What is a condensing gas boiler?

Gas condensing boilers are gaining more and more popularity in the market as they have proven to be very efficient devices. Condensing boilers have a fairly serious efficiency factor. It is almost 96%. While in conventional boilers, the efficiency hardly reaches 85%. Condensing boilers are very economical. These boilers are very popular in Europe, since the Europeans have a rather acute issue of fuel economy. Despite the slightly higher cost of a condensing boiler compared to a conventional boiler, condensing gas heating units pay off rather quickly. Boilers of this type are confidently looking into the future, because the principle of their operation is the most promising today.

Advantages and disadvantages of boilers

Wanting to install wall-mounted or floor-standing gas condensing boilers, consumers analyze their strengths and weaknesses, and only then come to a final decision. Therefore, in addition to rationality and environmental friendliness, it is worth highlighting other characteristics of the operation of boilers. They must be carefully scrutinized and weighed by consumers.

The advantages of devices include the following parameters:

- safety due to the hermetically sealed boiler design;

- versatility, allowing the device to be used in heating circuits of various types;

- a wide range of capacities, which makes it possible to use the boiler for heating buildings with different areas;

- simple process of operation and periodic maintenance;

- minimum "carbon footprint" from boiler operation;

- compatibility of the heater with a simplified chimney system;

- deep modulation;

- silent work;

- low vibration.

The disadvantages of the device should also be taken into account, among them:

- rather high cost;

- the presence of special installation requirements that make the boiler installation process difficult and time consuming.

As you can see, condensing gas boilers whose price is at least a thousand dollars have more advantages than disadvantages. These boilers are in great demand in the countries of Western Europe and are gradually replacing outdated ineffective counterparts from domestic markets.

The history of the appearance of the condensing gas boiler

In the distant fifties, models of condensing-type boilers began to appear for the first time. These models were not perfect as they are today, and have undergone numerous changes during their evolution. Well, already in those distant years, boilers of this type demonstrated rather serious indicators of fuel economy. This important factor is still the main one that makes air-conditioning boilers very attractive to buyers.

In those years, heat exchangers made of cast iron or steel were used, which made them short-lived. Under the influence of condensate, the boilers quickly failed due to severe corrosion. Only in the seventies did new materials and technologies replace cast iron from steel. Many boiler elements, including heat exchangers, began to be made of stainless steel. Such modernization significantly extended the service life of the condensing boiler. Many experts agree that boilers of this type in their modern form are reliable, very environmentally friendly, and very efficient heating devices in terms of efficiency. Experts also believe that air conditioning boilers have a very promising future.In the USSR, research was also carried out in this direction, but this technology did not receive any serious development.

The principle of operation of the condensing boiler

The principle of operation of the condensing boiler

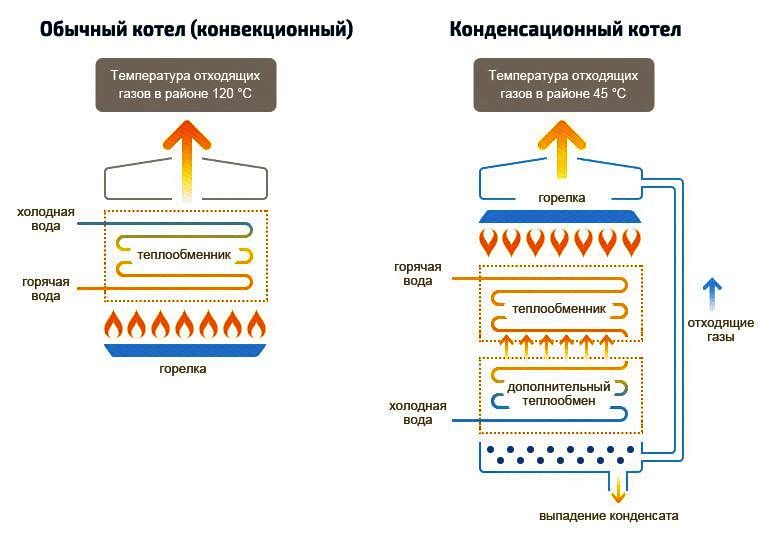

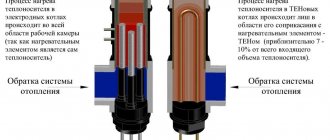

The principle by which many heating boilers work is very simple. It includes only one action - fuel combustion. As you know, when fuel is burned, a certain amount of thermal energy is released. With the help of a heat exchanger, heat energy is transferred to the coolant, and then, with the help of circulation, it enters the heating system. Circulation can be carried out both forcibly and by gravity. The vast majority of modern boilers use forced circulation of the coolant.

