dimensions of the case individually, in accordance with your needs.

Fourth step. Make the base of the boiler. Earlier it was said that the design of steam boilers is based on a system of communicating pipes.First of all, prepare a piece of pipe about 11 cm long with a wall thickness of about 3 mm.

Cut a pipe 11 cm in diameter into 12 elements - they will function as smoke tubes. Cut the pipe with a larger diameter into flame tubes.

Select the length of the pipes in accordance with your schemes.

Copper pipes

Fifth step. Make the required number of bulkheads and walls of the steam boiler. To do this, use stainless steel sheet.

Sixth step. Prepare holes in the walls of the unit to accommodate the flame and smoke tubes. Attach the mentioned elements in expanded form to the base of the boiler. The welding machine will help you with this. At this stage, also focus on the existing drawings and diagrams.

Seventh step. Attach the relief valve and steam manifold to the unit body. In the future, you will release residual steam through the valve.

Eighth step. Insulate the boiler with an asbestos sheet.

Steam generator connection diagram

Thus, having understood the basic provisions of the instructions, you can independently assemble a simple steam generator and include it in the heating system of your own home. At each stage of the work, be guided by the drawings you have, because it is impossible to understand the assembly order of the unit based on only textual recommendations.