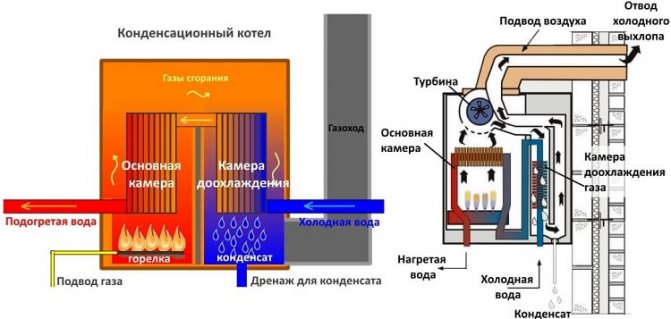

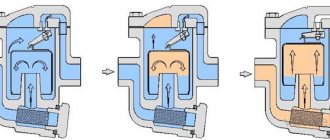

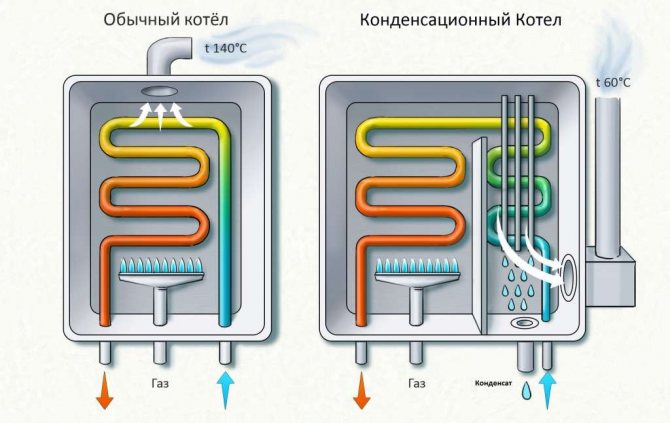

In a conventional boiler, a certain amount of heat energy is emitted through the chimney pipe. This heat can be removed and reused. Simply, a conventional boiler partially heats the atmosphere with water vapor, which is formed when the gas is burned. The most important feature is hidden here. According to the principle of their work, condensing gas boilers are able to store and direct again into the heating system that steam energy, which in an ordinary boiler simply goes into the chimney. The whole trick of a condensing-type boiler lies in its heat exchanger.

The condensing boiler is focused on absorbing the energy that is released when steam condenses. The same heat energy is absorbed by the water that comes in the return line, and which pre-cools the steam to the dew point temperature, thus releasing thermal energy. This heat energy must be returned to the heating system, thereby increasing the efficiency of the condensing boiler.

Currently, all heat exchangers for condensing boilers are made of anti-corrosion materials. These include silumin or stainless steel. A special container is provided for collecting condensate in condensing boilers. Excess condensate is discharged into the sewerage system.

Condensate is considered to be a rather corrosive liquid. Therefore, in some countries, condensate must be neutralized before being discharged down the drain. There are neutralizers for this procedure. A neutralizer is a kind of container that is filled with special granules. These granules can contain magnesium or calcium.

general information

Condensing boilers are an improved version of the conventional convection type boiler. At the same time, the principle of the latter is familiar even to those who have never before been interested in technical issues or physics. As a source of energy for such installations, gas is used in two forms:

- natural (mainline);

- liquefied (balloon).

During the combustion of fuel, like any other organic matter, carbon dioxide and water are formed, which leads to the release of an impressive amount of energy. This causes heating of the coolant - a special fluid that circulates through the pipes of the heating system.

In this video, we will consider which boiler is better to choose:

The efficiency indicators reach 90%, which exceeds the analogous indicators of boilers operating on liquid and solid fuels. However, as science and technology developed, people tried to maximize boiler productivity and achieve 100% results. After all, some products of gas combustion, which make up 10 percent of the total mass, simply go out through the chimney. By the way, they are heated up to + 150 ... + 250 ° С.

In search of optimal solutions, scientists and engineers tried to ensure a more complete recovery of the thermal potential, but it was possible to translate this into reality only 10 years ago, when the first condensing boilers were born.

How a condensing boiler works and what are the fundamental differences from traditional installations is simple to tell. After working out the basic procedure of fuel combustion and transfer of the released heat, the apparatus begins to automatically cool the gaseous products to + 50 ... + 60 ° С, i.e. before water condensation begins.

How to determine the efficiency of a condensing boiler

Today there are low temperature and traditional heating systems. Low-temperature systems include, say, underfloor heating. Condensing devices integrate very well into these heating systems and show high efficiency results in such systems. This is because these heating systems provide very good conditions for the best condensation. If you correctly mount a tandem from a condensing boiler plus a warm floor, then in this case you can not use radiators at all. "Warm floor" will perfectly cope with the task of heating a room, no worse than a system that uses radiators. All this thanks to the high efficiency of the condensing boiler.

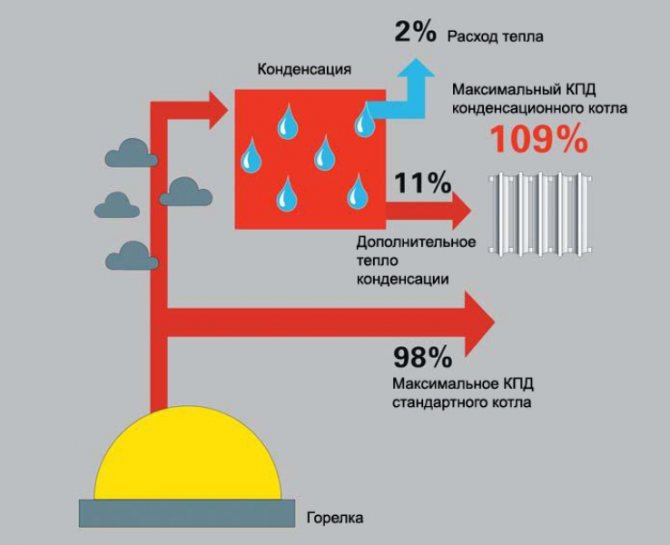

It is often believed that condensing gas boilers have incredible efficiency, which even goes beyond 100%. Of course it is not. The well-known laws of physics work everywhere and no one has canceled them yet. Therefore, such statements from manufacturers are nothing more than marketing.

If, however, to approach the issue of evaluating the efficiency with all objectivity condensing gas boiler, then we get somewhere around 95% efficiency. This indicator largely depends on the conditions of use of this equipment. Also, efficiency can be increased by using "weather-dependent" automation. With this equipment, it is possible to achieve differentiated boiler control based on the average daily temperature.

When a person thinks about the upcoming installation of a heating system, the question inevitably arises before him - which wall-mounted heating boiler is the best on the market?

In our opinion, the answer is simple: the best is the boiler, the operation of which the owner of the house knows practically nothing about, which reminds of itself only by the date of the next service in the calendar. Behind this question, the following inevitably arises - where do ideal boilers come from? And here is an obvious and self-explanatory phrase from the movie about Pinocchio, beloved since childhood - "Out of the big wallets!" - will not be the most correct answer.

An expensive gas boiler from a renowned brand, with a long, positively proven history - this, of course, is very important in choosing and highly desirable, but not enough.

The heating system is a complex of not only boiler and heating system equipment, but also preliminary measures. The ideal functioning of a gas boiler depends on many parameters, each of which is very important - the correct configuration of the heating system, its competent design and calculation, the correct interconnection of all components of the boiler room and the heating system, and of course, accurate and flawless installation, made in compliance with the regulatory requirements. documents, technologies and recommendations, accurate and even beautiful. An ugly plane won't fly, the great Tupolev once said. These winged words apply to boiler rooms in full measure.

More recently, wall-mounted condensing gas boilers were a rare rarity. Almost one and a half times the cost, compared to a conventional wall-mounted boiler, more complex installation, a more expensive chimney did not contribute to their promotion, and obscure assurances about the fantastic efficiency of condensing boilers and the extraction of higher heat of combustion, squeezing heat from the energy carrier to the last calorie, seemed only advertising slogans.

But today, condensing boilers are confidently marching on the market, which is aided by customer requirements for higher standards, quality and comfort of heating systems, and the proven reality of 15-20 percent fuel savings by condensing boilers turned out to be not at all superfluous, with the constantly increasing gas price.

Given the current market situation, and there was a desire to write this article in order to familiarize customers with the general rules and standards for the installation of condensing boilers, and to warn against mistakes that can lead to significant costs for alterations and additional work, or even the deprivation of the warranty for sufficient expensive equipment.

- Boiler installation location.

It is forbidden to install gas boilers in residential premises, condensing boilers are subject to the same requirement. As a last resort, it can be installed in the kitchen, but it is better to use a separate, isolated, non-residential room with a ceiling height of at least 2.2 meters.

The walls are plastered, ideally they are finished with tiles. It is forbidden to decorate the boiler room with fire hazardous materials.

The floor is flat, with a non-combustible coating.

The width of the doorway to the boiler room is from 80 centimeters or more.

The dimensions of the window for natural lighting of the boiler room are calculated based on the required glazing area of at least 0.3 square meters for every 10 cubic meters of the boiler room volume.

The required volume of the boiler room is determined based on the total heat output of the installed boilers, up to 30 kW - 7.5 cubic meters, from 30 to 60 kW - 13.5 cubic meters, over 60 kW - 15 cubic meters.

A sewage system must be installed in the boiler room.

If a cascade of condensing boilers is installed, each gas line is equipped with a separate shut-off valve.

The boiler room must be connected to the exhaust ventilation of the house.

Supply ventilation of the boiler room can be carried out from the premises of the house through the ventilation grill in the door, or from the street.

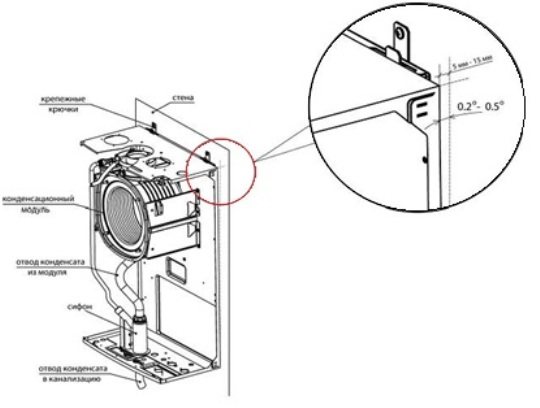

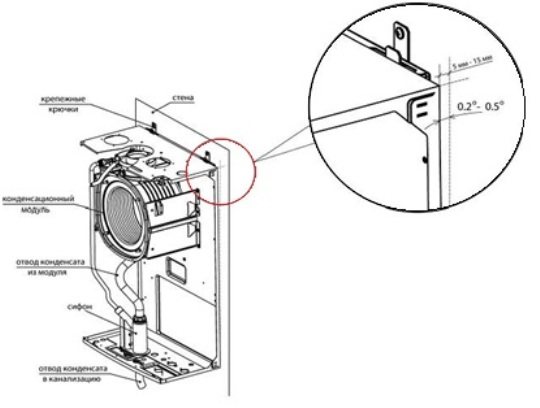

- Hanging the condensing boiler on the wall.

Usually the boiler is mounted on the wall using the hooks included in the kit, which are fastened to the wall with dowels, and the boiler is hung on them. If the boiler is hung in such a way that its upper part protrudes from the wall more than the lower one, the boiler will be tilted forward.

This is a mistake for a condensing boiler.

When the boiler is tilted in any direction, forward or sideways, the condensate of combustion products, instead of being drained into a siphon, may partially begin to overflow into the combustion chamber and evaporate on a heated heat exchanger.

Condensate vapors can cause the ionisation electrode, which controls the presence of a flame in the combustion chamber, to close with the boiler drum. In such a situation, the boiler, of course, will shut down and enter the error mode due to the absence of flame. And then you can look for the reason for the absence of the flame, which in fact did not exist, for a very long time. So, any roll of the boiler is inadmissible.

- Chimneys for condensing boilers

The longest and tedious point, because it is with the chimneys of condensing boilers that installers have the greatest number of mistakes and blunders.

ANDUse of galvanized, steel or cheap stainless steel pipes for sauna stoves.

Condensing boilers do not like saving on materials for chimneys very much. And a seemingly good chimney from an ordinary boiler, or conditionally stainless steel chimney from a country stove, capable of withstanding high temperatures of exhaust gases, fails when working with a condensing boiler. Because the condensing boiler differs from all others in the low temperature of the flue gases, which in most cases is below the dew point - 57-60 degrees.

Yes, condensate from combustion products forms at such temperatures, in our opinion, high.And a lot of it is formed, a condensing boiler of average power, 30-40 kW, can emit up to 7 liters of condensate per hour. Condensation of flue gas vapors occurs not only in the boiler, some of them manage to leave the boiler and condense already in the chimney. The acidity of the condensate is low, of the order of pH = 4, but long-term exposure to condensate will sooner or later destroy a poor-quality chimney.

For this reason, only high-quality chimneys made of heat-resistant polymers, acid-resistant high-quality stainless steel or aluminum are used for the chimneys of condensing boilers. I don't even want to mention the use of pipes for sewerage as a chimney, but it is necessary, because some craftsmen, hoping for a low temperature of flue gases, manage to do this. It is absolutely impossible to do this, over time, the sewer pipes from constant heating, although at uncritical temperatures, will inevitably deform and their joints will lose their tightness. I don’t want to write what will happen next.

In addition, the temperature of the boiler exhaust gases can become much higher than usual, if it is necessary to heat a large amount of hot water or to quickly warm up the house after a long absence of the owners, who switched the boiler to the economical mode of maintaining the minimum temperature during their absence.

Errors in the slope of the chimneys of condensing boilers.

The incline of the chimney of the condensing boiler must be such that the condensate formed in the chimney flows back into the boiler, i.e. the slope is directed towards the boiler. Naturally, in this case, the chimney must be protected from precipitation. Chimney sockets are assembled "by condensate" - so that the pipe joints do not form sides inside the pipe, blocking the free drainage of condensate.

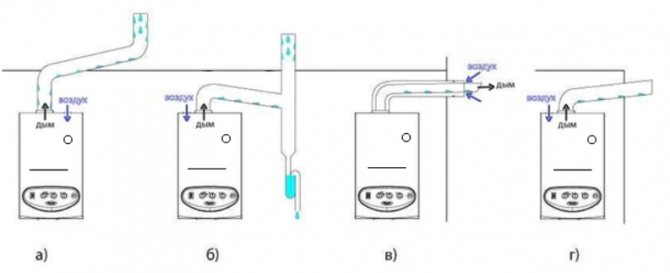

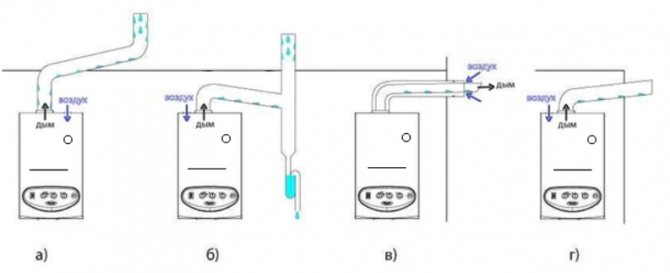

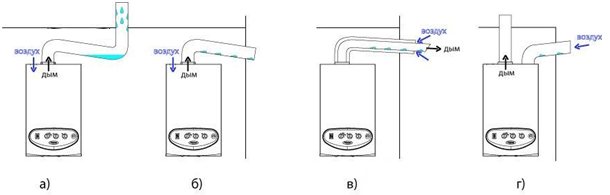

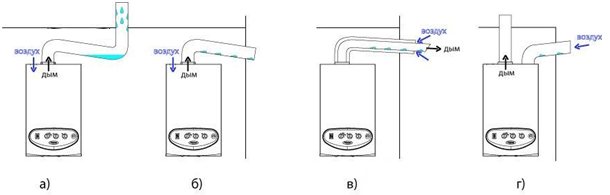

Chimney installation options:

but) Chimney outlet diagram vertically, with combustion air intake from the boiler room. It is necessary to provide a chimney head that protects against precipitation. In the boiler room, the organization of supply ventilation is mandatory, 10 cubic meters of air for each cubic meter of combustion gas, the maximum consumption of cubic meters x 10.

b) Boiler chimney outlet into the existing building chimney, with air intake from the boiler room. It is imperative to provide for the drainage of condensate into the sewer with a water seal. The chimney must be lined with acid-resistant materials. Requirements for ventilation of the boiler room are similar to point a).

in) Coaxial standard chimney for the condensing boiler. Its internal flue gas outlet has its own slope towards the boiler.

d) Horizontal chimney with wall outlet. It is necessary to observe the slope towards the boiler and provide protection against precipitation. Requirements for ventilation of the boiler room are similar to point a).

Chimney installation errors:

but) The lowered section in the flue creates an area of condensate accumulation, which can lead to a change in the aerodynamic properties of the flue and, accordingly, prevent the fan from working with the activation of the smoke exhaust control protection and subsequent blocking of the boiler.

b) and in) The installation of chimneys of condensing boilers, by analogy with the installation of conventional boilers, leads to a large amount of dripping condensate, freezing of ice stalagmites under the chimneys and even freezing and blocking of the chimney with ice.

d) Outside air intake, organized without protection from atmospheric precipitation and made with a slope towards the boiler, leads to the ingress of precipitation into the boiler and a possible short circuit with the failure of the boiler.

Chimney

The removal of exhaust gases and the supply of air to the combustion chamber in a condensing boiler is carried out forcibly, since boilers of this type have a closed combustion chamber.Condensers are quite safe because they don't need a traditional chimney to use them. Boilers of this type use a coaxial or two-pipe flue system. These systems are made of plastic, as the condensation tank has a negligible flue gas temperature. The use of cheap materials in the manufacture of smoke removal systems can significantly reduce the cost of the boiler.

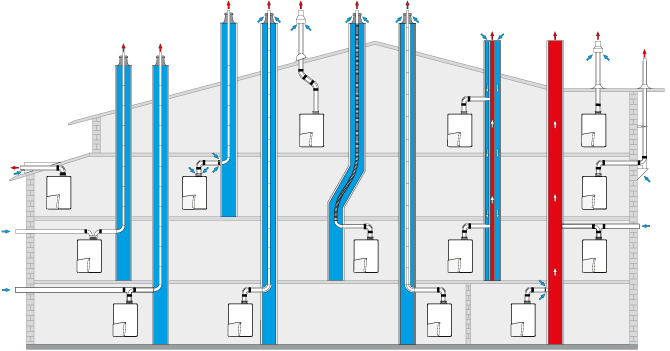

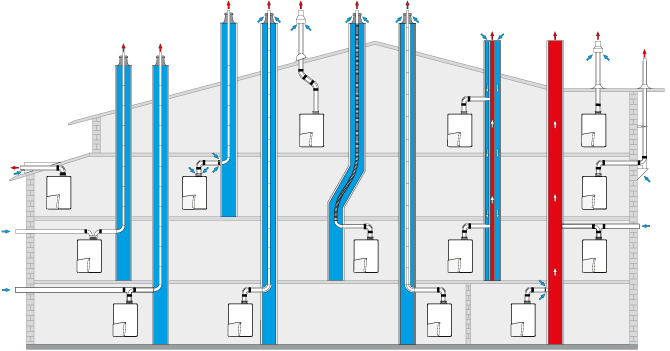

Basic schemes for installing chimneys for condensing boilers

All chimney schemes for condensing boilers are divided into two main types: with combustion air intake from the room and from the street. Naturally, in the domestic regulatory documentation these types of smoke removal and the requirements for them are described, but in the documentation for boilers, names are usually found in accordance with European standards. A chimney with air intake from the boiler room is designated as “Bxx”, from the street - as “Cxx”. The first index varies depending on the specific scheme, the second - on the location of the fan relative to the boiler heat exchanger. In all modern condensing boilers, the fan is located in front of the heat exchanger, which is indicated by the index “3”. Below are the basic diagrams using the example of wall-mounted boilers:

For domestic facilities, the calculation of the chimney is usually not necessary, it is enough to follow the recommendations of the boiler manufacturer for the maximum length, taking into account the shaped elements (elbows, tees, etc.). In the case of industrial boiler rooms, the calculation of the smoke exhaust is mandatory, you can contact the chimney manufacturer for it.

Combustion air intake from the room

| The easiest way to organize the flue gas outlet. Almost always used for large capacity boilers: industrial or commercial, when floor-standing boilers are used. It is also often found in household use. There are two main requirements when using such schemes: ensuring the necessary air flow into the boiler room and its purity. For boiler houses of large capacities, this is usually not a problem, since these points are carefully taken into account at the design stage. In private boiler houses, a situation often occurs when a sufficient air flow is not ensured; or it is carried out through adjacent rooms, where after the boiler starts up, finishing work continues, which contributes to the presence of fine dust in the air and clogging of the internal elements of the boiler. Naturally, this state of affairs should be avoided or special air filters on the boilers should be used. |

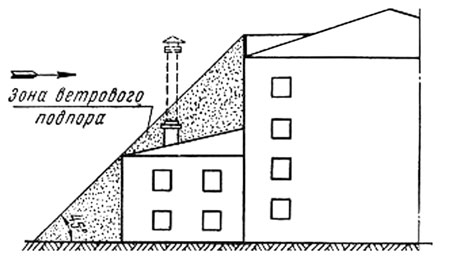

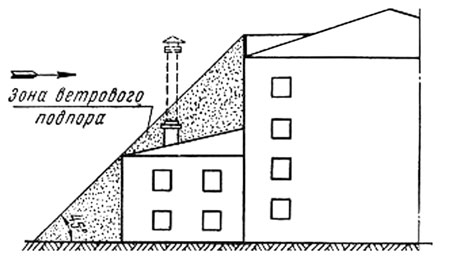

In this case, the chimney must be brought out above the roof level from the zone of the so-called “wind back”.

This is necessary in order to exclude the influence of fluctuations in air pressure on the smoke extraction process.

Combustion air intake from outside

In this case, two main subtypes of the chimney are used: coaxial and separate.

Do I need to buy a condensing boiler?

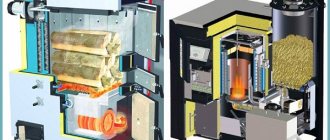

Like traditional gas boilers, there are several types of condensing boilers:

- The first type is floor-standing boilers. "Napolniki" have a higher power, which sometimes reaches 320 kW and more.

- The second type is wall-mounted boilers, the power of which is up to 120 kW.

If it becomes necessary to increase the capacity, then several heating boilers can be combined into a single heating cluster. Condensing gas units have different purposes, and therefore they are double-circuit or single-circuit. In addition to heating, double-circuit condensing boilers are also engaged in the preparation of hot water, while single-circuit condensing boilers are engaged only in heating the premises.

Boilers of this type have very high performance, which fully meet all the most serious requirements imposed by the relevant authorities on heating boilers.Condensing boilers are very popular in resort areas, holiday homes and other tourist destinations. It's all about efficiency and sustainability.

A condensing gas boiler has much less harmful emissions, almost 10 times less than a conventional gas boiler.

Equipment pluses

The list of advantages of condensing boilers is very extensive, which explains the high popularity of this type of heating systems. The key advantages include:

- Profitability. If we compare condensing boilers with conventional convection models, they consume 35% less fuel, which can significantly reduce the cost of heating the room.

- Environmental friendliness. The percentage of harmful emissions reduction reaches 70% in comparison with traditional gas installations.

- Possibility of installing plastic chimneys due to the low temperature of the flue gases. Plastic models are much cheaper than classic steel ones.

- Quiet operation that enhances indoor living comfort.

As for the fuel consumption, it is determined both by the power of the equipment and the load imposed on the boiler. To fully heat a dwelling with an area of 250 square meters, a 28 kW boiler with a fuel consumption of 2.85 m3 / h is quite suitable. For comparison, classic gas units will require at least 3.25 m3 / h. As a result, a savings of about 3 thousand rubles will be obtained over a six-month period of operation.

Another important advantage of the system is the minimum amount of harmful emissions. During the combustion of the organic fuel mixture, carbon dioxide is formed, which produces carbon dioxide. In addition, any fuel contains chemical compounds of sulfur, nitrogen, phosphorus and many other elements, which also give acids when in contact with water.

Conventional gas boilers emit water vapor with various impurities into the air, polluting it. Condensing units do not have this disadvantage, because all acids do not leave the condensate.

Advantages of condensing boilers

- Very compact;

- They are lightweight;

- Boilers of this type are highly efficient;

- Capacitors have a fairly deep modulation;

- Equipped with an inexpensive smoke exhaust system;

- Boilers of this type have very good environmental performance and do not pollute the environment;

- These boilers have practically no vibration;

- Low noise, and this property makes them very comfortable to use;

- Condensing boilers are very economical. Fuel economy is sometimes up to 40%, which will greatly delight potential buyers.